Mounting device for combustor of kiln

A technology for installing devices and burners, which is applied in the direction of rotary drum furnaces, furnaces, lighting and heating equipment, etc., can solve the problems of difficult installation, high labor intensity, and high risk, and achieve convenient construction and installation, reduce labor intensity, and change installation way effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the examples, but the protection scope of the present invention is not limited by the examples.

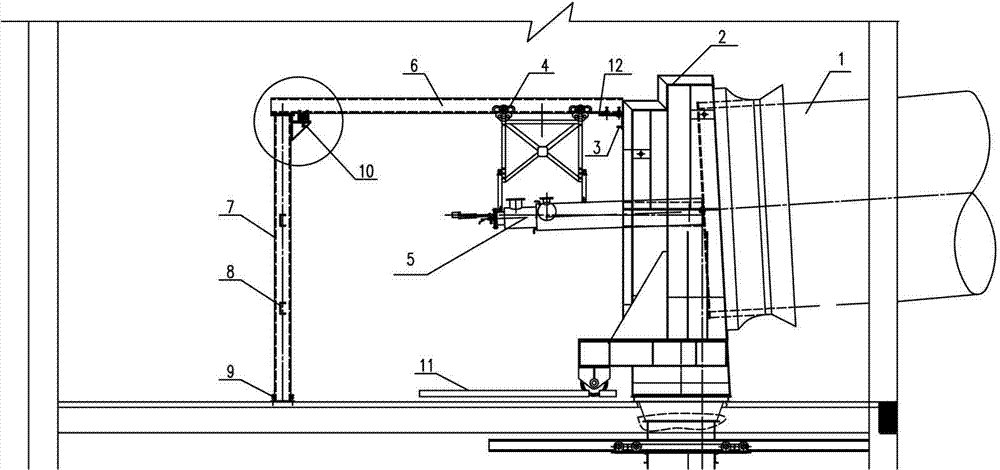

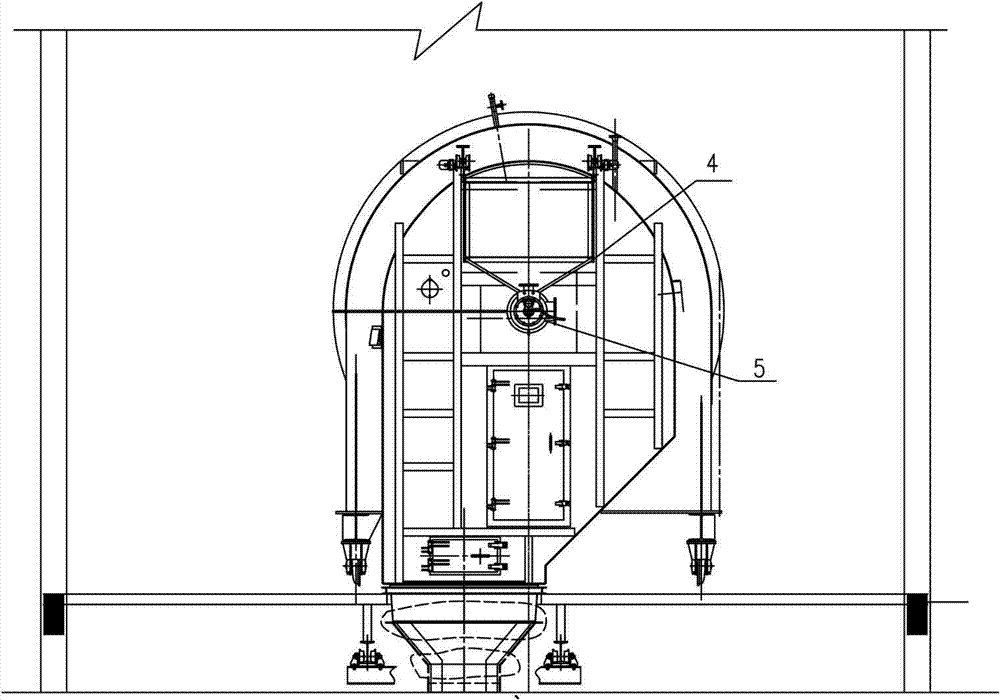

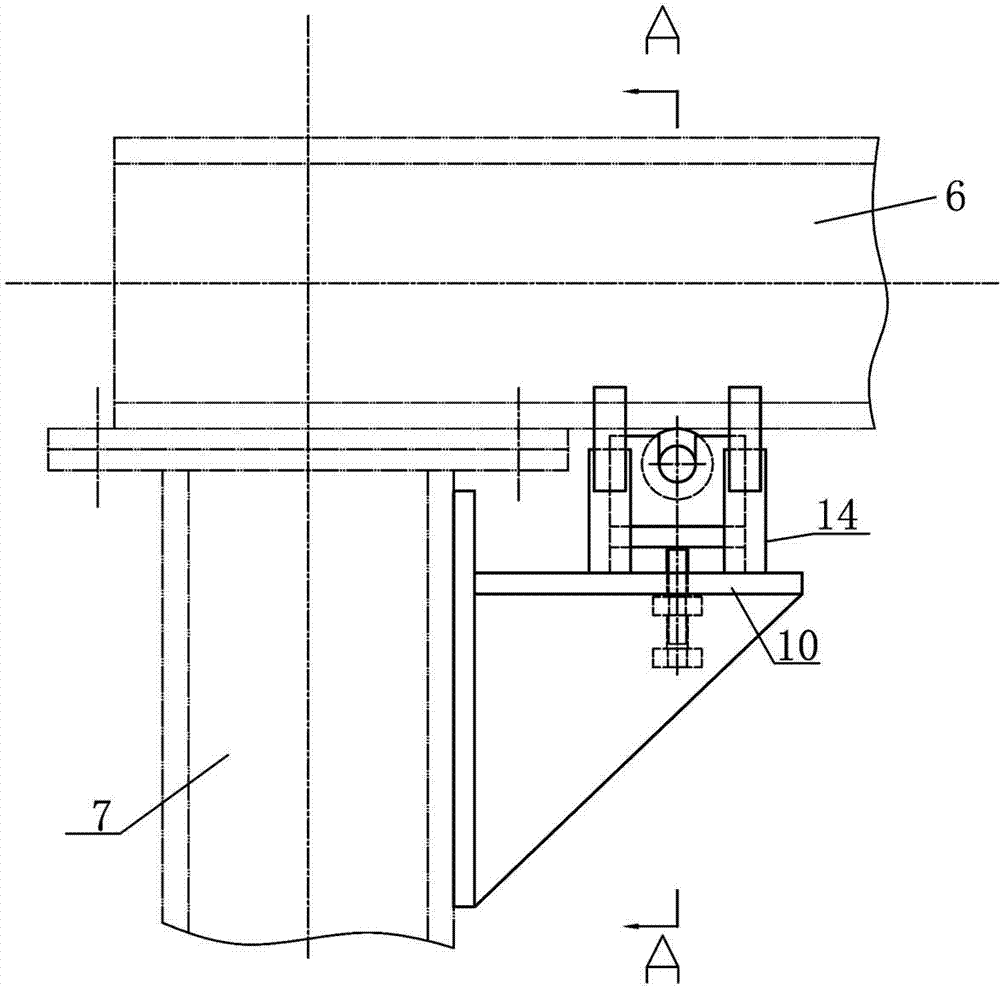

[0018] As shown in the figure, the rotary kiln burner installation device of the present invention is composed of the following structure: a horizontal I-shaped steel 6, one end of the horizontal I-shaped steel 6 is fixedly connected to the upper part of the kiln head wall, and the other end of the horizontal I-shaped steel 6 is connected to the vertical Connect to the top of the I-beam 7, slide and connect the top of the horizontal I-beam 6 and the burner hanger 4, and the lower part of the burner hanger 4 is fixedly connected to the burner 5, so that not only can the level of the burner be adjusted, but also the inclination Angle, and the burner can be easily pulled out. The bottom of the vertical I-beam 7 is fixed with the steel plate on the floor by the expansion anchor bolt 9, which pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com