Castellated head bolt

A bolt and tooth technology, applied in the direction of bolts, screws, nuts, etc., can solve the problems of inconvenient installation and low installation efficiency, and achieve the effect of convenient installation, improved installation efficiency and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

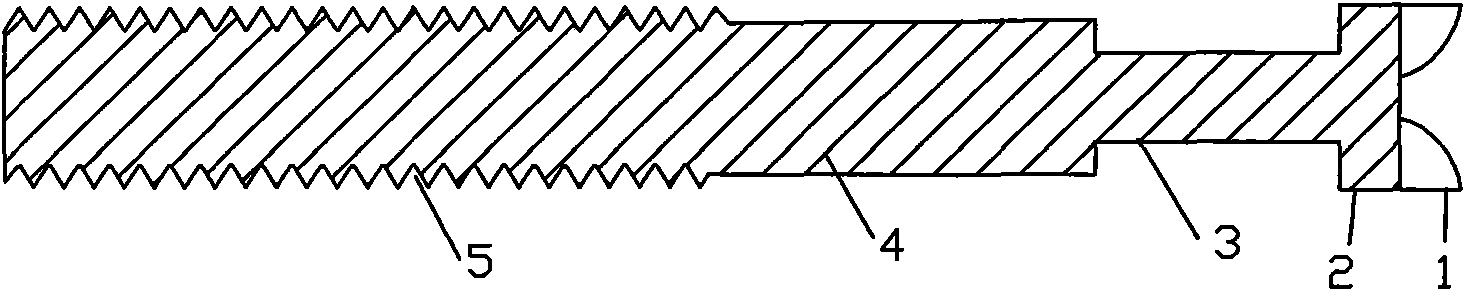

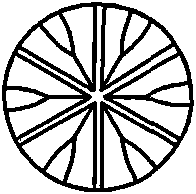

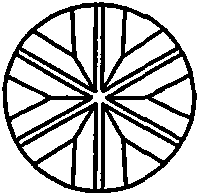

[0056] Refer to the attached Figure 1-10 , the invention discloses a tooth-shaped head bolt, which includes a screw neck 3 and a nut 2 on the upper part of the screw neck 3. The top end of the nut 2 is provided with a plurality of rotating teeth extending along the axial direction of the bolt and driving the bolt to rotate. 1. The tooth gap formed between every two rotating teeth 1 matches the head of the screwdriver, and the screwdriver that is perpendicular to the axial direction of the bolt rotates to drive the rotating teeth 1 to rotate. The rotating tooth 1 is a bevel tooth or a straight tooth, and the bottom of the tooth is flat-bottomed or arrow-shaped or cylindrical with a taper. The lower part of the screw neck 3 is a screw body 4, the lower part of the screw body 4 is a threaded section 5, and the threaded section 5 is threadedly connected with the embedded nut, or the threaded section 5 is a self-tapping thread, or the end of the bolt is an expansion joint. bolt. ...

Embodiment 2

[0058] Refer to the attached Figure 11-36 , the screw neck 3 and the nut 2 are equipped with a bolt pad, the bolt pad includes a U-shaped groove 6 matched with the screw neck 3, an inner cavity 11 for accommodating the nut 2 and a support hole 7 for a screwdriver to extend into, The screw neck 3 is inserted in the U-shaped groove 6, the nut 2 is inserted in the inner cavity 11, the support hole 7 communicates with the inner cavity 11, and the top end of the nut 2 is facing the inner cavity 7 screwdriver. The U-shaped groove 6, the support hole 7 and the inner cavity 11 form an integral cylindrical structure; or the length of the support hole 7 and the inner cavity 11 is shorter than the length of the U-shaped groove 6, and the overall shape is L-shaped; Or the oblique section is an irregular structure. The U-shaped groove 6 forms a gasket that is independently matched with the screw neck 3, and the support hole 7 and the inner cavity 11 form an installation tool support. Th...

Embodiment 3

[0060] As the best implementation mode of the present invention, the bolts described in Example 1 and the bolt pads in Example 2 are used in combination to achieve better results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com