Method for mounting cable bridge on gas pipeline

An installation method and cable bridge technology, applied in the direction of pipeline supports, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of increasing construction costs and large limitations, so as to avoid cross operations, reduce high-altitude operations, and improve labor efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

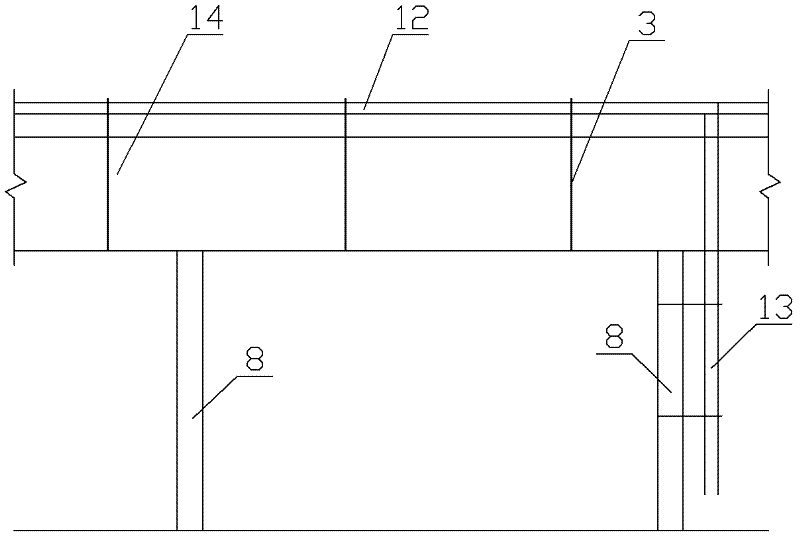

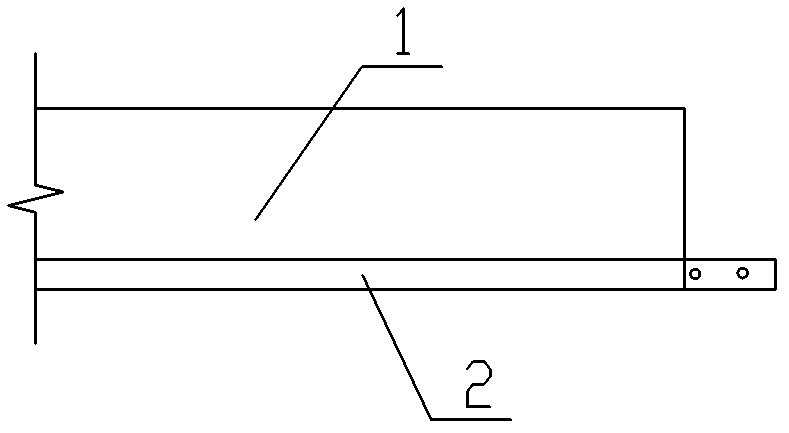

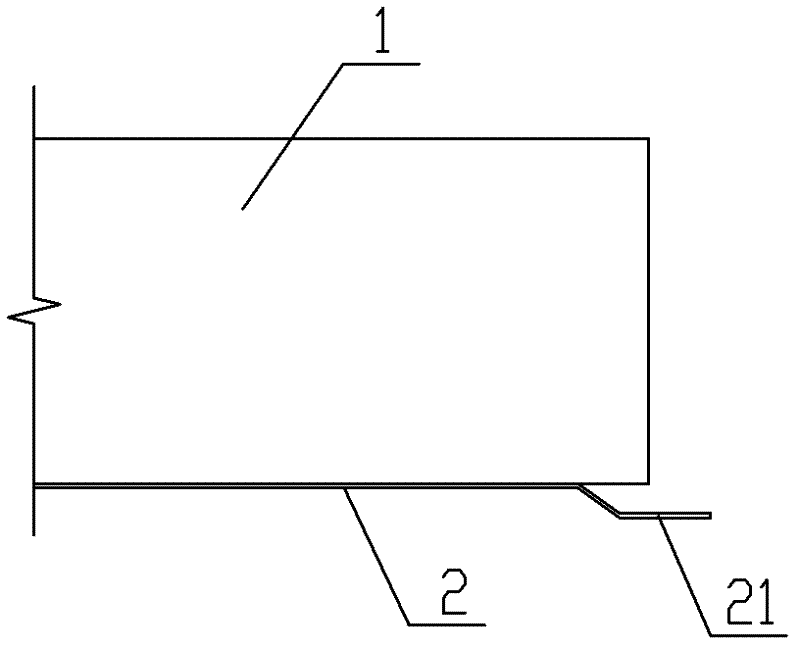

[0022] A method for installing a cable bridge on a gas pipeline includes a method for erecting a horizontal bridge 12 and a method for installing a vertical lower bridge 13.

[0023] The erection method of the horizontal bridge 13 includes the following steps:

[0024] A) See figure 1 The work that needs to be completed at this stage is mainly through the inspection of the environmental conditions of the construction site, according to the construction requirements, combined with the number of ribs 3 on the pipe 14 and / or the number of heat tracing pipe supports, plan the bridge path, and determine the bridge support position. The number and spacing of the approved pipe reinforcement and / or the existing heat tracing pipe supports on the pipe are assembled on the ground ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com