LED cleaning lamp

A technology of cleaning and placing grooves, applied in lighting devices, light sources, fixed lighting devices, etc., can solve the problems of loose packaging and the inability to fully embed clean lights.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

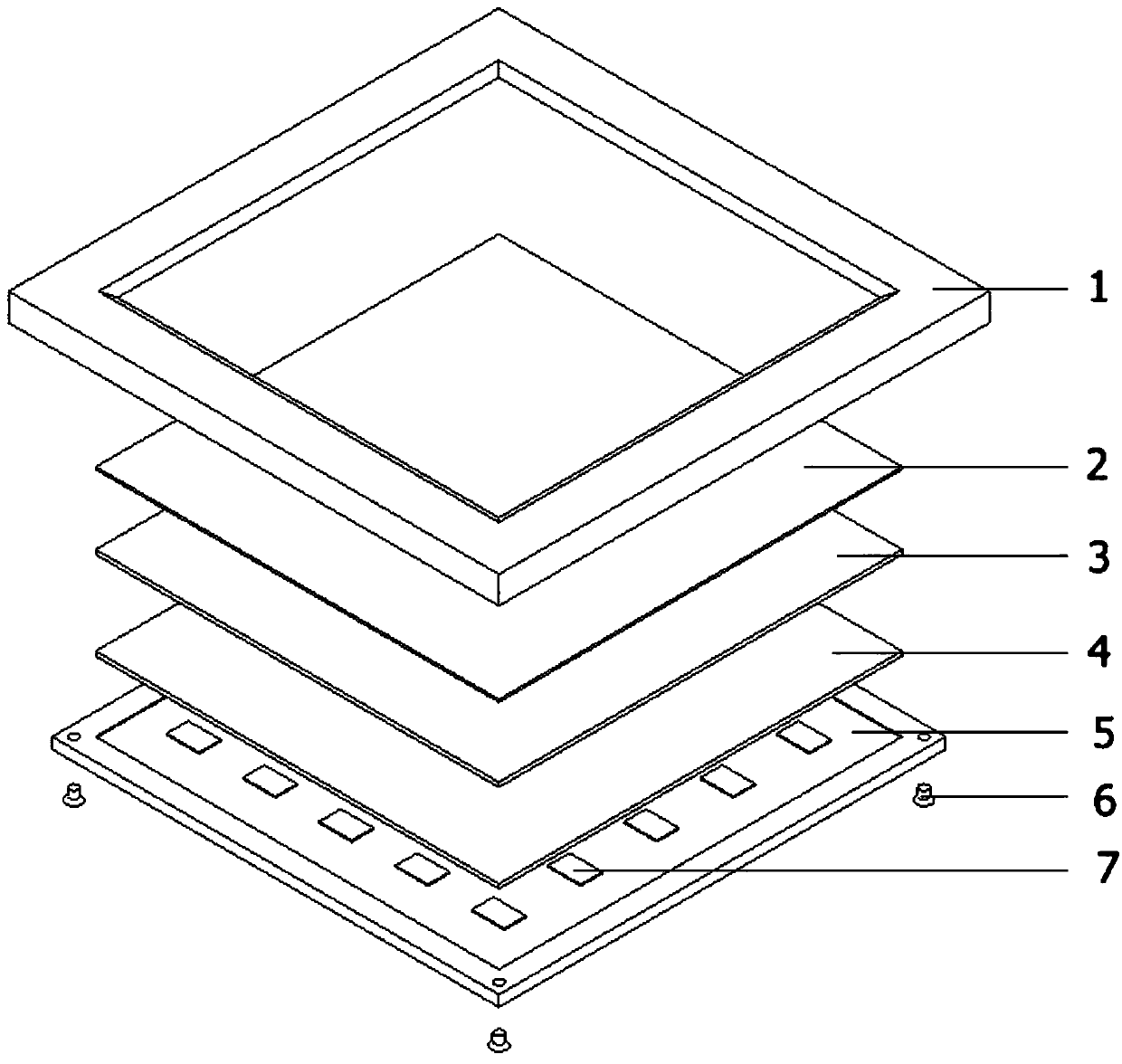

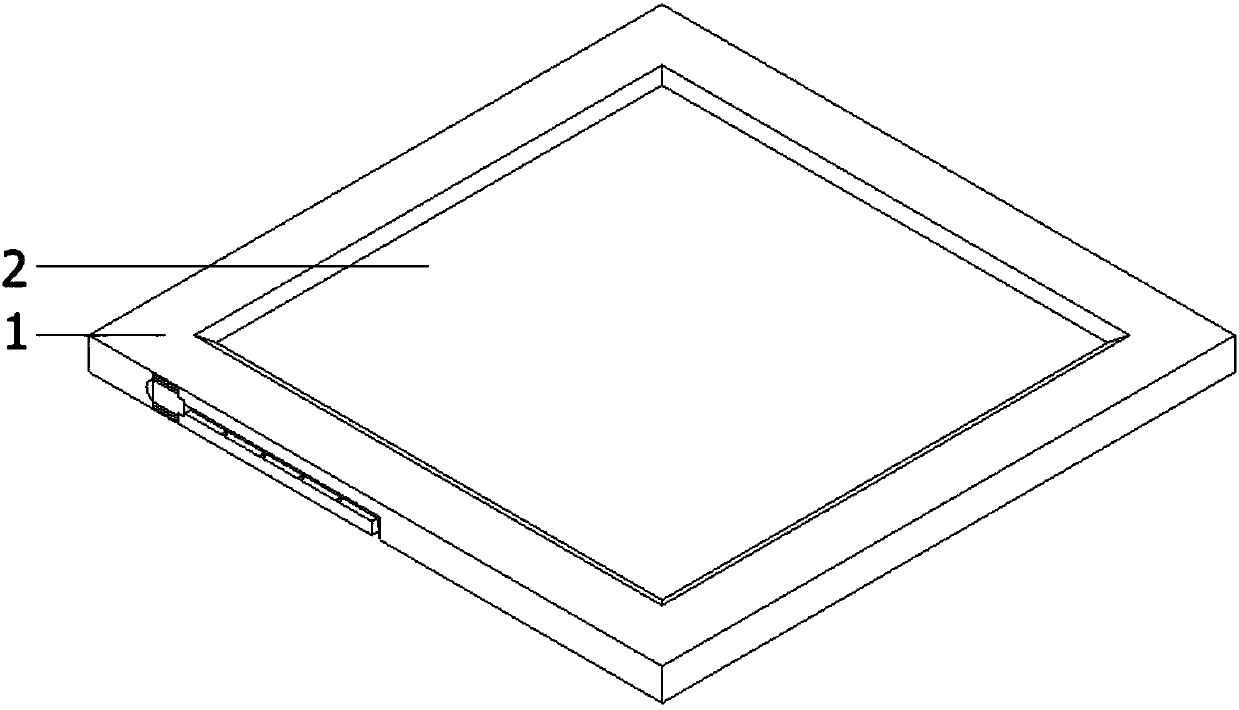

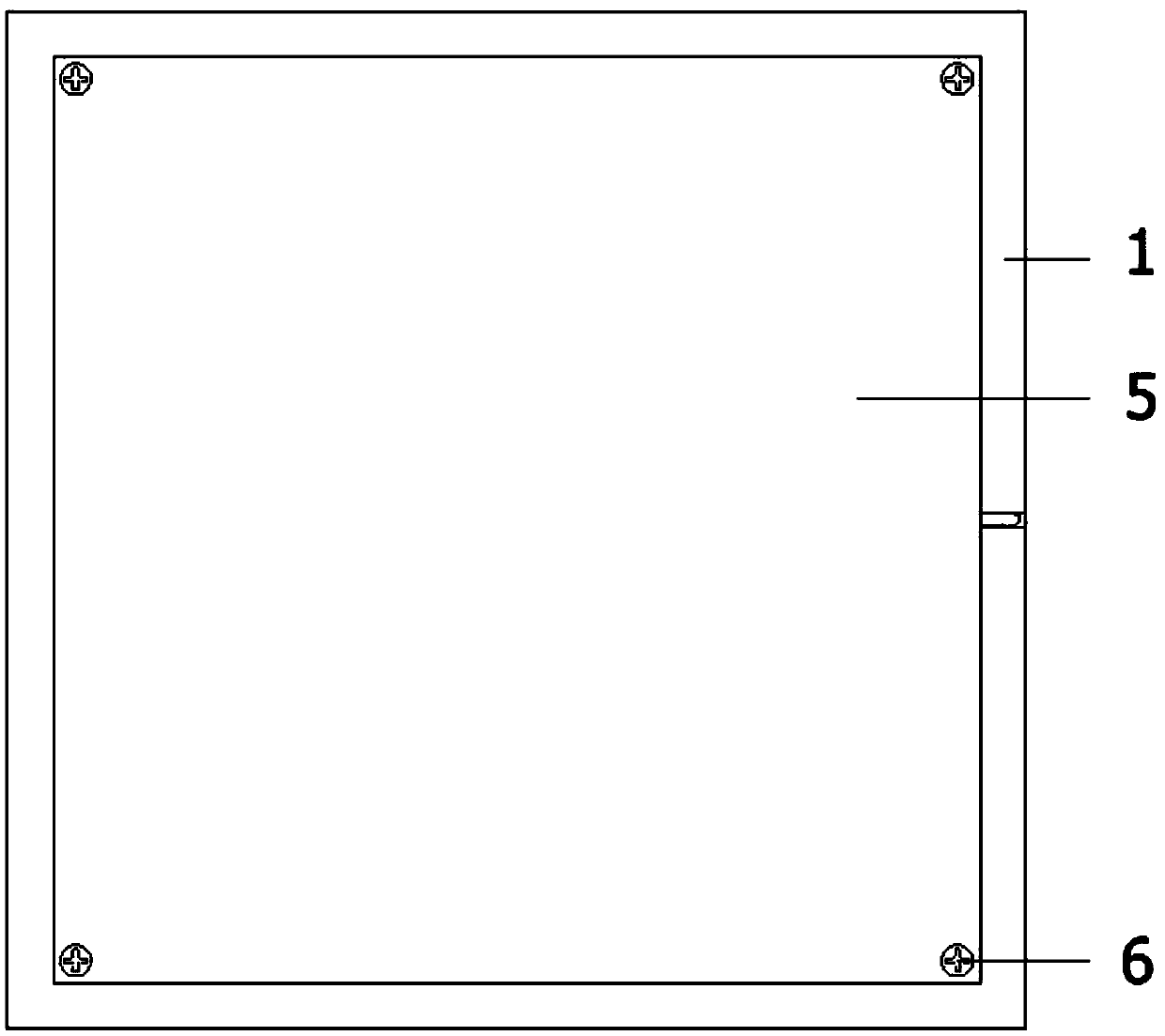

[0026] as attached figure 1 To attach Figure 7 Shown:

[0027] The invention provides an LED clean lamp, including an aluminum frame 1, a diffusion plate 2, a light guide plate 3, a reflective paper 4, an aluminum substrate 5, a screw 6, an LED chip 7, a wire 8, an extrusion block 9, a spring 10, and an arc groove 11 , semicircular protrusion 12, wire placement groove 13, wire connector 801 and wire connector placement groove 1301; the top of the aluminum substrate 5 is inlaid with a number of orderly distributed LED chips 7; the top of the aluminum substrate 5 is sequentially Reflective paper 4, light guide plate 3 and diffusion plate 2 are provided; the aluminum frame 1 buckles the diffusion plate 2, light guide plate 3, reflective paper 4, and aluminum substrate 5 together to form a whole, and the aluminum substrate 5 passes through four groups The screws 6 are fixedly connected to the four corners of the aluminum substrate 5 by threads; the left end surface of the alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com