DC contactor packaging structure

A DC contactor and packaging structure technology, applied in the direction of relays, electromagnetic relays, electromagnetic relay details, etc., can solve the problems of increasing installation space, many processes, increasing production costs, etc., to reduce production costs, change installation methods, reduce The effect of product volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the scope of protection of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the patent scope of the present invention and the content of the description are still within the scope of the patent of the present invention.

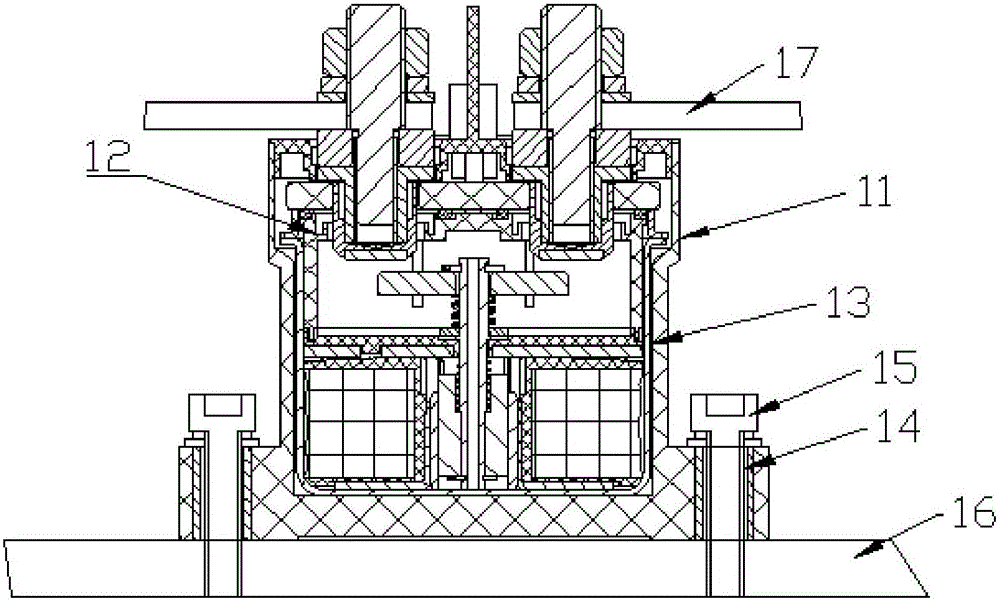

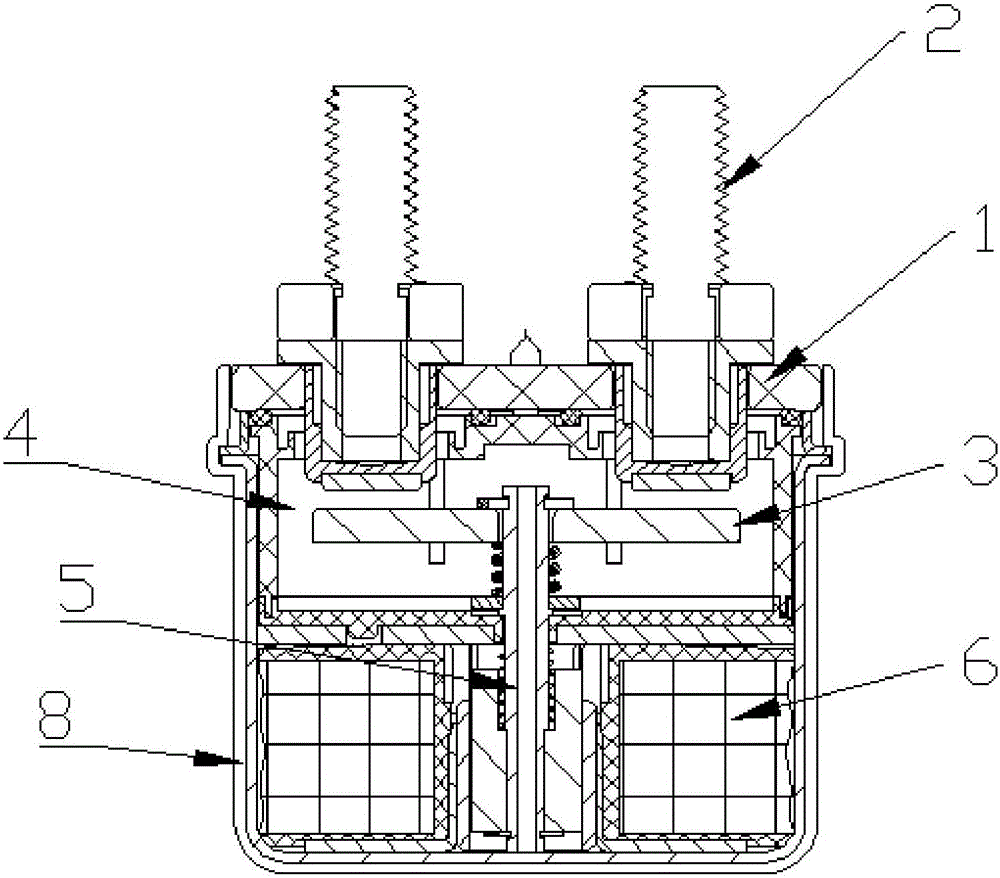

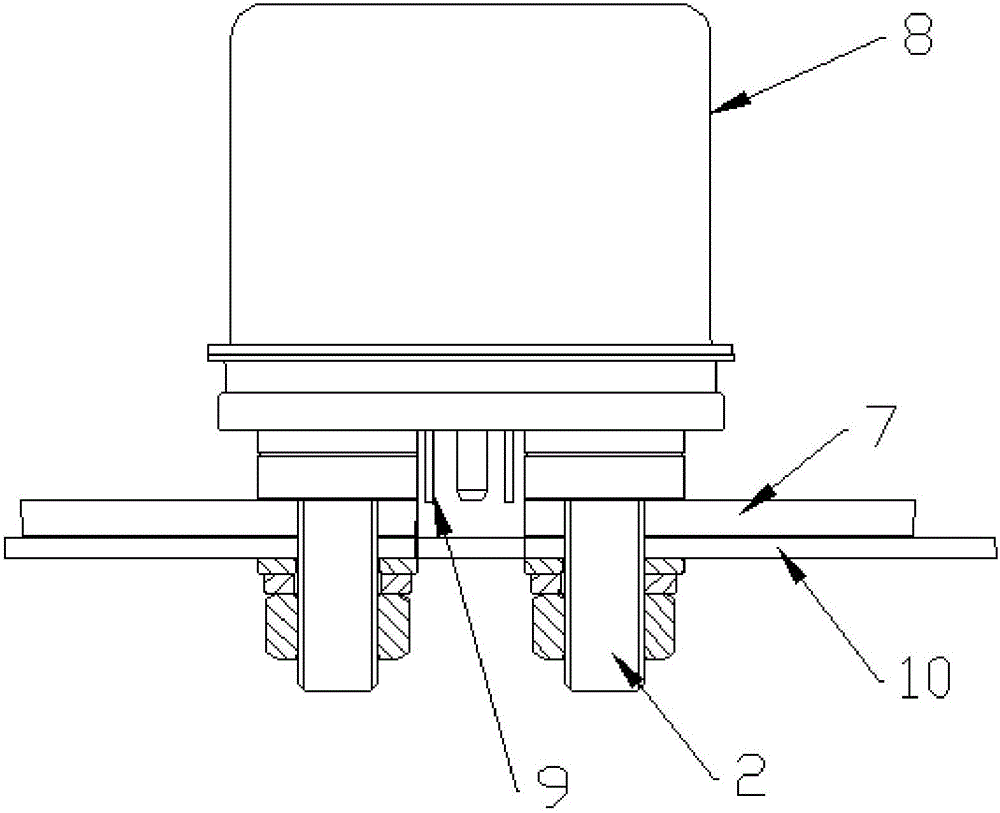

[0023] A DC contactor packaging structure, such as figure 2 As shown, it includes a DC contactor body 1, which is equipped with two screw rods 2 for forming static contacts, a moving contact piece 3 for forming moving contacts, an arc extinguishing chamber 4 for arc extinguishing, and In terms of the transmission part 5 and the coil structure 6 that drive the moving contact, the outer ends of the two screws protrude from the upper side of the DC contactor body, and the two screws, the moving contact piece and the coil are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com