Ultrasonic cutter head for machining small holes and application of ultrasonic cutter head

An ultrasonic and tool head technology, which is applied to tools for lathes, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to process tiny inner holes and inner holes, so as to reduce the structural size and avoid uncertain directions. , the effect of preventing rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

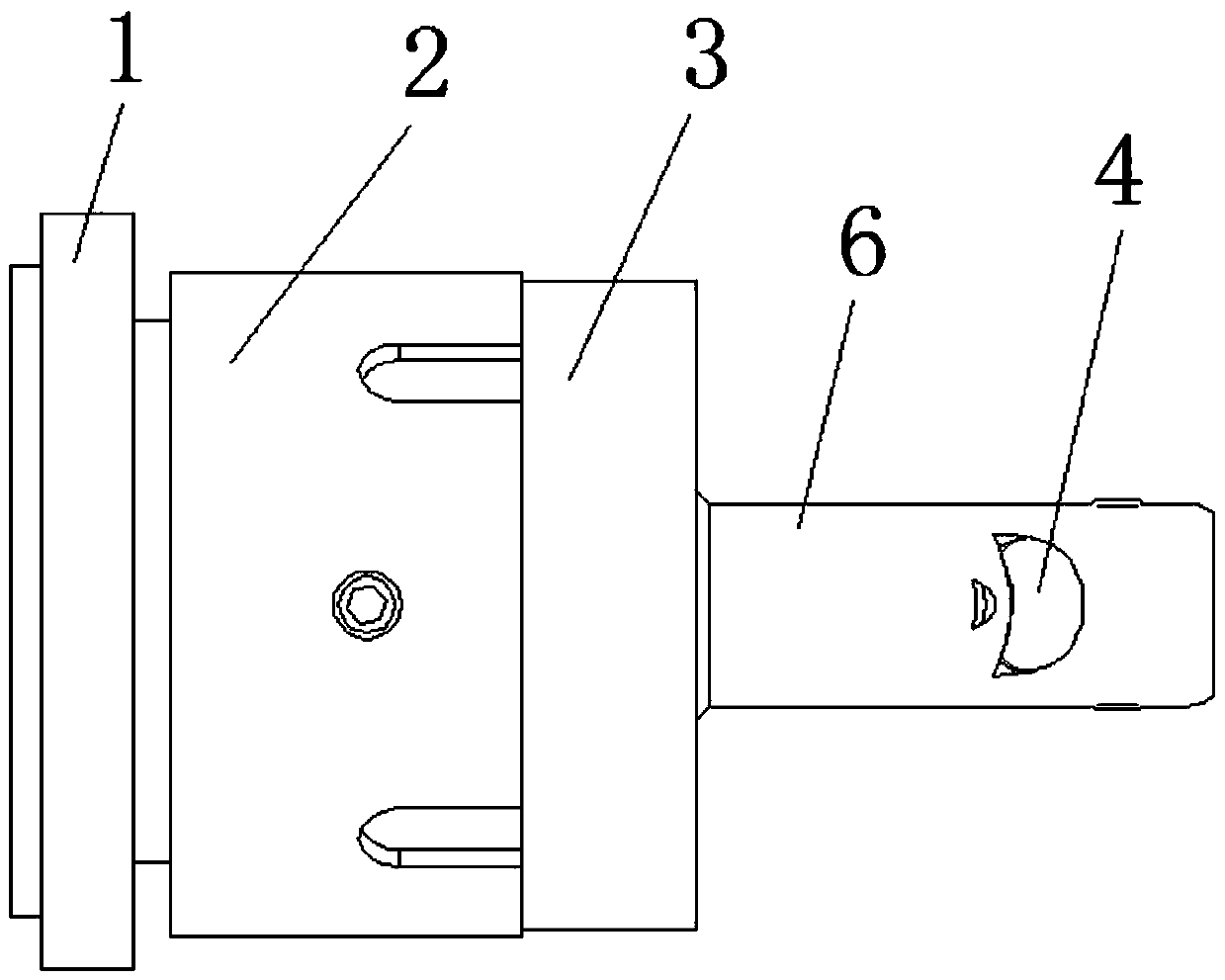

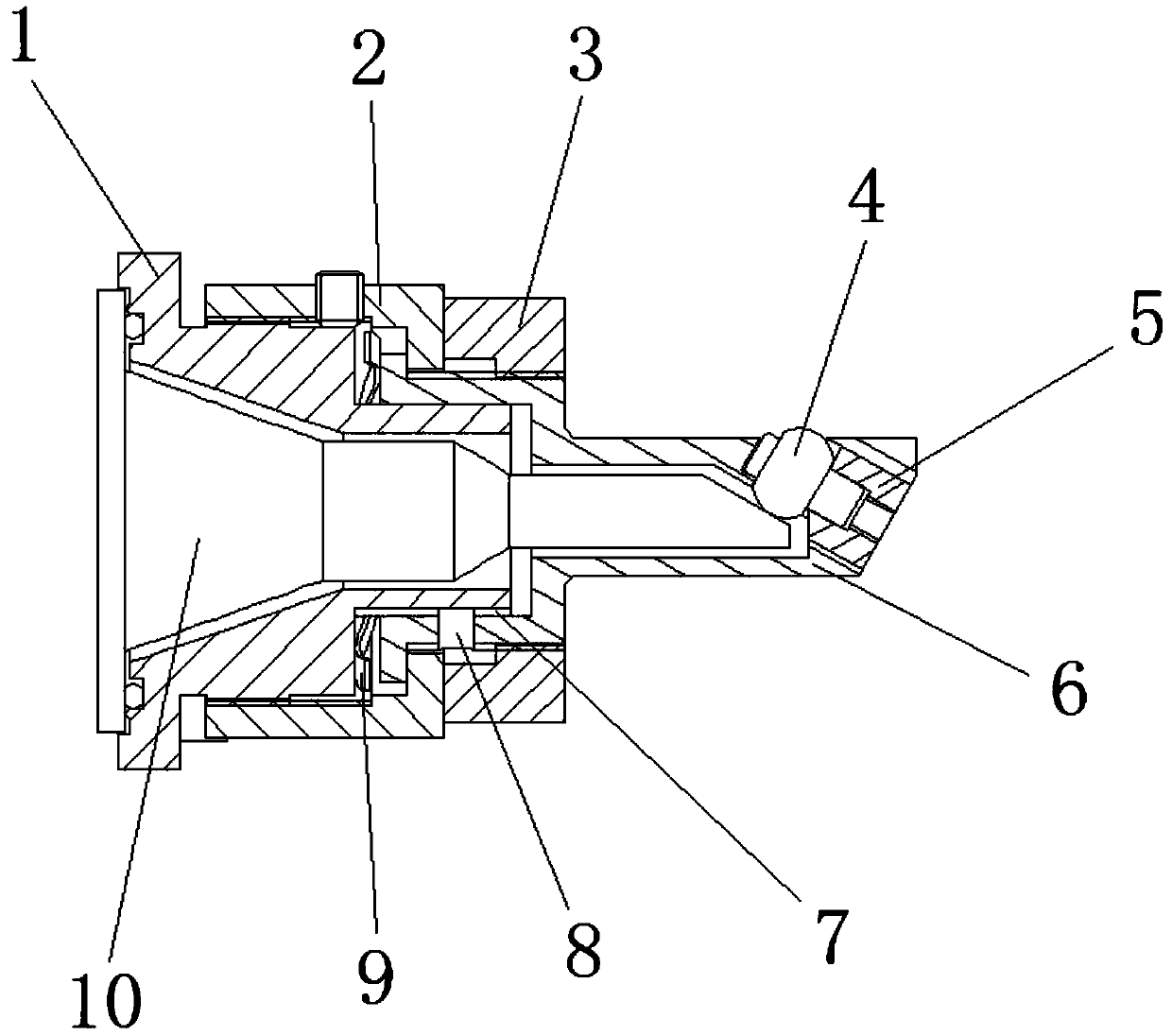

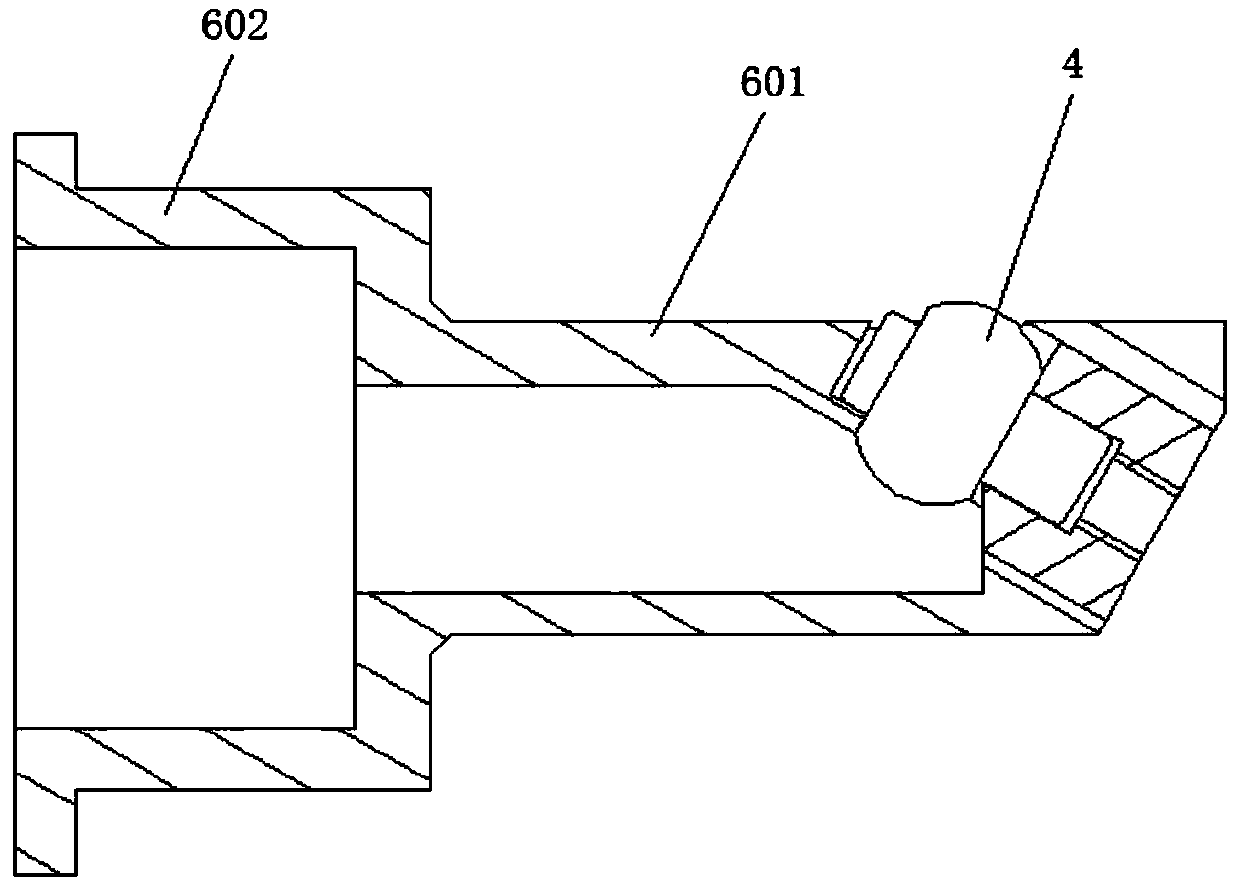

[0028] Such as Figure 1 to Figure 3 As shown, an ultrasonic tool head for processing small holes, the ultrasonic tool head includes a horn 10, a taper sleeve 1, a tool seat 6, a tool head 4 and an adjustment ring 2; The seat 6 is connected, and the adjustment ring 2 is a hollow cylinder with an internal thread at the end. The internal thread at the end of the adjustment ring is connected with the external thread at the front end of the taper sleeve, and the front end of the adjustment ring 2 is clamped with the tool seat 6. , the tool head 4 is embedded in the front end of the tool seat 6 and fixed by the positioning block 5. The horn sleeve 1 is provided with an inner hole for accommodating the horn, and the horn 10 extends into the taper sleeve 1 and the tool seat 6. The horn The front end of the tool head is set as a slope structure, and the outer circular surface of the tool head 4 is in vertical contact with the slope structure.

[0029] Specifically, the tool seat 6 in...

Embodiment 2

[0032] An ultrasonic tool head for machining small holes, the structure is as described in Embodiment 1, the difference is that a wave spring 9 is placed in the gap between the taper sleeve 1 and the tool seat 6 . On the one hand, the wave spring 9 can support the tool seat, so that the tool seat and the front end of the taper sleeve are clamped more firmly, and on the other hand, when adjusting the gap between the horn and the tool head, accurate fine adjustment can be achieved. The front end of the horn 10 is arranged in a spherical structure, and the outer circular surface of the tool head 4 is in vertical contact with the spherical structure.

Embodiment 3

[0034] An ultrasonic tool head for processing small holes, the structure of which is as described in Embodiment 1, the difference is that a locking ring 3 is also provided on the tool seat 6, and the locking ring 3 is threadedly connected with the tool seat 6 and is located in the adjustment ring 2 sides. When the adjusting ring is adjusted to a proper position, lock the adjusting ring through the locking ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com