Patents

Literature

113results about How to "Change the installation method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

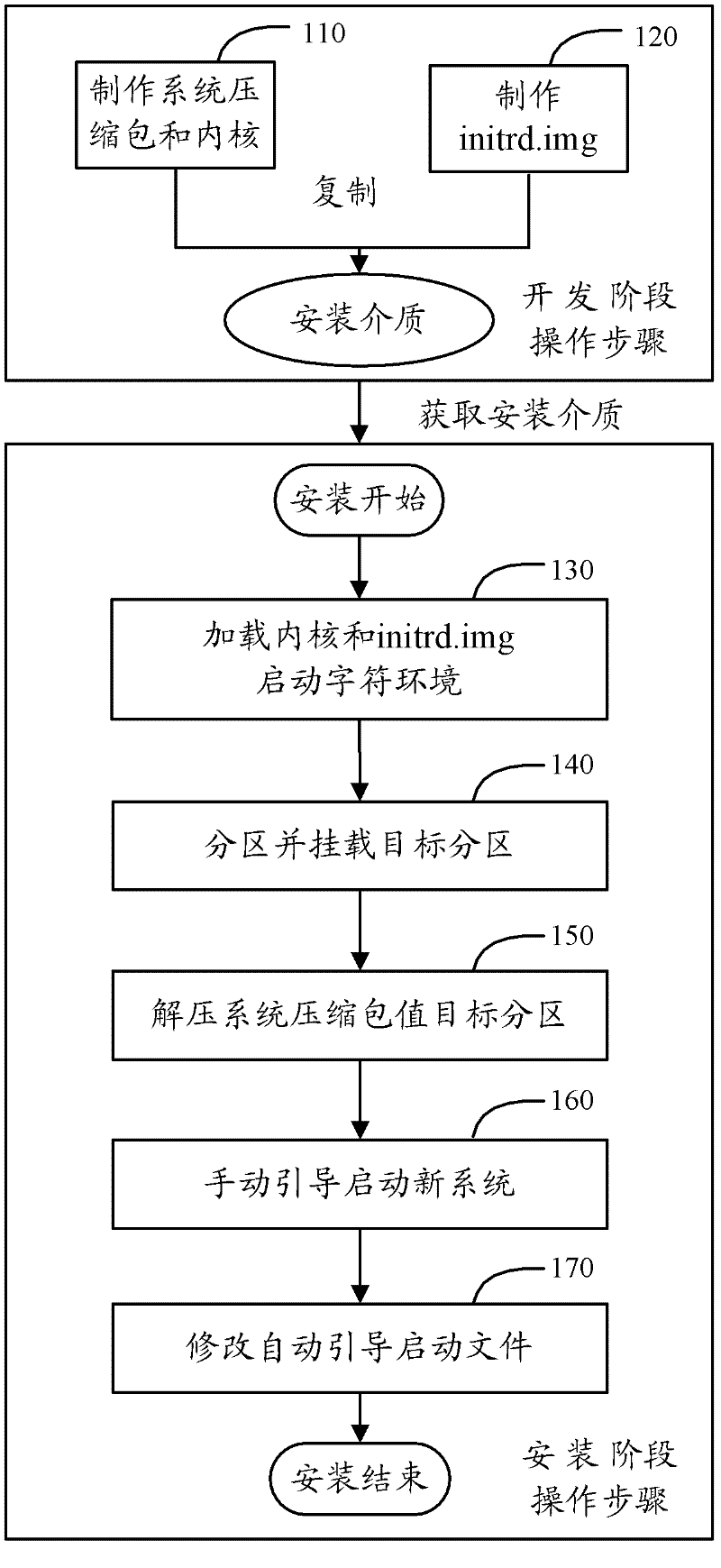

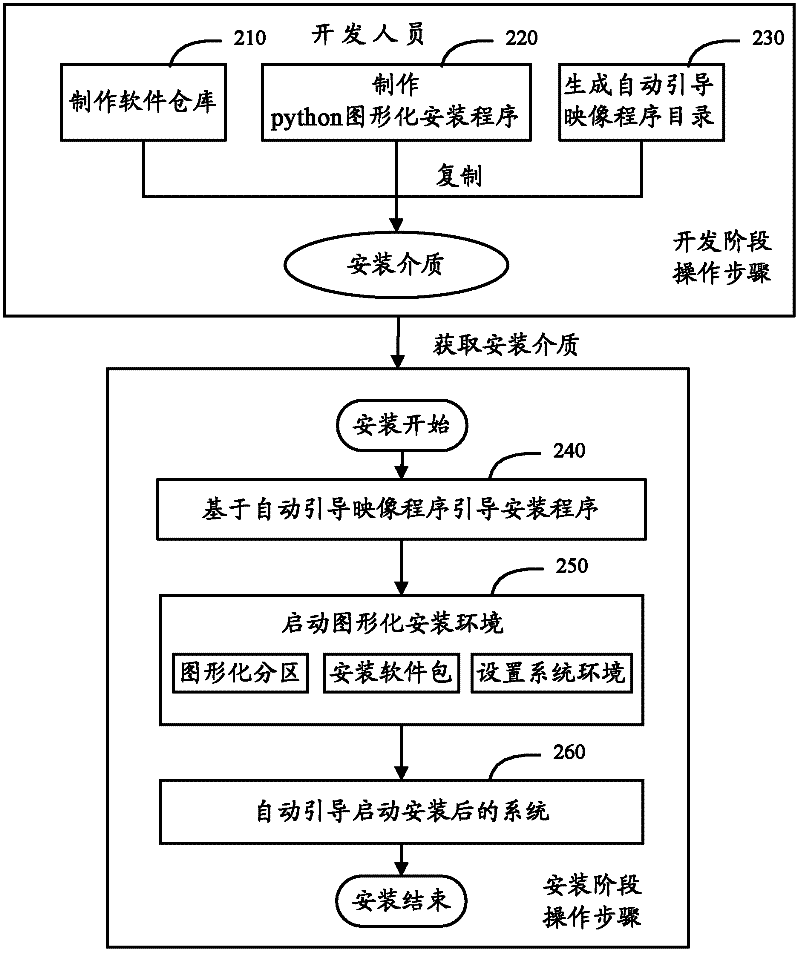

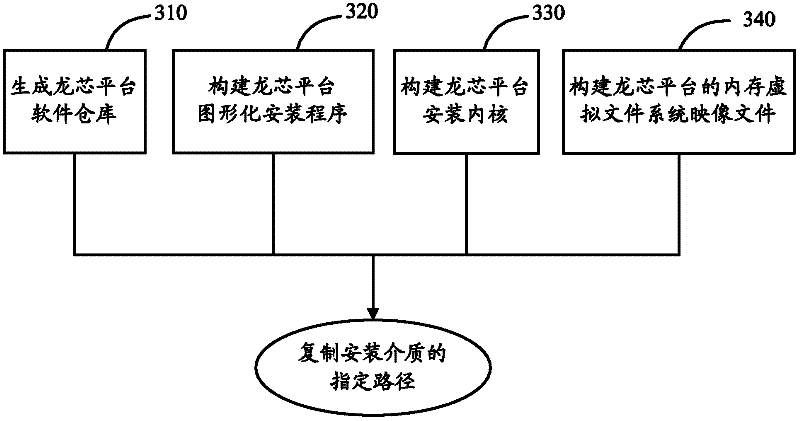

Method and device for preparing graphical installation system of Loongson platform

ActiveCN102567051AChange the installation methodShorten the timeProgram loading/initiatingVirtual file systemSoftware engineering

The invention discloses a method and device for preparing a graphical installation system of a Loongson platform. The method comprises the following steps of: generating a software repository applied to the Loongson platform; deleting content which is not supported by a Loongson architecture in an anaconda graphical installation system, setting the content supporting the Loongson architecture, and constructing a graphical installation program based on the anaconda graphical installation system after modification; placing kernel source codes of a Loongson into a catalog of a storage kernel of the anaconda graphical installation system, and performing kernel configuration to generate an installation kernel of the Loongson; and deleting the content which is not supported by the Loongson in a buildinstall script, loading a device driver and a kernel module which are suitable for the Loongson, and generating a mapping file of a memory virtual file system based on the buildinstall script after modification. According to the method and device disclosed by the invention, the installation way of the existing Loongson platform system is changed from the manual installation way to the automatic installation way, thus the installation time is saved.

Owner:CHINA STANDARD SOFTWARE

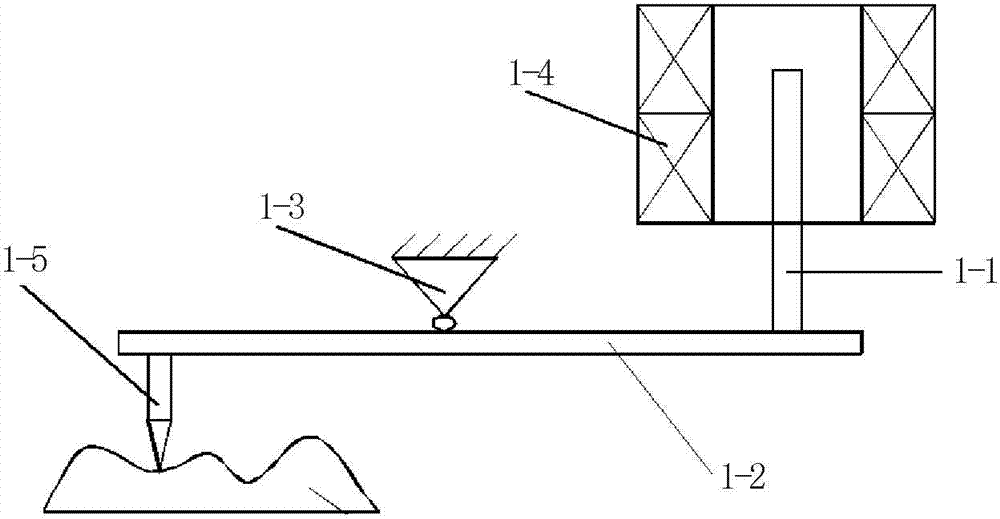

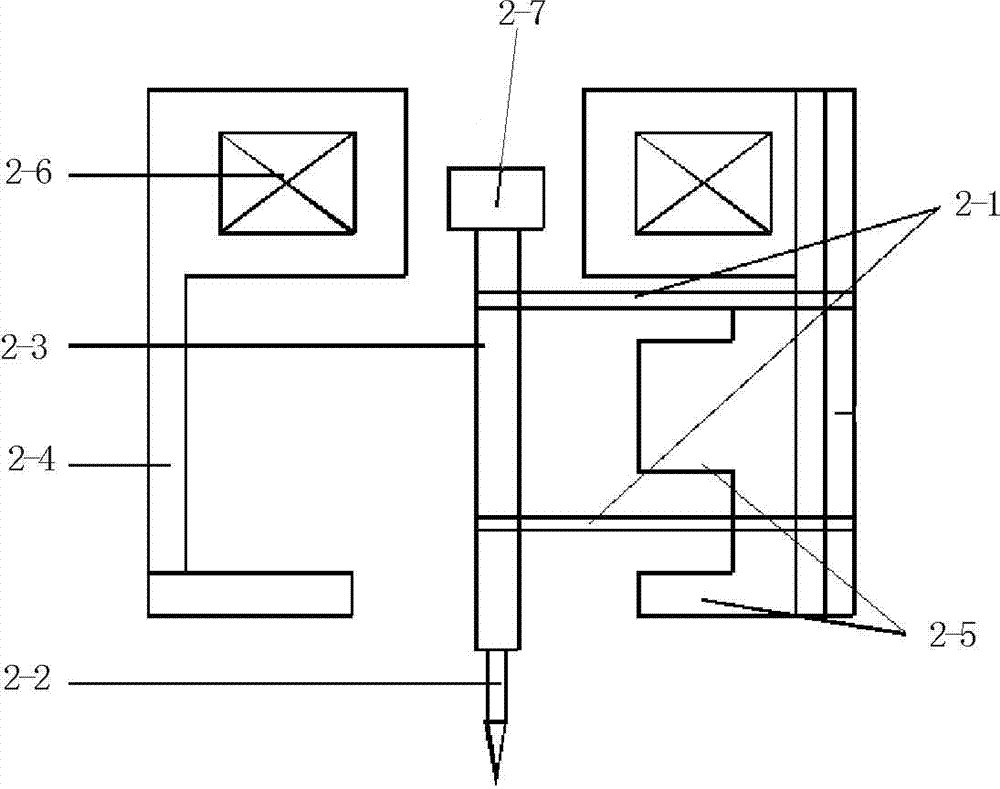

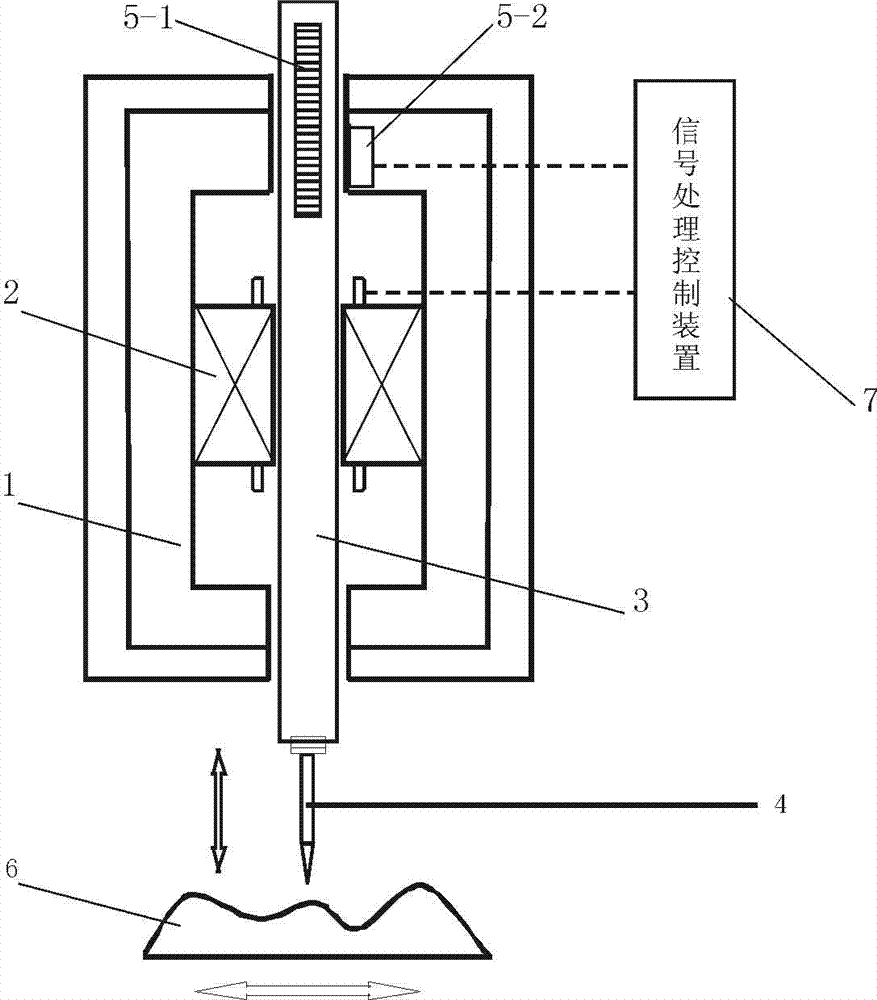

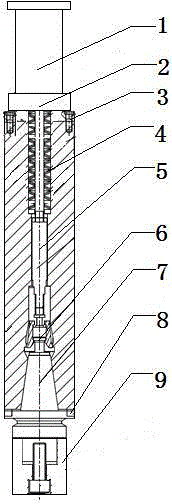

Magnetic suspension contact pin type displacement sensor for micro-topography measurement

InactiveCN104713496AChange the installation methodImprove complianceUsing optical meansEngineeringSignal processing

The invention provides a magnetic suspension contact pin type displacement sensor for micro-topography measurement. The magnetic suspension contact pin type displacement sensor comprises a measurement probe, a probe supporting seat, a reading sensor and a signal processing control device. A contact pin is installed at the lower end of a magnetic suspension type feeler lever, the feeler lever is a magnet and arranged in the probe supporting seat, a gap is reserved between the feeler lever and the probe supporting seat, and the probe supporting seat is an electromagnet. The reading sensor corresponds to the measurement probe. The signal processing control device is arranged and connected with the reading sensor and the probe supporting seat. The feeler lever and the contact pin are suspended through the magnetic force effect of the magnetic suspension supporting seat and the feeler lever, a traditional mechanical fixing contact type feeler lever installation method is completely changed, high adaptability of the feeler lever and the contact pin is guaranteed, the feeler lever can only linearly move perpendicular to the surface of a workpiece, non-linear errors of a traditional sensor are fundamentally eliminated, measurement accuracy is greatly improved, the measurement range of the senor is widened, and the magnetic suspension contact pin type displacement sensor is suitable for development of the precision machining technology and better meets the requirements of industrial measurement.

Owner:SICHUAN UNIV

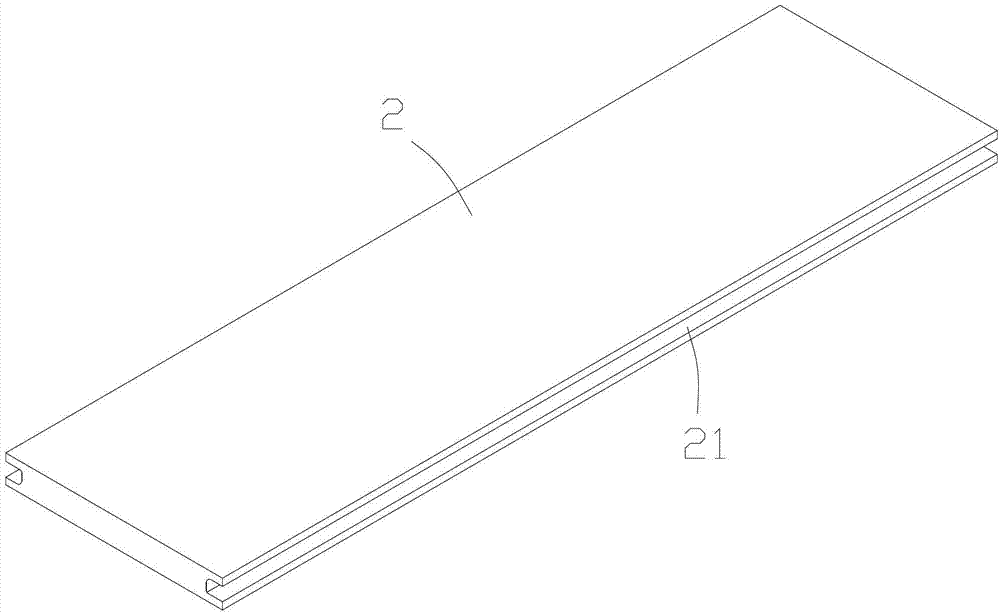

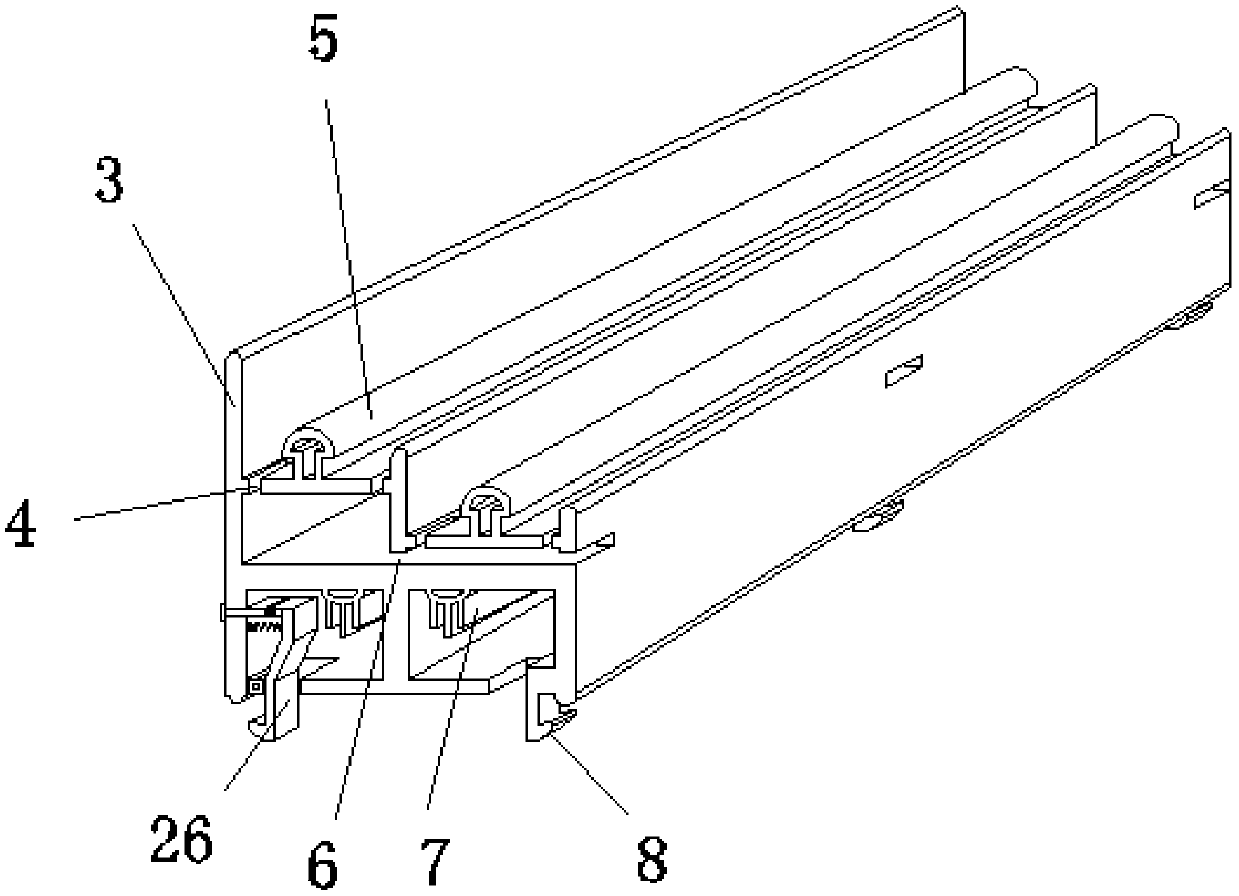

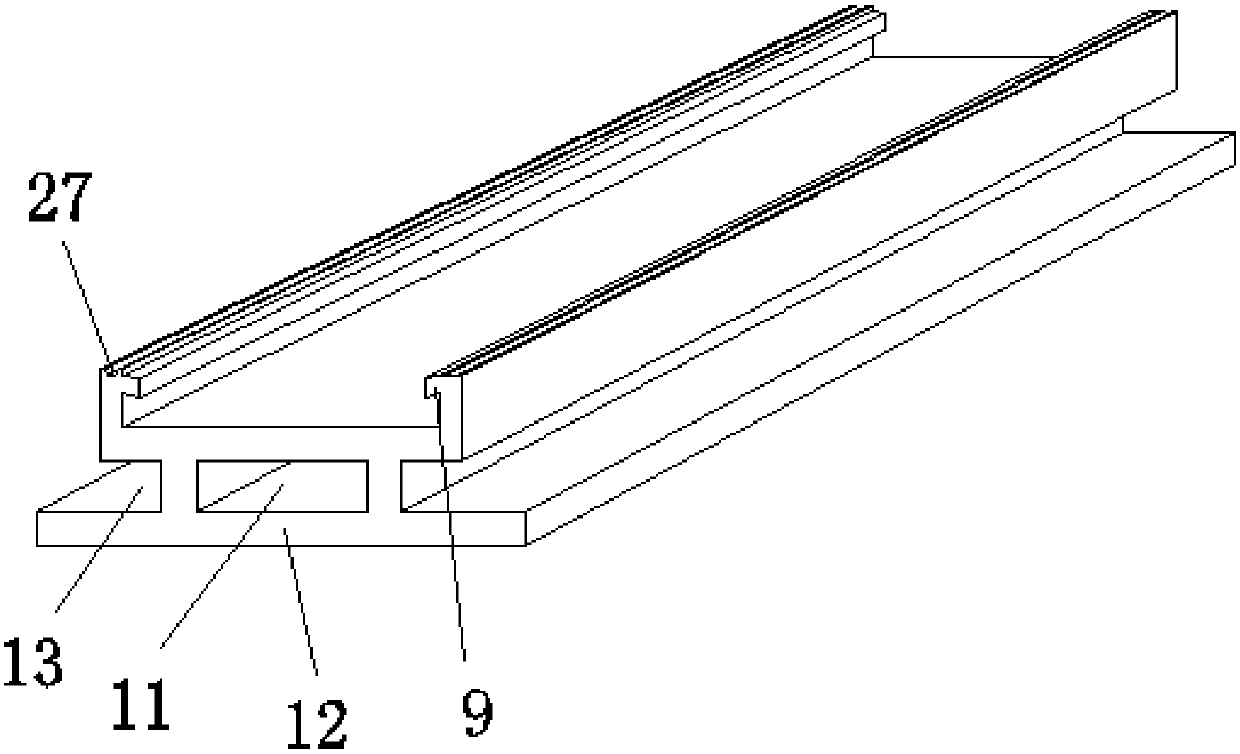

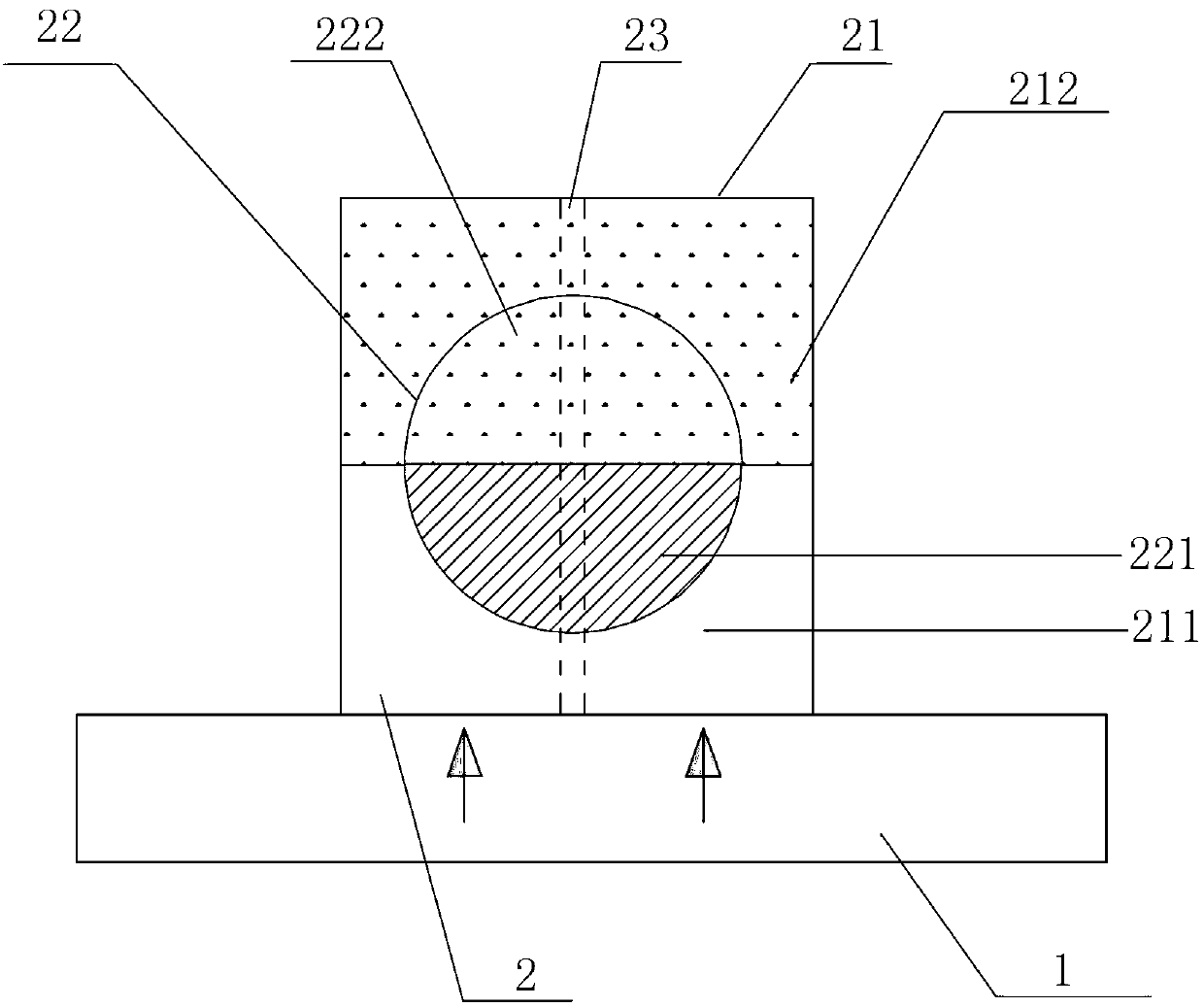

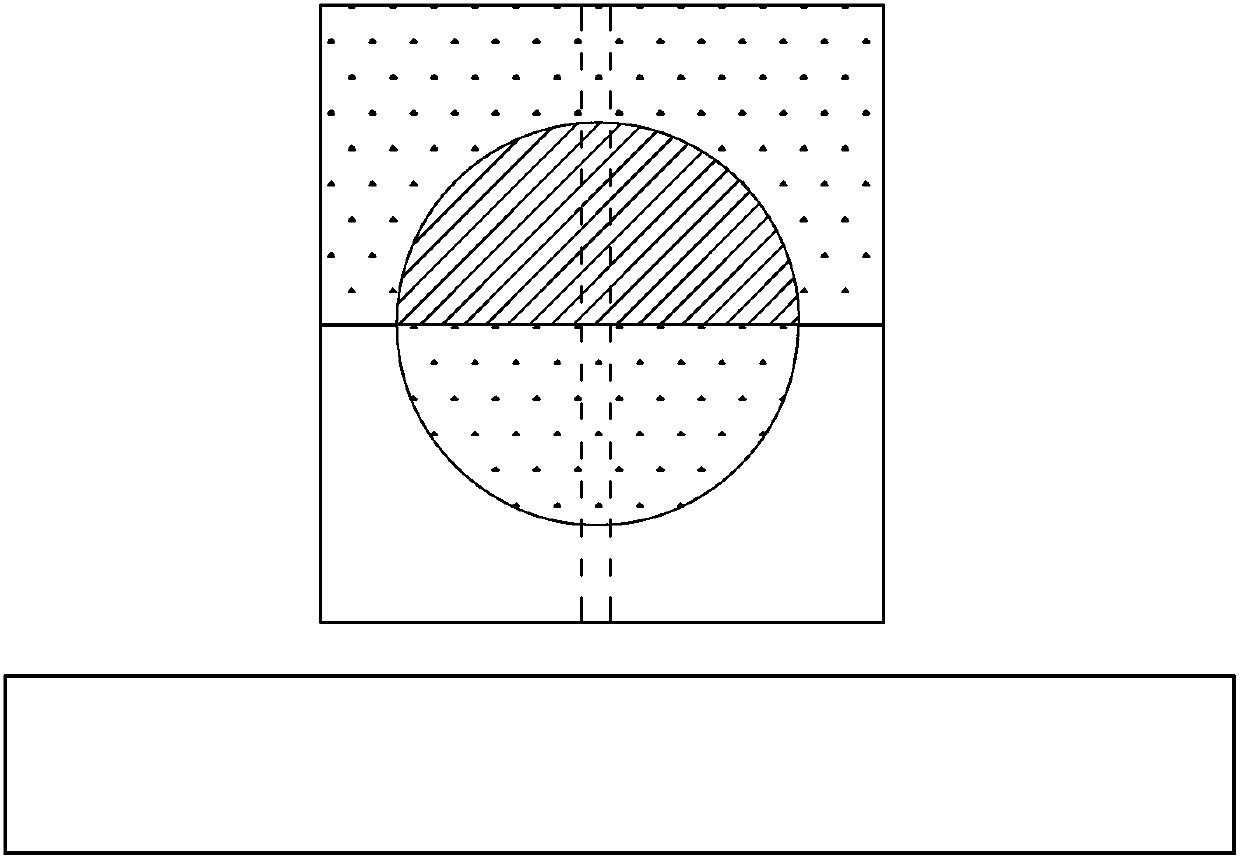

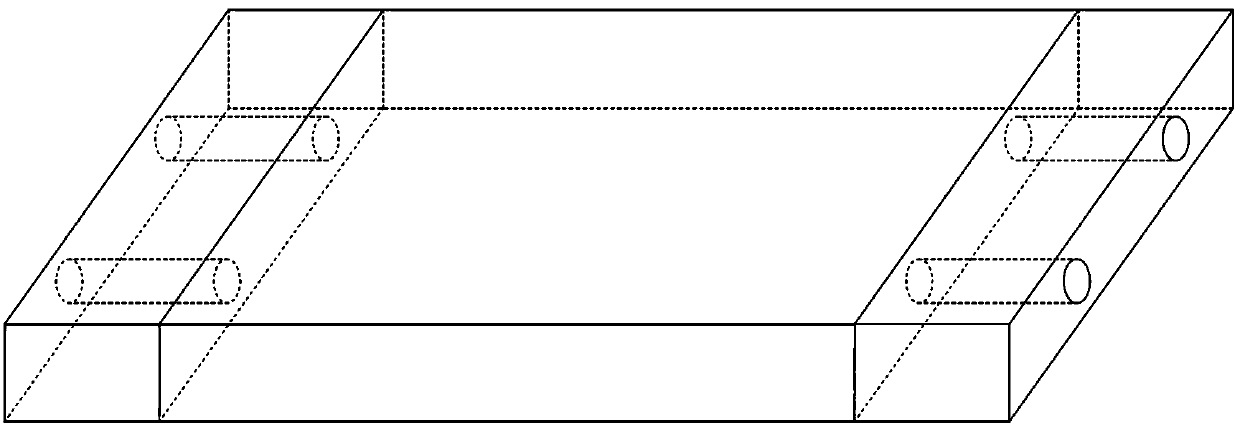

Outdoor wood plastic floor installation structure and installation method

The invention discloses an outdoor wood plastic floor installation structure, and relates to the technical field of floor installation. The installation structure comprises big joists, a wood plastic floor, starting clamping keys and rotary claming keys. The installation structure is characterized in that the starting clamping keys are arranged on two end portions of the big joists, the wood plastic floor is installed on the upper portions of the big joists, one end of the wood plastic floor is connected with the big joists through the starting clamping keys, and the other end of the wood plastic floor is arranged on the big joists through the rotary clamping keys. The installation structure and an installation method change a traditional installation method and a traditional installation structure, and greatly improve installation efficiency. The installation method is simple and reliable, and therefore pavement work is enabled to be more standard, Due to the fact that clamping technology is adopted, a floor system can be disassembled and assembled conveniently in lateral repair and maintenance, and not only can the floor not be damaged, but also repair cost is reduced.

Owner:ANHUI SENTAI WPC GRP CO LTD

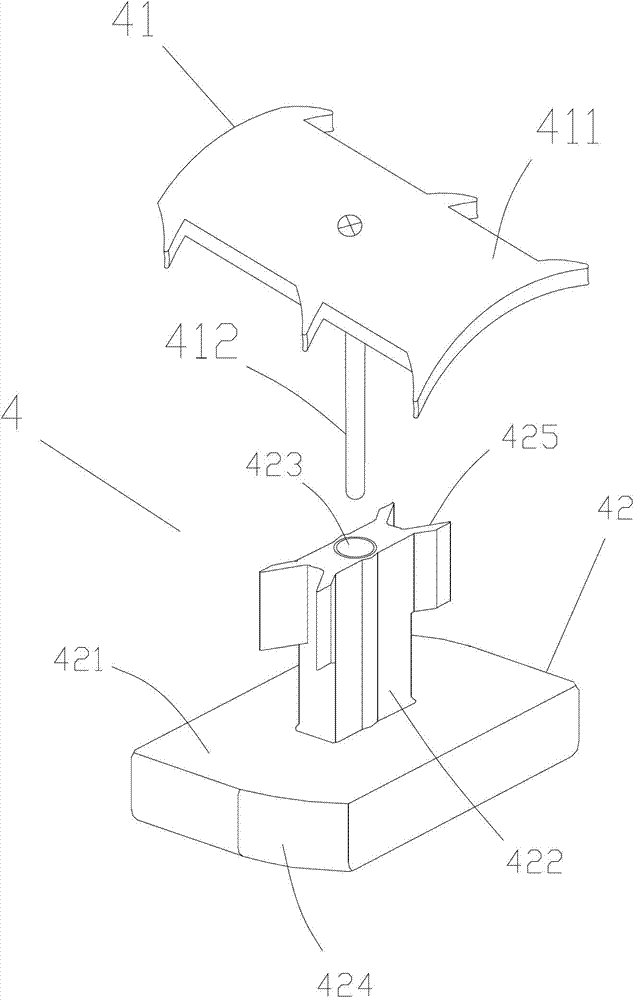

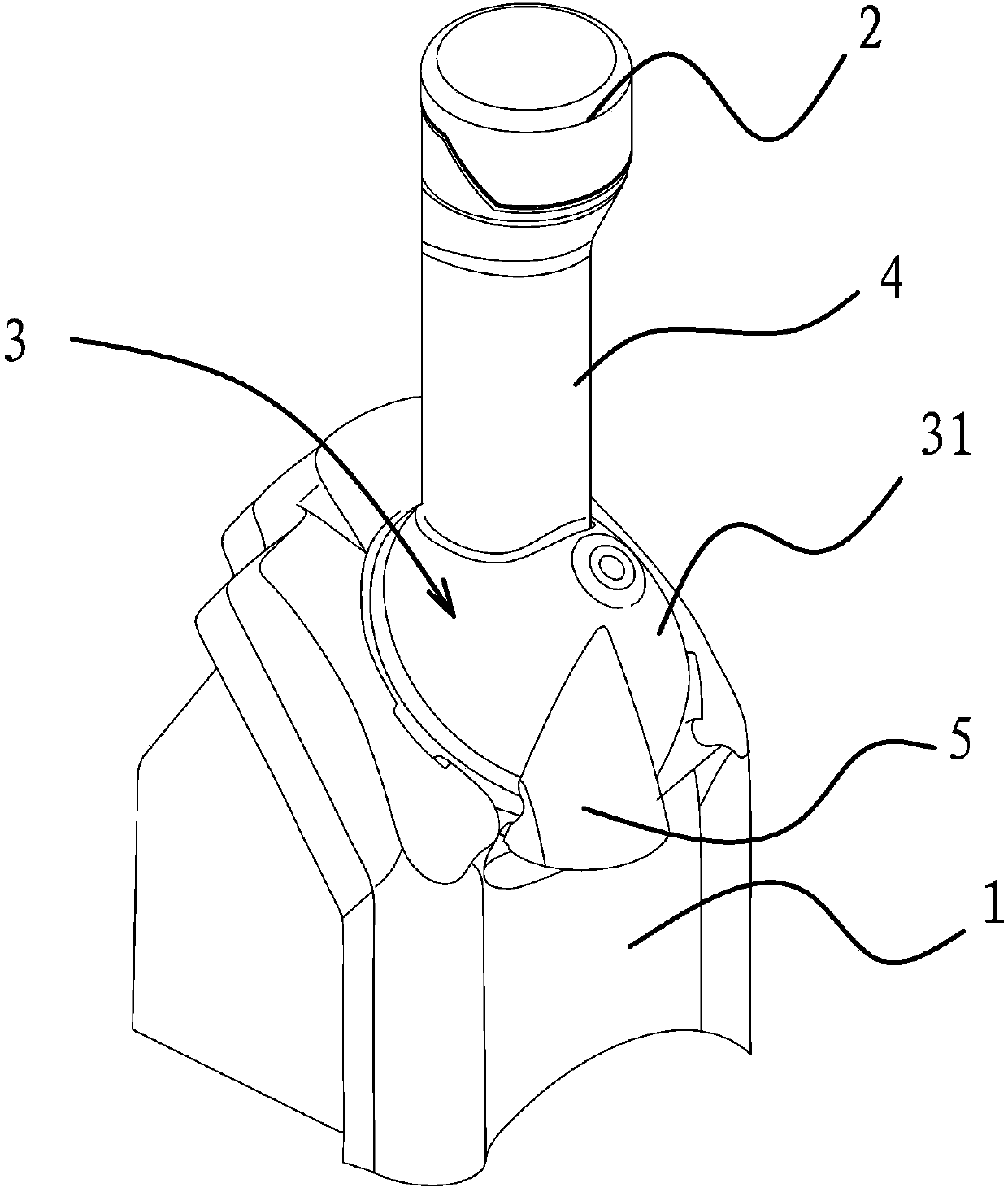

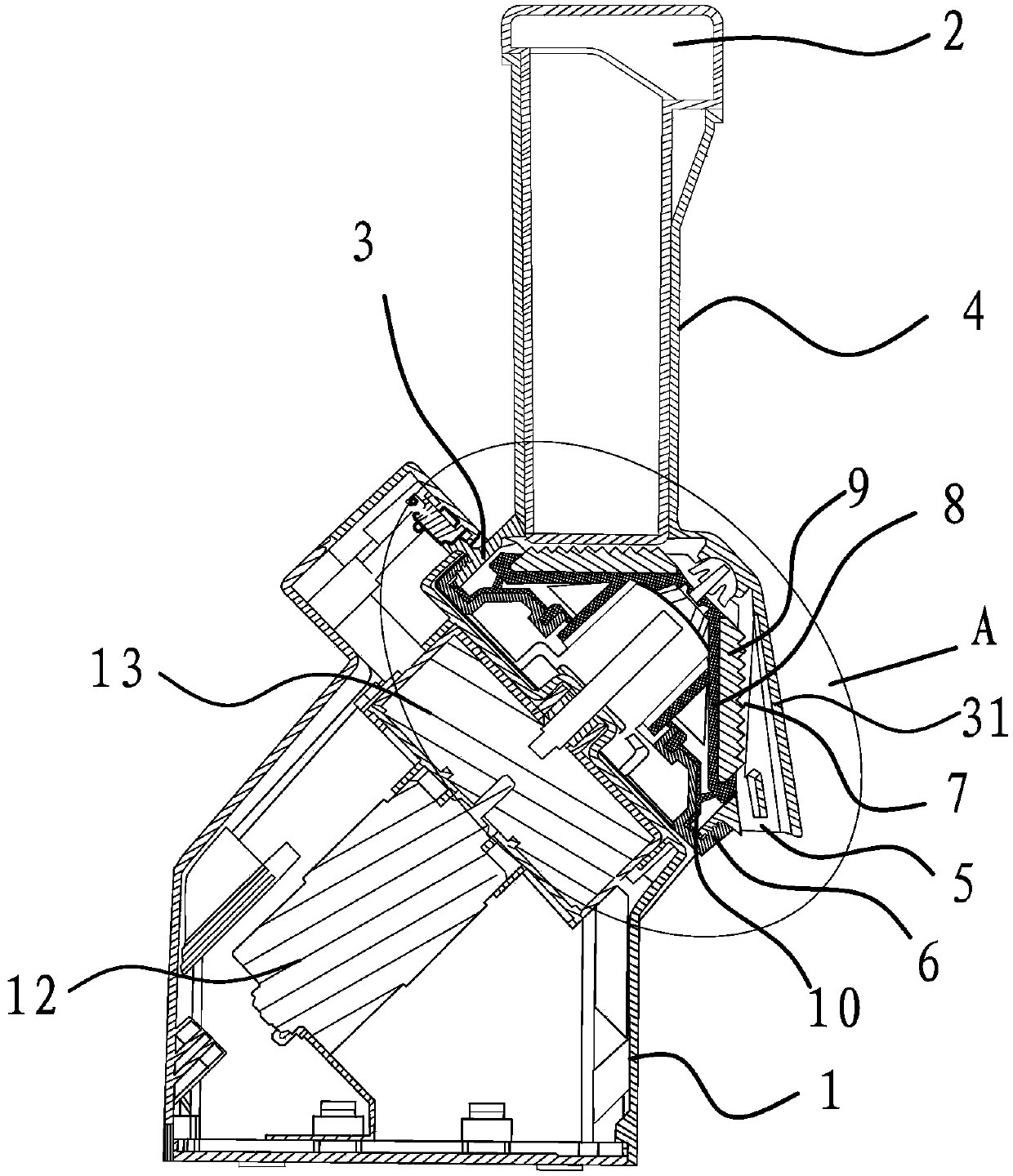

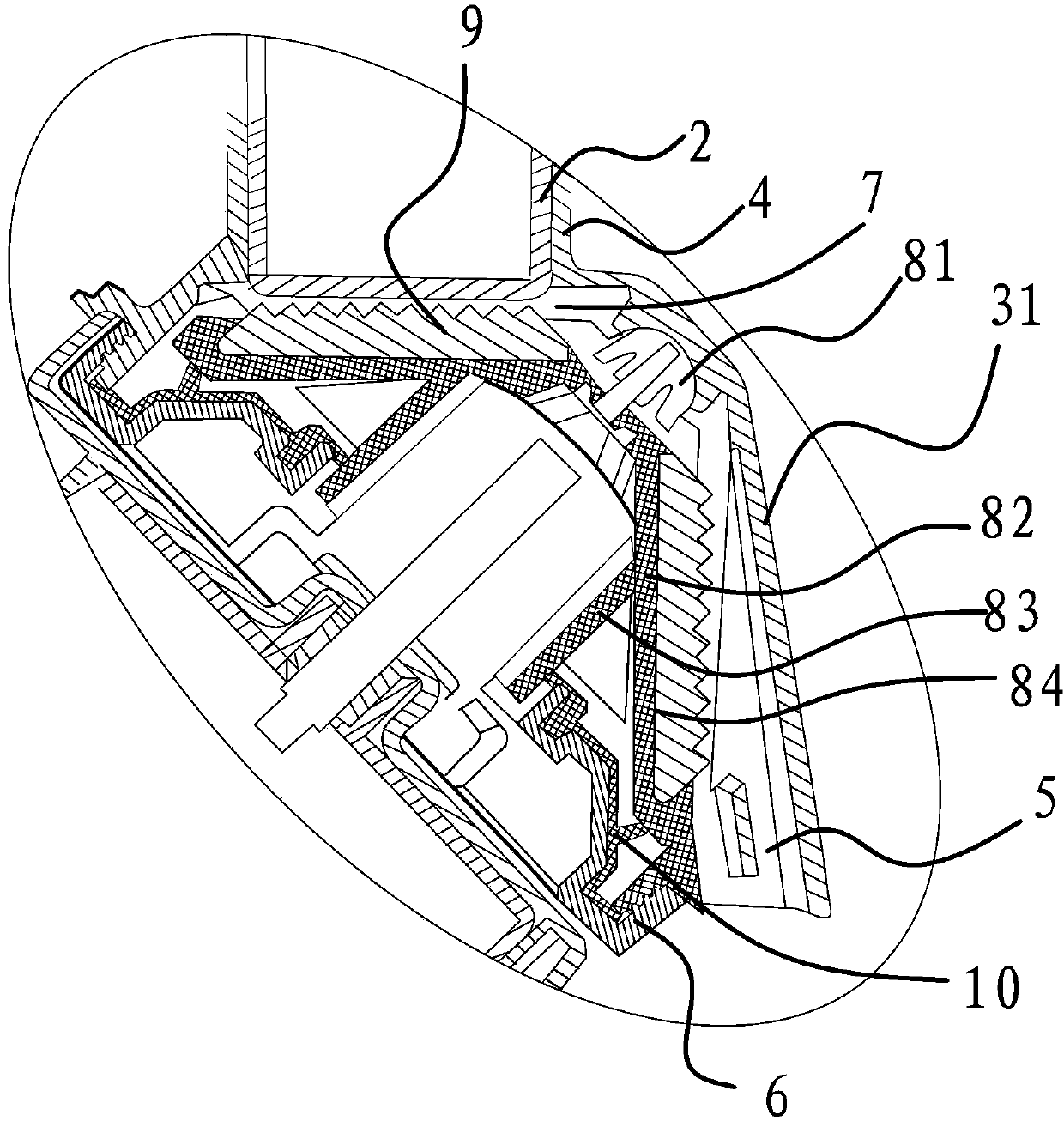

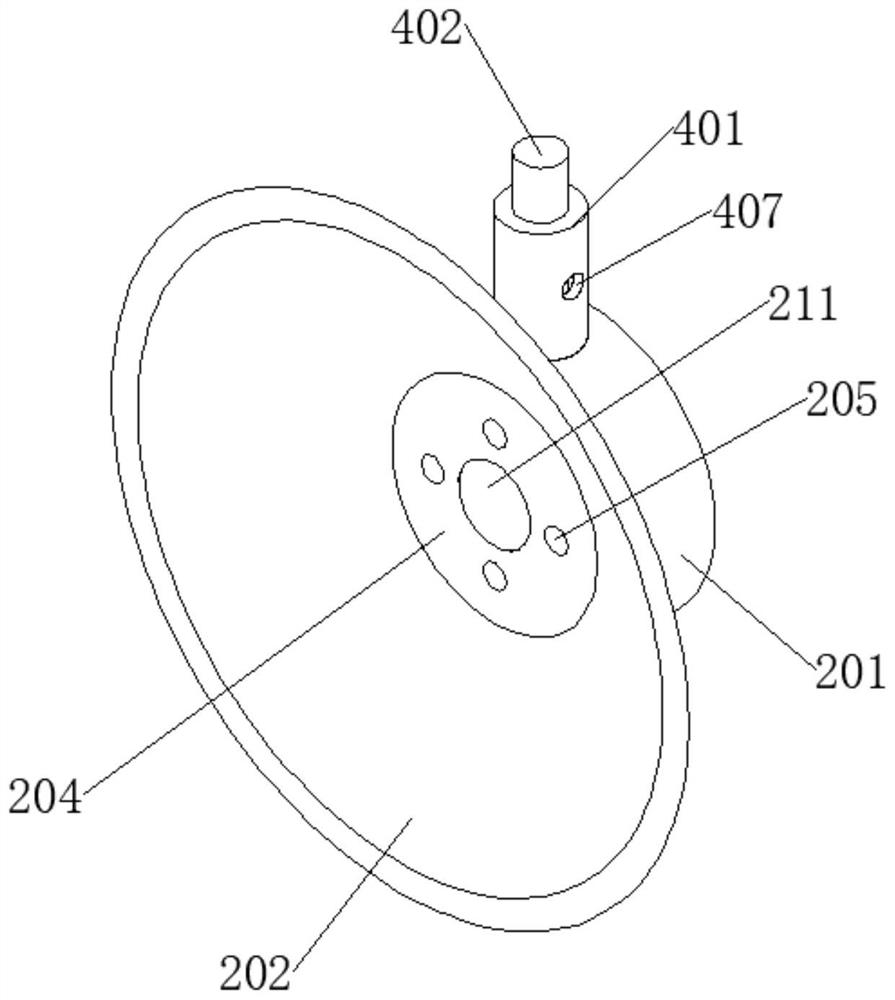

Fruit ice cream machine

InactiveCN103168908AChange the setting directionIncrease the output speedFrozen sweetsReduction driveElectric machinery

The invention provides a fruit ice cream machine, belongs to the technical field of food equipment, and solves the problems of the existing fruit ice cream machine that the discharging speed is low and residual food remains in a stirring cavity. The fruit ice cream machine comprises a machine base, an abrasive disc and an electric motor arranged inside the machine base, wherein the electric motor is connected with the abrasive disc through a speed reducer; the abrasive disc can be driven to rotate through the electric motor; a material containing bin is further arranged above the machine base; the material containing bin consists of a cylindrical feeding barrel and a conical gland; a discharging port is formed in the gland; a plurality of strip-shaped serrated blades are uniformly fixed on the outer circular conical surface of the abrasive disc; each blade is arranged along the rotation direction of the same abrasive disc relative to the straight edge line of the outer circular conical surface of the abrasive disc according to the same inclined angle; and a concave material storage groove is formed in the outer circular conical surface of the abrasive disc between two adjacent blades. According to the fruit ice cream machine, the discharging speed can be increased, and residual ice-cream-shaped food inside the stirring cavity is reduced.

Owner:马剑峰

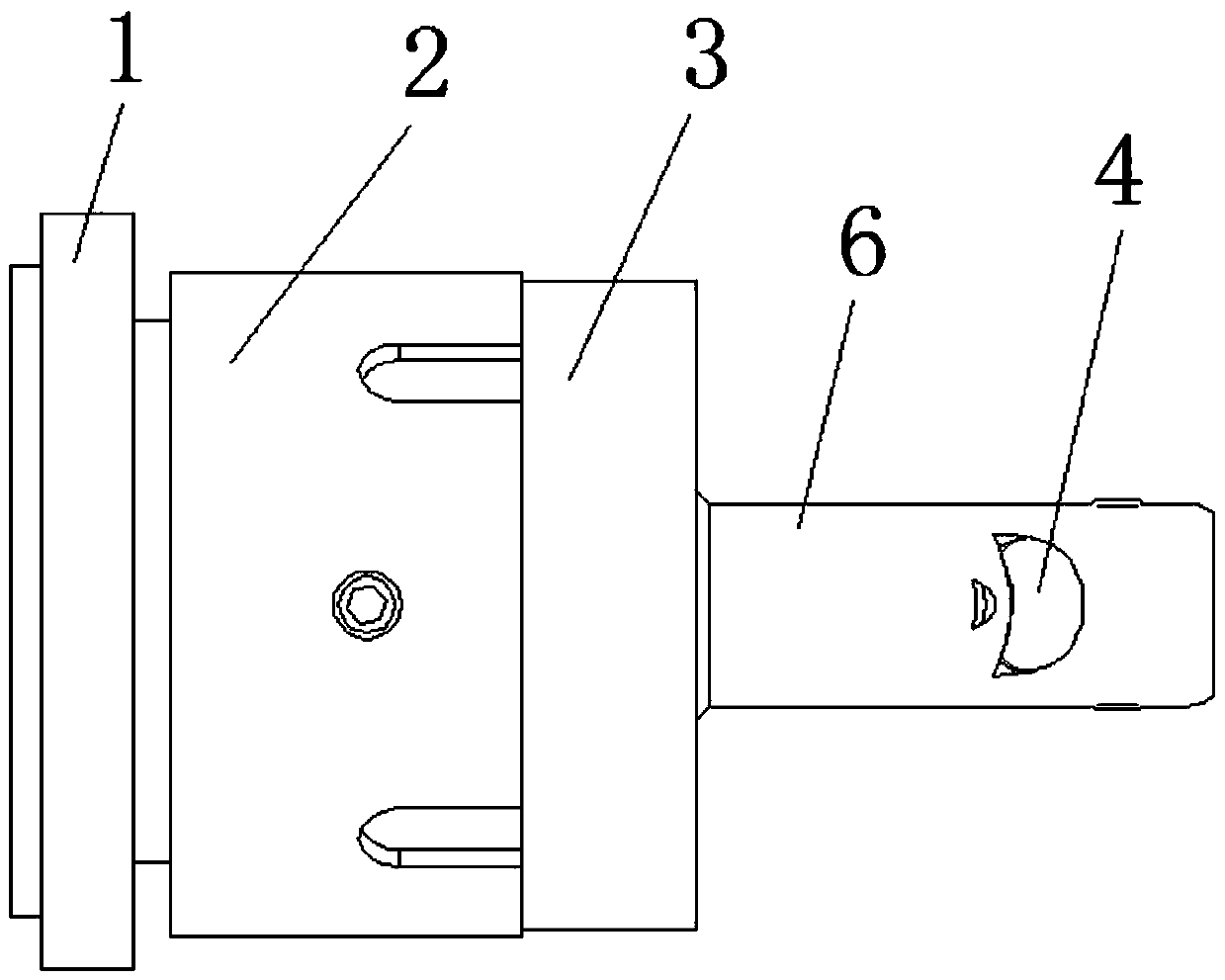

Programmable general tyre pressure sensor installation system and installation method

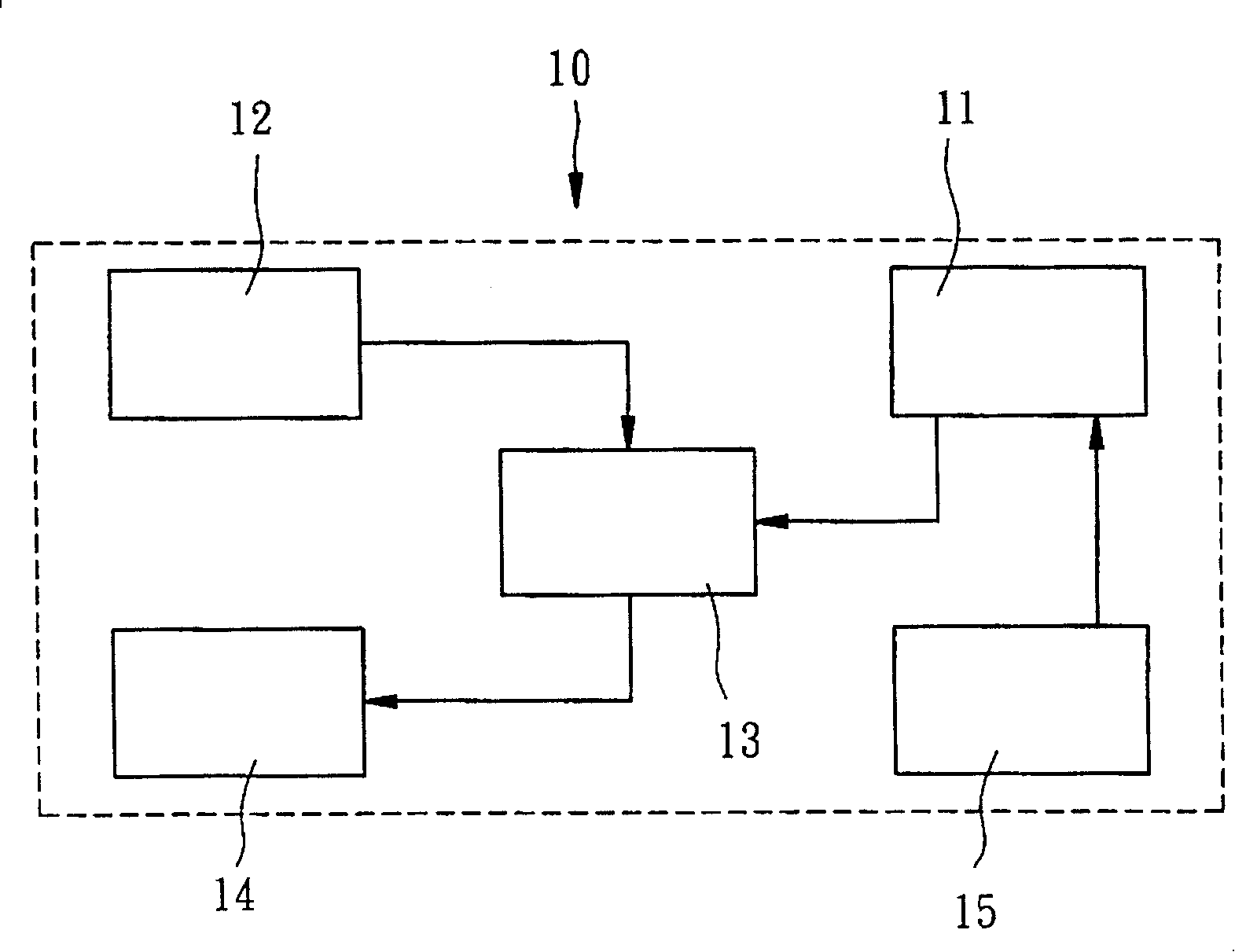

ActiveCN101169344AChange the installation methodReduce cost pressureElectric signal transmission systemsInflated body pressure measurementPneumatic pressureProgram code

The invention relates to a programmable universal tire pressure sensor setting system and setting method, which includes a tire pressure sensing device, the tire pressure sensing device includes a sensor for sensing the air pressure and temperature inside the tire, and a sensor for receiving external signals A receiver, a storage processing group connected to the sensor and the receiver, a transmitter connected to the storage processing group; a power supply group providing power required by the tire pressure sensing device. Its setting method is to first take an unactivated tire pressure sensing device, and then select a specific activation signal by a processing device, transmit the activation signal to a program coding device, activate the tire pressure sensing device through the program coding device, and make the tire pressure The sensing device becomes a sensing device conforming to a specific coded program, which in turn communicates in telecommunication with an external specific monitoring device. The present invention not only changes the conventional installation method, makes the installation method simpler, but also greatly reduces the cost pressure on stock preparation, and obviously improves the problem of conventional products.

Owner:CUB ELECPARTS

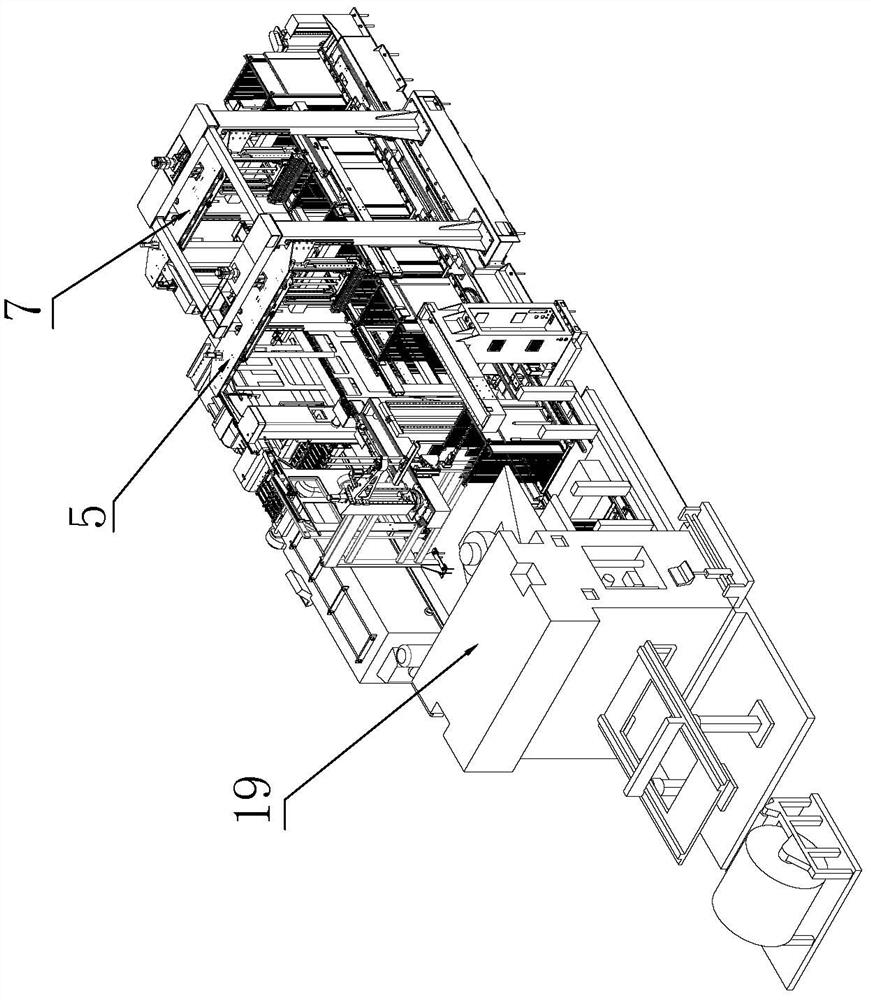

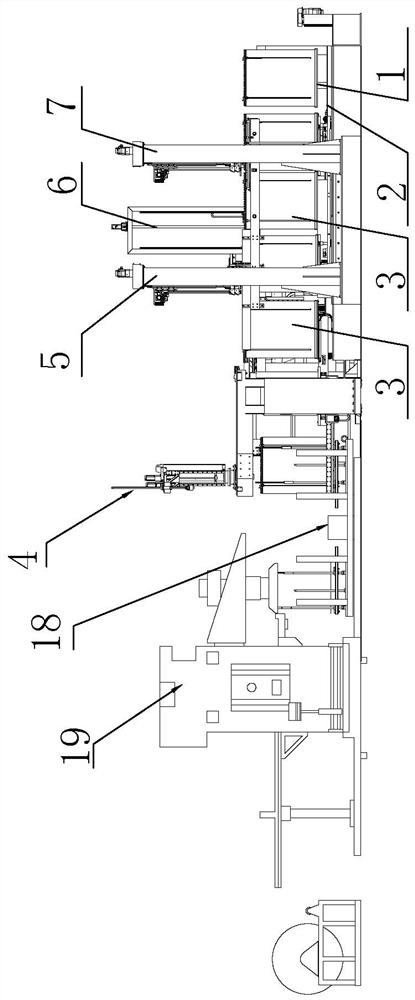

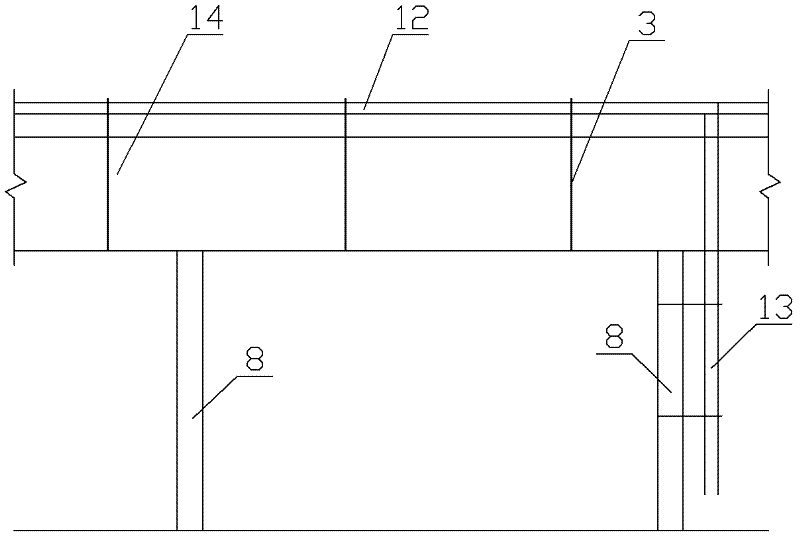

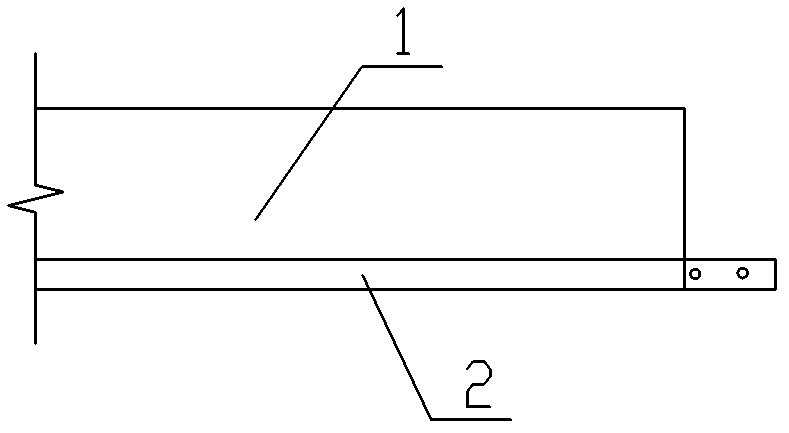

Semi-automatic corrugated beam guardrail board mounting machine and working method thereof

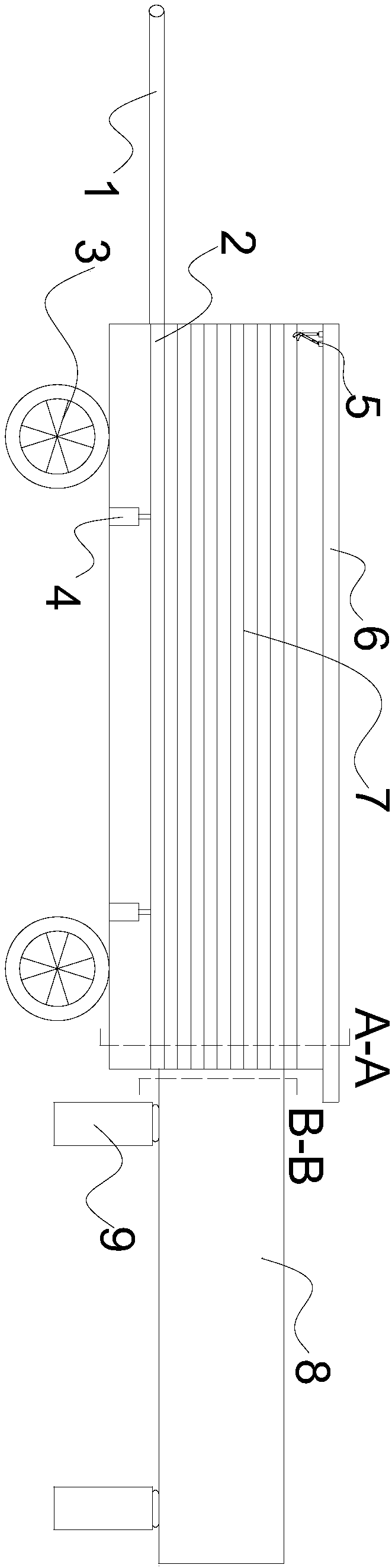

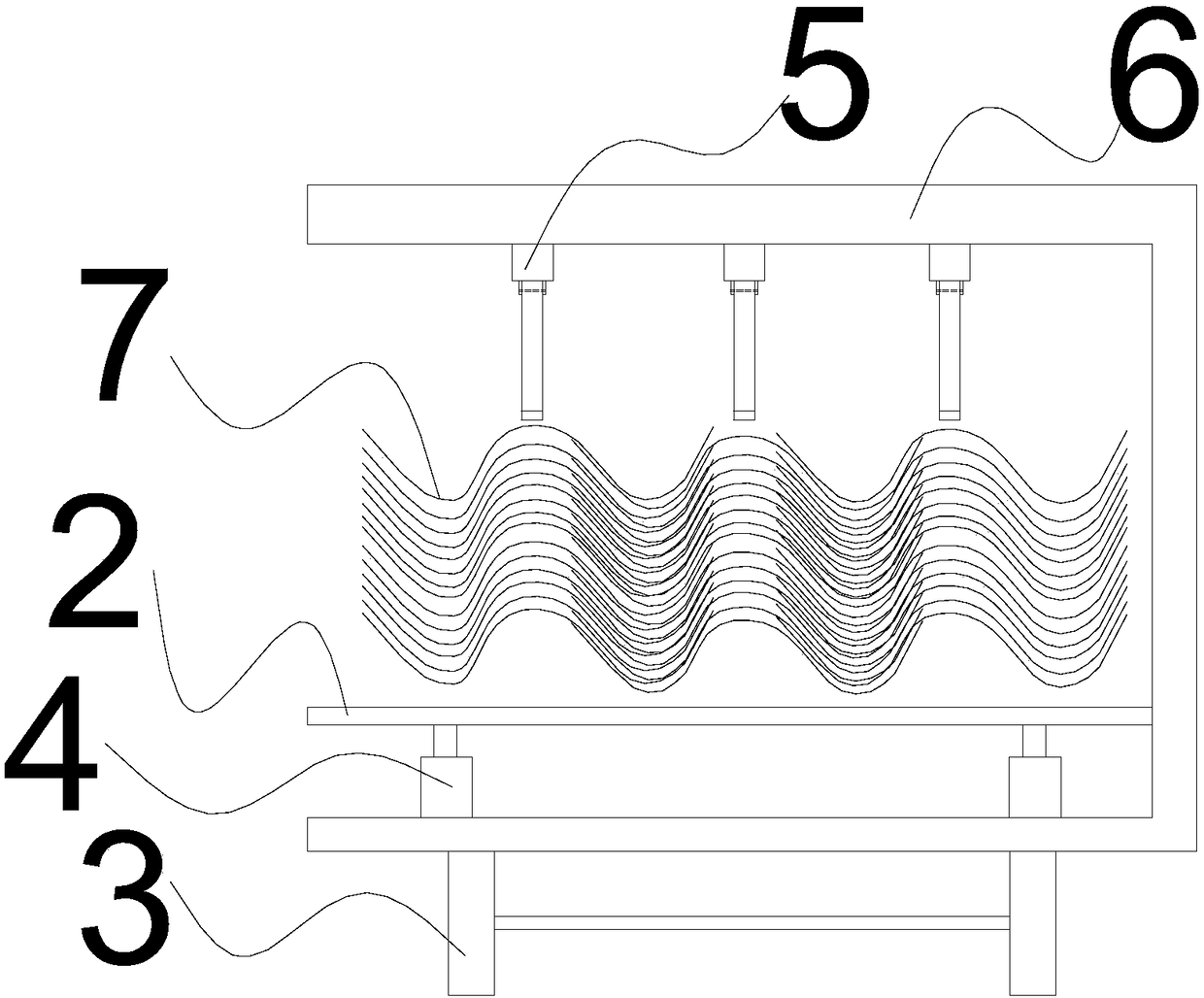

InactiveCN108589596AChange the installation methodFree laborRoadway safety arrangementsHydraulic cylinderSemi automatic

The invention provides a semi-automatic corrugated beam guardrail board mounting machine. The semi-automatic corrugated beam guardrail board mounting machine comprises a traveling mechanism. A traction rod is fixed to the front end of the traveling mechanism, and a bottom plate of the traveling mechanism is divided into two parts. The first part is a corrugated beam guardrail board holding area, and the second part is a corrugated beam guardrail board transfer area. Hydraulic cylinders are fixed into the corrugated beam guardrail board holding area, and a support plate is fixed to output shafts of the hydraulic cylinders. A top cover is arranged on the support plate, and a track is installed on the lower bottom surface of the top cover. Hooks are connected to the track. A conveyor belt isfixed to the corrugated beam guardrail board transfer area, and movable brackets are connected to the conveyor belt. The invention further provides a working method of the semi-automatic corrugated beam guardrail board mounting machine. According to the semi-automatic corrugated beam guardrail board mounting machine and the working method thereof, a current installation method of corrugated beam guardrail boards is changed, and the labor force is liberated; and only the manual installation of the corrugated beam guardrail boards on installation columns is required, the labor is saved, and thework efficiency is improved.

Owner:丁敬荣

Fruit ice cream machine

InactiveCN103168908BChange the setting directionIncrease the output speedFrozen sweetsReduction driveElectric machinery

The invention provides a fruit ice cream machine, belongs to the technical field of food equipment, and solves the problems of the existing fruit ice cream machine that the discharging speed is low and residual food remains in a stirring cavity. The fruit ice cream machine comprises a machine base, an abrasive disc and an electric motor arranged inside the machine base, wherein the electric motor is connected with the abrasive disc through a speed reducer; the abrasive disc can be driven to rotate through the electric motor; a material containing bin is further arranged above the machine base; the material containing bin consists of a cylindrical feeding barrel and a conical gland; a discharging port is formed in the gland; a plurality of strip-shaped serrated blades are uniformly fixed on the outer circular conical surface of the abrasive disc; each blade is arranged along the rotation direction of the same abrasive disc relative to the straight edge line of the outer circular conical surface of the abrasive disc according to the same inclined angle; and a concave material storage groove is formed in the outer circular conical surface of the abrasive disc between two adjacent blades. According to the fruit ice cream machine, the discharging speed can be increased, and residual ice-cream-shaped food inside the stirring cavity is reduced.

Owner:马剑峰

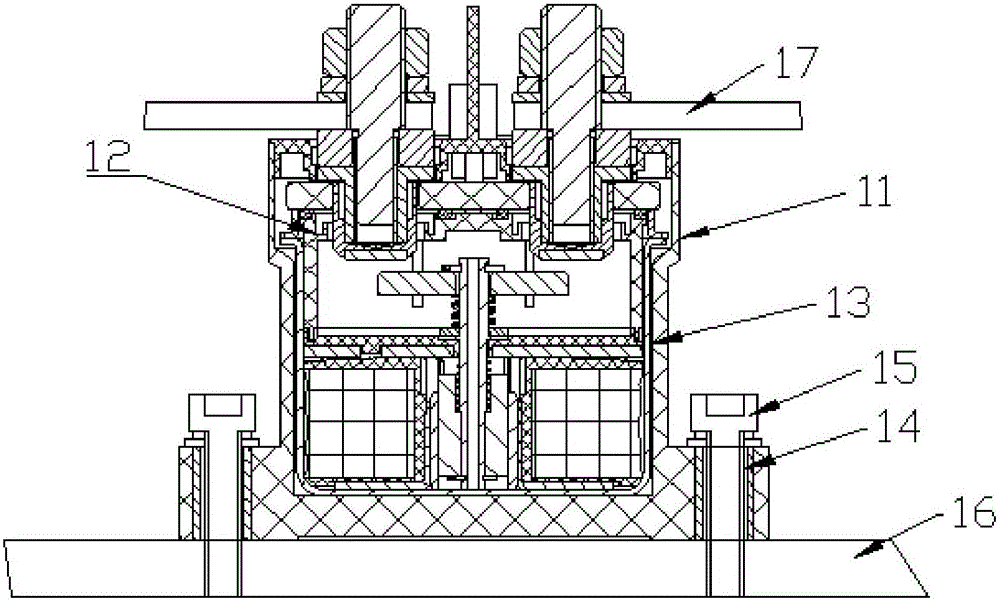

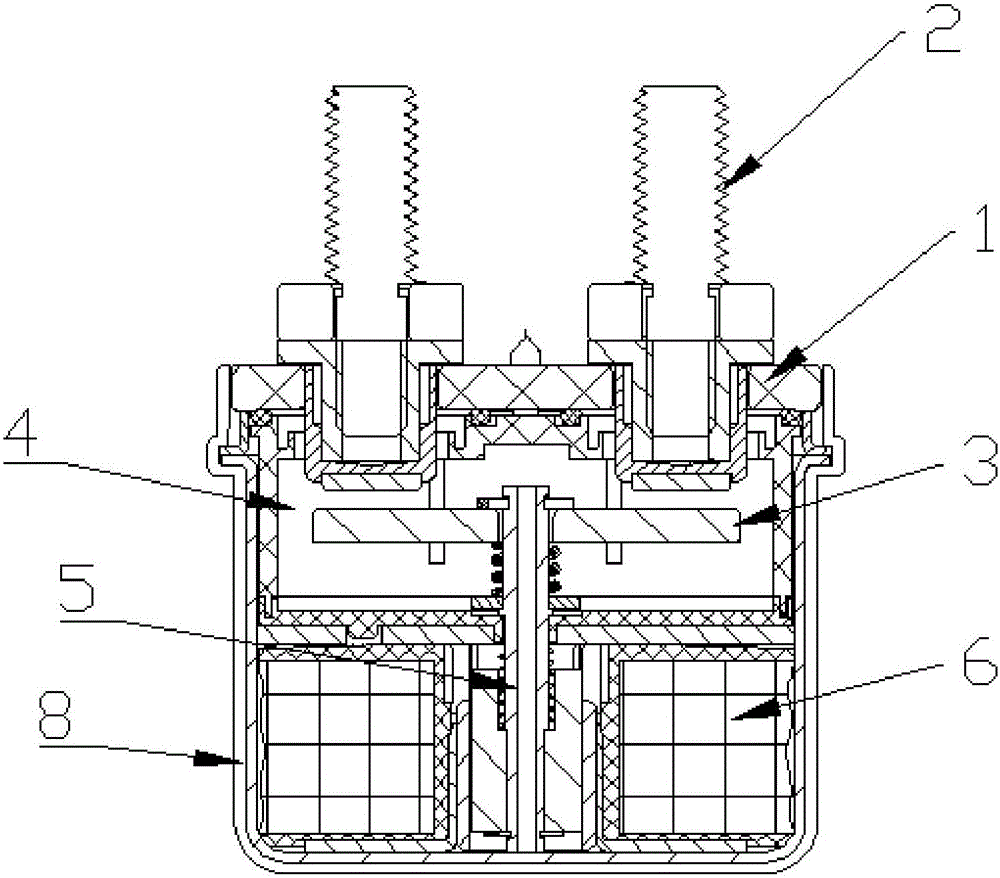

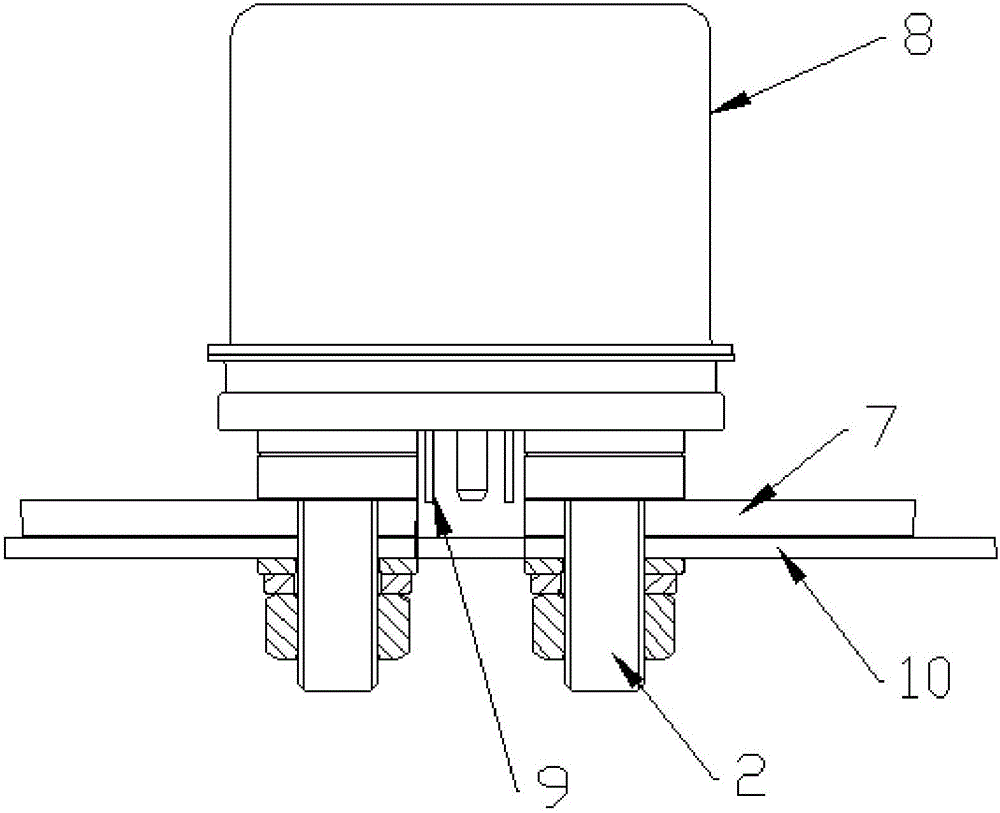

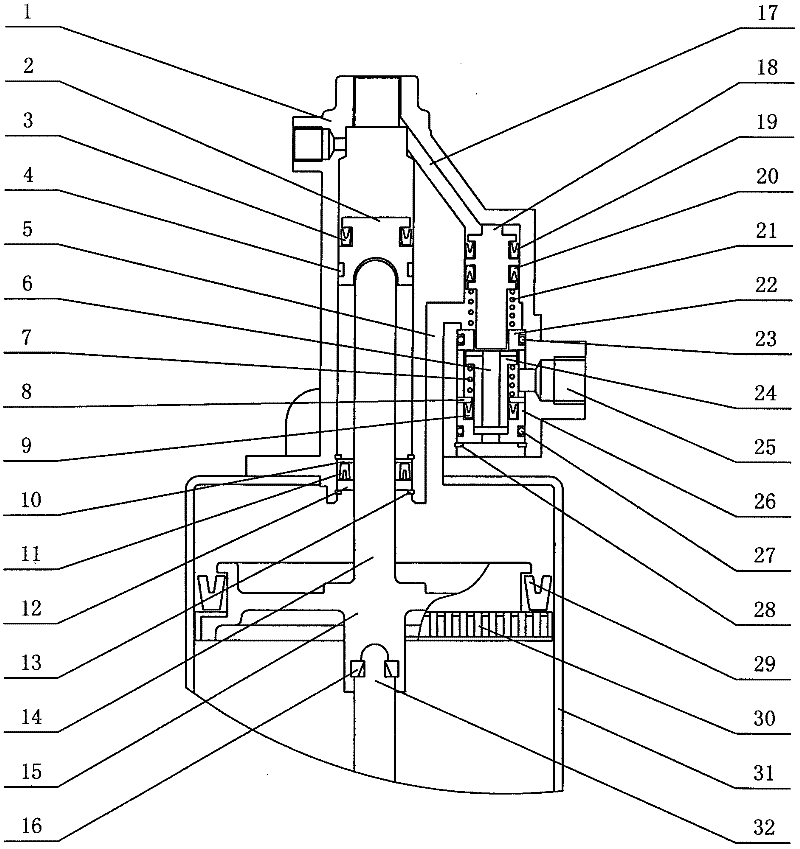

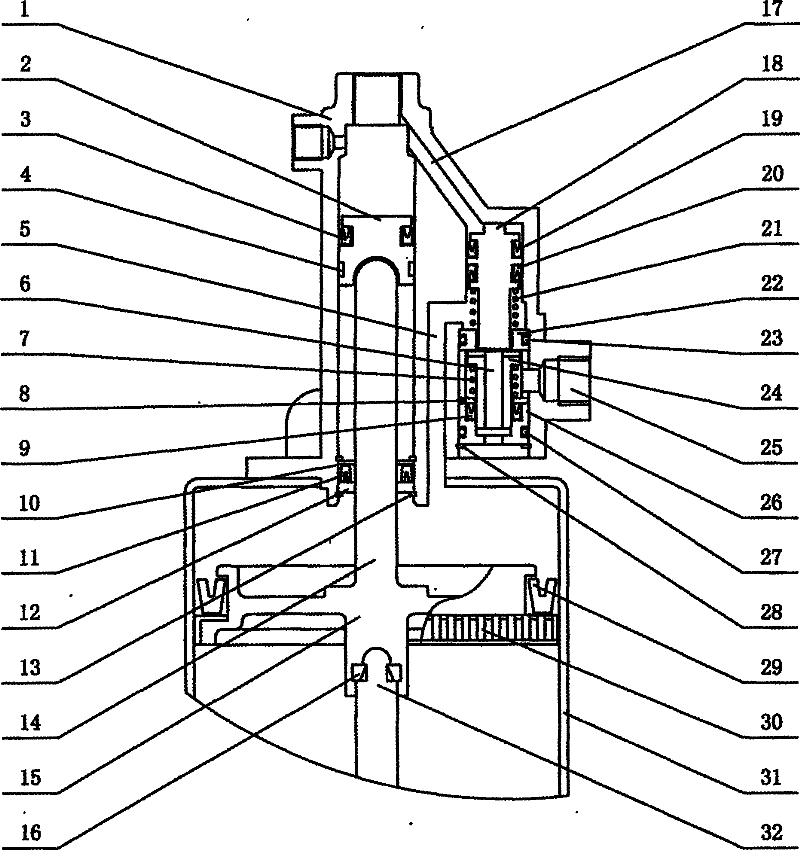

DC contactor packaging structure

InactiveCN105070592AReduce volumeReduce manufacturing costElectromagnetic relay detailsThin metalSealant

The invention discloses a DC contactor packaging structure, which comprises a DC contactor body. The DC contactor body is internally provided with two screw rods for forming static contacts, a moving contact sheet for forming a moving contact, an arc extinguishing chamber for arc extinguishing, a transmission part for driving the moving contact to move and a coil structure, wherein outer ends of the two screw rods extend out of the upper side surface of the DC contactor body; the two screw rods, the moving contact sheet and the coil introduce connection lines outwardly on the upper side surface of the DC contactor body; the lower side surface and the outer side surface of the DC contactor body are fixedly sleeved with a metal casing; and the metal casing and the DC contactor contact parts are firmly connected and sealed. The DC contactor packaging structure uses a light and thin metal casing to replace a mounting casing and a pouring sealant, parts are simplified, the product size is reduced, the manufacturing cost is reduced, the traditional mounting mode is changed, mounting is more convenient and quicker, and the occupied space is small.

Owner:KUNSHAN GUOLI VACUUM ELECTRIC

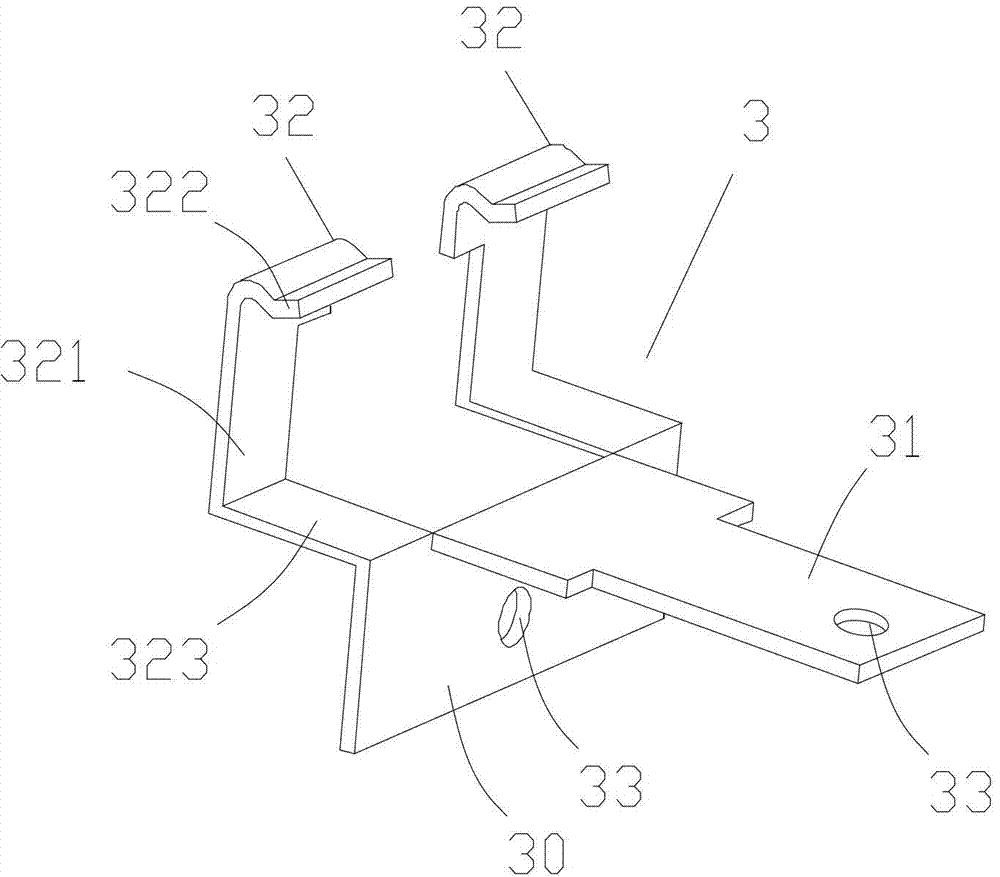

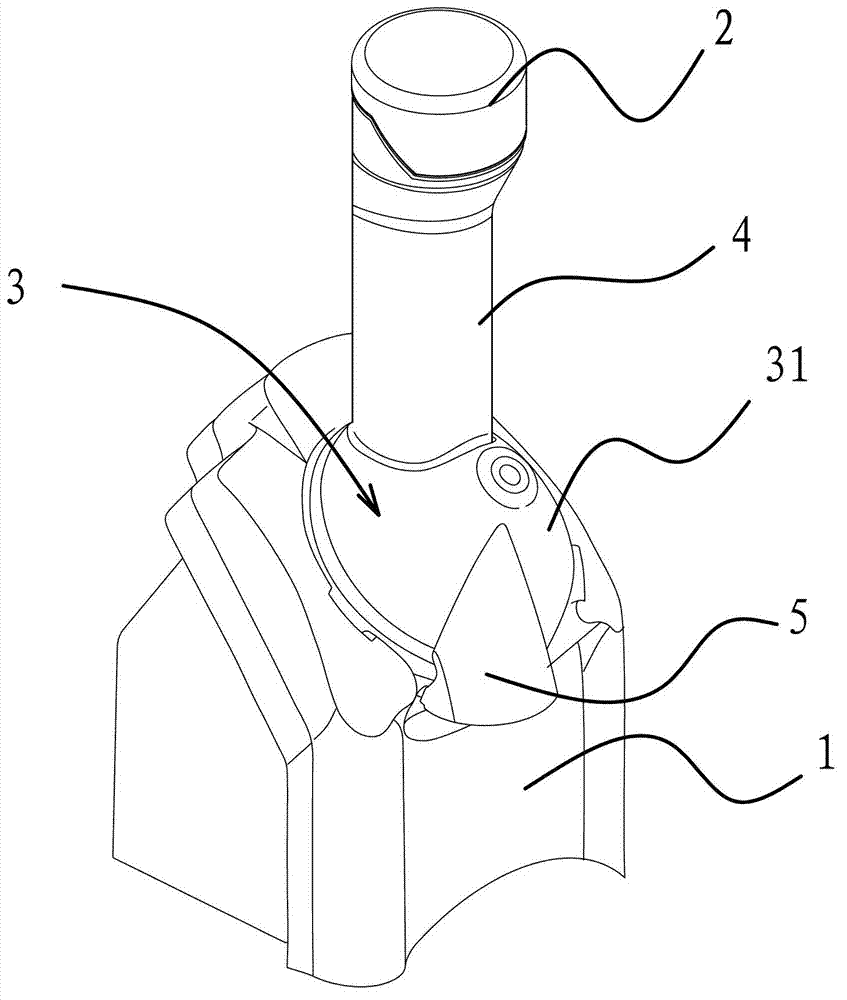

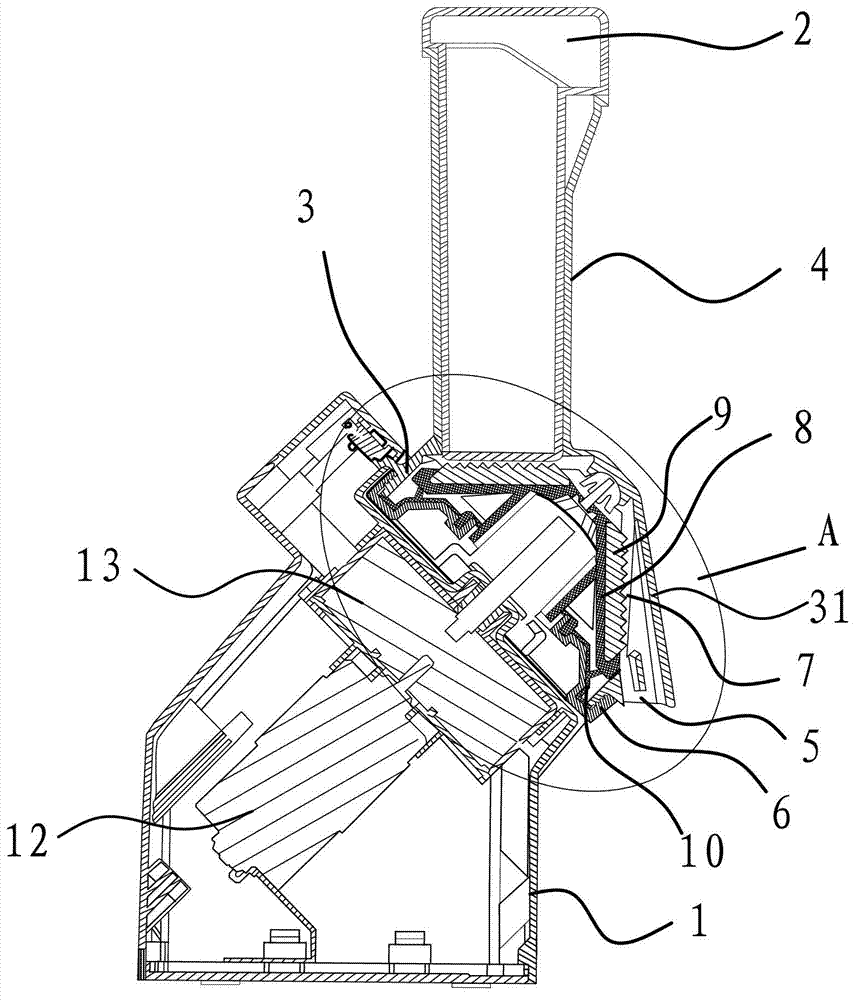

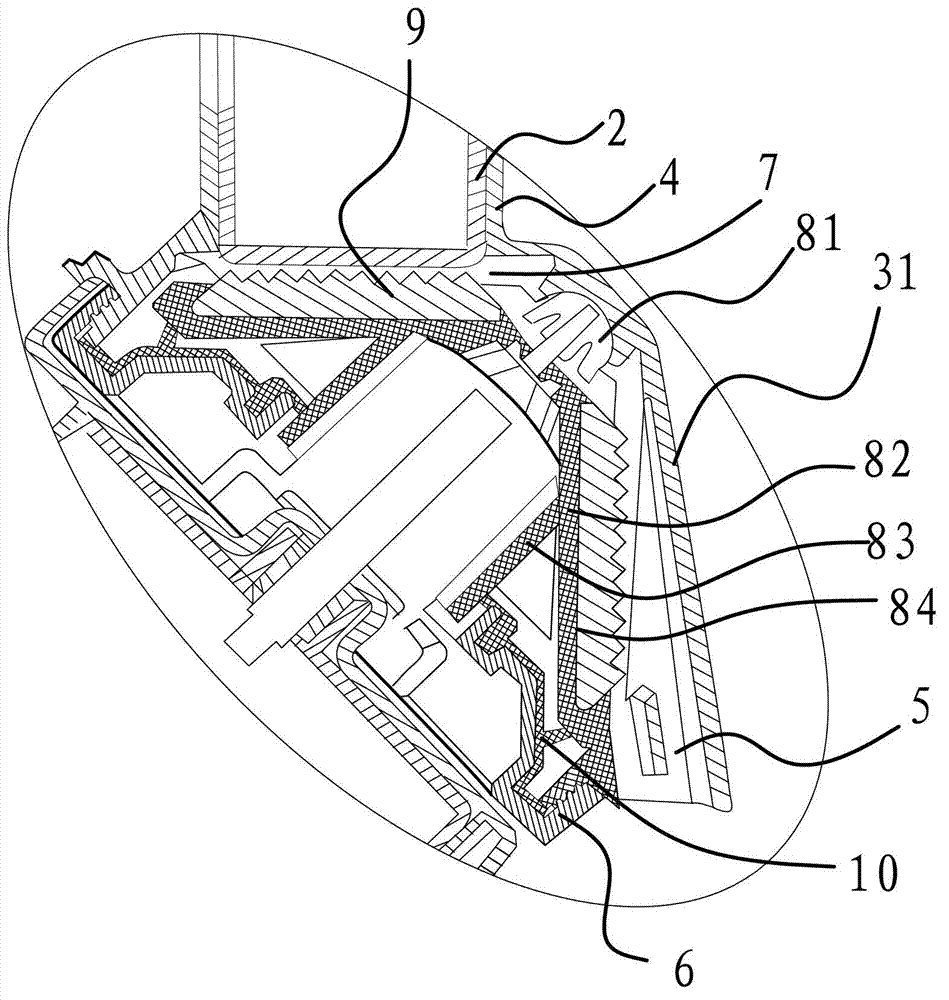

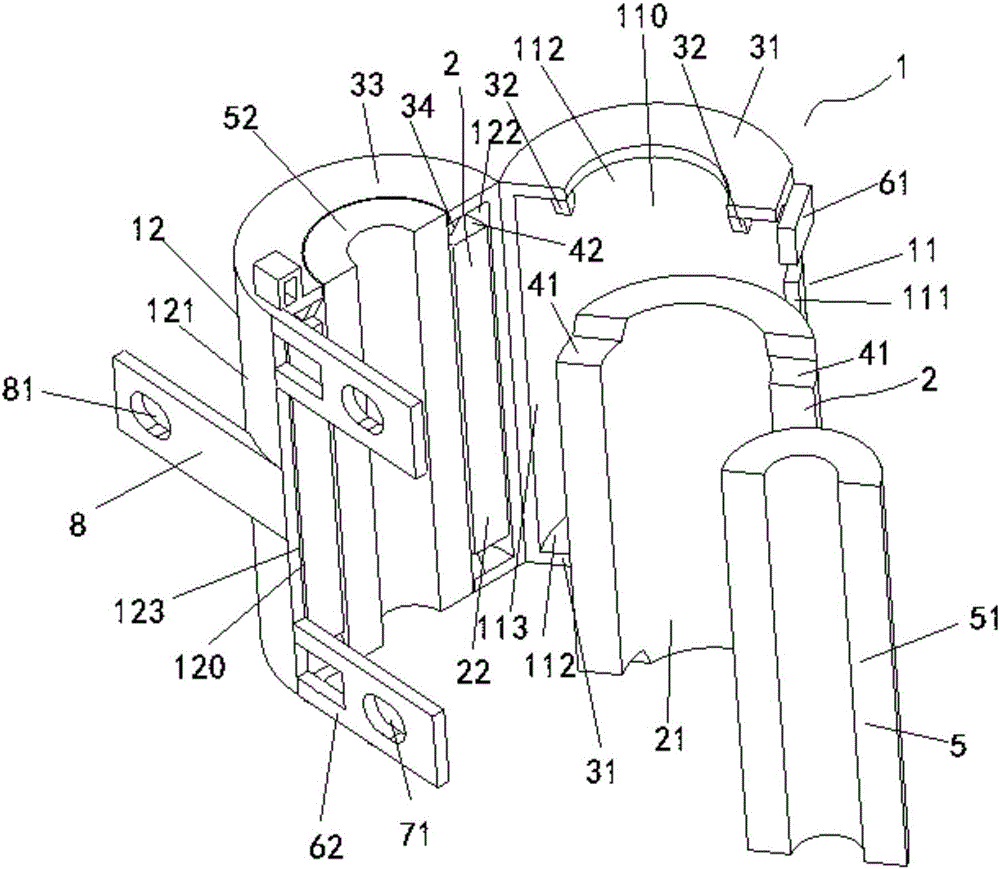

Wire fixing clamp

InactiveCN106300162AImprove installation efficiencyAvoid lossElectrical apparatusElectrical and Electronics engineeringEngineering

Owner:GREE ELECTRIC APPLIANCES INC

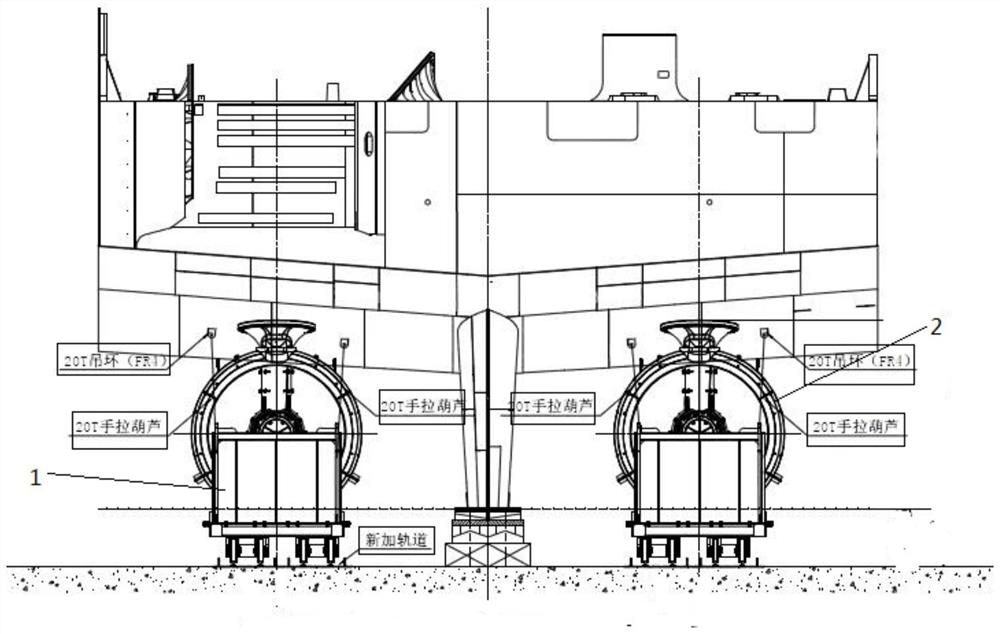

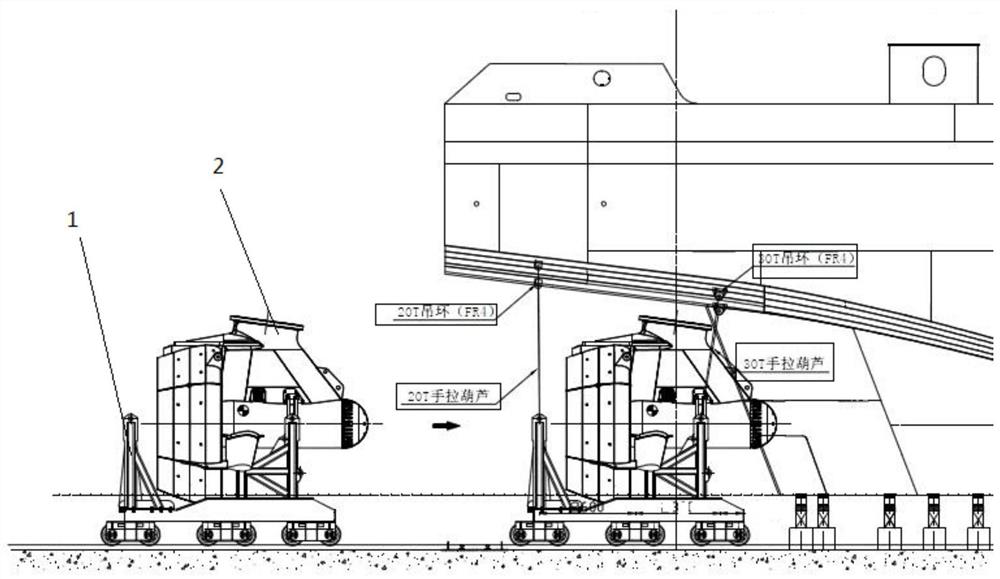

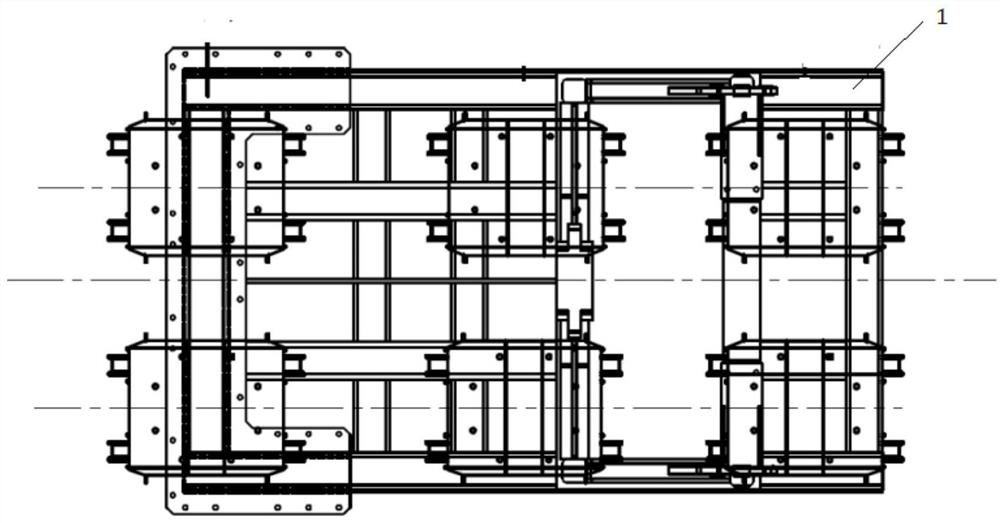

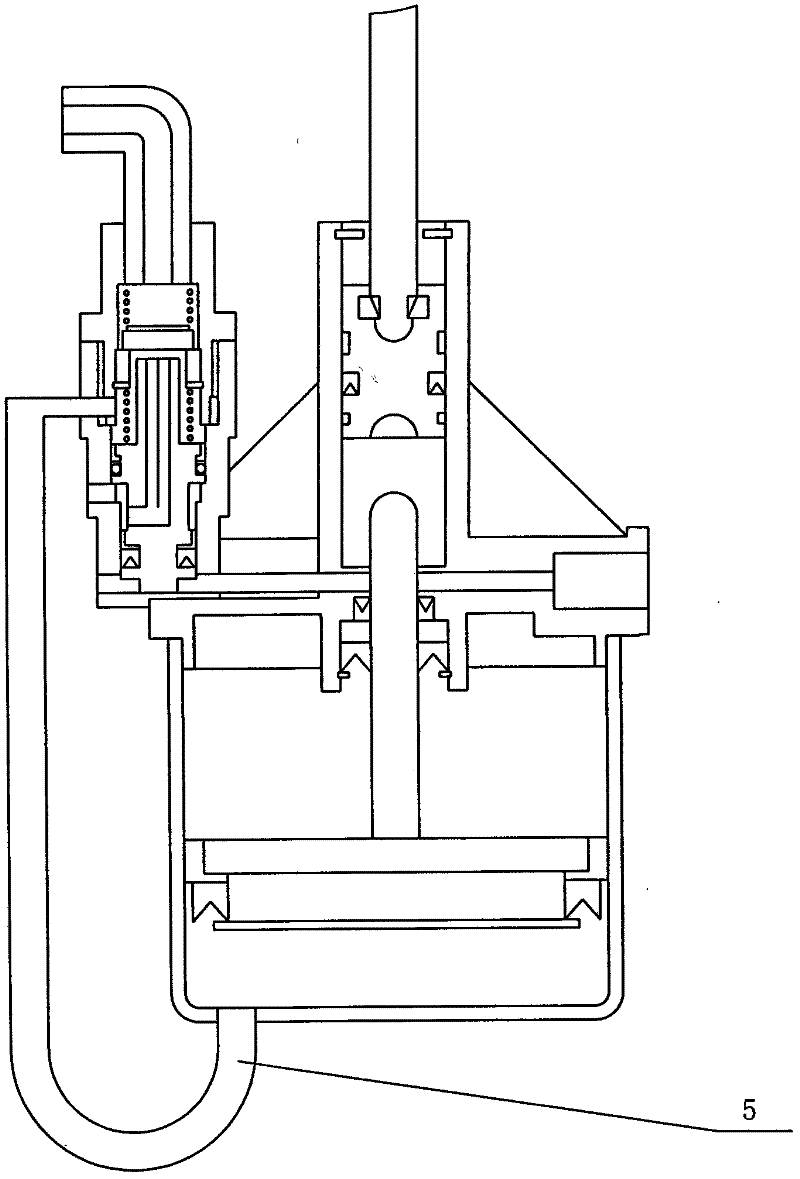

Engineering ship full-rotation main thruster installation process

ActiveCN111891315AGuarantee the construction qualityEnsure construction safetyWaterborne vesselsButt weldingShaped beam

The invention discloses an engineering ship main thruster installation process which comprises the following steps that 1, an applicable main thruster base is manufactured, and the main thruster basecomprises a flange plate and a cylindrical web plate; 2, a main pusher base is installed; 3, butt welding is conducted on the T-shaped beam extending out of the periphery of the flange plate in the step 2 and a T-shaped beam structure of a ship body; 4, a main thruster is installed, wherein the main thruster is divided into a propelling module, a steering module and an auxiliary and cooling module; 5, a steering module is installed; 6, a propelling module is installed; 7, installation of an auxiliary and cooling module; according to the process, the conventional mounting method of drilling from a deck and hoisting the propeller from the upper part by a crane is changed, the propeller is located on the special tray and is mounted in a manner of being held from bottom to top, and the problemthat the device is ultrahigh and overweight and cannot be conventionally mounted is well solved.

Owner:JIANGSU UNIV OF SCI & TECH

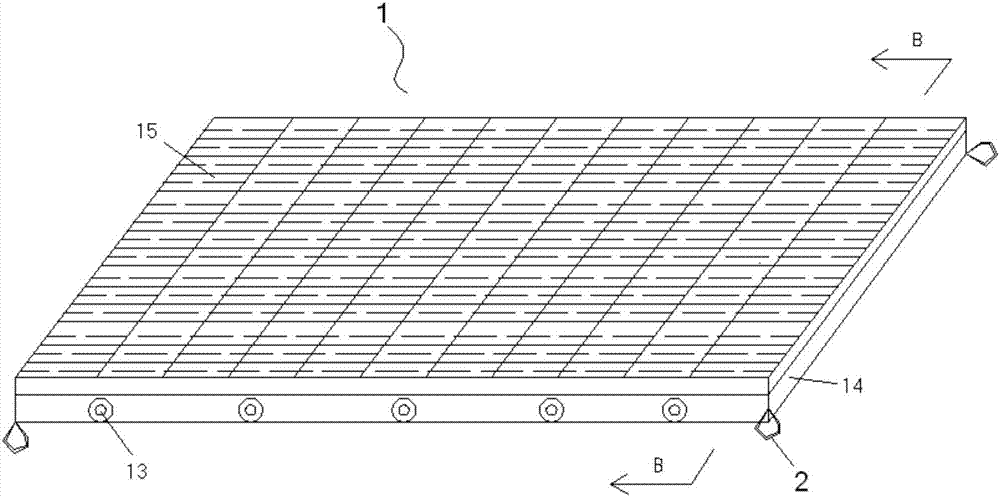

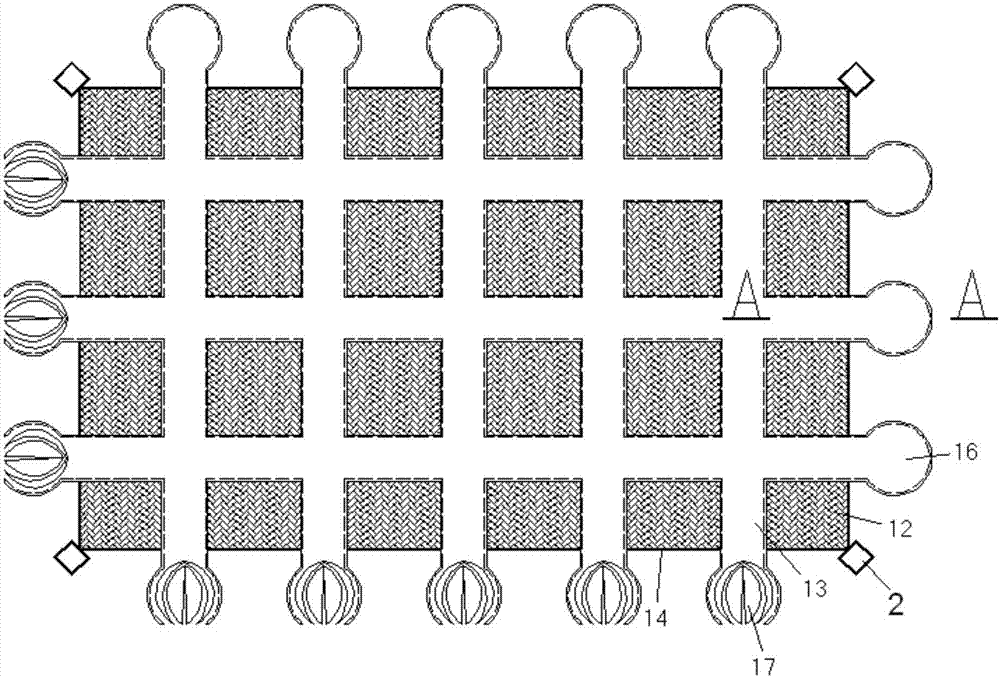

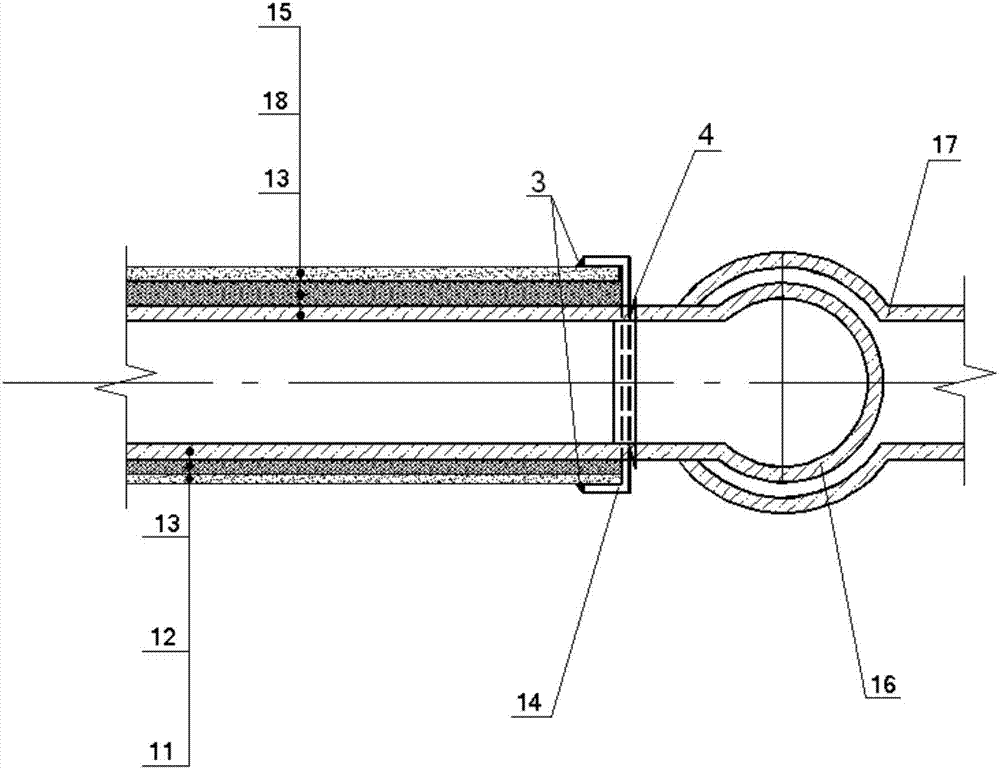

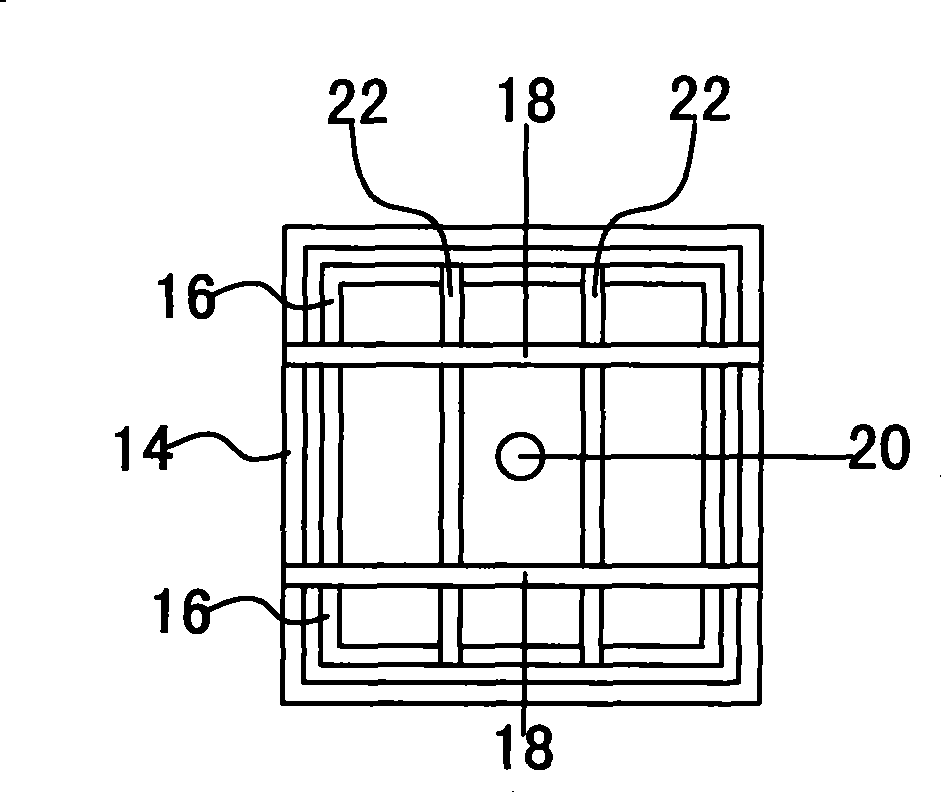

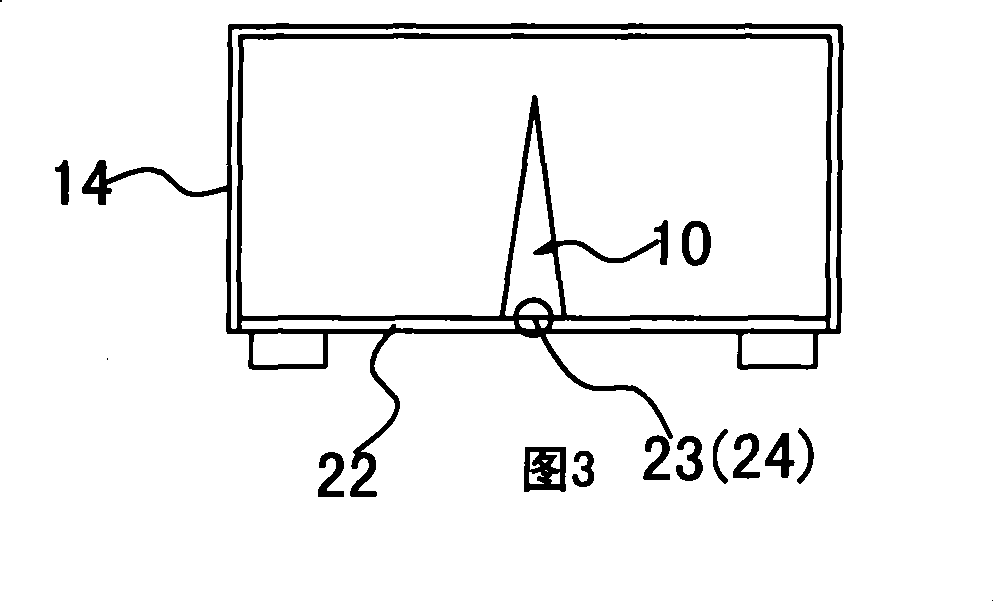

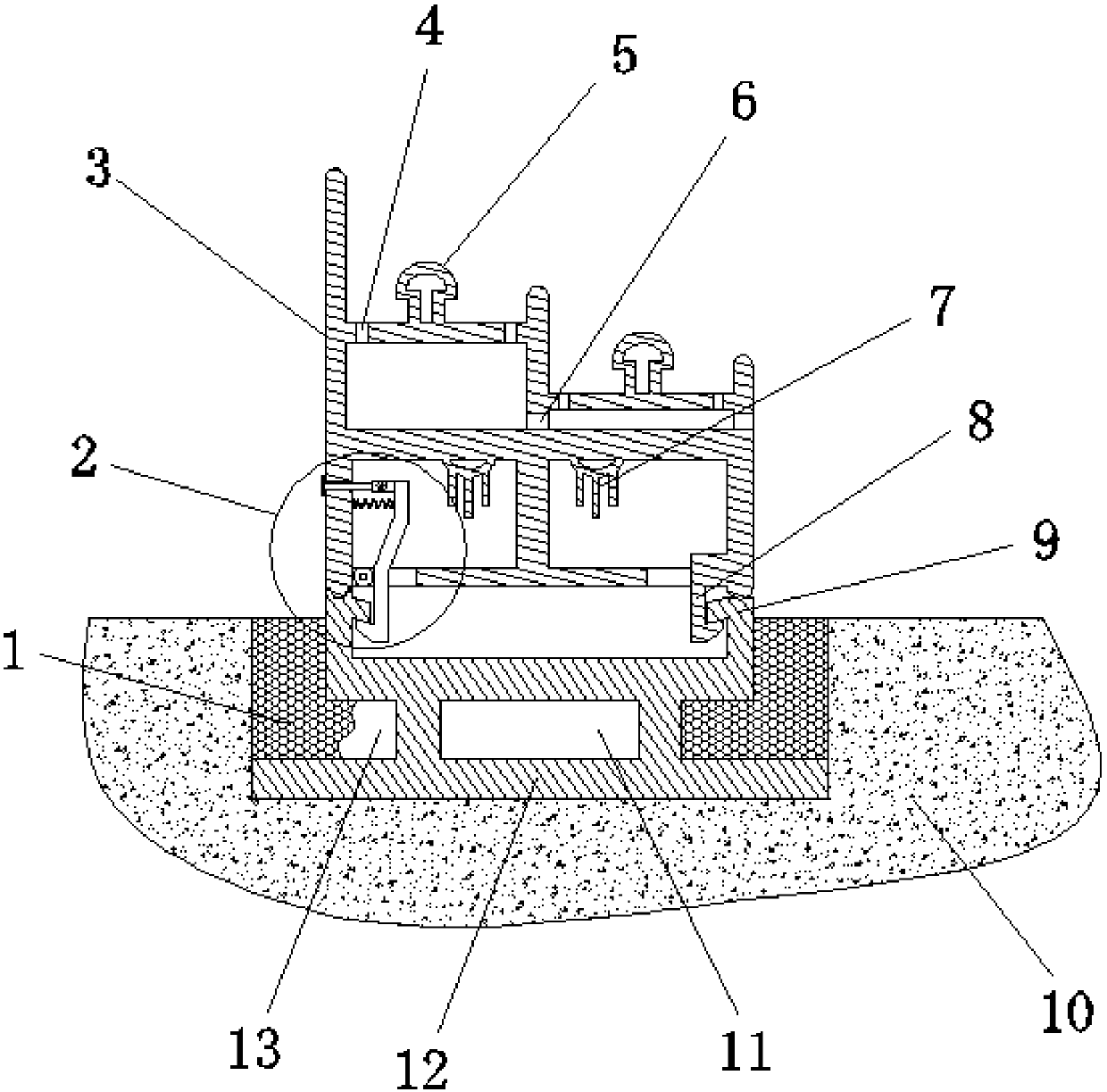

Novel floating type photovoltaic module

PendingCN107204737AChange the installation methodSave cost spacePhotovoltaic supportsSolar heat devicesMarine engineeringEnergy conservation

The invention discloses a novel floating type photovoltaic module. The novel floating type photovoltaic module comprises a plurality of photovoltaic module units; each photovoltaic module unit comprises a backboard, a first waterproof layer, floating pipes, a frame and a photovoltaic panel; the first waterproof layer is arranged at the top of the backboard; multiple groups of floating pipes are arranged on the top surface of the first waterproof layer in a longitudinal and transverse intersection mode; the tail end of each group of floating pipe stretches out of the backboard; a spherical secondary button is arranged at one end of each floating pipe; a spherical primary button is arranged at the other end of each floating pipe; a second waterproof layer is arranged at the top of each floating pipe; the photovoltaic panel is arranged at the top of the second waterproof layer; the frame adopts a U-shaped structure; the tail end of each floating pipe is sleeved with the frame in clamped connection with the periphery of the backboard and the photovoltaic panel; the plurality of photovoltaic module unites are in mutual sleeving connection through the spherical secondary button and the spherical primary button at the tail end of each floating pipe. The novel floating type photovoltaic module provided by the invention adapts to large-area water areas at home and abroad, basically does not use a floating barrel, does not need basic investment such as piling, and realizes new concept of low carbon, energy conservation and environmental friendliness.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST

Improved automobile clutch booster

InactiveCN102678785AExtended service lifeChange the installation locationClutchesPiston rodValve seat

The invention relates to an improved automobile clutch booster, namely, the cross-sectional area of a piston rod becomes small, so that the required effective area of a large piston when the large piston does work is increased, the resistance is also reduced, and the power of the clutch booster can be increased by 10% on the basis of the original product. The phenomena of sticking, powerless property and non-thorough separation of the clutch booster during the use can be avoided. In addition, wear rings containing lubricating grease are increased at the parts which are adjacent to leather cups in the clutch booster, so that all the leather cups can regularly work under a lubricational state, and the service life of the clutch booster is greatly prolonged. Simultaneously, the mounting position and the way of a valve seat are also changed, the operation is easy, and potential risks are also eliminated.

Owner:李立军

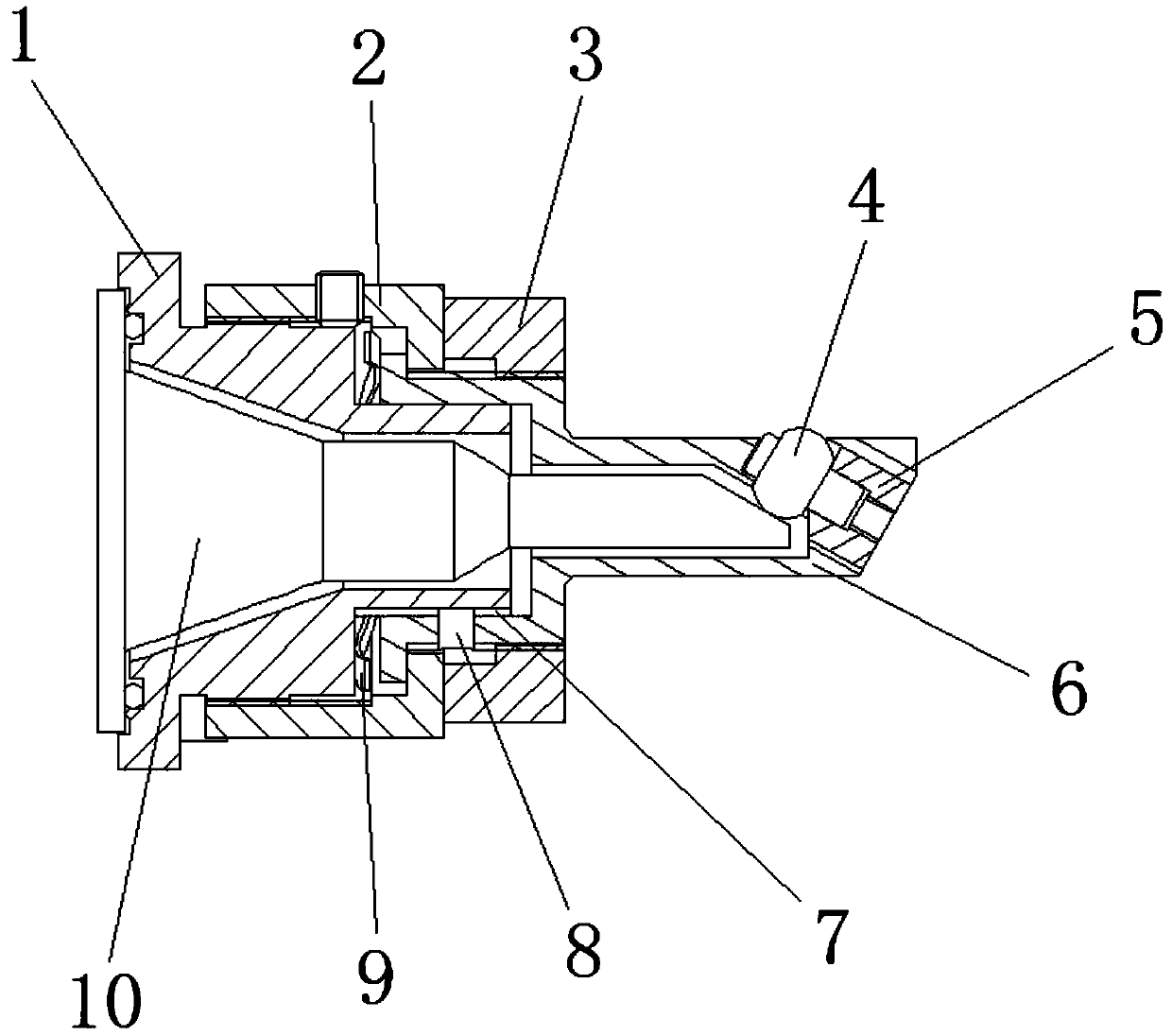

Ultrasonic cutter head for machining small holes and application of ultrasonic cutter head

ActiveCN105499617AChange the installation locationChange the installation methodTurning toolsSmall holeUltrasound

The invention relates to an ultrasonic cutter head for machining small holes and an application of the ultrasonic cutter head. The ultrasonic cutter head comprises a variable-amplitude bar, a taper sleeve, a tool seat, a tool head and an adjusting ring, wherein the taper sleeve is connected with the tool seat by the aid of the adjusting ring, the tool seat is step-shaped, the tool head is arranged at the front end of the tool seat, the variable-amplitude bar extends into the taper sleeve and the tool seat, and the tool head is perpendicularly contacted with the front end of the variable-amplitude bar. According to the ultrasonic cutter head, the structural form of the tool seat is improved, the overall structure size of the tool seat is reduced, the ultrasonic cutter head can be used for machining inner holes with diameters smaller than 30 mm, and the machining range of the ultrasonic cutter head is wider. Meanwhile, the taper sleeve and the tool seat are in guided connection by the aid of a key or a pin, the tool seat can be effectively prevented from rotating when the clearance between the variable-amplitude bar and the tool head is adjusted, and the problem that the direction of the tool head is not determined due to rotation of the tool seat is solved.

Owner:SHANDONG HUAWIN ELECTRICAL & MECHANICAL TECH

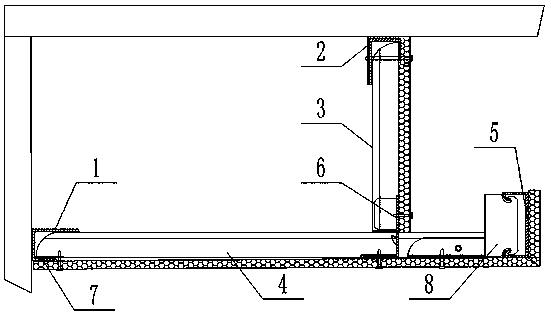

Assembled lightgage steel joist gypsum paper panel ceiling system and construction method thereof

The invention provides an assembled lightgage steel joist gypsum paper panel ceiling system and a construction method thereof. The system comprises a U-shaped edge joist, a right-angle edge joist, a backdrop assembly which is fixedly connected to the right-angle edge joist, a plane assembly which is fixedly connected to the U-shaped edge joist and the lower end of a backdrop clamp connecting inserting part, and a vertical surface assembly which is vertical to the plane assembly and is fixed to one end, far away from the wall, of the plane assembly. According to the technical scheme, the systemhas the advantages that the card connecting inserting part, etc. are provided; a gypsum board can be covered with the joist in advance; the mounting method is completely changed; the mounting steps are decreased; the mounting efficiency is improved; the cost of the assembled lgihtgage steel joist gypsum paper panel ceiling is decreased; and meanwhile, the problems such as high material loss and high pollution caused by mounting construction can be decreased.

Owner:河南智展建材科技有限公司

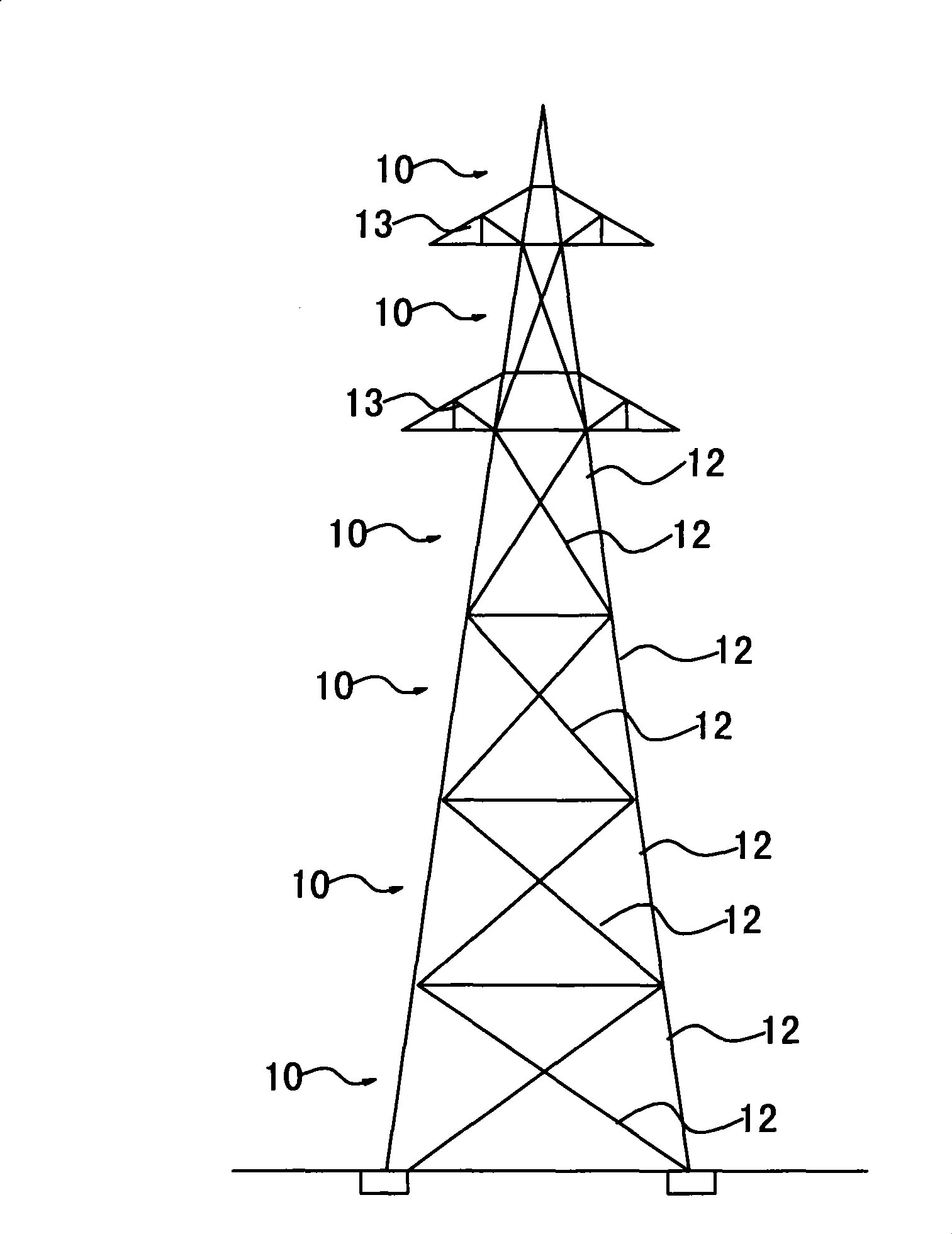

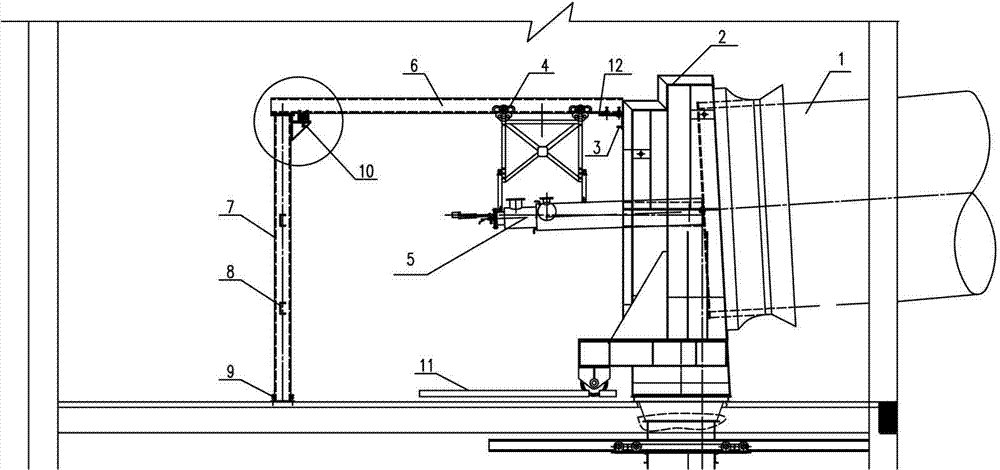

Installation method for pylon

The present invention discloses a method for installing a tower frame. In the installation method, a section of a tower body is assembled; the upper section of the tower body adjacent to the section of the tower body is assembled and connected with the section of the tower body in a fixed way; subsequently, the section of the tower body is hoisted by an equipment moving frame; then the section of the tower body on the moving frame is positioned and supported over a support frame; the moving frame descends and is assembled and connected with another section of the tower body in a fixed way from top to bottom orderly by the method, until the last section of the tower body is left; the lowest section of the tower body is installed, and the lowest section of the tower body is assembled and connected with the base of the tower frame in a fixed way. The installer is not required to climb up the tower body and can finish the whole installation and assembly just by standing on ground or on the support frame, so the present invention has the advantages as follows: firstly, the present invention improves the installation condition and improves the safety; secondly, the present invention changes the installation procedure and improves the installation efficiency; thirdly, the present invention changes the installation method and improves the installation quality.

Owner:刘玉恩

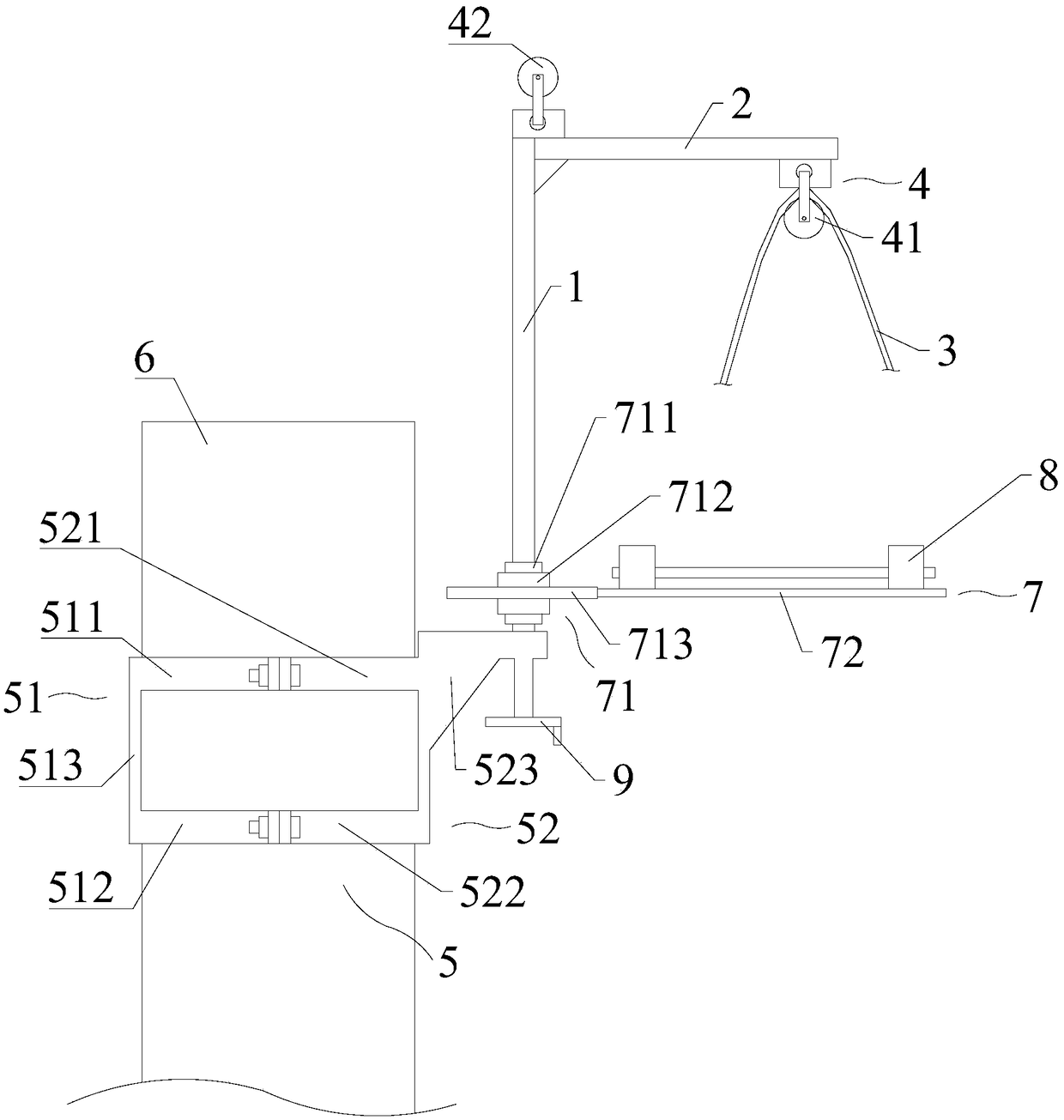

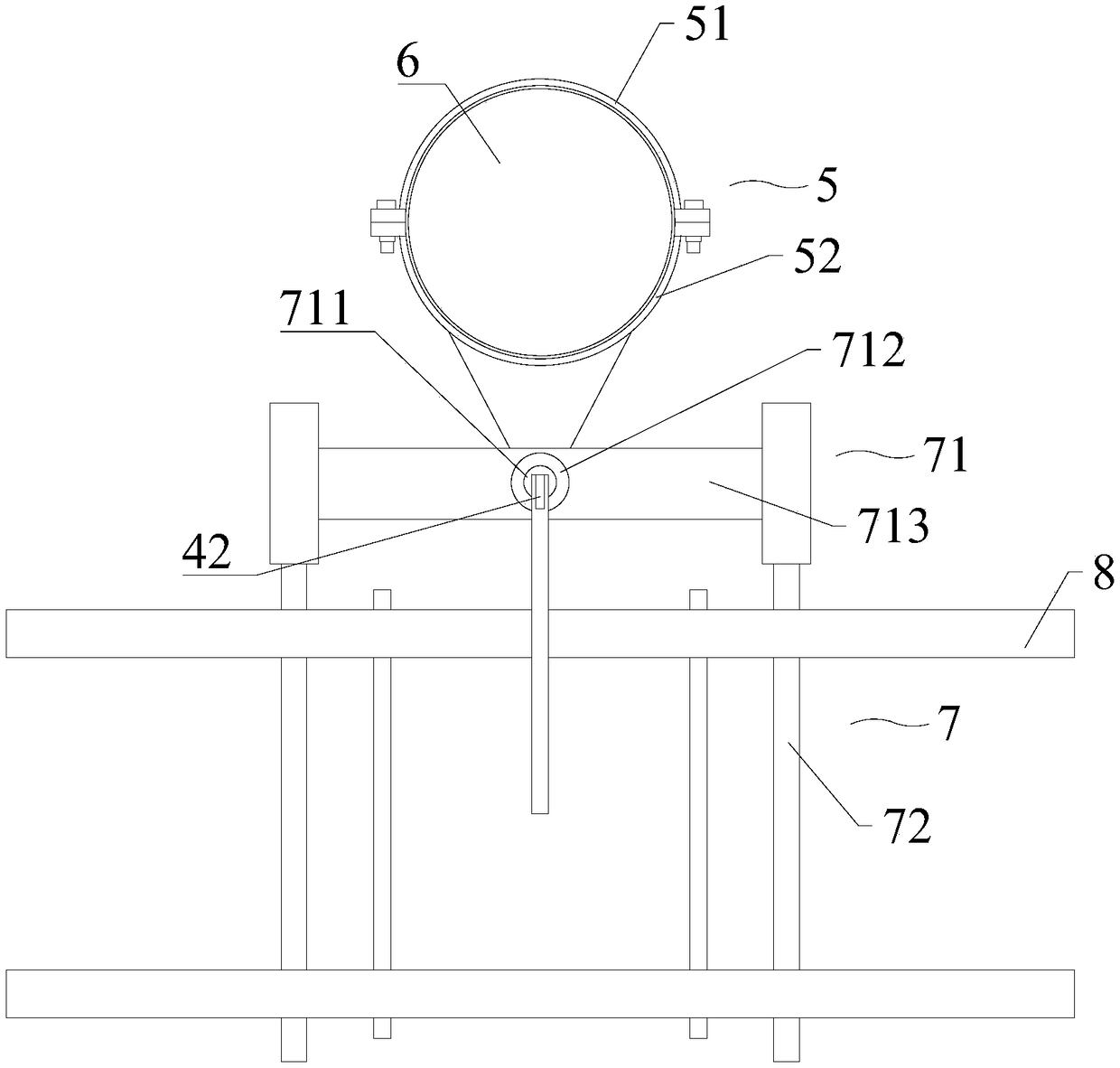

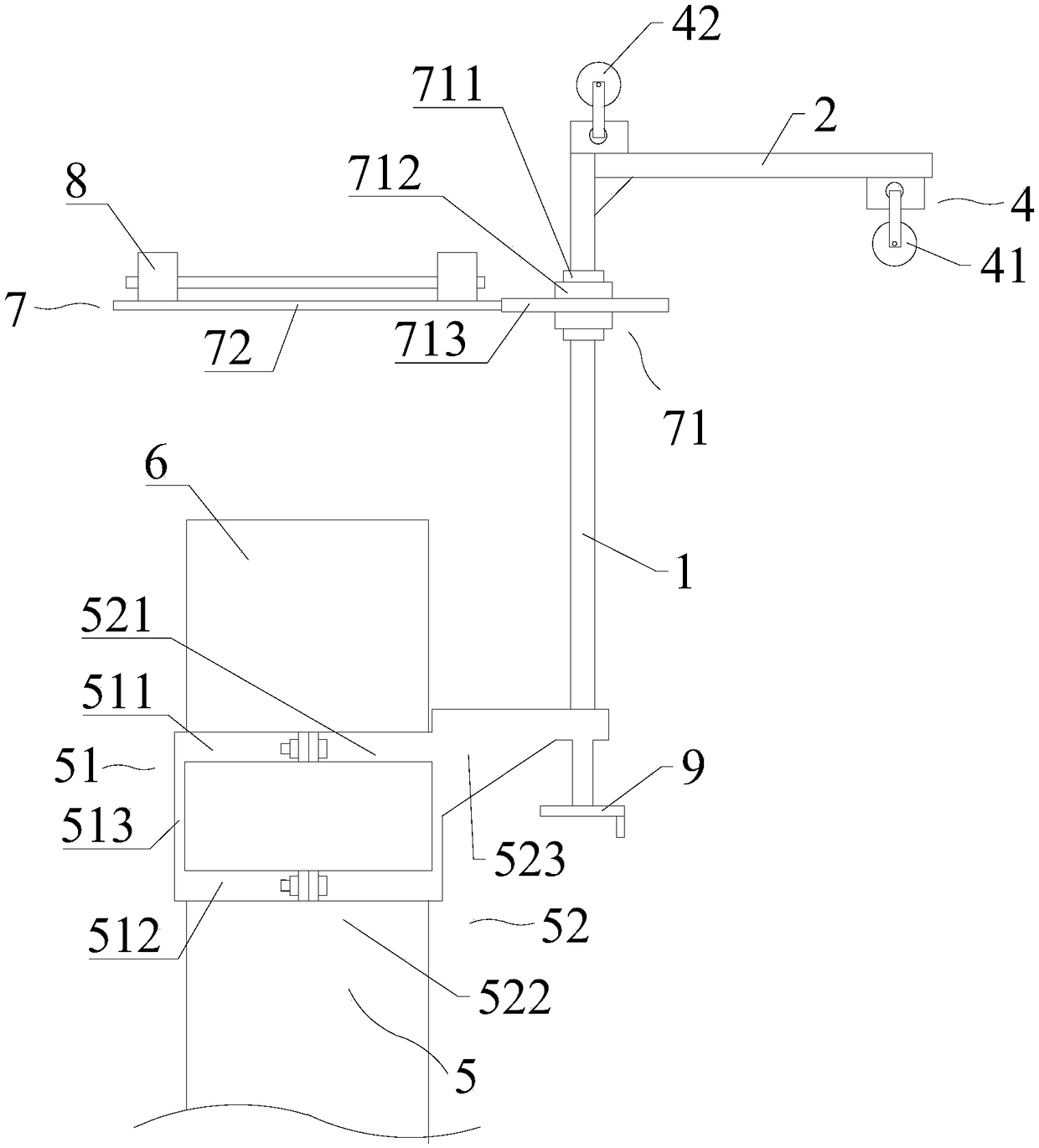

Overall installation device and method for power double cross arm assembly

ActiveCN108999458AChange the installation methodRealize process reengineeringTowersEngineeringUltimate tensile strength

The invention provides an overall installation device for a power double cross arm assembly. The device comprises a longitudinal strut, a transverse strut vertically disposed at an upper portion of the longitudinal strut, a holt hoop iron which is rotatably disposed at a lower portion of the longitudinal strut and is used for fixedly connecting with wire poles, and a bracket which is disposed between the transverse strut and the holt hoop iron, is in rotation lifting up and down connection with the longitudinal strut along the length direction of the longitudinal strut and is used for supporting double cross arms and taking the double cross arm assembly to move up and down, wherein a hanging member for hanging a traction rope is disposed on the transverse strut. The invention further provides an overall installation method for the power double cross arm assembly. The device is advantaged in that technical problems of long power-off time and large construction intensity of workers of the wire poles existing in the cross-arm installation technology in the prior art are solved.

Owner:STATE GRID CORP OF CHINA +1

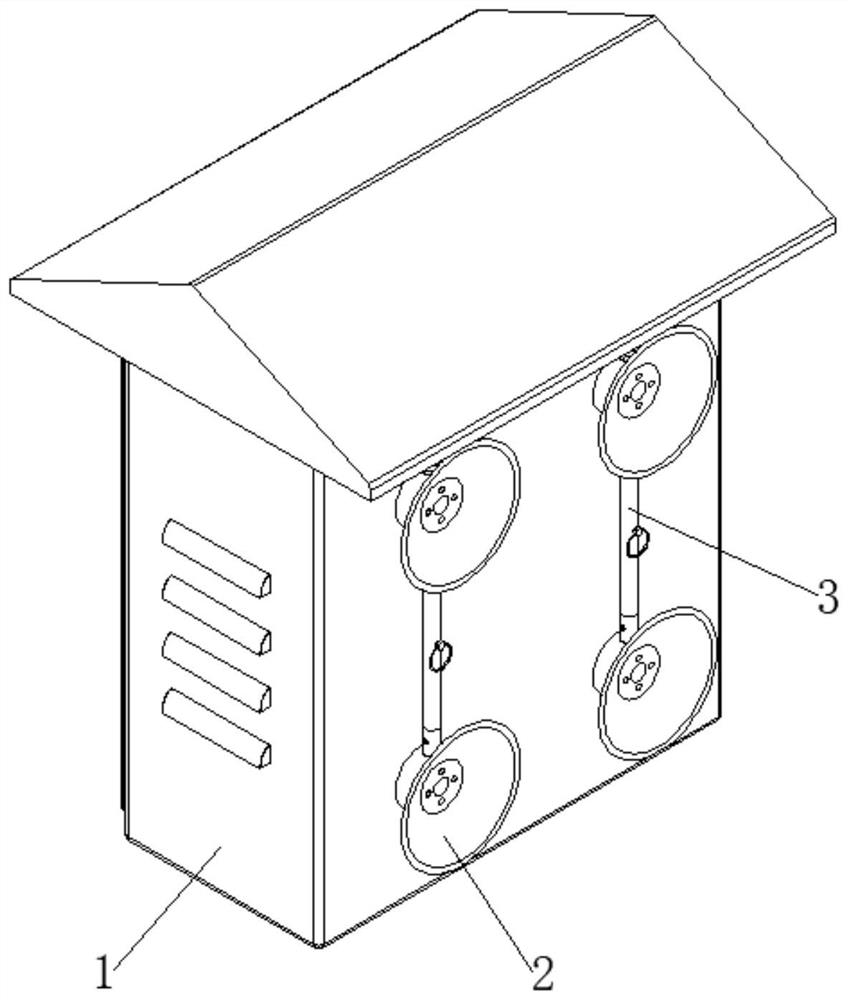

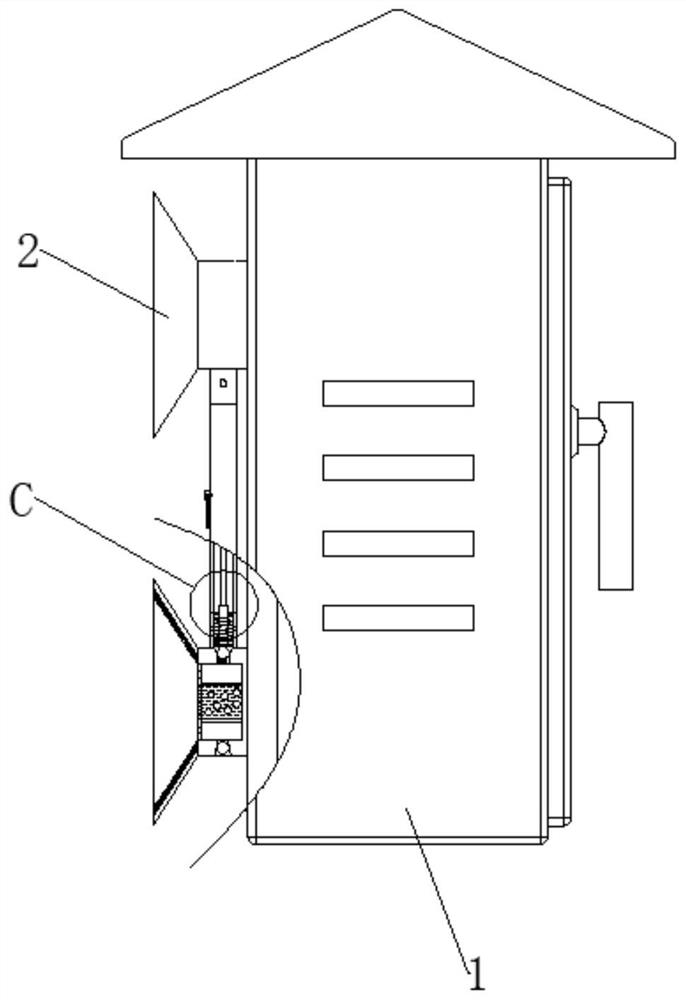

Distribution box for photovoltaic power station

InactiveCN111969449AChange the installation methodImprove installation efficiencyMachine supportsSubstation/switching arrangement cooling/ventilationEngineeringStructural engineering

The invention discloses a power distribution box for a photovoltaic power station. The power distribution box comprises a box body; the box body is connected with a pair of quick-mounting fastening anti-falling mechanisms; each quick-mounting fastening anti-falling mechanism comprises a pair of pressing fastening anti-falling mechanisms; and a connection protection mechanism is connected between the pair of pressing fastening anti-falling mechanisms. Each pressing fastening anti-disengaging mechanism comprises a connecting piece; a suction cup is connected to the connecting piece; a gas fluidcavity is dug in the connecting piece; a sealing baffle is arranged between the gas fluid cavity and the suction cup; an air outlet cavity is dug in the connecting piece; and a first sealing ball is arranged in the air outlet cavity. According to the power distribution box for the photovoltaic power station of the invention, the power distribution box is provided with the quick-mounting type fastening anti-falling mechanisms, so that a traditional installation mode of the power distribution box is changed, an installer does not need to carry out a series of complex installation processes, theinstallation efficiency of the installer is greatly improved, the working intensity of the installer is greatly reduced; and meanwhile, the wall body is prevented from being damaged, and the problem that the wall body is not attractive due to installation of the power distribution box is avoided.

Owner:雷全

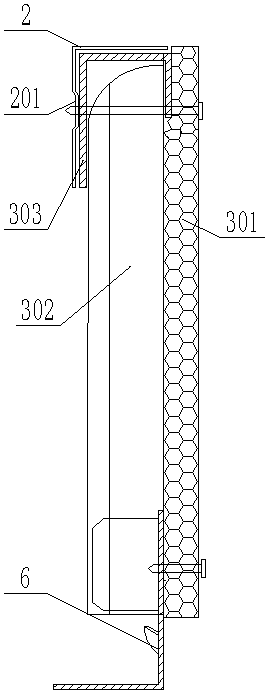

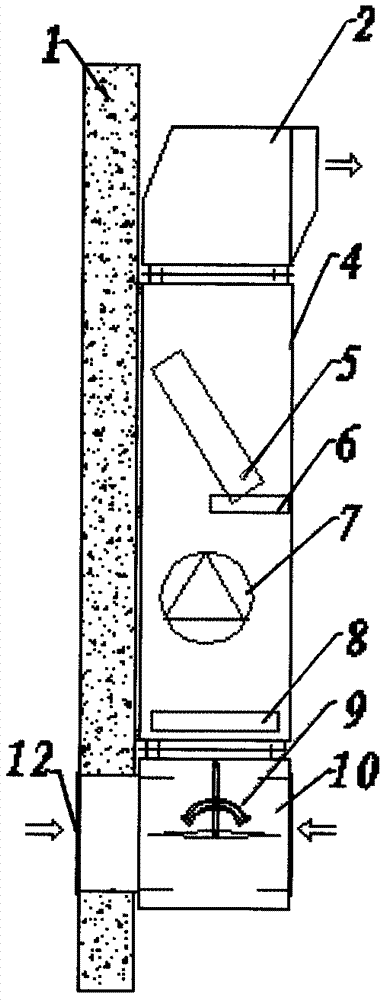

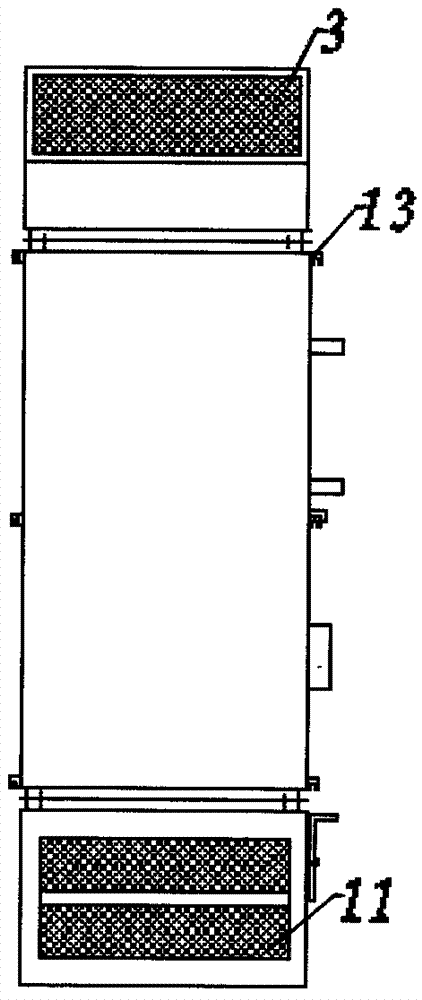

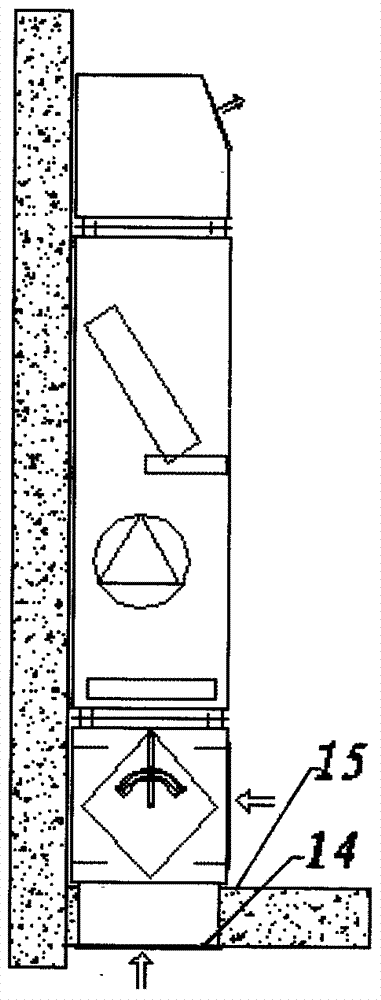

Wall-mounted direct blowing type air processing set

InactiveCN104776493ACompact structureReduce points of failureLighting and heating apparatusAir conditioning systemsAir treatmentAir conditioning

The invention relates to a wall-mounted direct blowing type air processing set. The wall-mounted direct blowing type air processing set comprises an air inlet device, a box body and an air outlet device, and is characterized in that the air inlet device comprises an air inlet box arranged at the lower end of the box body and an air port adjusting device arranged in the air inlet box, wherein the box body comprises a plate type primary filter, an air feeder, cold and hot coils, a water pan and a mounting rack; and the air outlet device comprises an air outlet box arranged at the upper end of the box body. The wall-mounted direct blowing type air processing set is directly mounted on an indoor wall to save the mounting space, adopts direct air intake and air feed to radically change the mounting mode and the system structure of a terminal set of an air conditioner so as to reduce the initial cost and the operation cost of users to an air conditioning system, and adopts upper air intake and lower air return to combine with multiple air return modes so as to prevent the problem of incapability of satisfying the indoor environment use requirement due to direct air return caused by upward floating of hot air in a mode of top air feed and top air return.

Owner:FERDLIS NEW ENERGY TECH HANGZHOU CO LTD

Door and window external frame strongly connected to wall body and installation method for same

ActiveCN107605324AStandardize your installationShorten the installation cycleFrame fasteningCondensed water drain-offWater dischargeEngineering

The invention discloses a door and window external frame strongly connected to a wall body and an installation method for the door and window external frame. The door and window external frame comprises a lower frame body. A cavity is formed in an inner cavity of the middle of the lower frame body; filling slots are formed on two sides of the lower frame body; the filling slots are filled with foaming material fillers; the foaming material fillers are fixedly connected to the external side of the lower frame body and the wall body; necks are formed on two sides of the upper part of the lower frame body; the necks are movably connected to an upper frame body via a buckling device and a second buckling head; reinforcing ribs are disposed in the middle of an inner cavity of the upper frame body; guide rails are fixedly connected to the upper part of the upper frame body; water overflow gaps are formed on two sides of the guide rails; and a water discharging port is formed in the upper frame body. The door and window external frame strongly connected to the wall body is simply structured and easy and practical to use; doors and windows can be installed in place for one time, so finished doors and windows can be delivered to a user without damages; door and window production period can be greatly shortened; exchanges of the doors and windows later can be facilitated; and resource and cost can be effectively saved.

Owner:青岛鑫成源消防器材有限公司

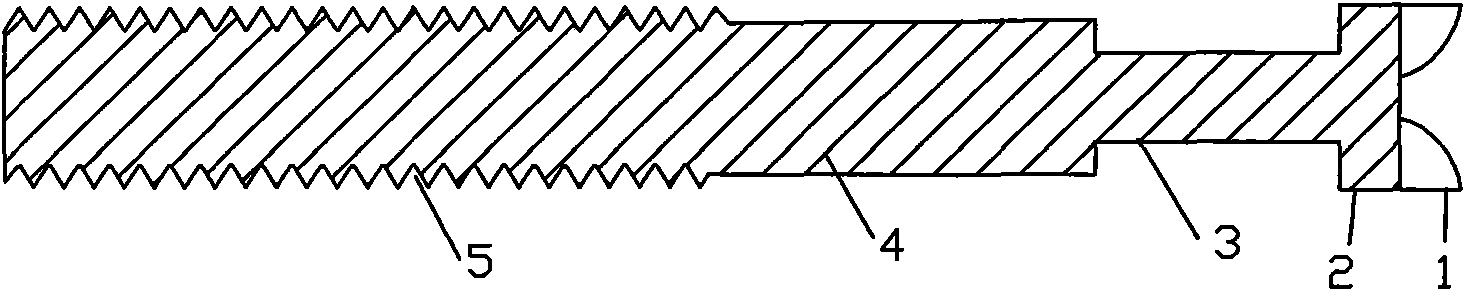

Castellated head bolt

The invention discloses a castellated head bolt which comprises a screw neck and a screw cap arranged at the upper part of the screw neck, the top of the screw cap is provided with a plurality of rotating teeth which extend in the axial direction of the bolt and drive the bolt to rotate, a tooth gap formed between every two rotating teeth is matched with the head of a screwdriver, and the rotating teeth can be driven to rotate by the rotation of the screwdriver perpendicularly matched with the axial direction of the bolt. By using the invention for connection, the bolt can be rotated without using a spanner, and has the advantages of convenient installation and high efficiency.

Owner:宋翔 +1

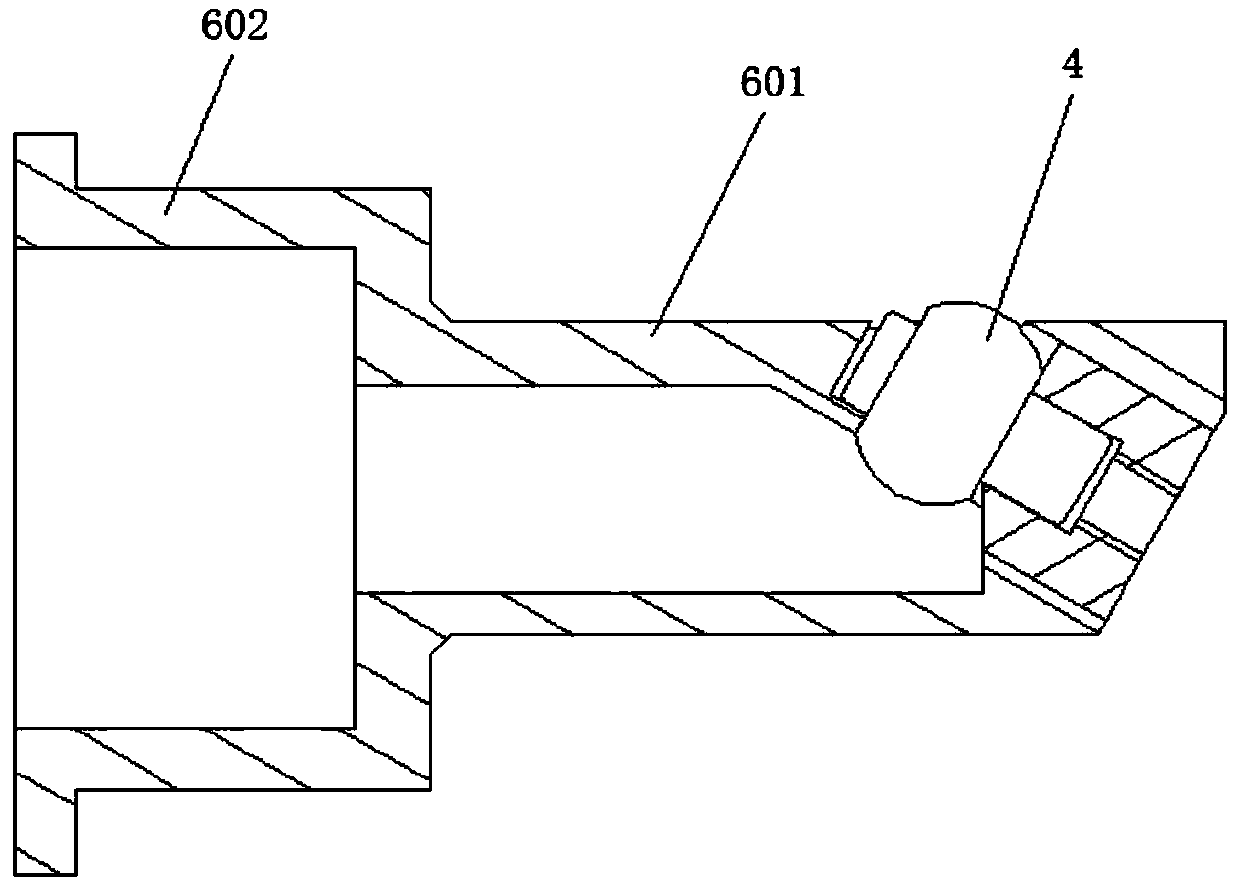

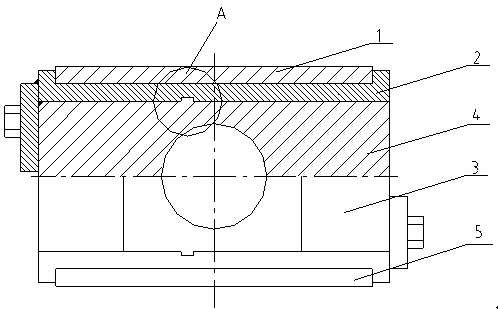

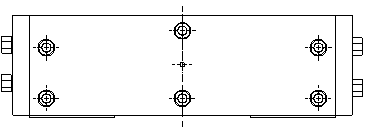

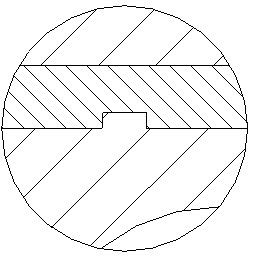

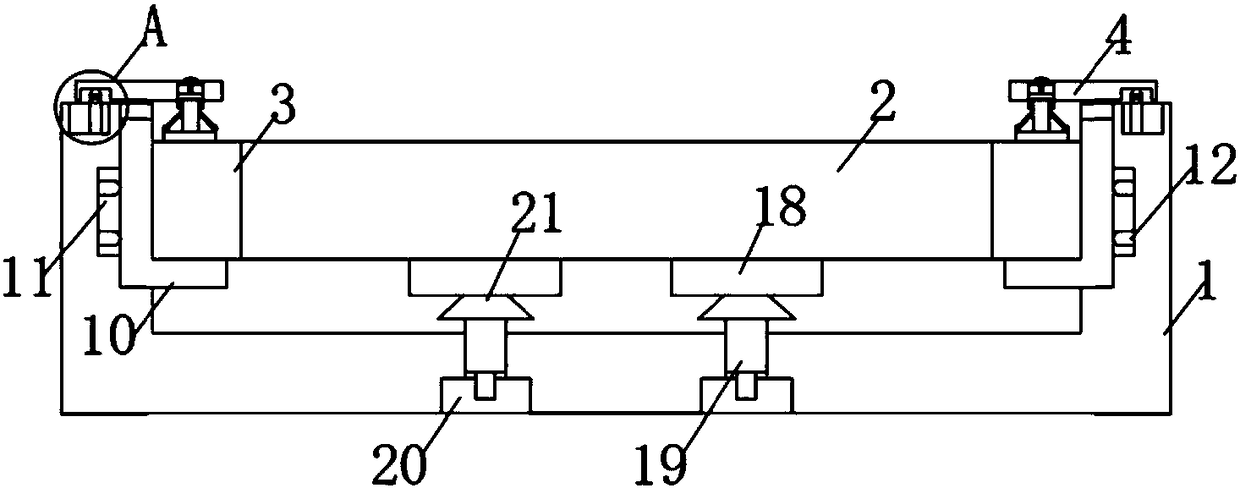

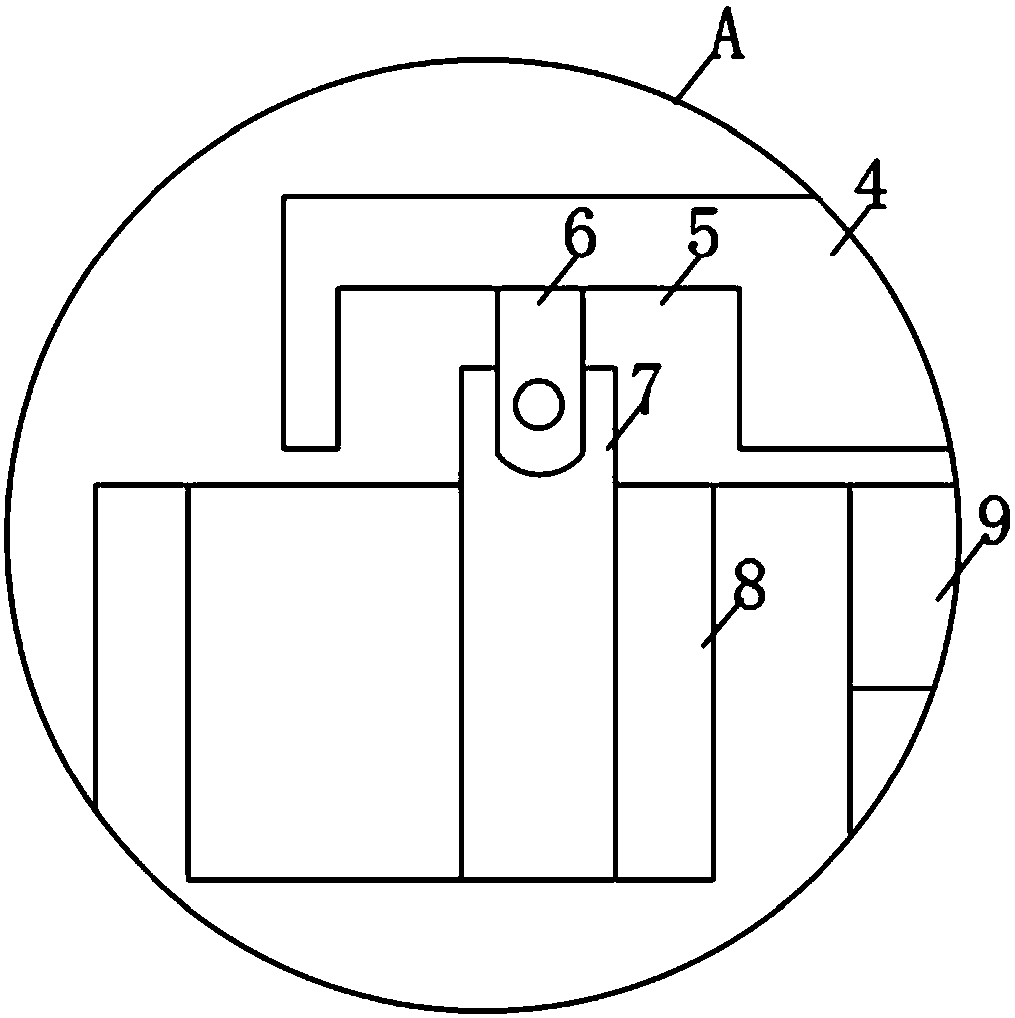

Main sliding block assembly of ring rolling mill

InactiveCN103521664AChange the installation methodEasy to assemble and disassembleMetal rollingRolling mill

The invention discloses a main sliding block assembly of a ring rolling mill. The main sliding block assembly comprises a transverse rack, machine body guide rails, a main sliding block, a wear-resisting copper plate I, a wear-resisting copper plate II and the like. The main sliding block assembly is characterized in that the main sliding block is connected with the wear-resisting copper plate I and the wear-resisting copper plate II through hook-headed plate brackets. The main sliding block assembly of the ring rolling mill has the advantages of changing the mounting mode of the wear-resisting copper plates on the main sliding block, being more convenient and faster to disassemble and assemble and simple and practical in structure, and improving work efficiency.

Owner:SHANDONG IRAETA HEAVY IND

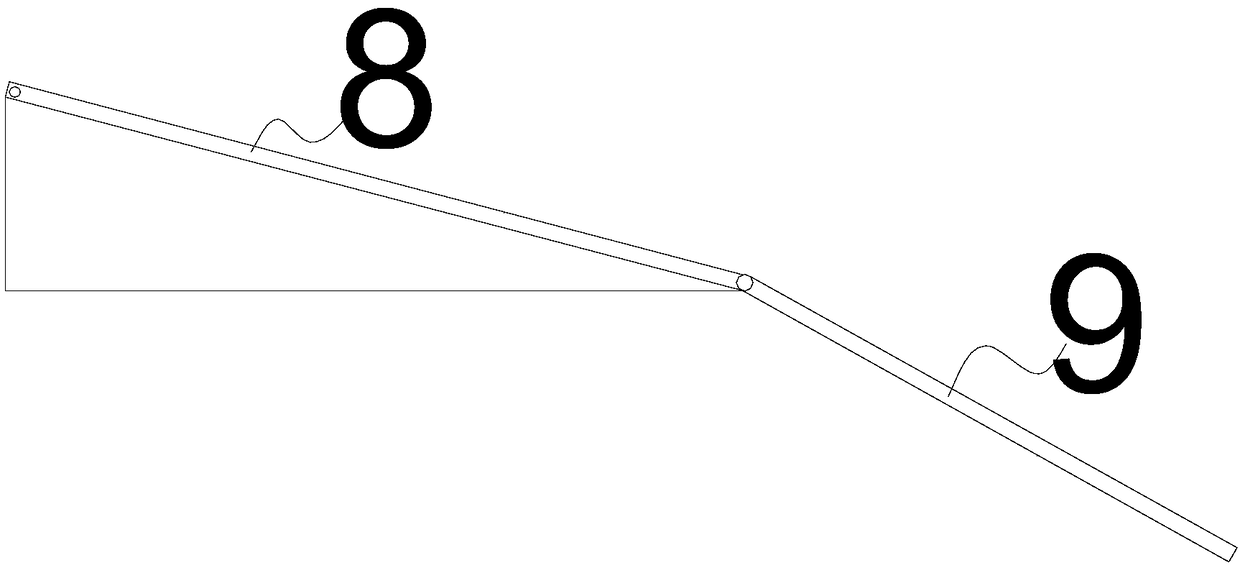

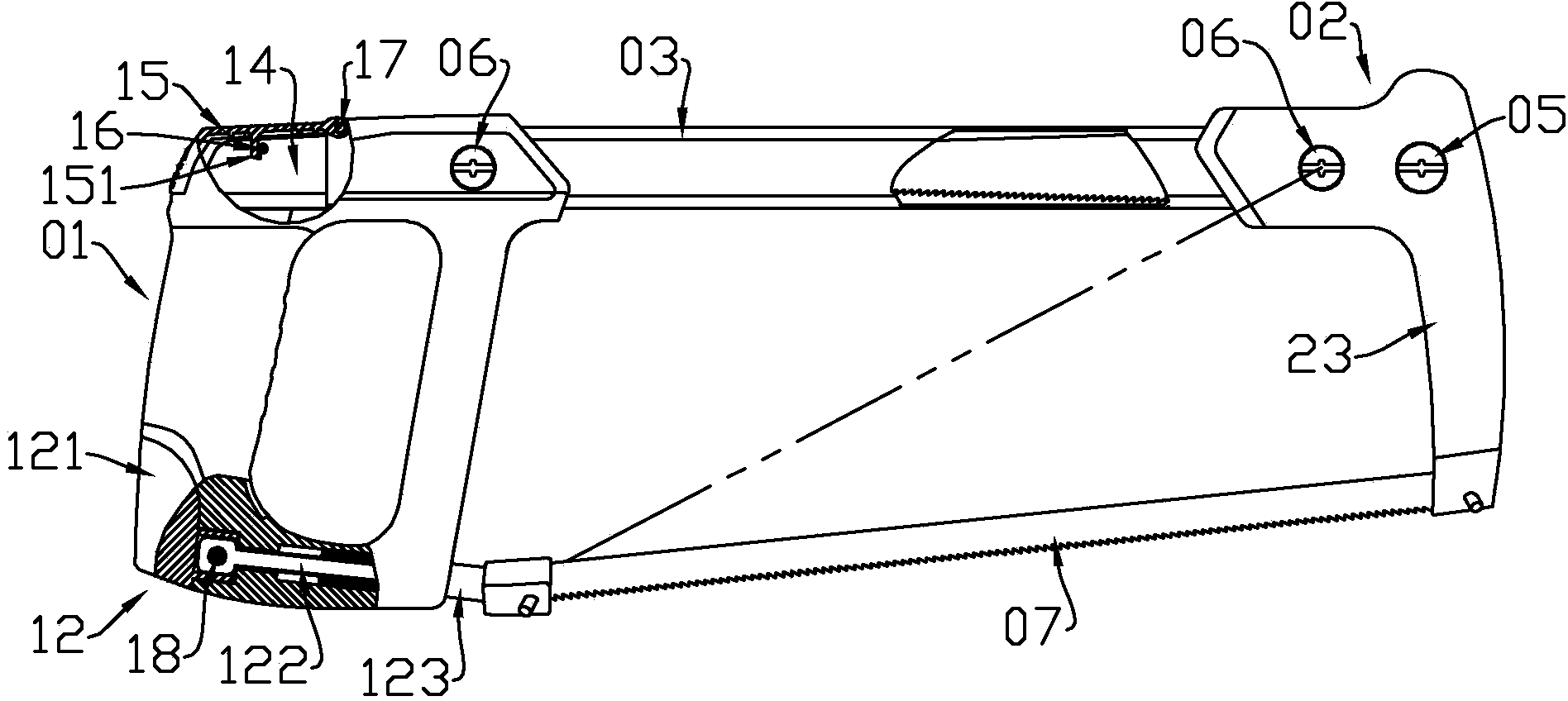

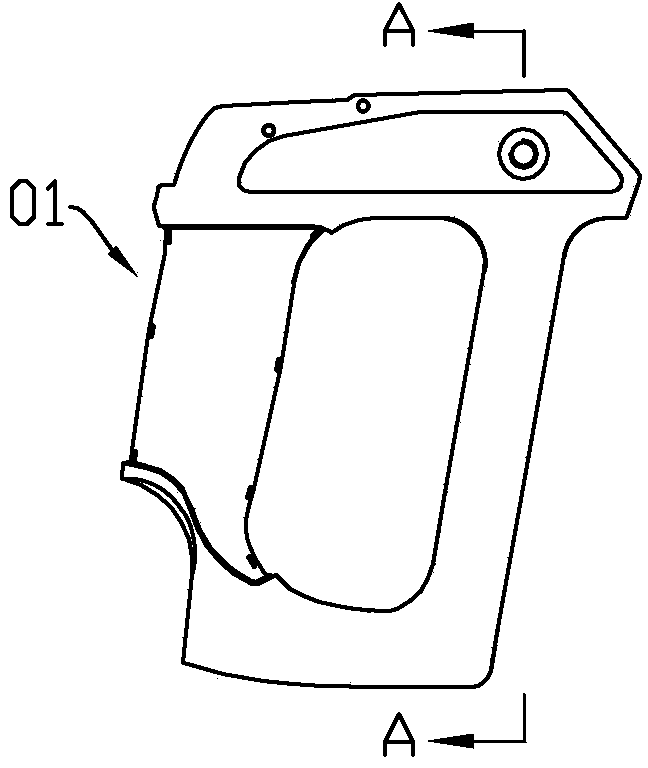

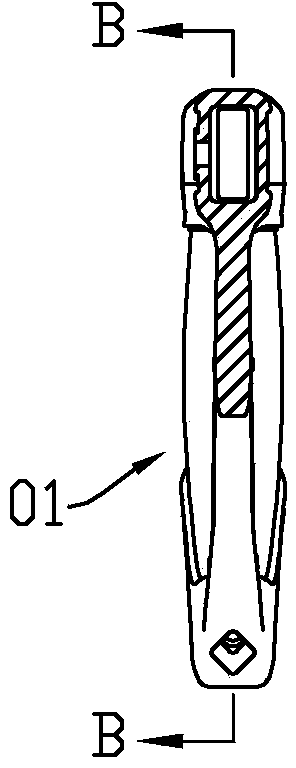

Hacksaw frame

InactiveCN103586534AChange the installation methodConvenience to workMetal sawing devicesEngineeringHand tool

The invention discloses a hacksaw frame, belongs to hand tools and aims to solve the problems that an existing hacksaw frame is single in working mode and does not have extended functions. The hacksaw frame comprises a handle, a frame head and an arched beam. The upper portion of the handle is provided with an insertion hole facing forwards, and the lower portion of the handle is provided with a tensioning assembly; the upper portion of the frame head is provided with an insertion hole facing backwards, and the lower portion of the frame head is provided with a hanging column; the arched beam is in a tube shape, an accommodating cavity is formed in the arched beam, and the two ends of the arched beam are inserted into the insertion hole in the handle and the insertion hole in the head frame respectively. When the hacksaw frame is used, a method for installing a hacksaw blade can be changed, and accordingly convenience is brought to work; the frame head can serve as the handle and be used with saw webs assembled; the accommodating cavity of the arched beam can be used for storing spare hacksaw blades and accommodating other saw blades installed on the frame head; the saw webs can be reliably assembled onto the frame head through lock screws without shaking.

Owner:HANGZHOU GREAT STAR IND CO LTD

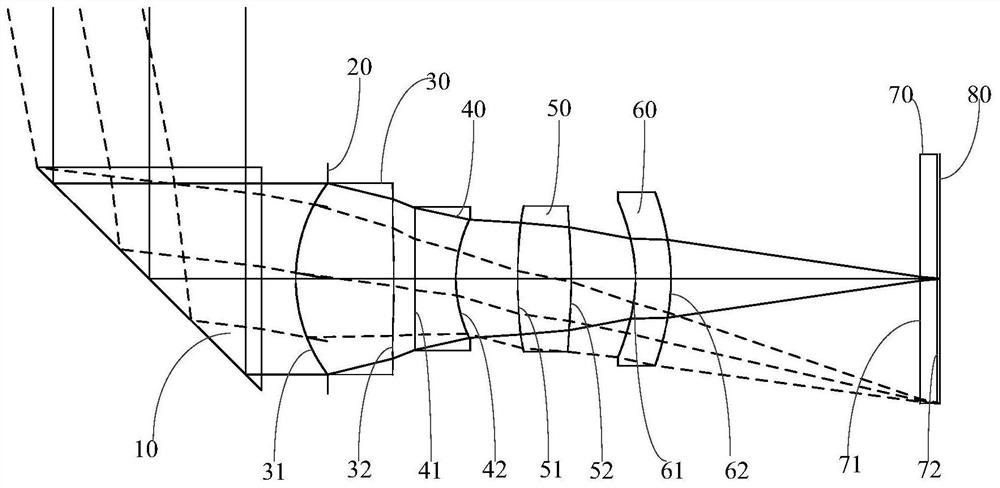

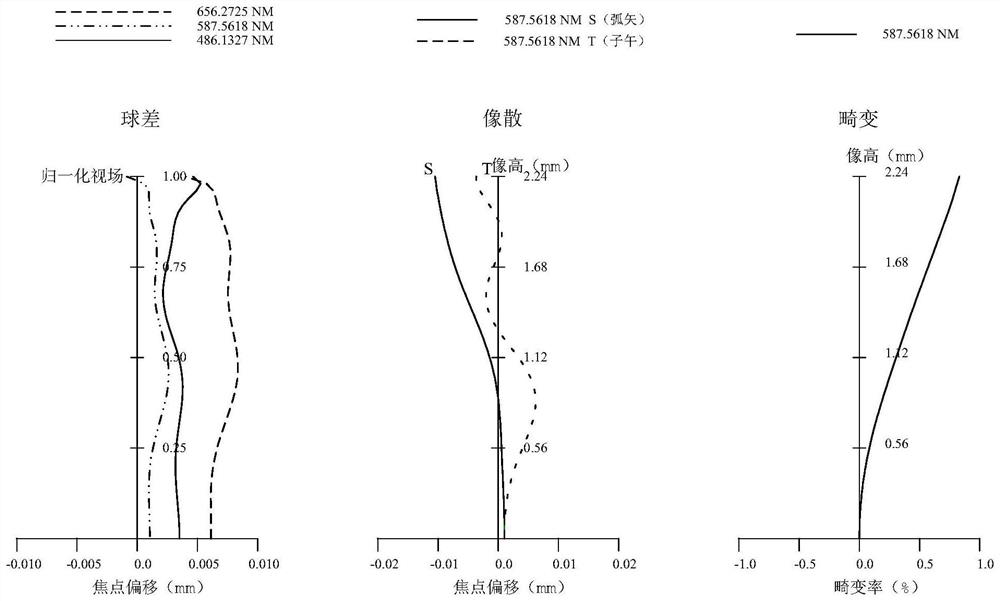

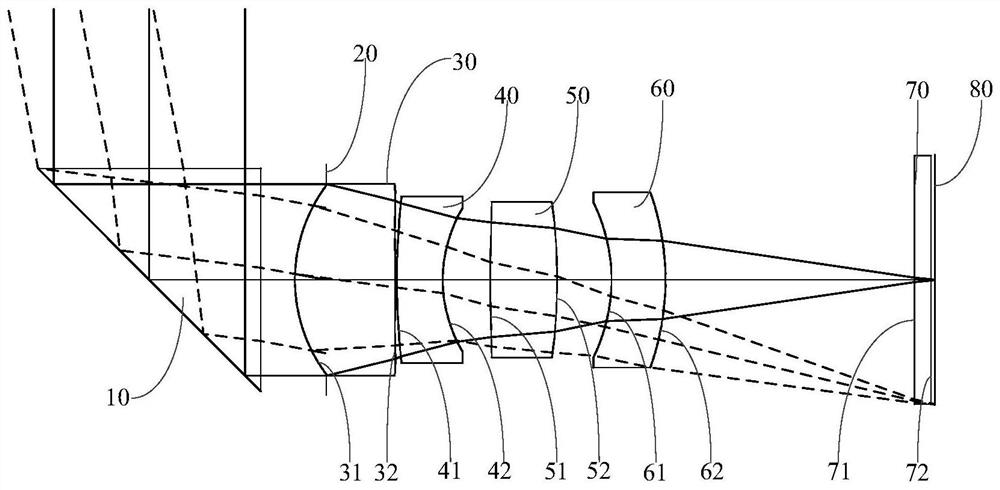

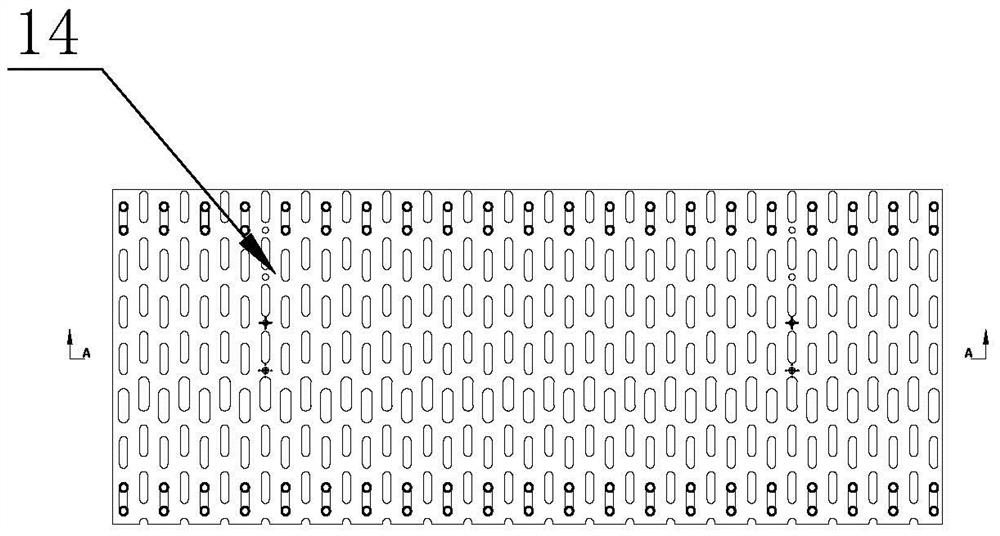

Imaging lens, camera module and electronic equipment

PendingCN112327457AGuaranteed assembly manufacturabilityShorten the lengthOptical elementsGrismOphthalmology

The invention discloses an imaging lens, a camera module and electronic equipment. The imaging lens comprises a prism, a first lens, a second lens, a third lens and a fourth lens which are sequentially arranged from the object side to the image side. The imaging lens satisfies the conditional expression that 0.4 mm<ET12+ ET23+ET34<2.5 mm, wherein ET12 is the distance from the maximum effective aperture of the image side surface of the first lens to the maximum effective aperture of the object side surface of the second lens on the optical axis, ET23 is the distance from the maximum effective aperture of the image side surface of the second lens to the maximum effective aperture of the object side surface of the third lens on the optical axis, and ET34 is the distance from the maximum effective aperture of the image side surface of the third lens to the maximum effective aperture of the object side surface of the fourth lens on the optical axis. The imaging lens achieves the long-focuscharacteristic, is short in transverse distance, and can meet the light and thin requirements of a cellphone.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

Air conditioner heat exchanger automatic pipe penetrating method and production line without pipe supplementing procedure

ActiveCN112296656ASolve the problem of automatic pipe penetrationShorten the lengthAssembly machinesMetal working apparatusProduction lineEngineering

An air conditioner heat exchanger automatic pipe penetrating method and production line without a pipe supplementing procedure are characterized in that two pipe penetrating machines of the same structures are used for completing stacking pipe penetrating with positioning pins and perforating without the positioning pins respectively, and when pipe penetrating is conducted without positioning, transverse positioning is achieved through a copper pipe pressing plate. According to the air conditioner heat exchanger automatic pipe penetrating method and production line, the full-automatic pipe penetrating problem of air conditioner radiator fins is fundamentally solved, and the length of the production line is fundamentally shortened.

Owner:NANJING GUOYOU INTELLIGENT SYST CO LTD

Method for mounting cable bridge on gas pipeline

InactiveCN102506232AChange the installation methodLess construction requirementsPipe supportsCable trayEconomic benefits

The invention discloses a method for mounting a cable bridge on a gas pipeline. A bridge fixing device and sectional bridges are made on the ground; grounding main lines are preset on the sectional bridges and a single bridge; and the structure of the bridge fixing device meets the requirement that the bridge fixing device can be fixed to an accessory of the pipeline through a bolt, and the requirement that the bridge can be spliced through bolts. The method has the advantages that: the constructional requirement is low; welding and flame operation in dangerous regions can be avoided; the cable bridge can be safely and conveniently constructed; the engineering cost is low; and the economic benefit is high.

Owner:TIANJIN 20 CONSTR

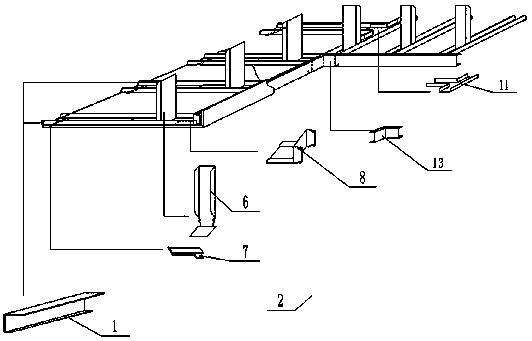

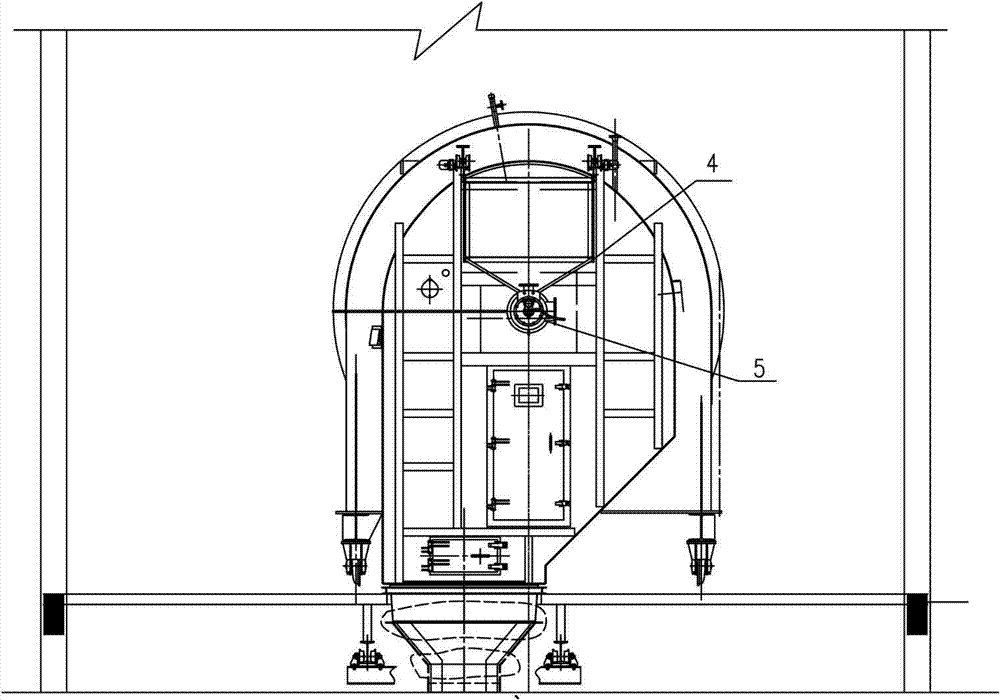

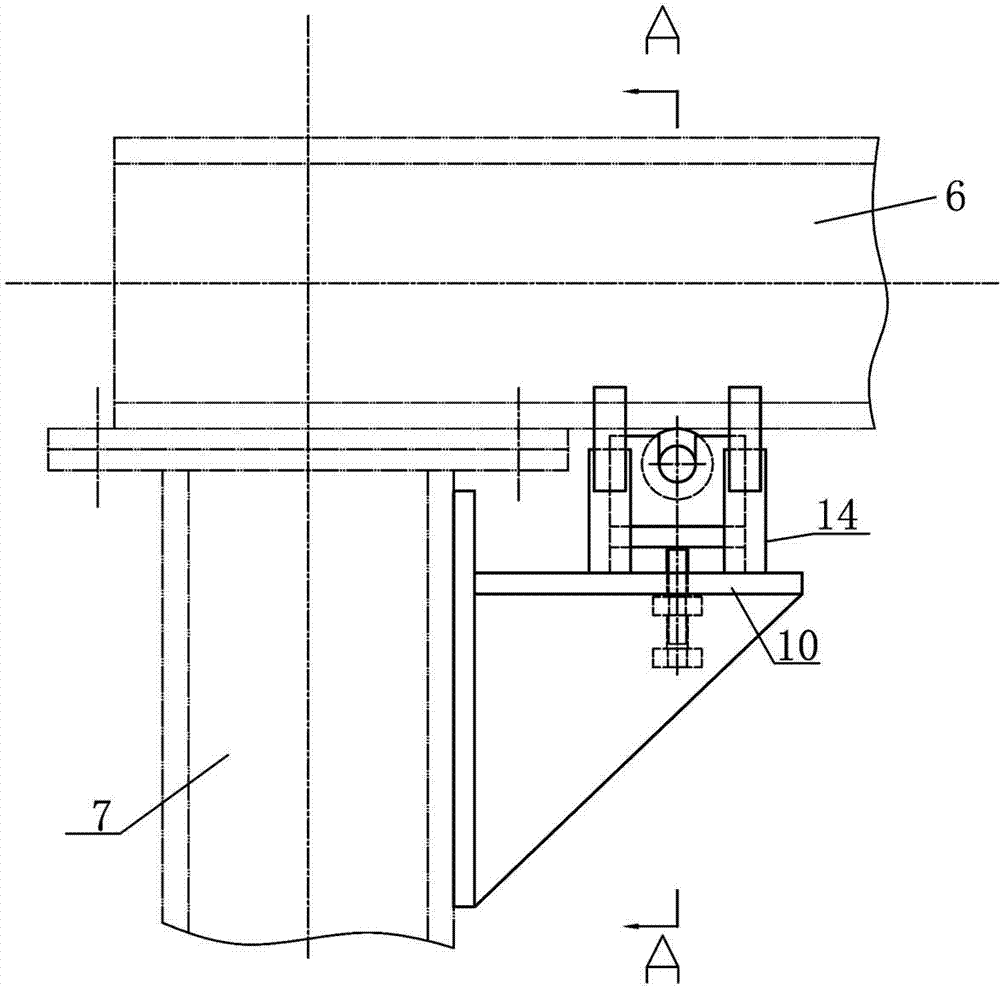

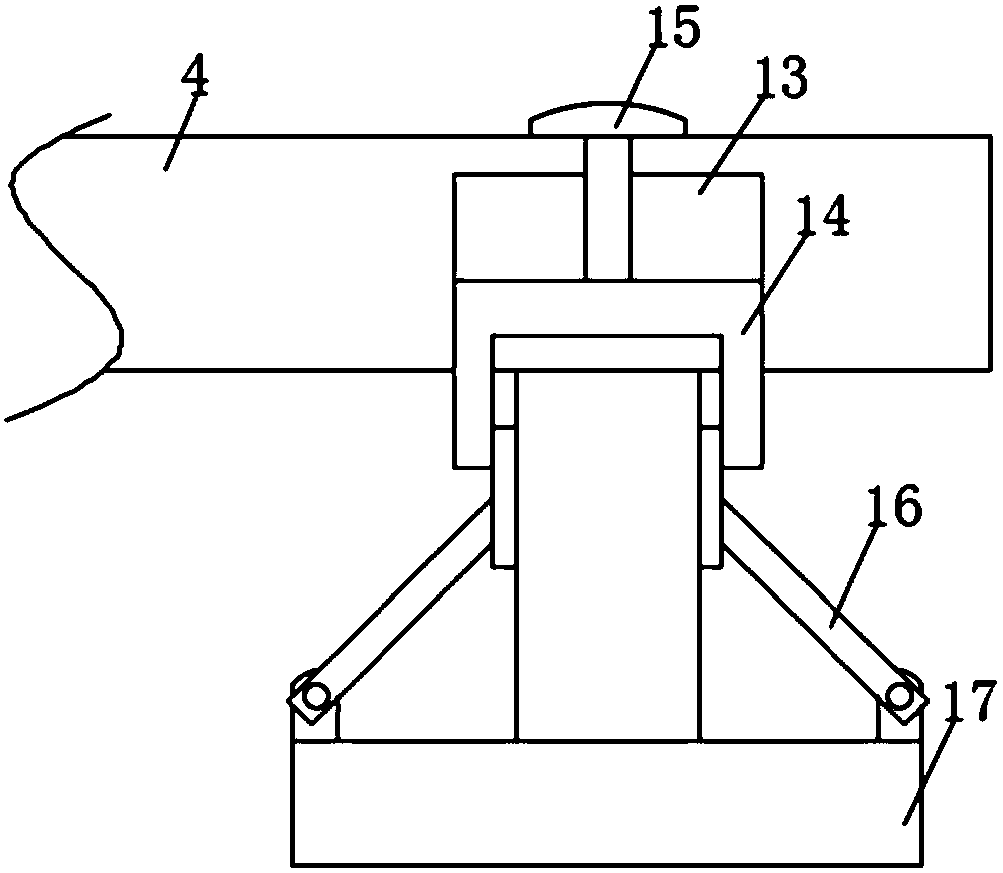

Mounting device for combustor of kiln

ActiveCN102901345AReduce riskQuick and easy extractionRotary drum furnacesCombustorArchitectural engineering

The invention relates to a mounting device, in particular to a device for mounting a combustor of a rotary kiln in industries such as carbon and metallurgy. The mounting device for the combustor kiln structurally comprises a transverse steel I-beam, one end of the transverse steel I-beam is fixedly connected with the upper portion of the wall of a kiln head, the other end of the transverse steel I-beam is connected with the top of a vertical steel I-beam, the transverse steel I-beam is slidingly connected with a combustor cradle at the top, the lower portion of the combustor cradle is fixedly connected with the combustor, and the bottom of the vertical steel I-beam is fixed with a steel plate on the floor. The mounting device for the combustor of the kiln has the advantages that the fixed vertical steel I-beam and a rolling bearing, the kiln head, the combustor and the transverse steel I-beam can transversely move together, and the kiln head or the combustor can be quickly and conveniently extracted out when the rotary kiln is paused and maintained or the combustor is replaced. Cost is reduced, and the dangerousness in combustor maintenance is reduced.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Novel efficient tool clamp device

InactiveCN105458804AImprove locking effectChange the installation methodPositioning apparatusMetal-working holdersEngineeringScrew thread

A novel efficient tool clamp device is characterized in that the novel efficient tool clamp device comprises an air cylinder, a nut, bolts, a telescopic spring, a pull rod, a lifting hook, a tool handle, a limiting block and a tool clamp, wherein the driving air cylinder is arranged at the uppermost end of the device and fixed through the nut and the bolts; the two fixing bolts are arranged on the two sides respectively; the telescopic spring and the pull rod are connected to and installed on the lower side of the driving air cylinder; a thread sleeve is arranged at the upper end of the pull rod and screwed; the lifting hook is welded to the lower end of the pull rod; the tool handle is installed in a conical hole of the lifting hook; the tool clamp is sleeved with the limiting block; the limiting block is used for positioning, and the tool clamp is installed on the tool handle through a bolt. The novel efficient tool clamp device has the advantages that the installation way is changed, and the locking effect is good; hydraulic control is achieved so that rapid replacing and positioning can be achieved, the frequency of repeated positioning is reduced, and the working efficiency is effectively improved.

Owner:石勇

Magnetic mounting device and application thereof

InactiveCN103343949ASolve the separation problemEasy to useLighting applicationsLighting support devicesMagnetic tension forceMagnetic switch

The invention relates to a magnetic mounting device and application of the magnetic mounting device. The magnetic mounting device is characterized by being composed of a magnetism-conducting base plate and a magnetic switch. According to the application, the magnetic mounting device can be used for mounting an LED lighting lamp on a fully mechanized face of a coal mine. The magnetic mounting device has the advantages that magnetic material is selected as a mounting platform, and equipment can be mounted on a steel iron structure fast; meanwhile, dismounting is achieved by the utilization of the situation that a magnetic field interferes with the magnetic system of a permanent magnet, and the problem of separation between a strong magnet and the steel iron structure is solved ingeniously; the magnetic mounting device is used for mounting the LED lighting lamp on the fully mechanized face of the coal mine, the position and the mode of mounting of the LED lighting lamp on the fully mechanized face of the coal mine are changed, so that the size of a shell body of the LED lighting lamp is not limited, and the shell body of the LED lighting lamp is provided with enough space for filling of heat transfer paste. Heat energy generated by an LED substrate is fast transferred to an aluminum shell of the lamp through the heat transfer paste and then transferred to a hydraulic support top plate for mounting the lamp through the shell, and thus normal use of the LED lamp is ensured.

Owner:郜业伟

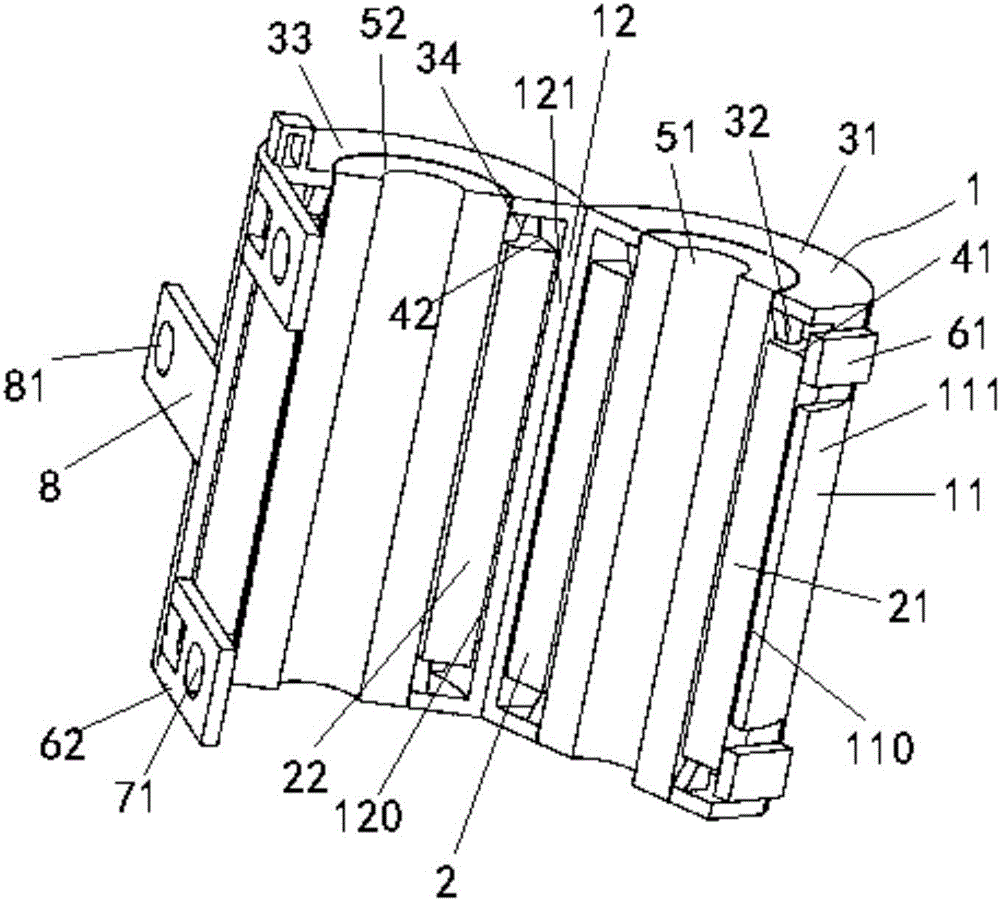

Flexibly mounted capacitive sensor and electrode structure thereof

ActiveCN108388383AChange the installation methodStrong use stabilityInput/output processes for data processingEngineeringCapacitive sensing

The invention discloses a flexibly mounted capacitive sensor and an electrode structure thereof. The flexibly mounted capacitive sensor comprises a mounting platform and a capacitive sensor; a gap isformed in the upper end of the mounting platform; the capacitive sensor is transversely arranged in the gap; the left and right sides of the capacitive sensor are fixedly connected with one ends of extension branches; the lower ends of the extension branches are fit and connected with the upper sides of one ends of L-shaped support plates; second empty slots are formed in two sides of the upper end of the mounting platform; the bottom surfaces of the second empty slots are fixedly connected with one ends of force bearing rods; one ends of the force bearing rods are located in the second emptyslots; a guiding transverse plate is located above the mounting platform; and a flexible mounting structure is arranged at the other end of the guiding transverse plate. Through the flexible mountingstructure, a mounting manner between the capacitive sensor and the mounting platform is changed, and when the mounting platform suffers vibration, the influences, on the capacitive sensor, of the vibration is decreased to a great extent under the action of the flexible mounting structure, so that the using stability of the capacitive sensor is strong.

Owner:SHENZHEN ZHILING WEIYE TECH

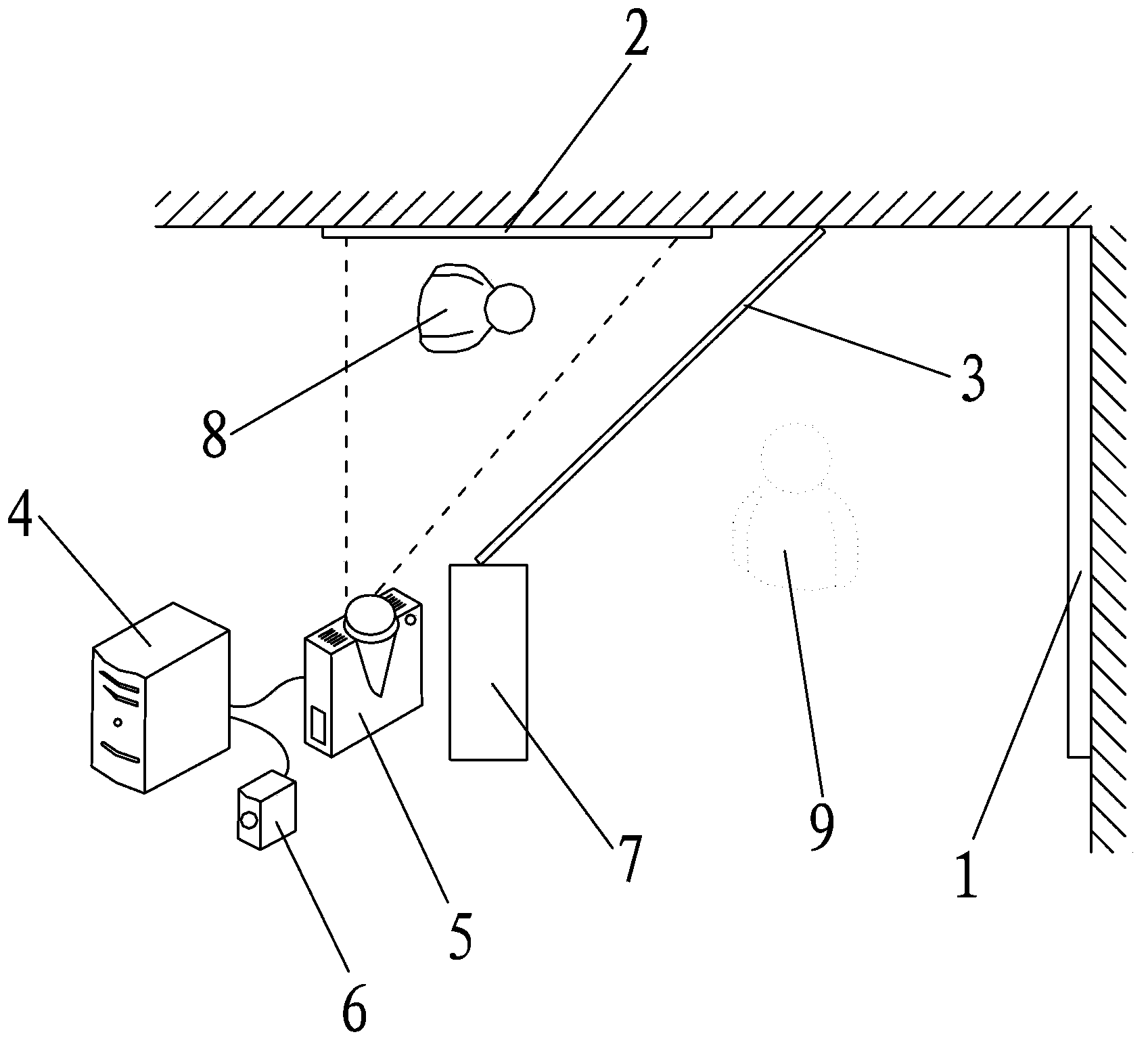

Projection-imaging-type phantom imaging system

InactiveCN103792777ASimple structureNovel and reasonable designProjectorsStereoscopic photographyProjection imageComputer science

The invention discloses a projection-imaging-type phantom imaging system comprising a background wall, a projection curtain arranged on a ceiling, a semi-transparent and semi-reflective mirror arranged in front of the background wall and located slantingly below the projection curtain, a computer host used for playing images, a projector connected with the computer host and used for projecting the images onto the projection curtain, and an audio device used for playing image sounds. The semi-transparent and semi-reflective mirror is arranged on a reflecting mirror frame which is located rightly below the projection curtain. One side of the semi-transparent and semi-reflective mirror is fixedly connected with the reflecting mirror frame. The other side of the semi-transparent and semi-reflective mirror is fixedly connected with the ceiling. The included angle between the semi-transparent and semi-reflective mirror and the ceiling is 30 to 60 degrees. The projection-imaging-type phantom imaging system provided in the invention has the advantages of simple structure, novel and reasonable design, convenient implementation, debugging and manipulation, large displayed virtual image, low cost, wide application range and good popularization and application effects.

Owner:XIAN TEKTONG DIGITAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com