Comprehensive cleaning machine

A technology for cleaning machines and materials, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc. Concentration and uniformity, high air bubble utilization, concentration and cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

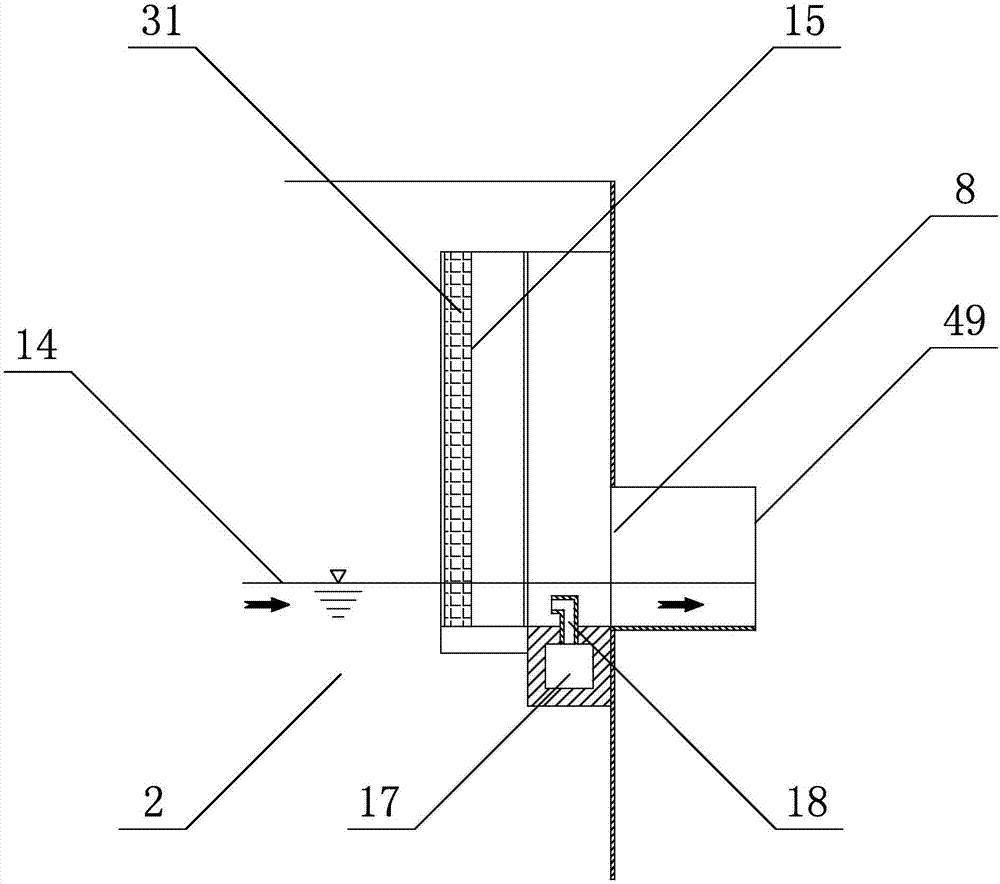

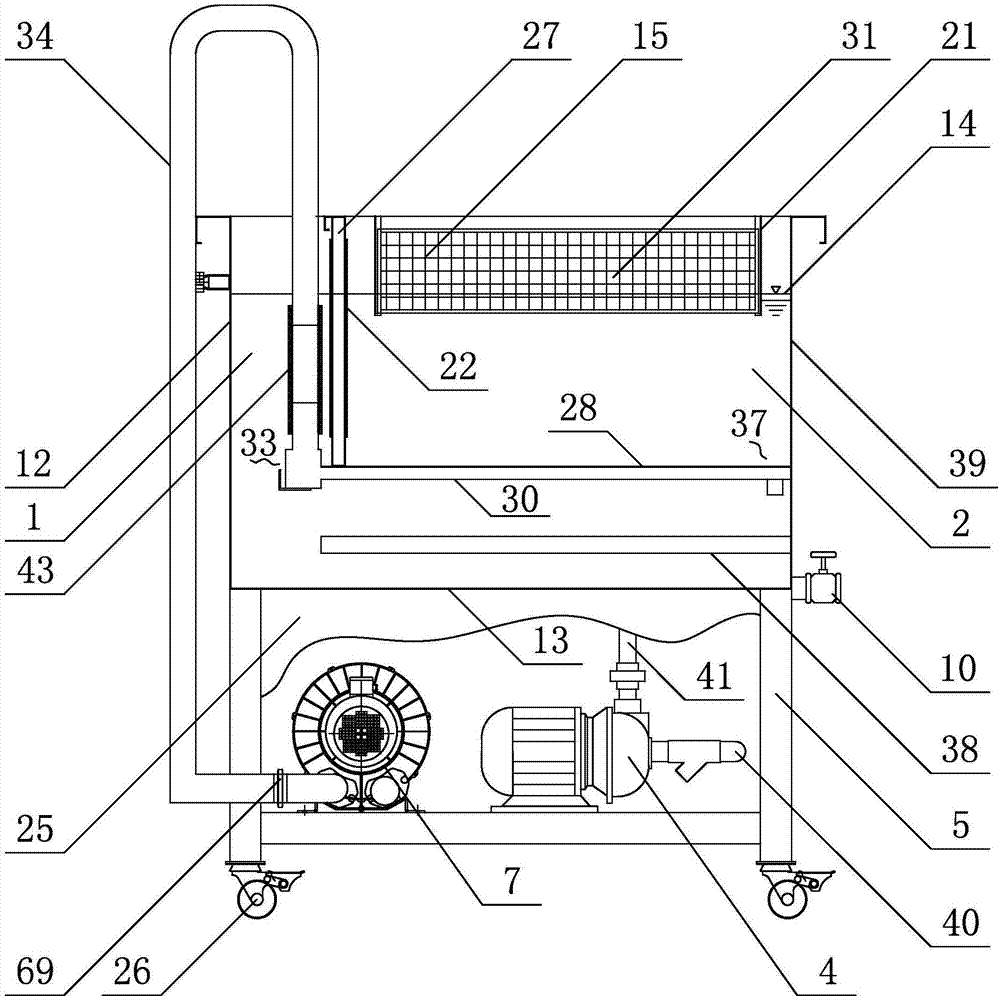

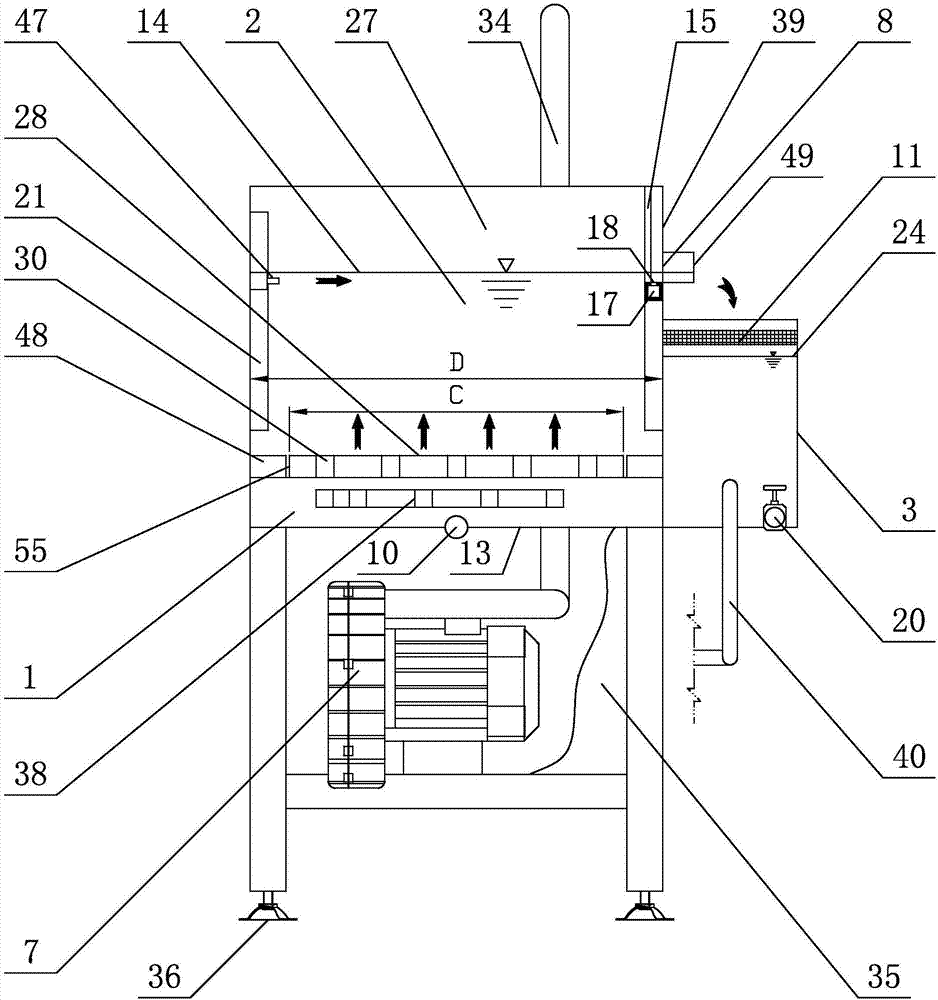

[0035] a. Such as figure 2 , image 3 Shown is a fixed integrated cleaning machine of the present invention, and the material pool bottom 28 is stationary. The material pool bottom 28 can be placed in the pool 1 or detachably connected, and the material pool bottom 28 is a plate. There are holes 29 on the bottom 28 of the material pool (such as Figure 4 ) Or no holes, the impurities in the material pool 2 can leak into the pool 1 from the holes 29. All or part of the two opposite sides 55 of the material pool bottom 28 are between the adjacent material pool walls, that is, the width of the material pool bottom 28 is close to the width of the material pool 2 in the same direction; or image 3 The transition block 48 is set between all or part of the two opposite sides of the material pool bottom 28 and the material pool wall. That is, the width C of the material pool bottom 28 plus the width of the transition block 48 is close to the material pool 2 in the same direction The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com