Novel efficient tool clamp device

A kind of tool holder, high-efficiency technology, applied in the direction of positioning device, clamping, support, etc., can solve the problems of low efficiency and easy wear and tear, and achieve the effect of rapid replacement and positioning, changing the installation method, and reducing repeated positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

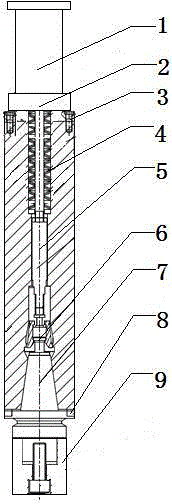

[0012] This embodiment provides a new high-efficiency tool holder device, which is characterized in that: the new high-efficiency tool holder device includes a cylinder (1), a nut (2), a bolt (3), a telescopic spring (4), a pull rod (5 ), hook (6), tool handle (7), limit block (8), tool holder (9);

[0013] Among them: there is a driving cylinder (1) at the top of the device, and the driving cylinder (1) is fixed with a nut (2) and a bolt (3), and a fixing bolt (3) is provided on each side, and a telescopic spring (4) and a pull rod ( 5), the upper end of the pull rod (5) is screwed with a threaded sleeve, the lower end of the pull rod (5) is welded with a hook (6), the tool handle (7) is installed in the tapered hole of the hook (6), and the limit block (8 ) is set on the tool holder (9), positioned with a limit block (8), and the tool holder (9) is installed on the tool handle through bolts.

[0014] A fixing bolt (3) is provided on both sides of the lower end of the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com