Chain sheet joint

A chain piece and outer chain piece technology, applied in the direction of chain elements, belts/chains/gears, mechanical equipment, etc., can solve problems such as unsatisfactory use, danger, obstruction, etc., and achieve the effect of reducing collisions and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

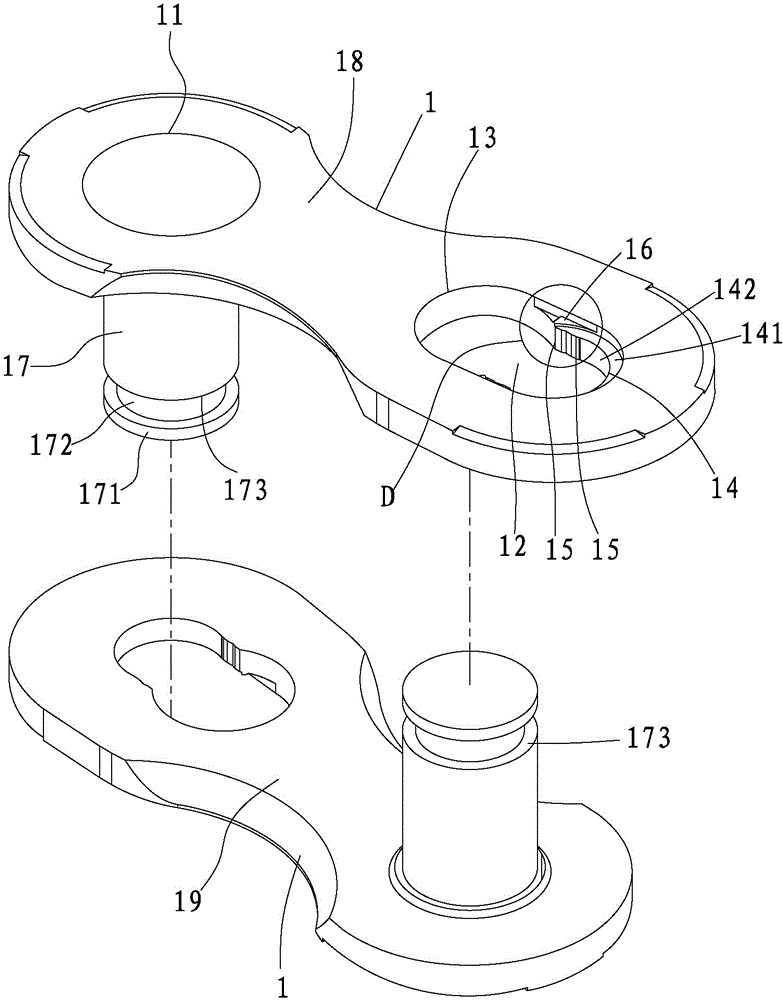

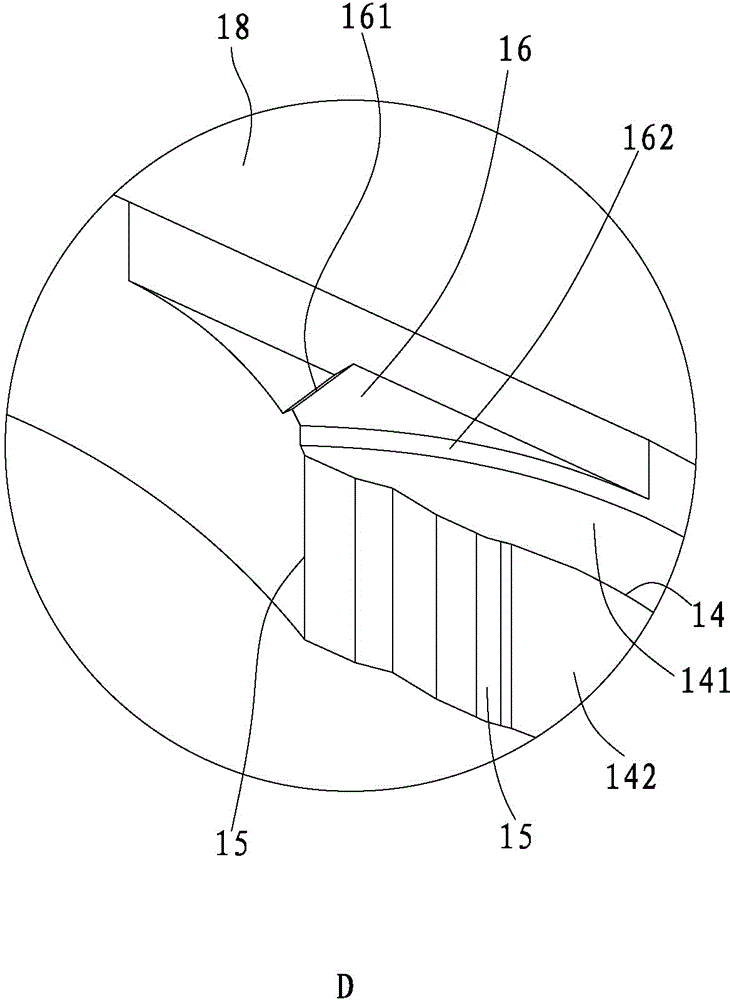

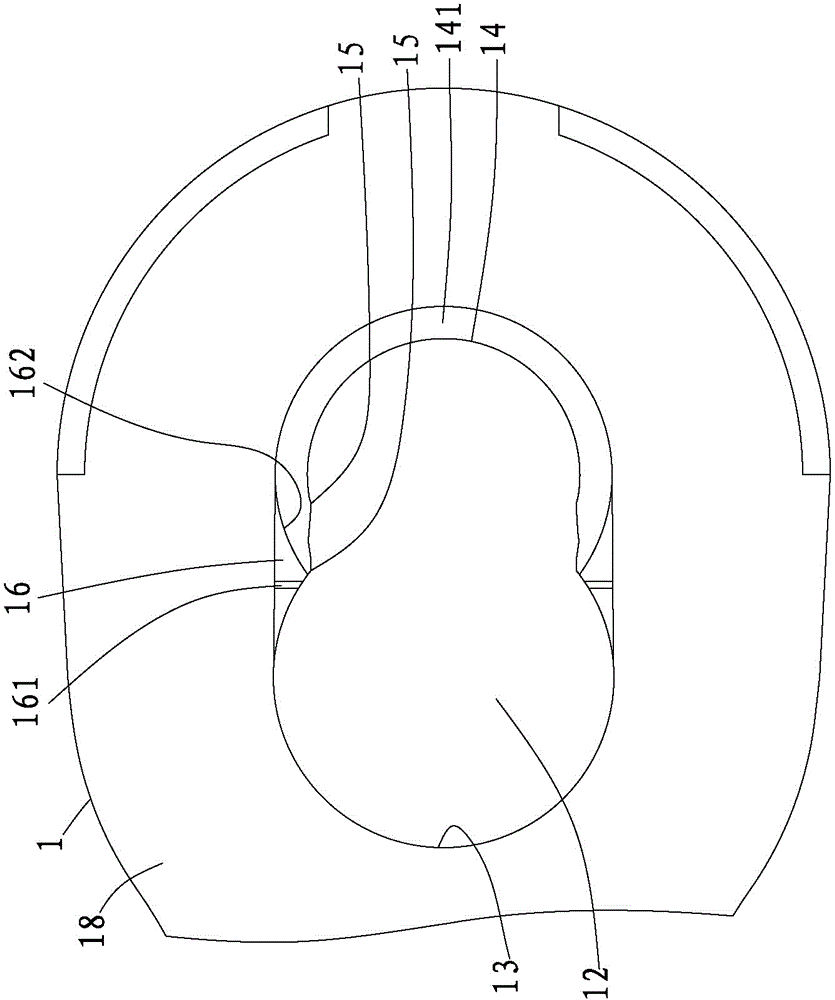

[0037] First, see figure 1 , figure 2 and image 3As shown, the embodiment of the present invention is provided with two opposite outer chain pieces 1, and the two outer chain pieces 1 are respectively provided with a first side 18 and a second side 19, and the outer chain piece 1 is provided with a 18 to the second side 19 through a perforation 11 and an adjacent snap-in hole 12 at an appropriate distance, the snap-in hole 12 is formed with a large-diameter portion 13 and a small-diameter portion 14 intersecting, wherein the periphery of the small-diameter portion 14 is in the The first side 18 is concavely provided with a fastening surface 141, and the small diameter portion 14 is provided with an inner edge surface 142 perpendicular to the fastening surface 141, and the inner edge surface 142 is close to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com