Engine oil bottom case

A technology of engine oil and oil pan, applied in the direction of engine components, machine/engine, engine lubrication, etc., can solve the problems of cylinder block processing difficulty, small layout space, complex cylinder block, etc., and achieve optimized structural manufacturability and processing Manufacturability, meeting the requirements of space structure, and the effect of reasonable location arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

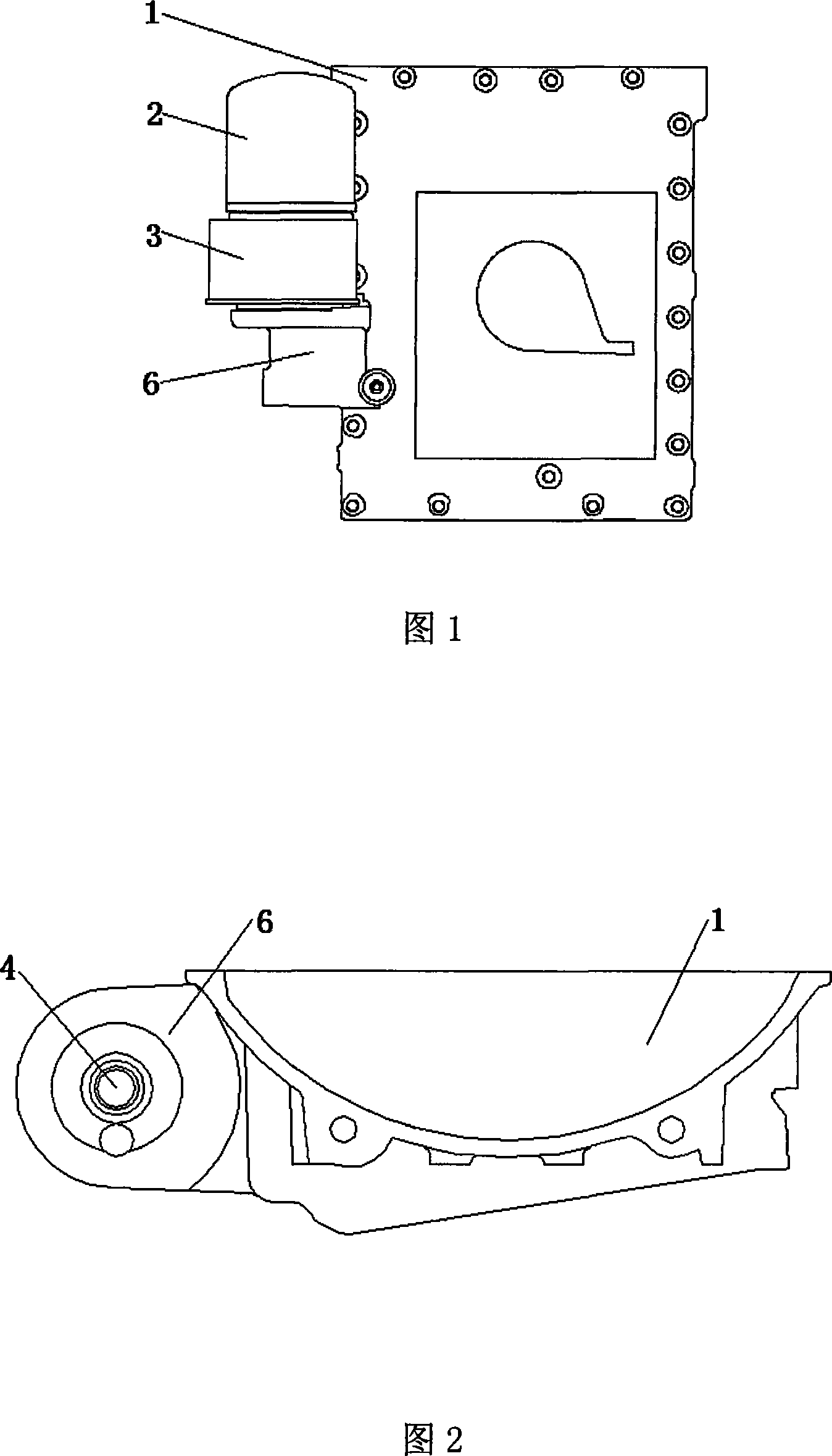

[0027] The setting of the oil cooler 3: between the oil filter 2 and the filter installation boss 6, there is also an oil cooler 3, and the oil cooler 3 and the filter installation boss 6 and the oil filter 2 are tightly connected.

Embodiment 2

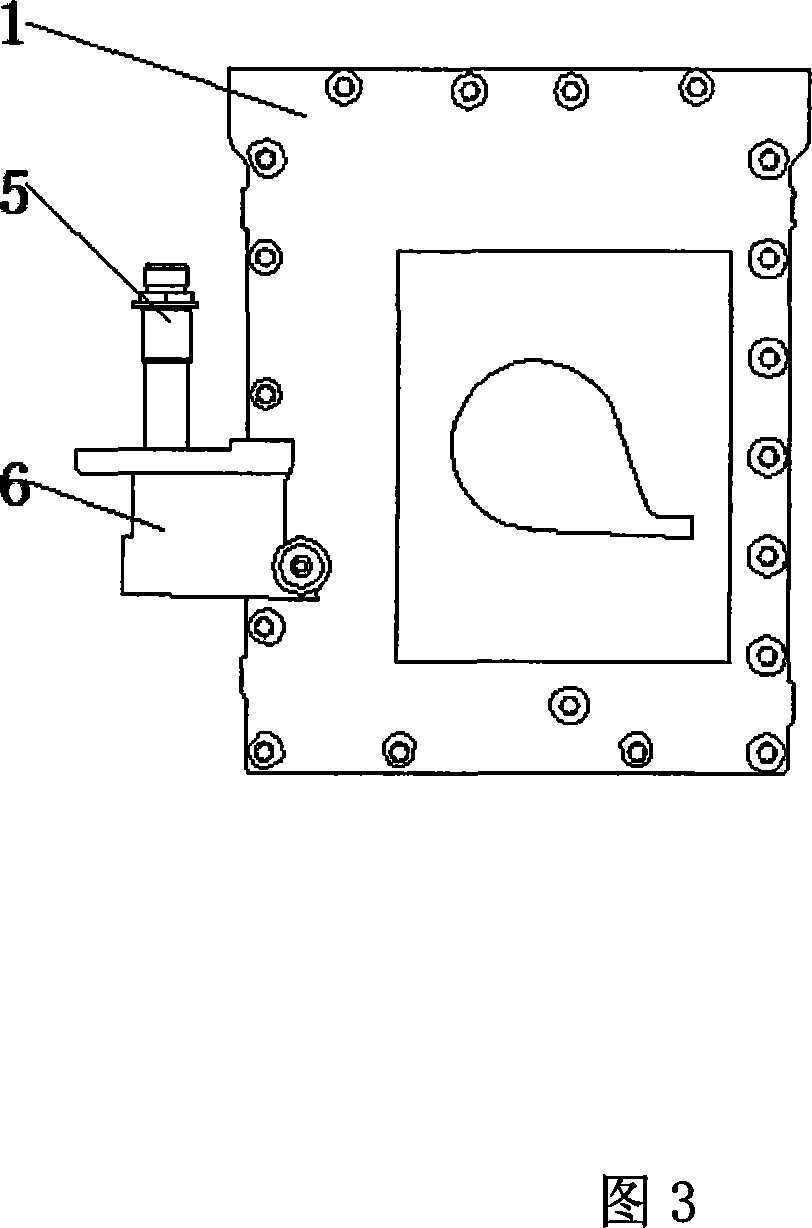

[0029] On the basis of Embodiment 1, the specific connection method: a threaded connection hole 4 is provided on the filter mounting boss 6, an oil cooler joint 5 is provided, and the end of the oil cooler joint 5 is Thread, the threaded portion is tightly connected to the threaded connection hole 4; the oil cooler 3 is firmly connected to the oil cooler joint 5; the oil filter 2 is tightly connected to the oil cooler joint 5 thread on one end.

[0030] In the technical solution proposed by the present invention, the oil cooler 3 and the filter installation boss 6 of the filter are installed on the side of the oil pan 1, and the oil cooler joint 5 is connected to the thread of the oil cooler 1 installed on the oil pan. In the connection hole 4, install the oil cooler 3 on the filter installation boss 6 through the oil cooler joint 5, and then install the oil filter 2 on the oil cooler 3 through the other end of the oil cooler joint 5 , thus completing the installation of the ...

Embodiment 3

[0033] The specific installation position of the oil filter 2: as shown in Figure 2, the position of the oil filter 2 is set on the side of the connection direction between the oil pan 1 and the engine block. The position setting method of the above-mentioned oil filter 2 and the oil cooler 3 integrated with its side is to make the installation of the whole engine in the vehicle body convenient, without affecting other structures, and for the oil pan 1 In terms of processing, it is also more convenient and has better process performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com