Patents

Literature

38results about How to "Avoid hot work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

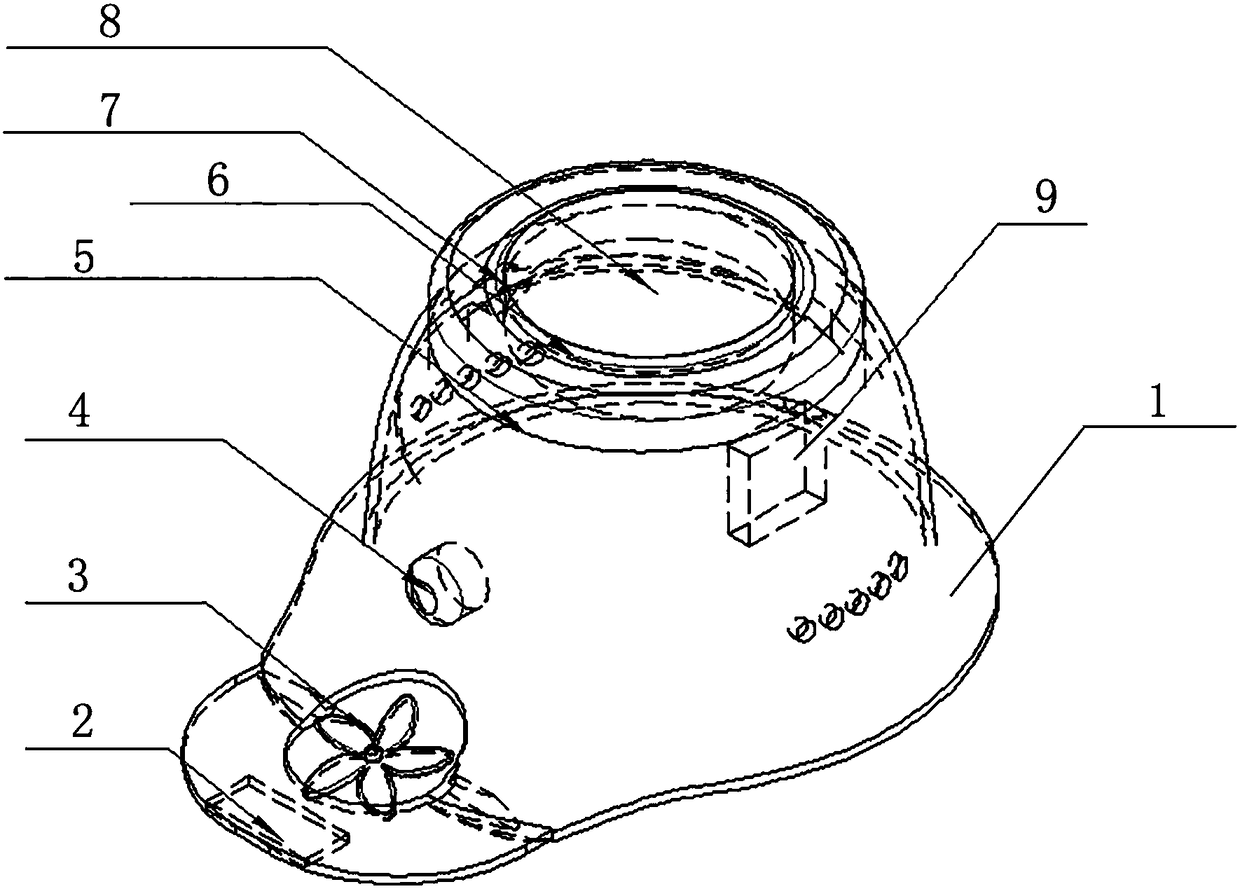

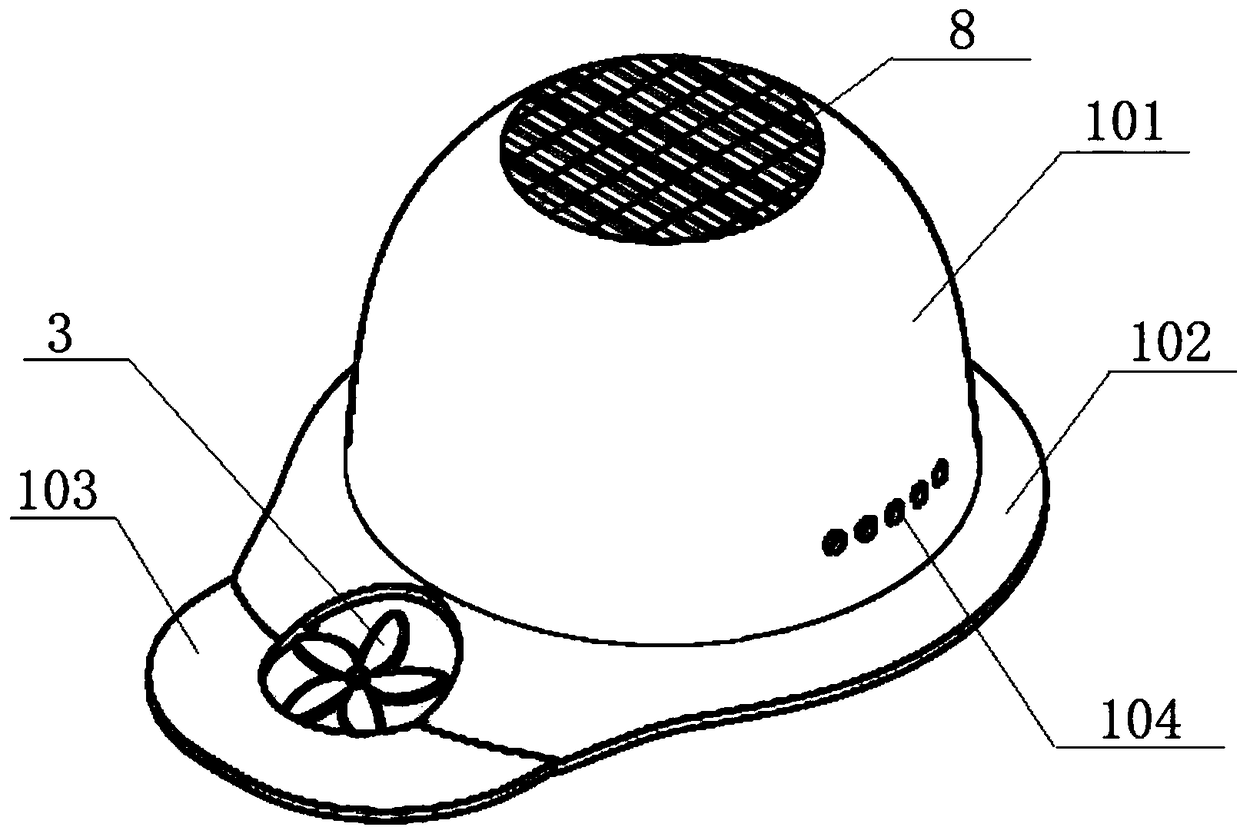

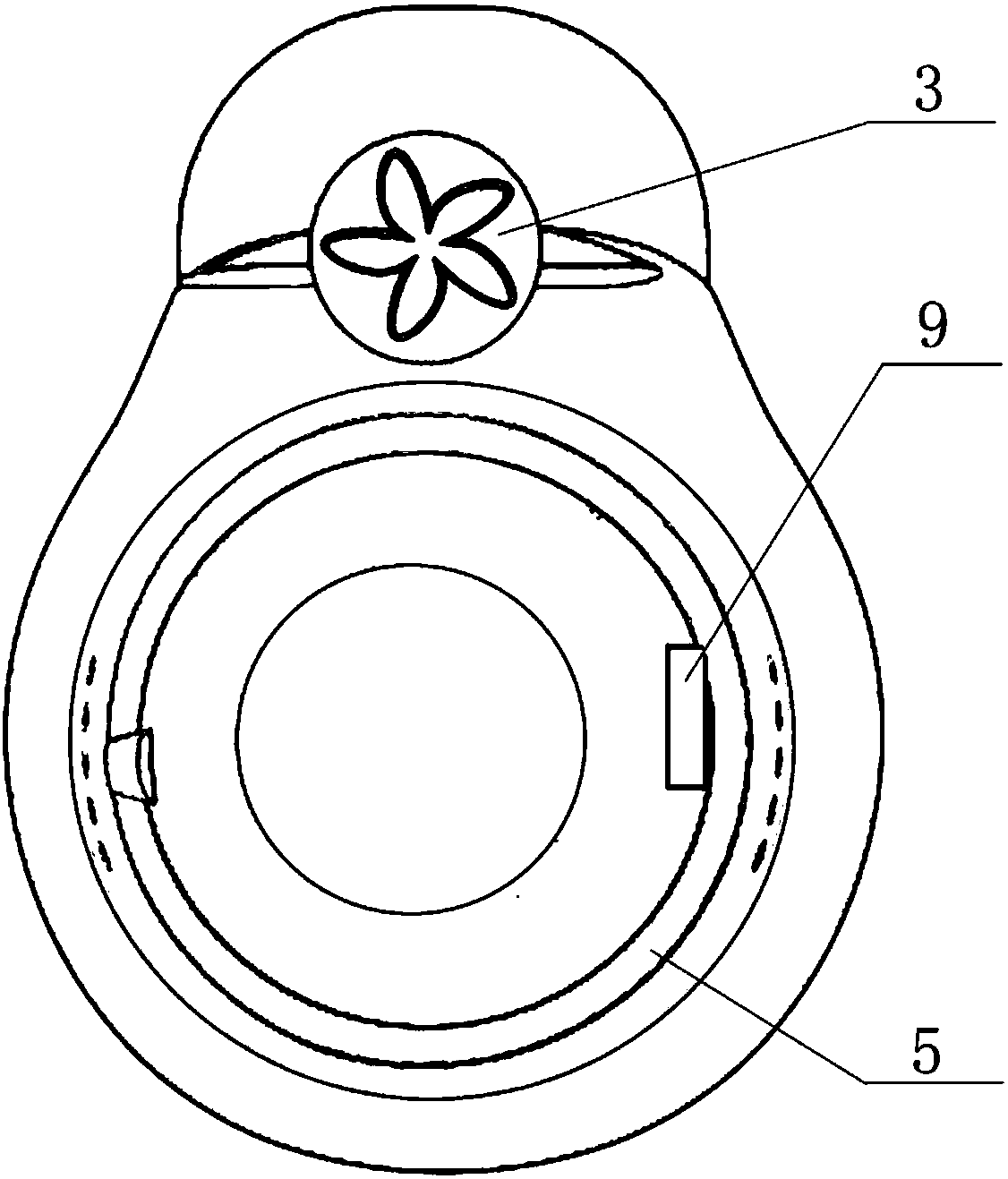

Intelligent safety helmet and method for implementing safety management thereof

InactiveCN108477735AAvoid hot workCo-operative working arrangementsHelmetsComputer moduleEngineering

The invention discloses an intelligent safety helmet. The intelligent safety helmet comprises a safety helmet main body; the main body of the safety helmet comprises a cap body, a circle of cap edgesprotruding outwards along the bottom end of the cap body and a brim extending outwards from the front end of the cap edge; the cap body is provided with an intelligent controller, a temperature monitoring sensor, a camera, a power supply module, an illumination module, an RFID label, an intelligent airbag and an intelligent fan; the intelligent controller is arranged at the side of the cap body, the body temperature monitoring sensor and the power supply module are arranged on the top of the cap body, the RFID label is arranged on the brim, the illumination module is arranged on the front sideof the cap body, and the intelligent airbag is arranged along the inner side of the top of the cap body; a ventilation hole is arranged at the connection part of the brim and the cap edge, and the intelligent fan is arranged at the ventilation hole; the intelligent controller comprises a processor and a positioning module, a voice module, a wireless communication module and an alarm module whichare connected with the processor. The intelligent safety helmet provides an intelligent safety helmet, which has high technical content and multiple functions, and can provide all-directional protection for staff.

Owner:南京烽源物联网科技有限公司

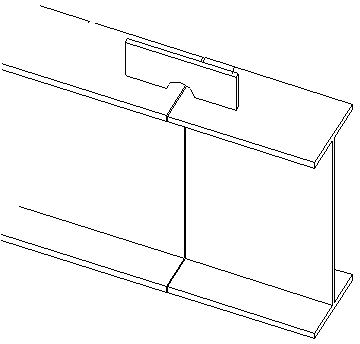

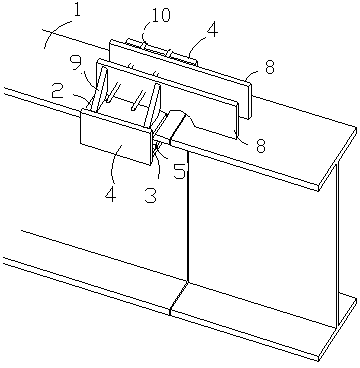

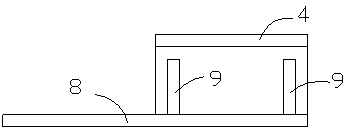

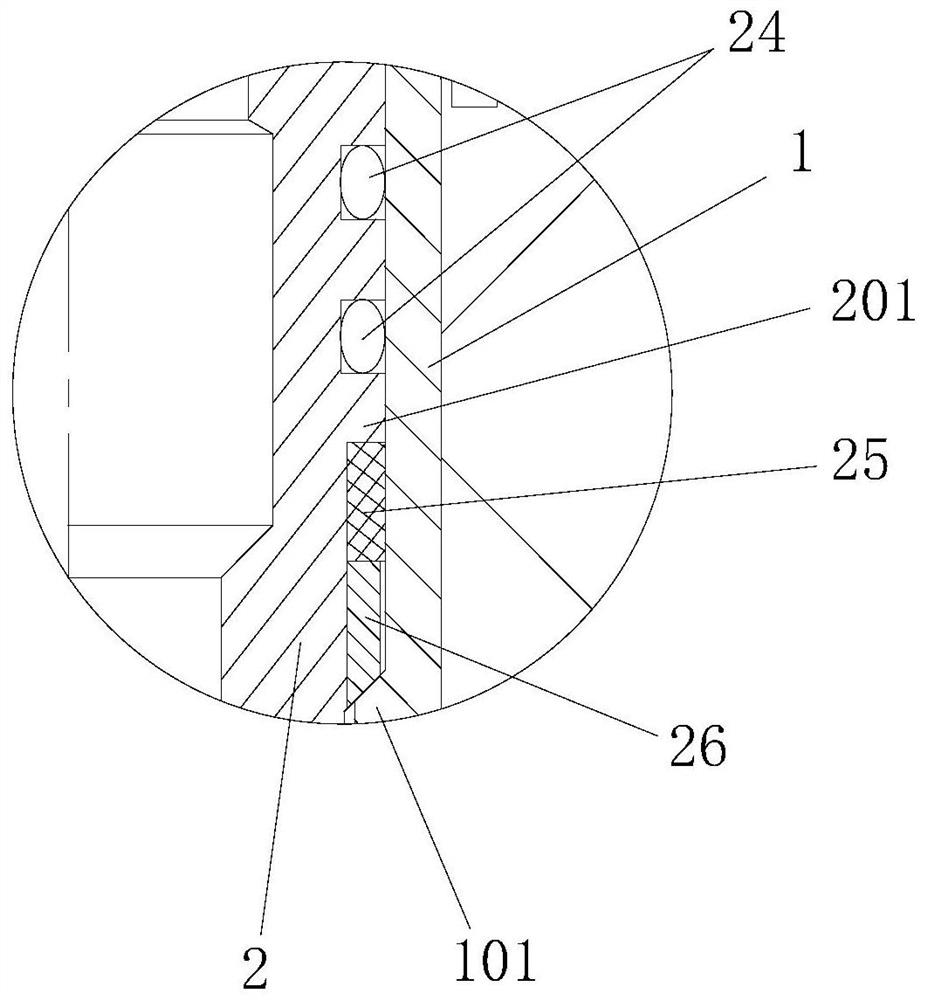

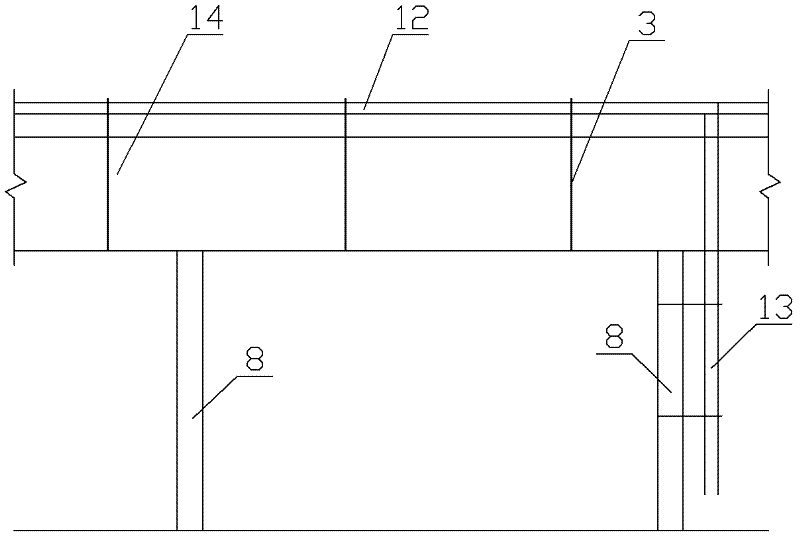

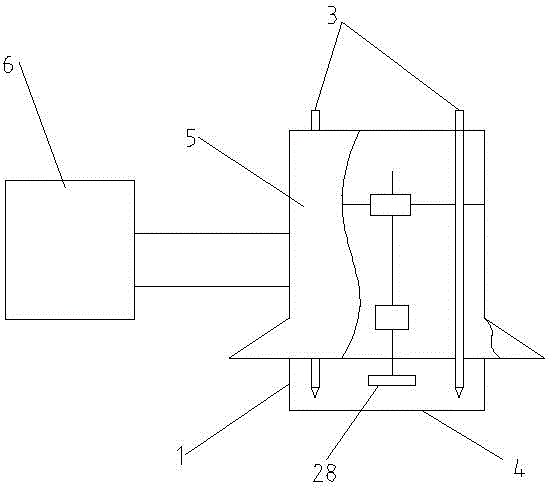

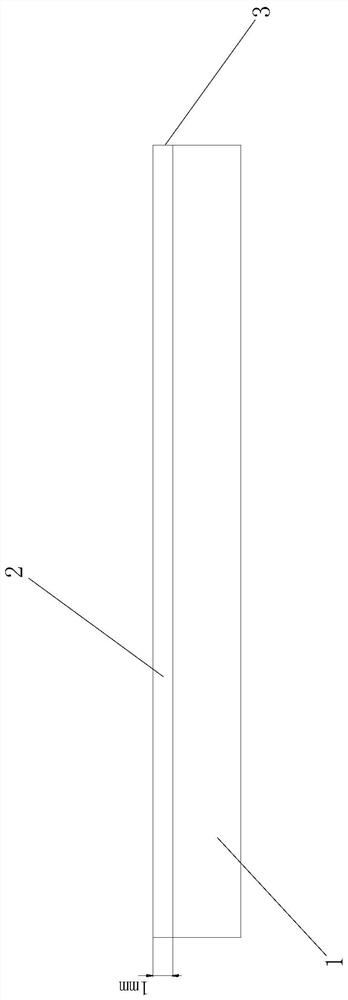

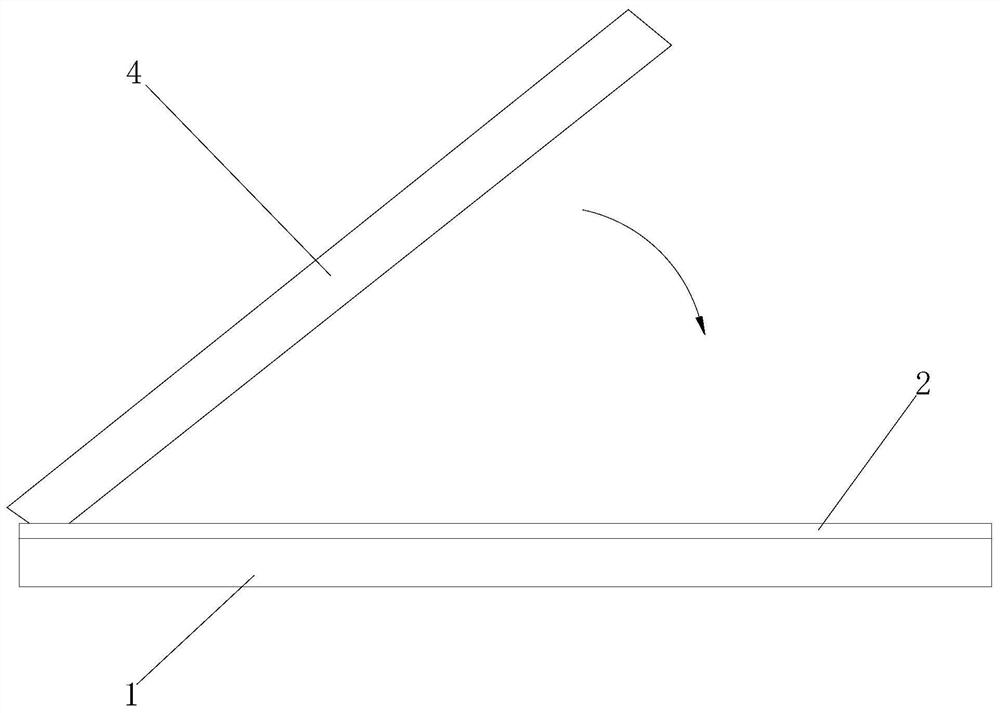

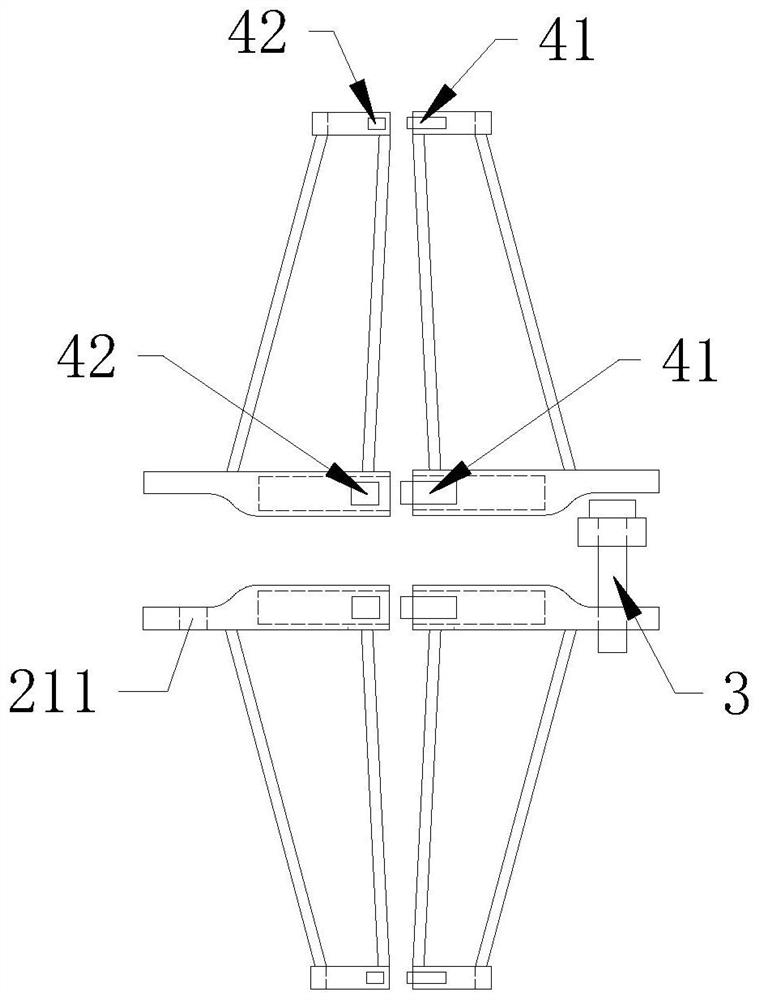

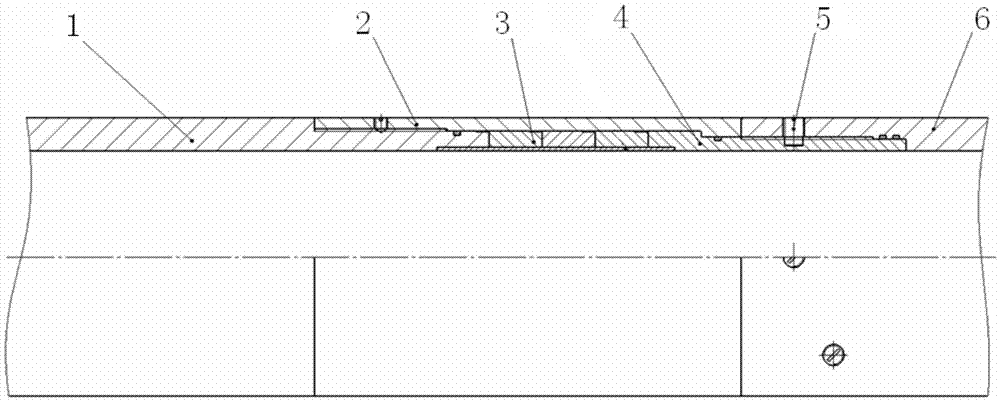

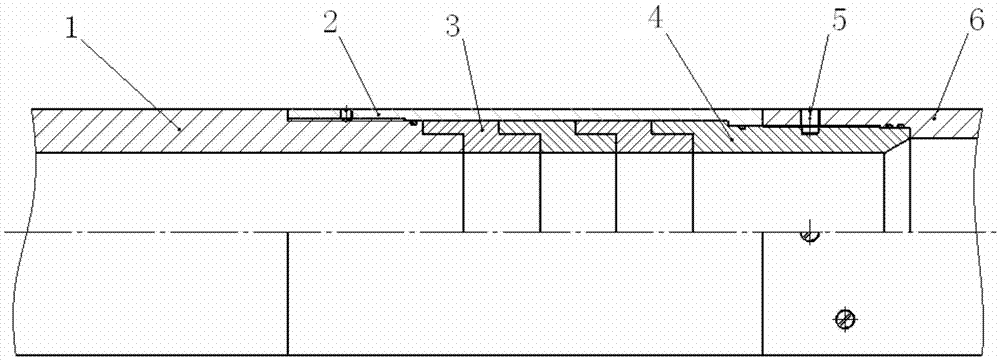

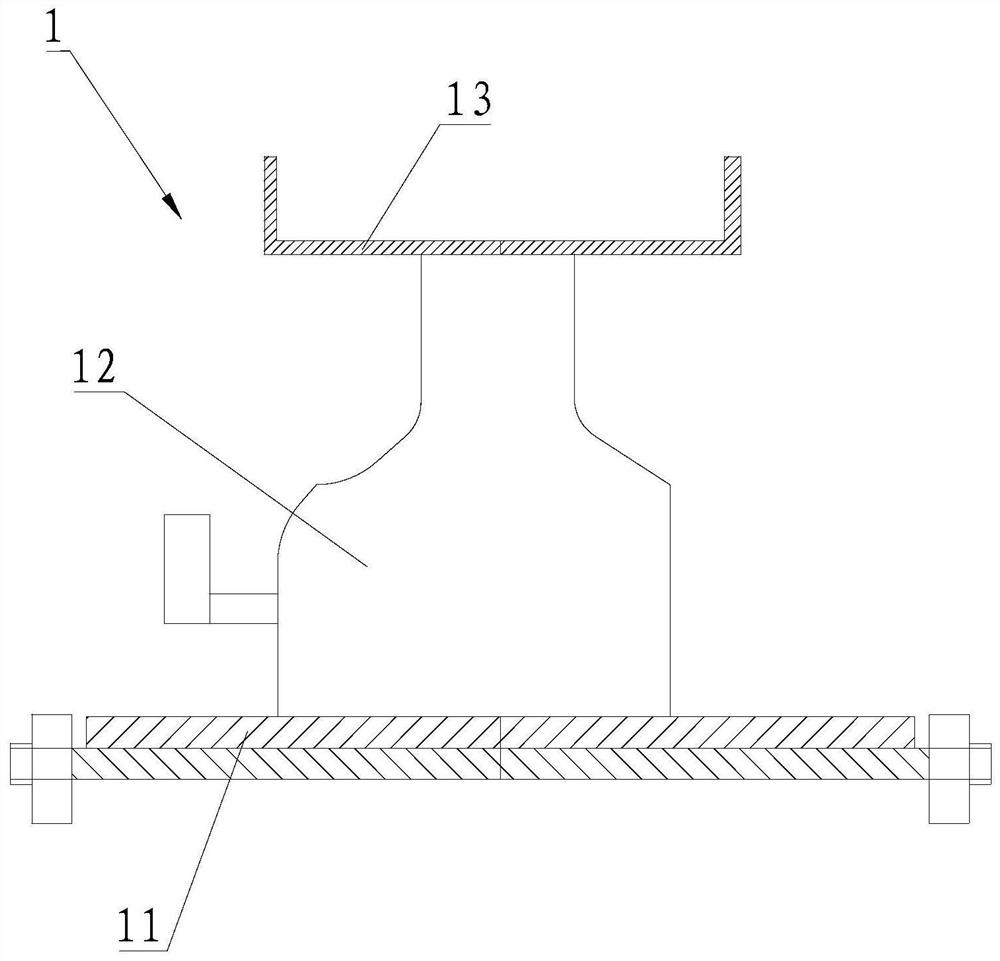

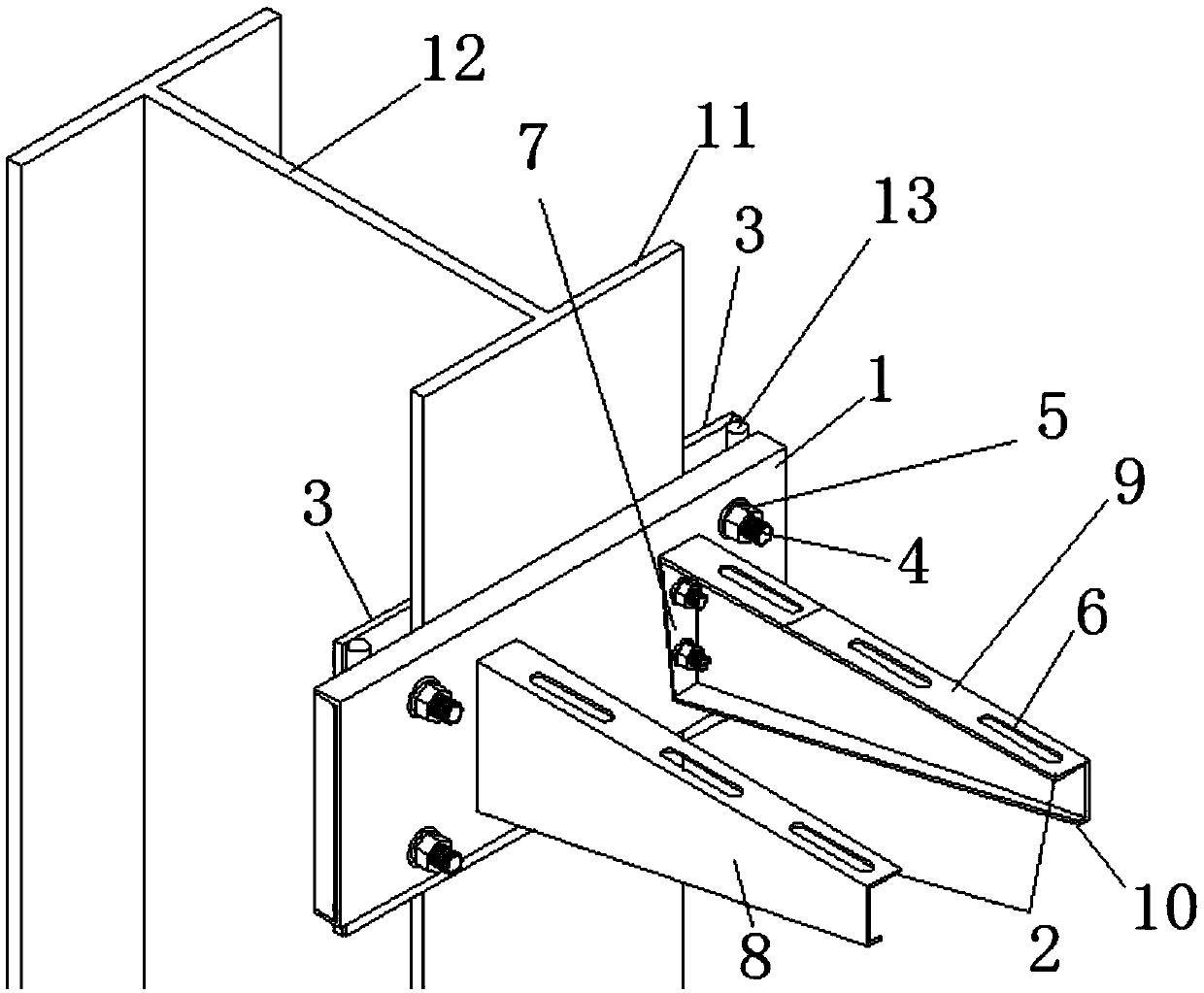

Adjustable steel beam in-place mounting device

InactiveCN103993746AEasy to installEasy to transportBuilding material handlingMaterial consumptionFlange

The invention discloses an adjustable steel beam in-place mounting device, and belongs to the field of steel structure engineering construction. The device comprises a U-shaped clamp sleeve, an adjusting component, a split bolt and an in-place plate. The U-shaped clamp sleeve is formed by welding an upper clamping plate and a lower clamping plate through a vertical plate, a clamping groove capable of containing a steel beam flange plate is formed between the upper clamping plate and the lower clamping plate, and an adjusting bolt hole is formed in the lower clamping plate. The adjusting component comprises a base plate, an adjusting screw rod and an adjusting nut, and the base plate is arranged between the upper clamping plate and the lower clamping plate of the U-shaped clamp sleeve, and is connected with the U-shaped clamp sleeve through the adjusting screw rod and the adjusting nut. The in-place plate is a rectangular plate strip with a split bolt hole, and is in welding connection with the upper clamping plate of the U-shaped clamp sleeve. The device is suitable for in-place mounting of various common steel beams with an H-shaped section or I-shaped steel beams, and the hosting speed of the steel beams is effectively improved. Damage caused by welding and cutting of the in-place plate to base metal is avoided, meanwhile, material consumption is reduced, and construction cost is saved.

Owner:CHINA CONSTR STEEL STRUCTURE JIANGSU CO LTD

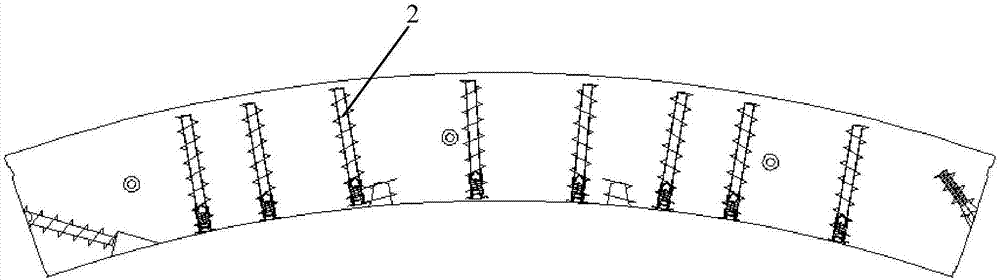

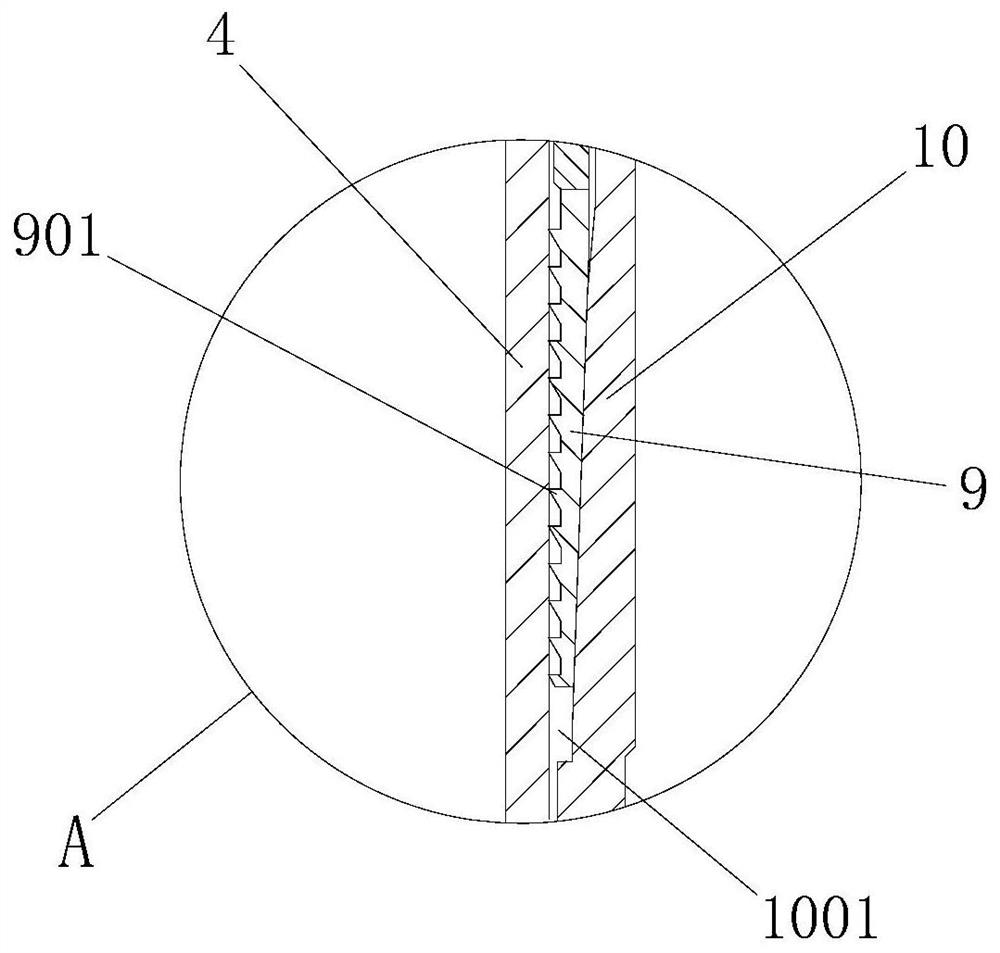

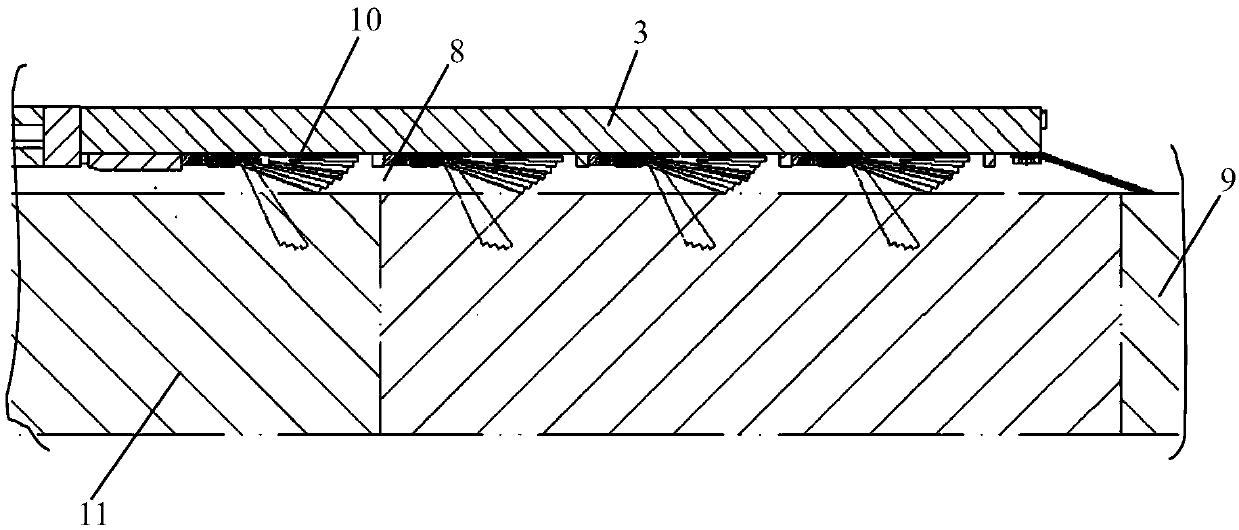

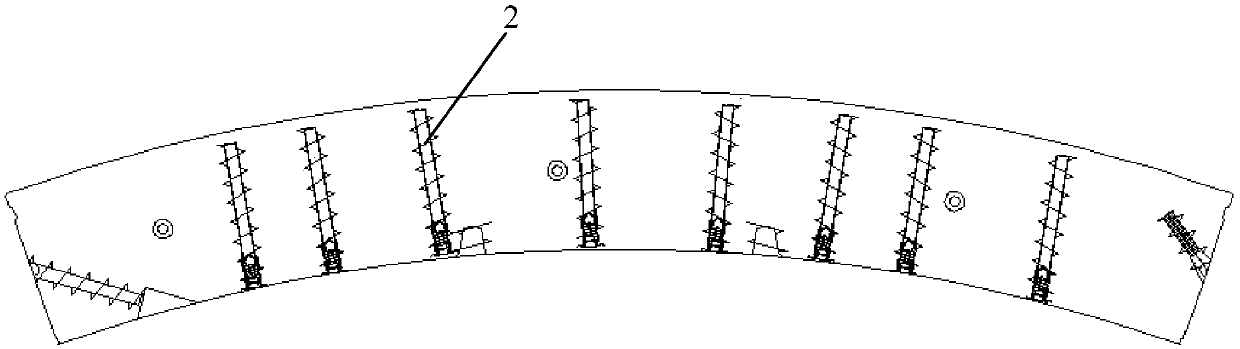

Replacing method of shield tail brushes of super-large-diameter shield machine under high water pressure condition

ActiveCN107035378AEasy to replace, safe, stable and efficientSolve the difficulty of replacementUnderground chambersTunnel liningSlurryEngineering

The invention provides a replacing method of shield tail brushes of a super-large-diameter shield machine under a high water pressure condition. In the propelling process of last ring pipe pieces before shutdown, in addition to the last ring pipe piece before shutdown, gaps between a shield tail and the pipe pieces is filled with elastic water absorbing materials or elastic waterproof materials; in the propelling process of the last ring pipe pieces before shutdown, ordinary grease is injected into a grease cavity of the shield tail brushes in a pressure mode, and the other grease cavities of other shield tail brushes of the super-large-diameter shield machine are injected with waterproof grease in a pressure mode; in the replacement position, a mud tank of the super-large-diameter shield machine is subjected to new slurry replacement; and in the replacement position, a shield shell hoop of the super-large-diameter shield machine is injected with filling slurry body in a pressure mode. Preferably, the shield tail brushes are detachable. According to the replacing method of the shield tail brushes of the super-large-diameter shield machine under the high water pressure condition, replacement of the shield tail brushes under the high water pressure condition is easy, safe, stable and efficient, the problem that replacement of the shield tail brushes of the super-large-diameter shield machine under the high water pressure condition is difficult can be solved, design is ingenious, construction is simple, convenient, safe and efficient, and large-scale application and promotion is adaptable.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

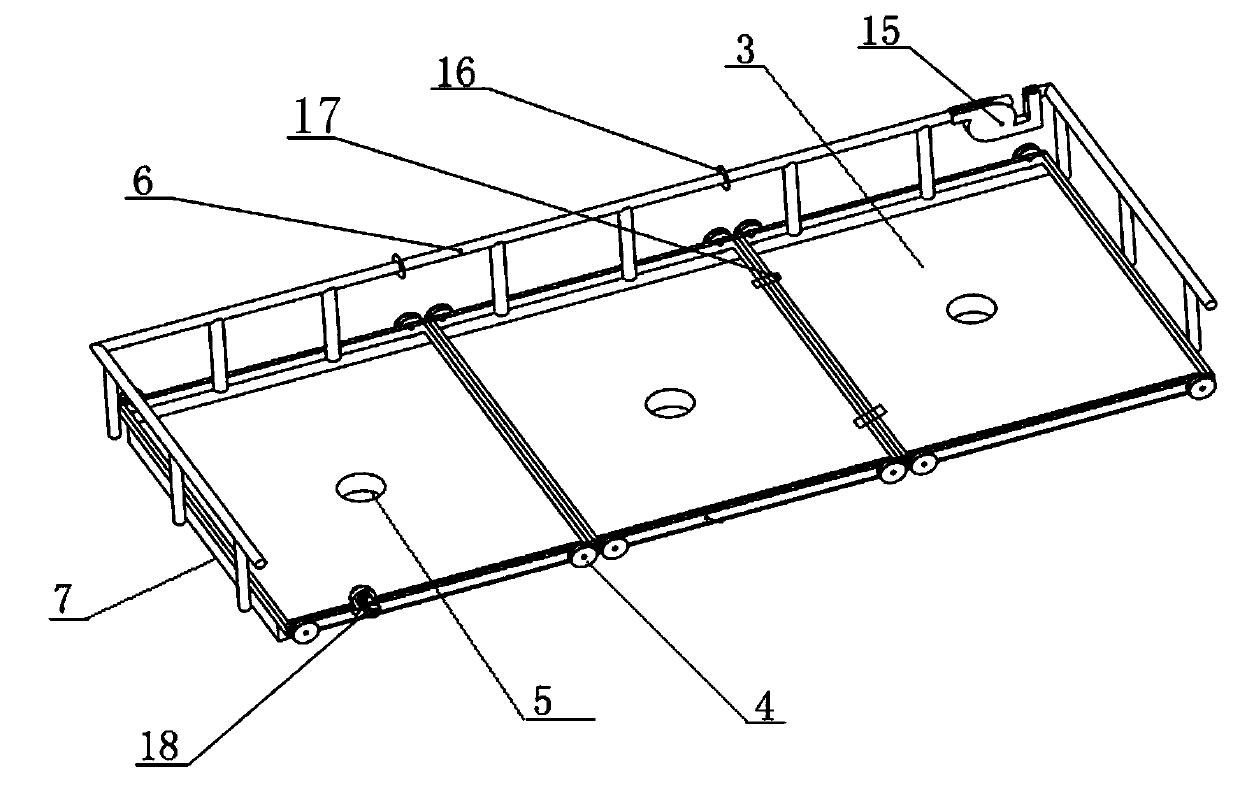

Annular kiln with movable flat top

InactiveCN103499213AIncrease productionFlexible splicing and lengtheningFurnace crowns/roofsWaste heat treatmentBrickLap joint

The invention discloses an annular kiln with a movable flat top. The annular kiln with the movable flat top comprises a kiln body, a kiln crown and kiln walls arranged on the two sides. Compared with the prior art, the annular kiln with the movable flat top is characterized in that the kiln crown is the movable flat top, wherein the movable flat top is formed by detachably connecting a plurality of steel structural frames which are in lap joint with one another; each steel structural frame is provided with idler wheels, wherein the idler wheels are matched with tracks arranged at the upper ends of the kiln walls; the lower end face of the movable kiln crown is provided with an insulating layer; a hot gas recycling pipeline is arranged on the kiln crown. The annular kiln with the movable flat top has the advantages of saving money, and being convenient to place, high in degree of mechanization, capable of lowering labor intensity for workers and improving work efficiency, good in heat preservation effect when green bricks are fired, high in rate of finished products, rapid in cooling speed, easy to cool for brick taking, convenient to maintain, and particularly suitable for overall transformation of an existing old kiln.

Owner:黄五三 +3

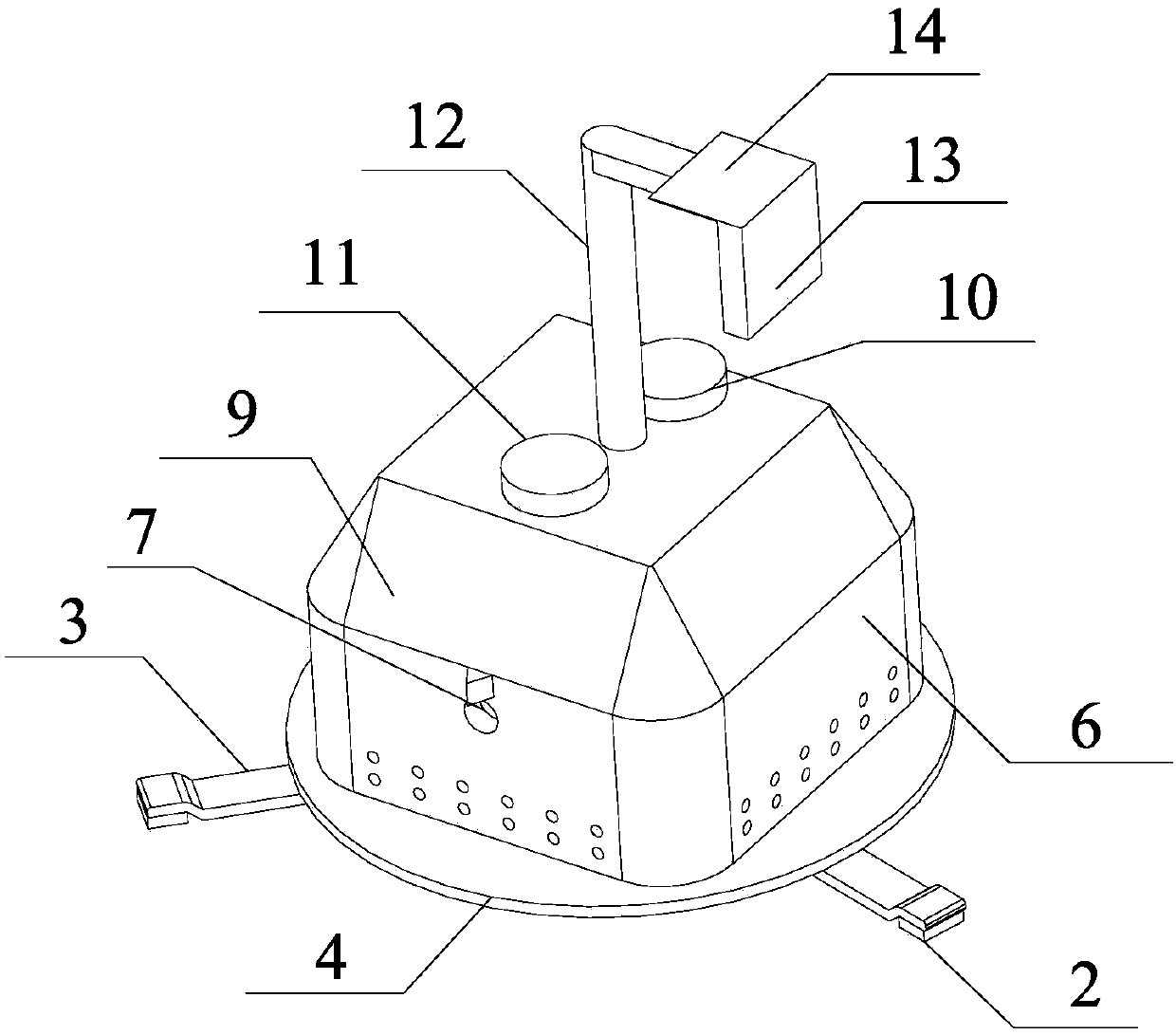

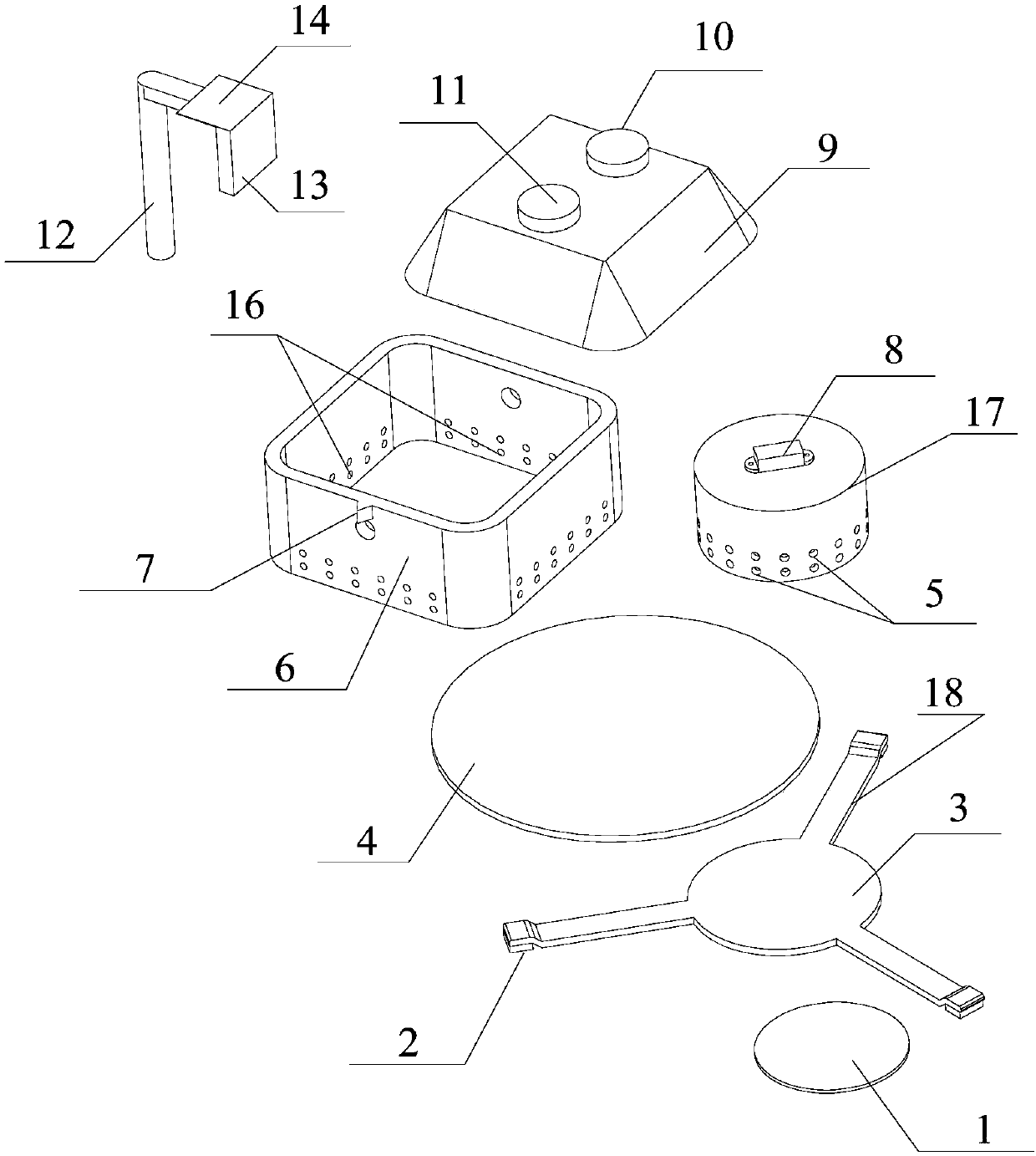

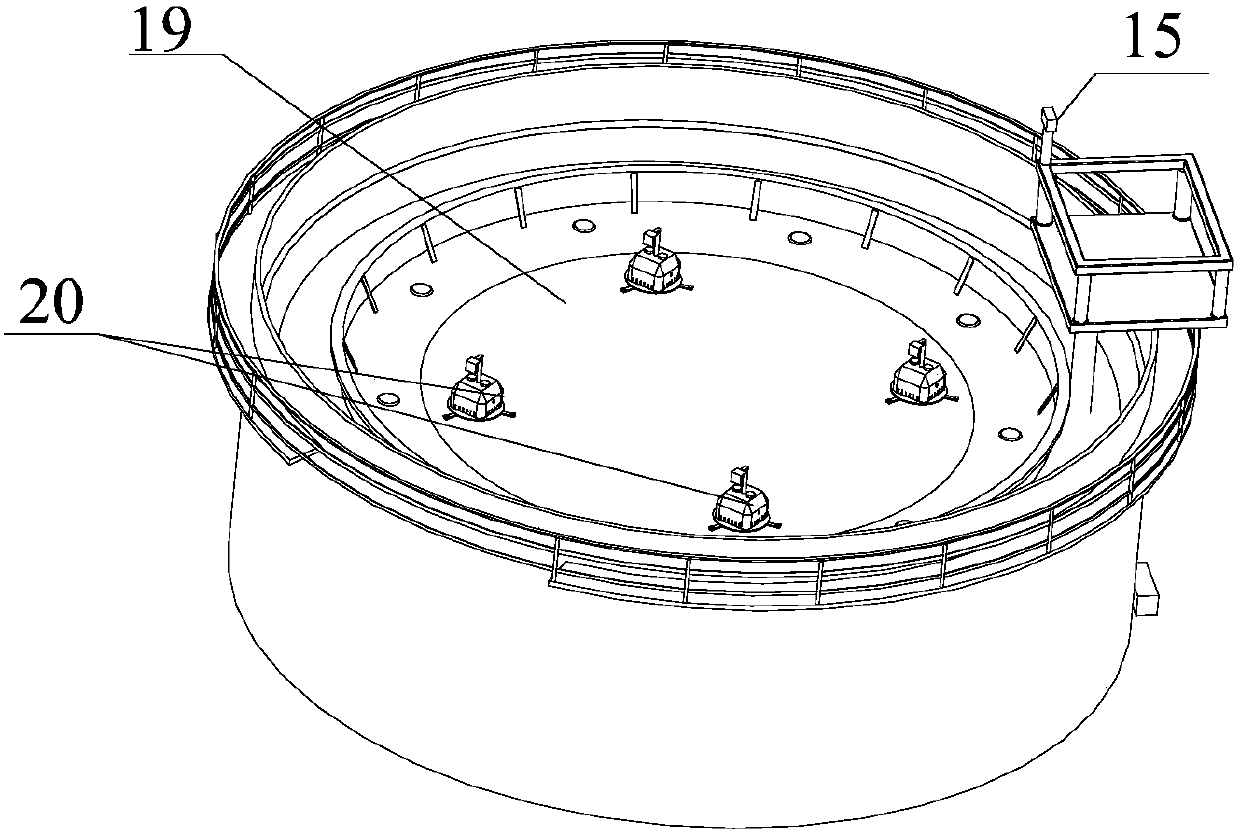

Monitoring device for outer floating roof storage tank floating tray state and outer floating roof storage tank floating tray

InactiveCN110274623AImprove securityEasy to installBatteries circuit arrangementsMeasurement devicesGratingElectrical battery

The invention discloses a monitoring device for an outer floating roof storage tank floating tray state and an outer floating roof storage tank floating tray. A tank is arranged on a base. The outer circumference of the tank is uniformly provided with multiple through holes. A direction indicator is arranged on one side of the tank. A fixed cylinder is arranged in the tank. The outer circumference of the fixed cylinder is uniformly provided with multiple optical fiber liquid level sensors. An optical fiber temperature sensor is arranged on the upper end of the fixed cylinder. A dome-shaped top cover is arranged on the tank. An optical fiber vibration sensor and an optical inclination angle sensor are arranged on the dome-shaped top cover. A fixed rod is arranged on the dome-shaped top cover between the optical fiber vibration sensor and the optical inclination angle sensor. A wireless communication module and a solar cell are arranged on the fixed rod. The adopted liquid level, temperature, inclination angle and vibration sensors are based on fiber optical grating sensing technology, are passive components, realize anti-electromagnetic interference and have high safety performance. The liquid level sensors adopt a strain beam floating drum structure and facilitate the flow of liquid into liquid level sensor floating drum for liquid level monitoring.

Owner:CHINA PETROLEUM & CHEM CORP +1

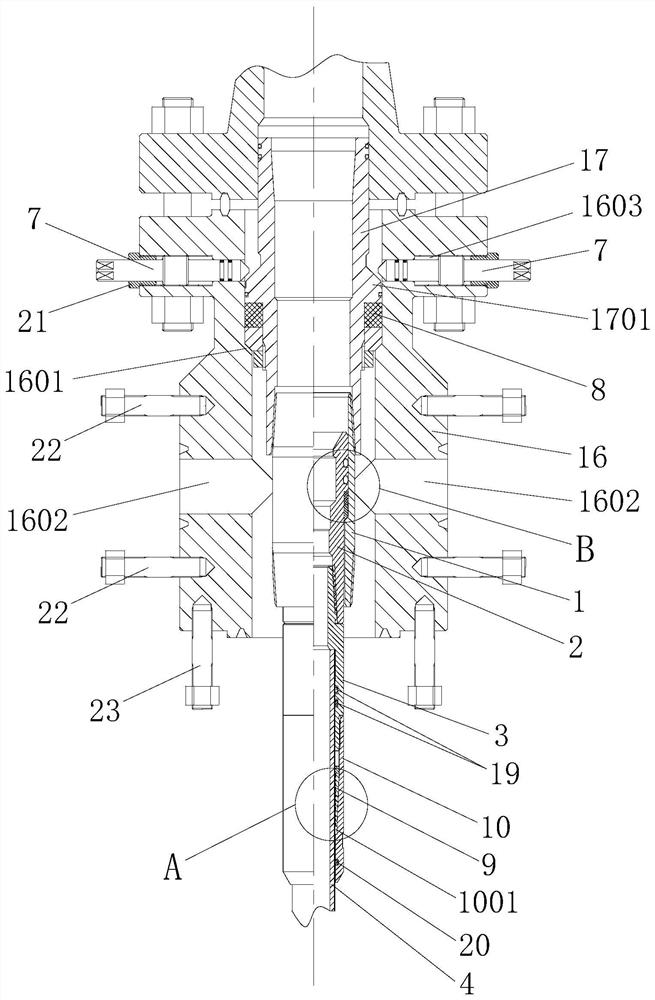

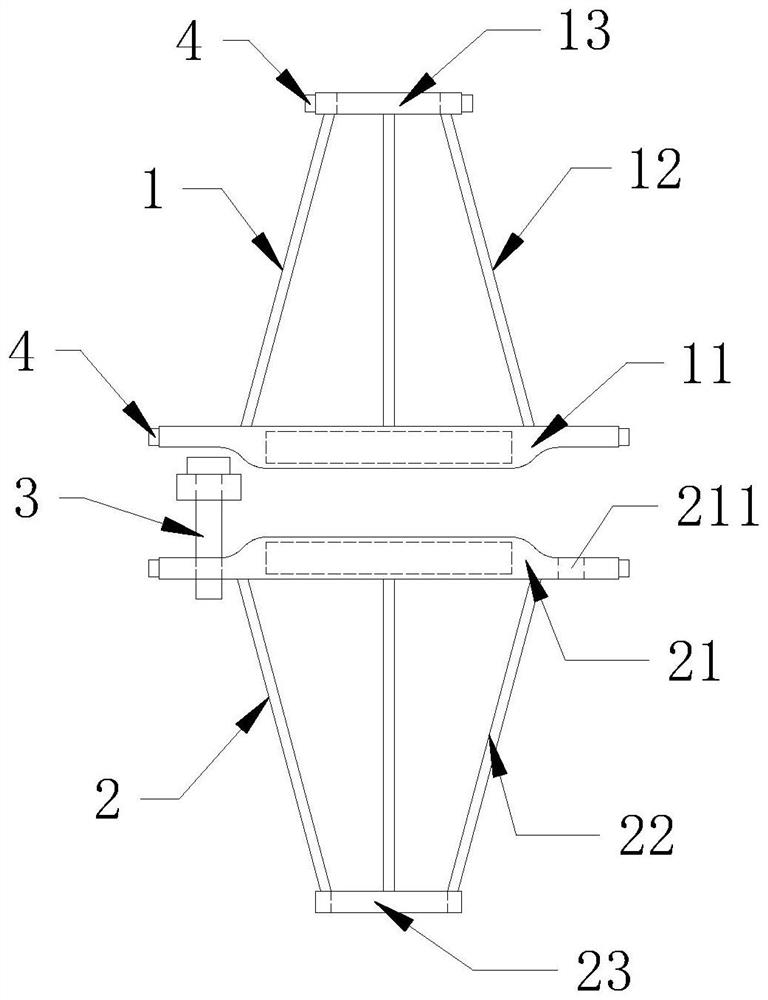

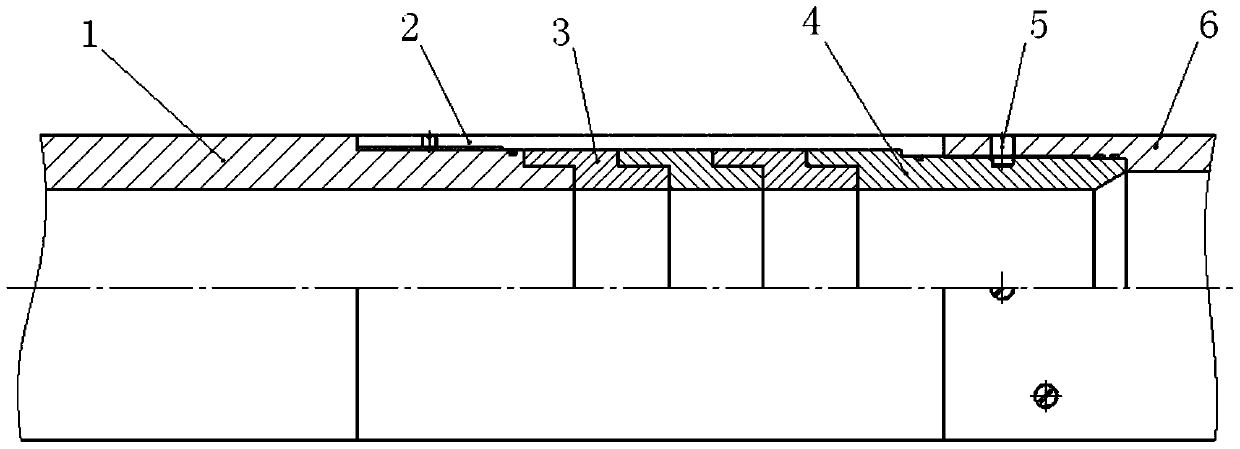

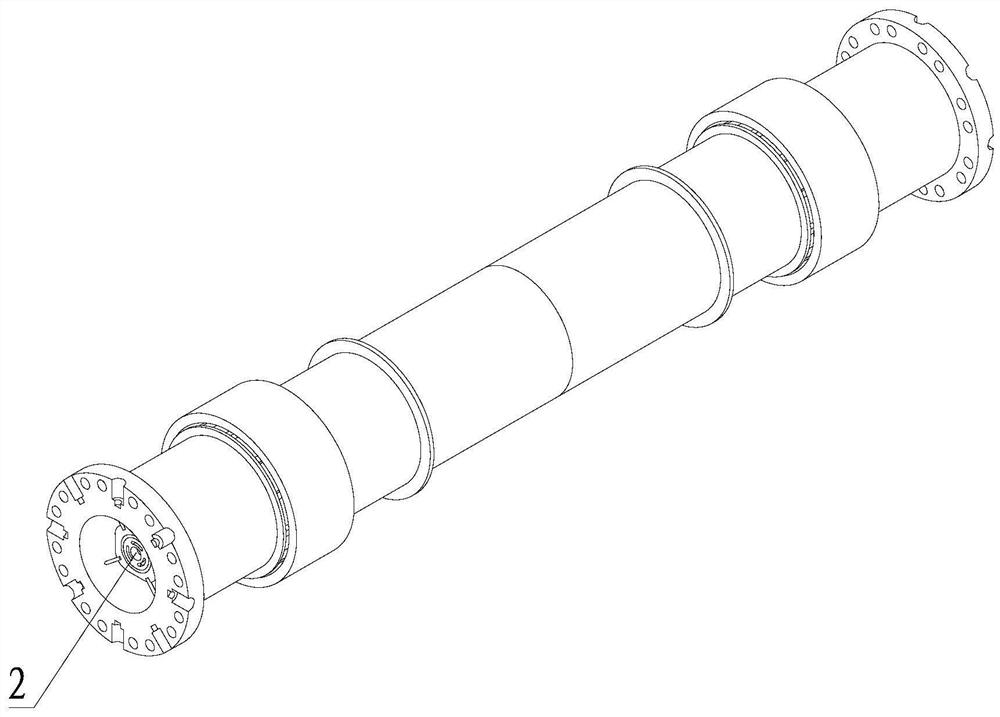

Coiled tubing suspension device, coiled tubing wellhead mandrel type suspension structure and method

The invention relates to a coiled tubing suspension device and a coiled tubing wellhead mandrel type suspension structure and method. The coiled tubing suspension device comprises a tubing head, a tubing hanger, a heavy load connector and a lower connector, wherein the tubing hanger is arranged in the tubing head, the tubing hanger, the heavy load connector and the lower connector are sequentially arranged from top to bottom, an adapter pup joint is connected between the bottom of the tubing hanger and the top of the heavy load connector or a suspension pup joint and a setting pup joint are sequentially connected from top to bottom, the bottom of the heavy load connector is connected with the top of the lower connector, the heavy load connector and the lower connector both sleeve the outer side of the top of a coiled tubing, and a locking ring is arranged between the lower connector and the coiled tubing; the outer wall of the locking ring is slidably connected with the inner wall of the lower connector, and the inner wall of the locking ring abuts against the outer wall of the coiled tubing. According to the coiled tubing suspension device, the technical problems that a suspension device for suspending the gas well coiled tubing is complex in structure, wellhead operation is inconvenient, and the matching cost is high are solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +3

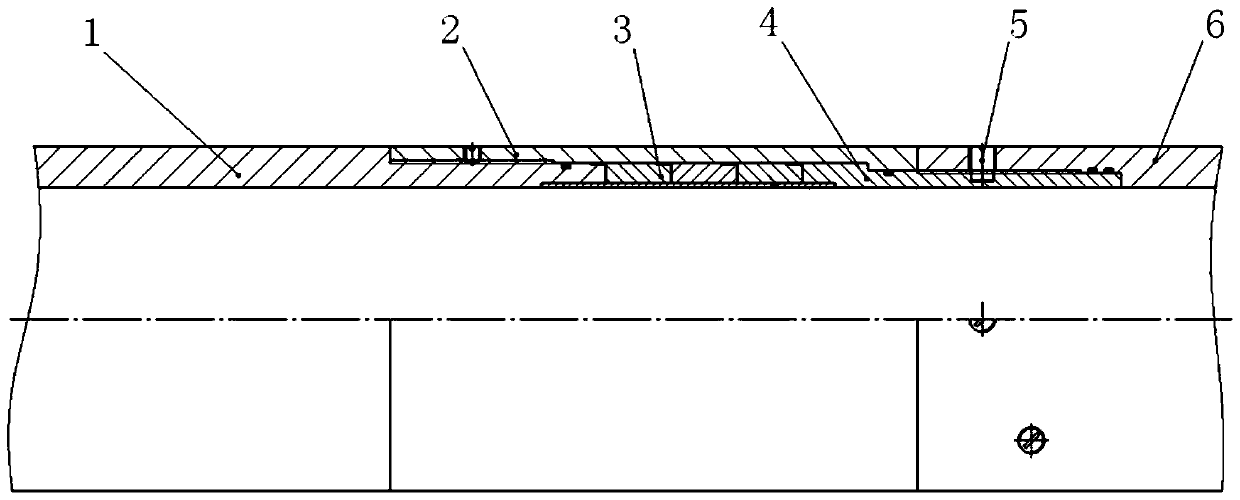

Method for mounting cable bridge on gas pipeline

InactiveCN102506232AChange the installation methodLess construction requirementsPipe supportsCable trayEconomic benefits

The invention discloses a method for mounting a cable bridge on a gas pipeline. A bridge fixing device and sectional bridges are made on the ground; grounding main lines are preset on the sectional bridges and a single bridge; and the structure of the bridge fixing device meets the requirement that the bridge fixing device can be fixed to an accessory of the pipeline through a bolt, and the requirement that the bridge can be spliced through bolts. The method has the advantages that: the constructional requirement is low; welding and flame operation in dangerous regions can be avoided; the cable bridge can be safely and conveniently constructed; the engineering cost is low; and the economic benefit is high.

Owner:TIANJIN 20 CONSTR

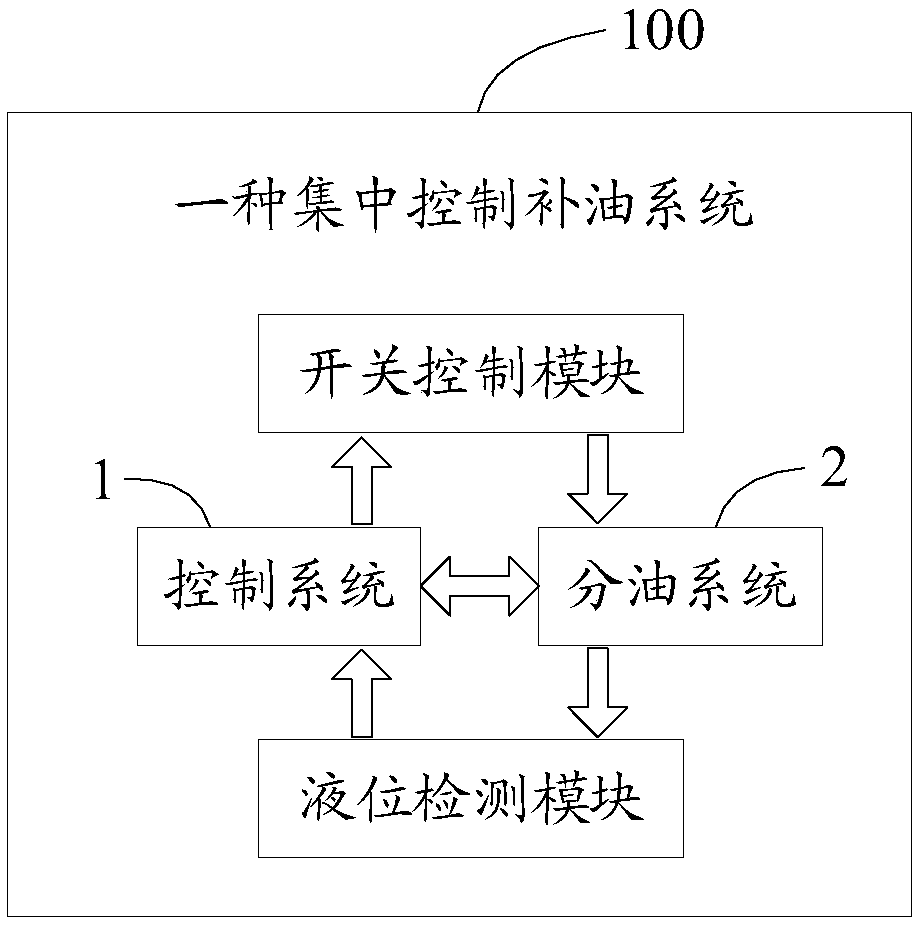

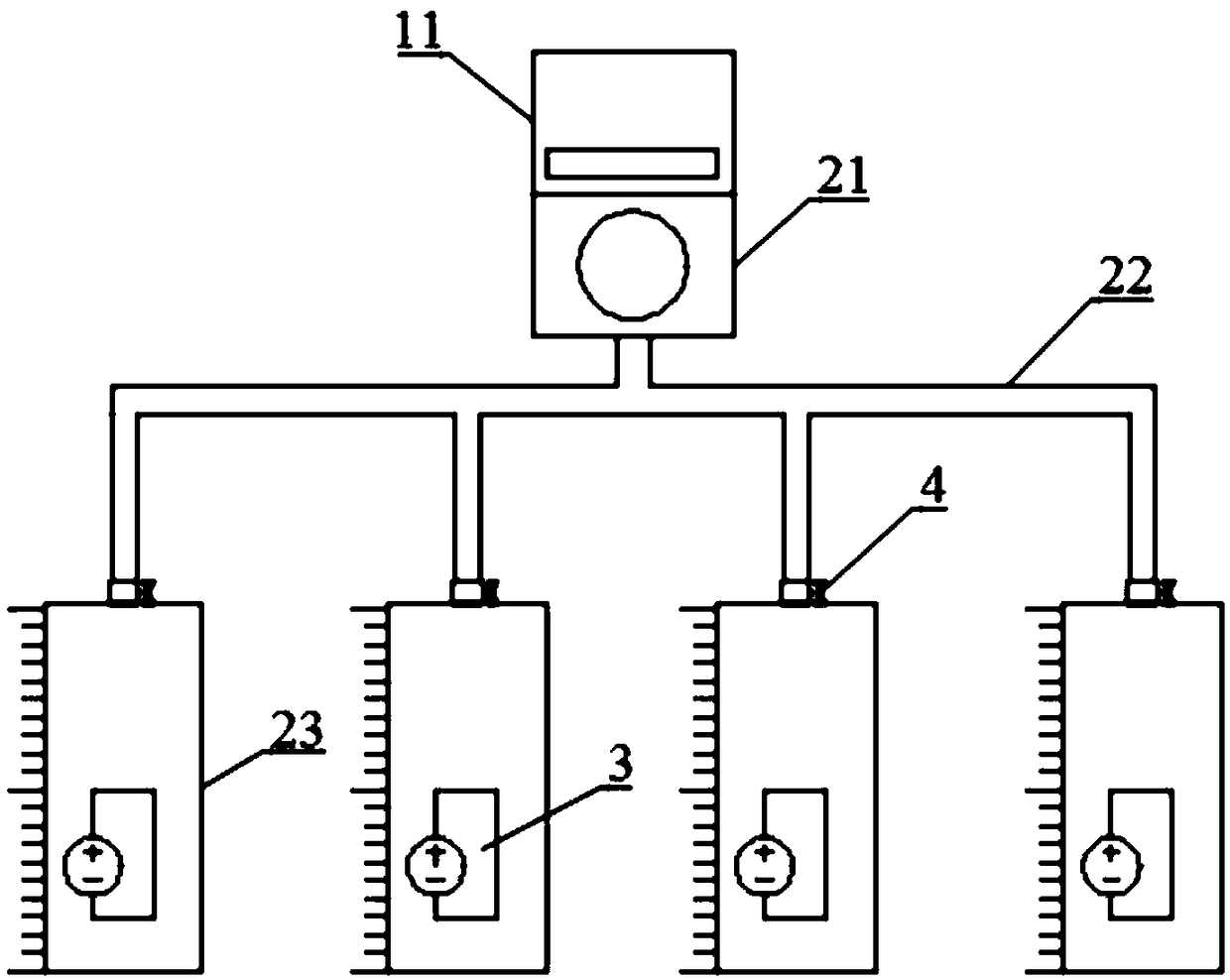

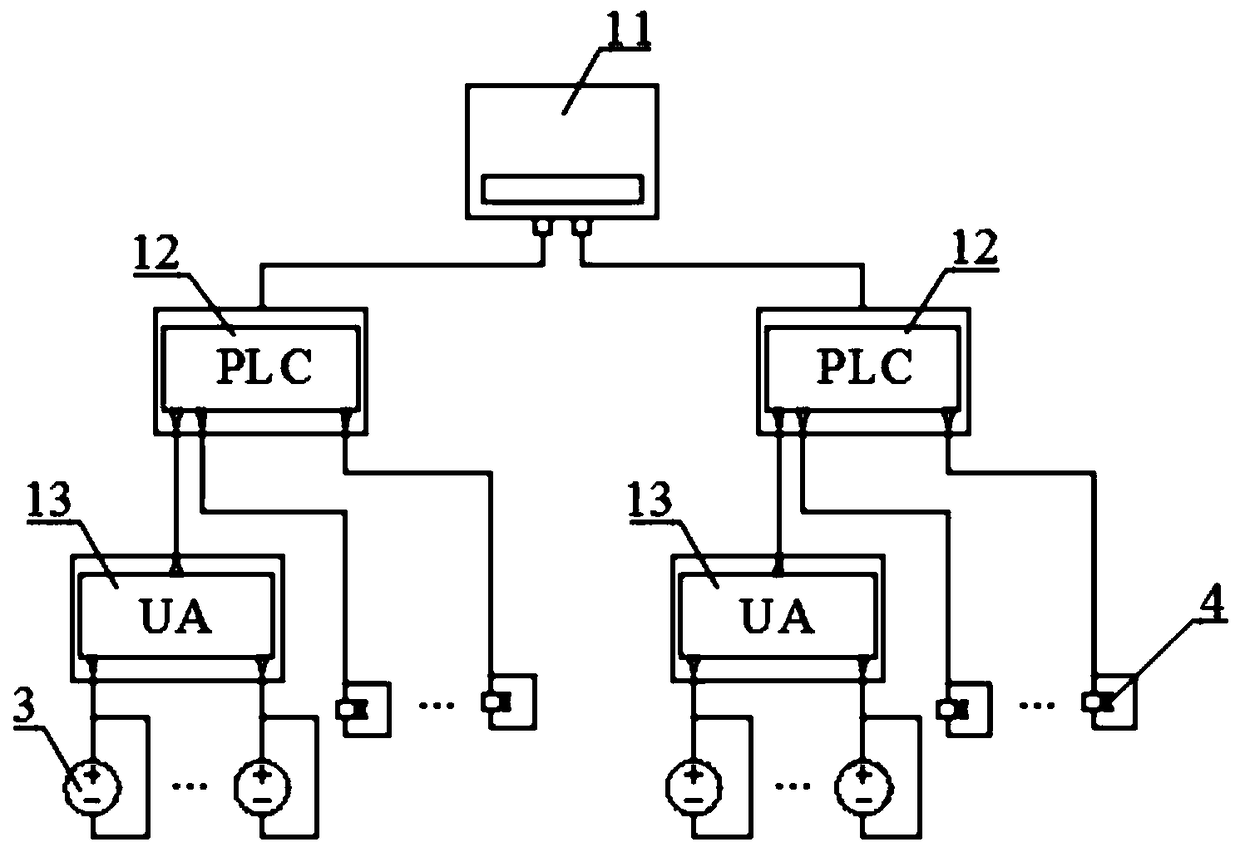

Centralized control oil replenishment system and decentralized oil replenishment method

The invention discloses a centralized control oil replenishment system and a decentralized oil replenishment method. The centralized control oil replenishment system includes a control system, an oildistribution system, liquid level detection modules and on / off control modules. The oil distribution system comprises a main oil tank, an oil pipeline and at least two sub oil tanks. The control system is connected with the liquid level detection modules and the on / off control modules. The main oil tank is connected with the sub oil tanks through the oil pipeline. The on / off control modules are arranged in the oil pipeline. The liquid level detection modules are arranged in the sub oil tanks. The on / off control modules and the liquid level detection modules are in one-to-one correspondence with the sub oil tanks. The liquid level detection modules detect the oil level signals in the sub oil tanks, the control system obtains oil replenishment signals according to the oil level signals, theon / off control modules carry out opening / closing according to the oil replenishment signals, so that timely and accurate automatic oil replenishment is realized. Through automatic oil replenishment, the safety of employees is ensured, the work efficiency is improved, and oil waste caused by over-replenishment and production stoppage caused by under-replenishment are avoided.

Owner:FUJIAN JINGFENG TECH

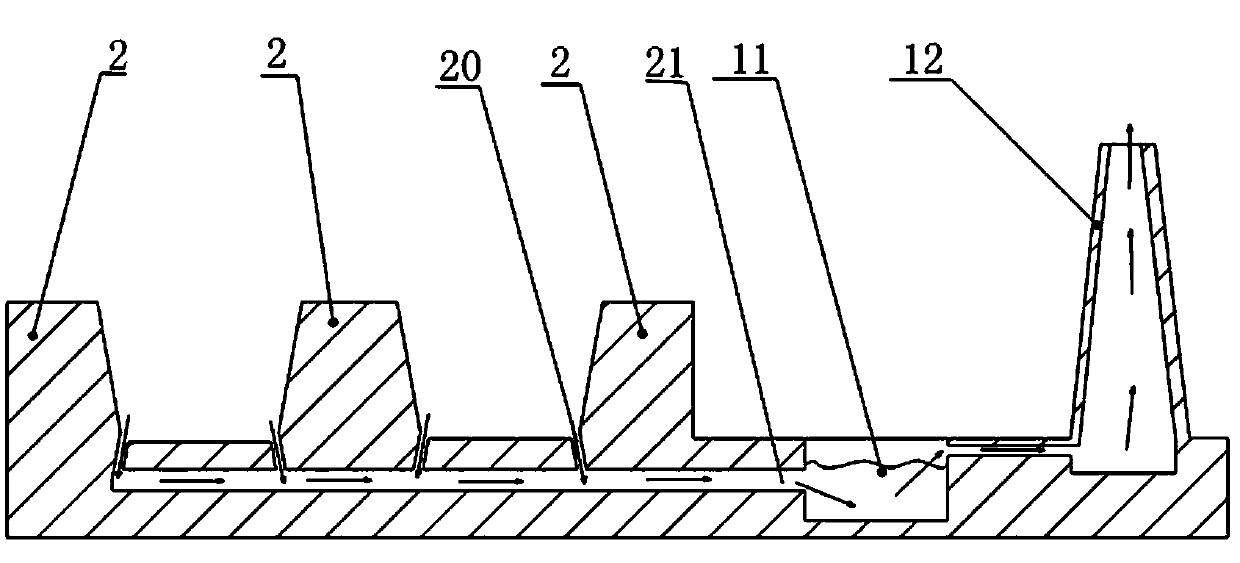

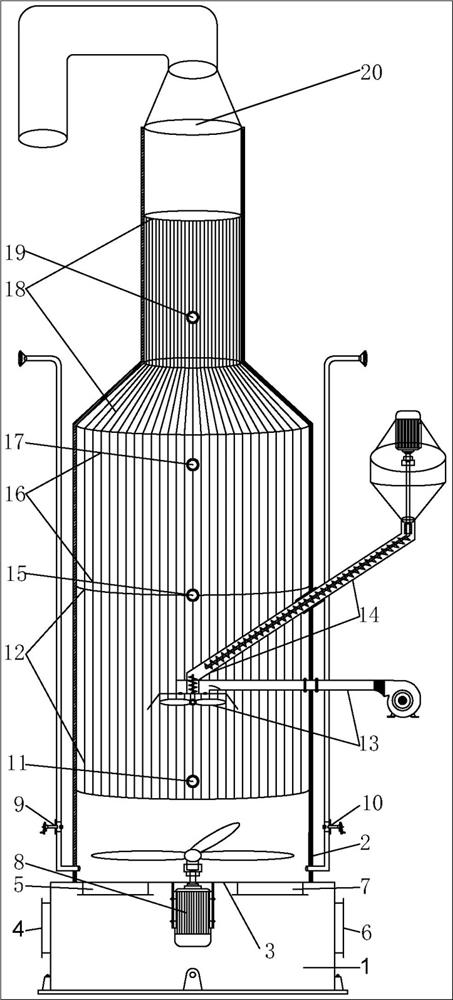

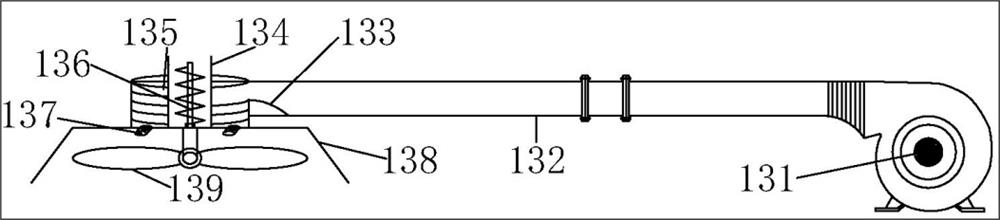

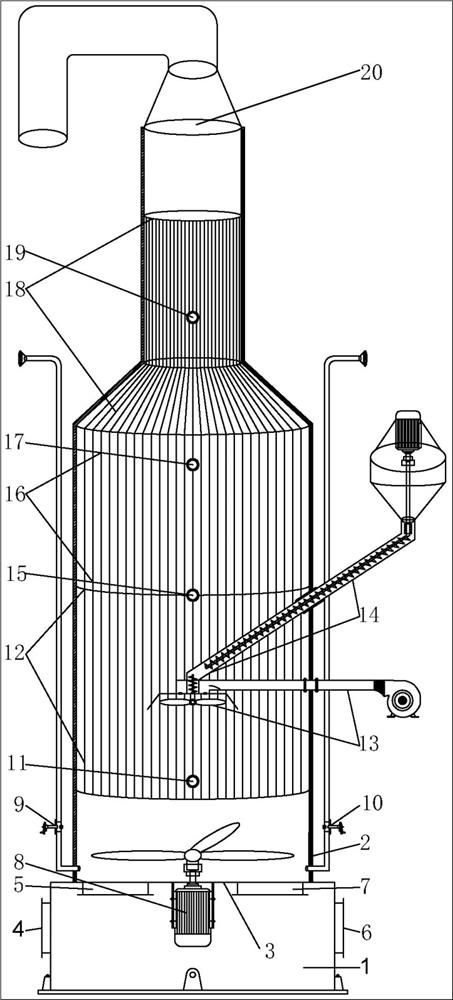

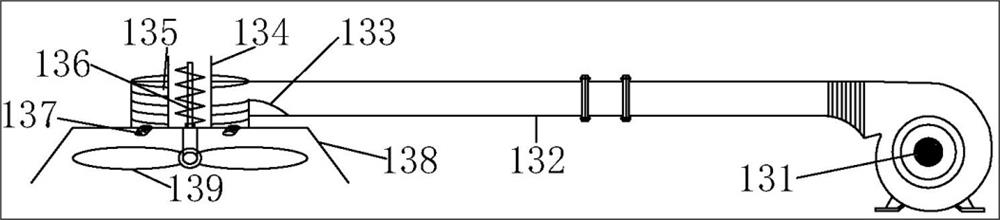

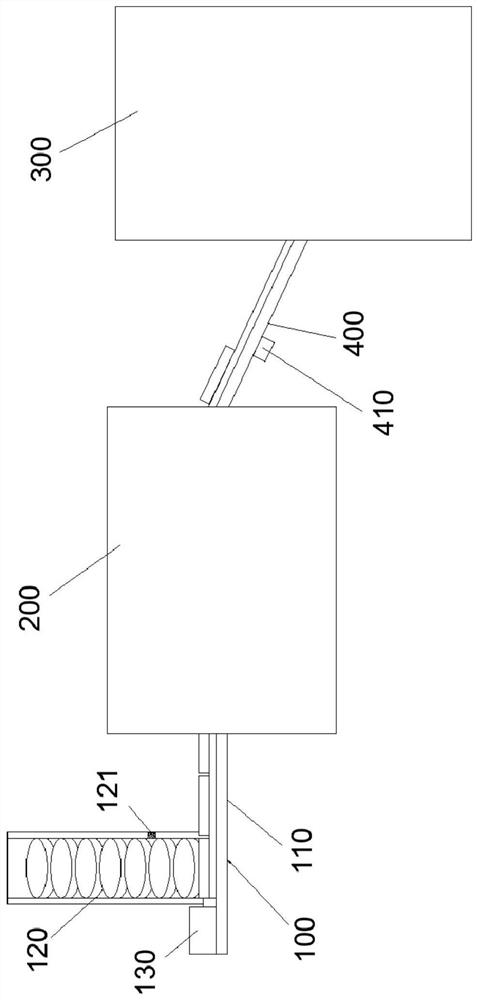

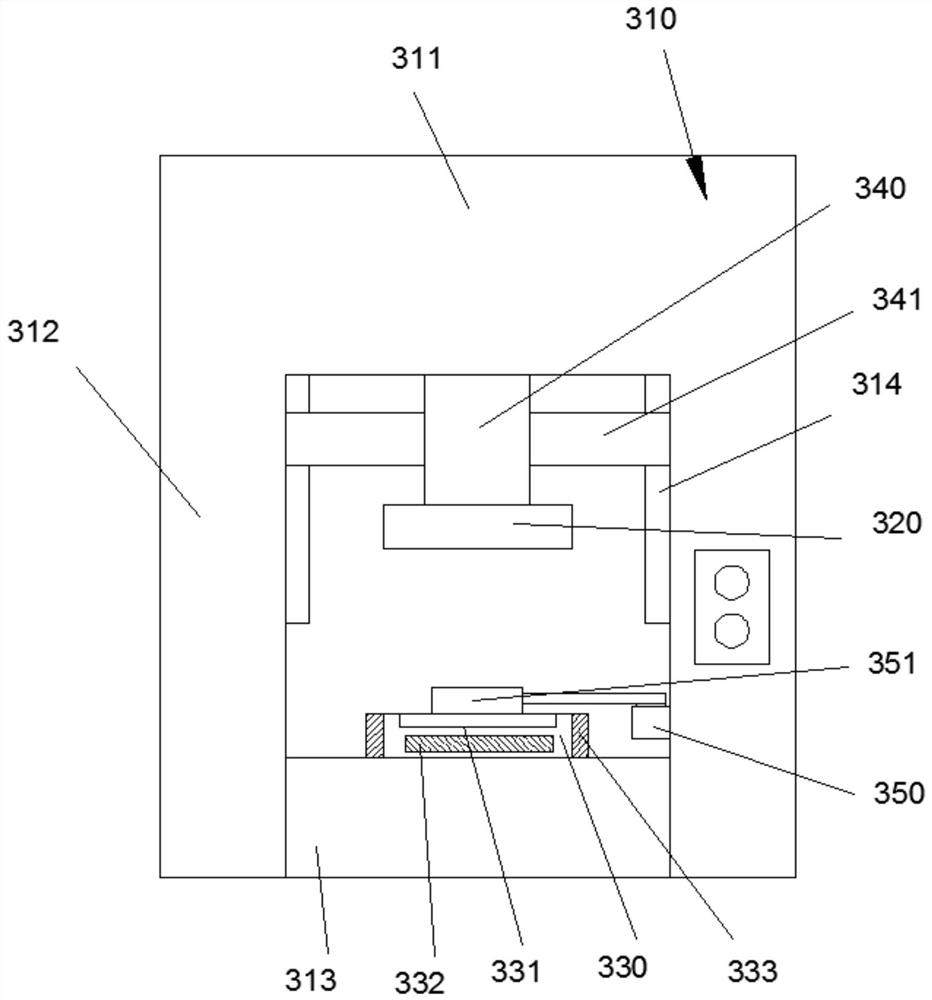

Sectional electric heating thermal oven for drying polyacrylamide and using method

ActiveCN113432409AIncrease profitEffective temperature controlDrying gas arrangementsDrying chambers/containersEngineeringFan blade

The invention relates to a sectional electric heating thermal oven for drying polyacrylamide and a using method, and relates to the technical field of chemical equipment. An oven base and an oven body are connected through an oven bottom plate, and heating pipes are arranged in a first-section heating area, a second-section heating area and a third-section heating area and installed in the oven body from bottom to top; the heating pipe in each section of heating area is controlled by a first-section detection piece, a second-section detection piece and a third-section detection piece respectively in a linkage manner; a feeding auger device is mounted on one side of the oven body; an external fan separator is horizontally installed on one side of the oven body through a flange and a gasket, the external fan separator is located below the feeding auger device, a main stirring fan is erected outside the oven body, the output end of the main stirring fan is rotationally connected with blowing fan blades, and the blowing fan blades are located in the oven body and located under the external fan separator. The sectional electric heating thermal oven for drying polyacrylamide has the advantages that sectional heating is conducted, the temperature of the tempering stage before materials are discharged from the oven can be effectively controlled, and thus the material drying effect is better.

Owner:山东蓝湾新材料有限公司

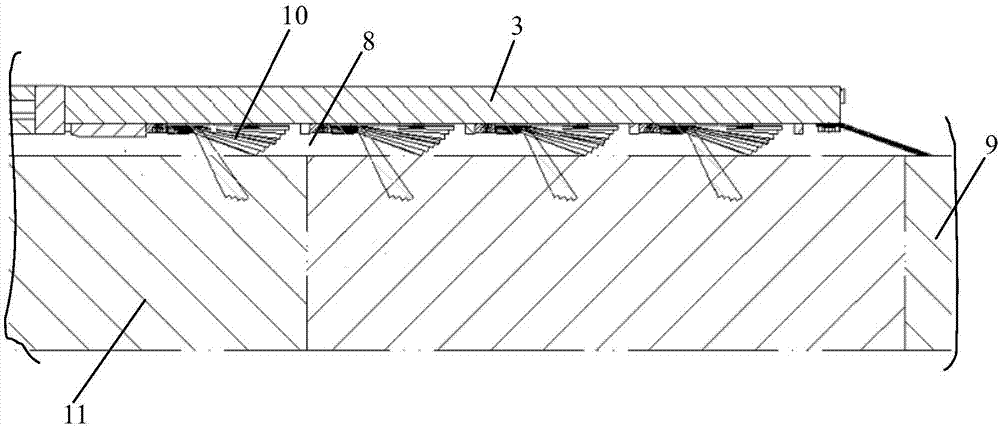

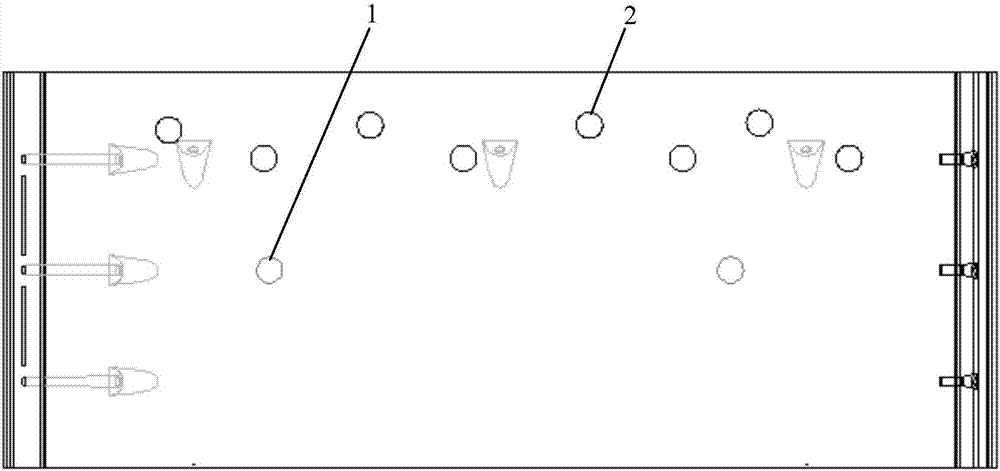

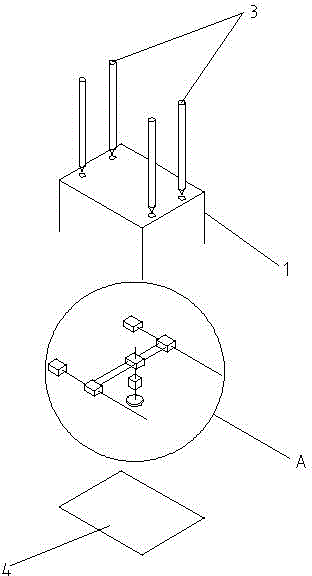

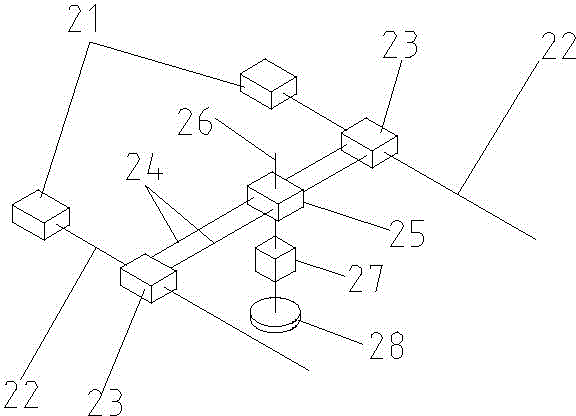

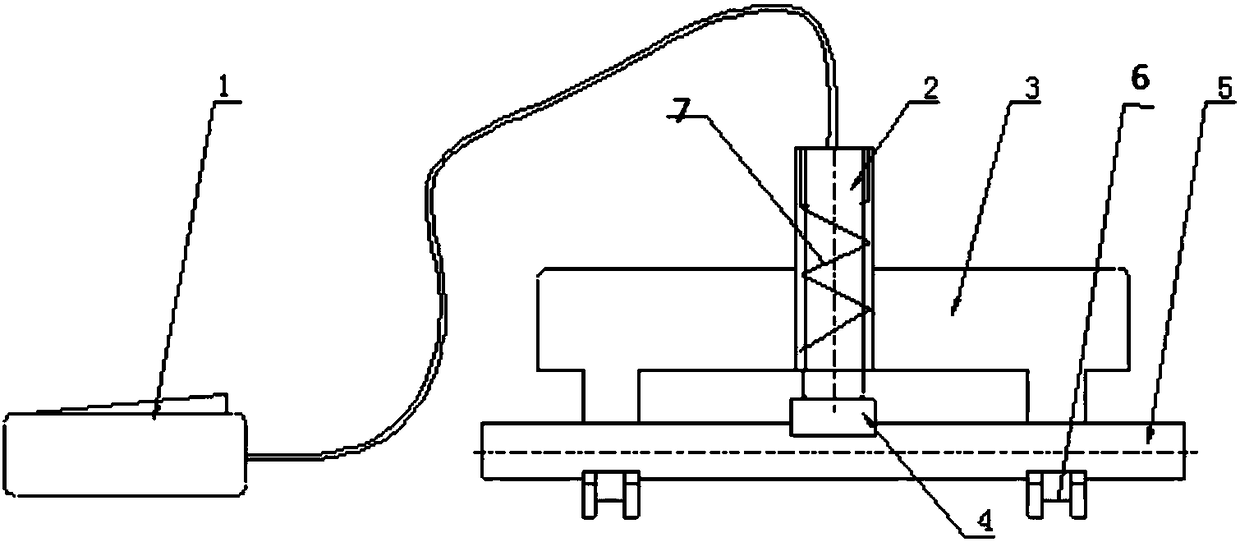

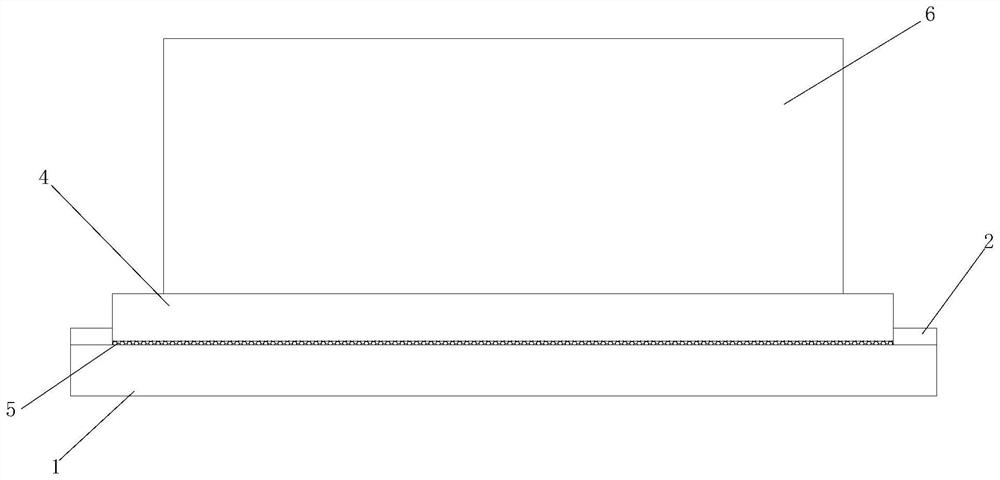

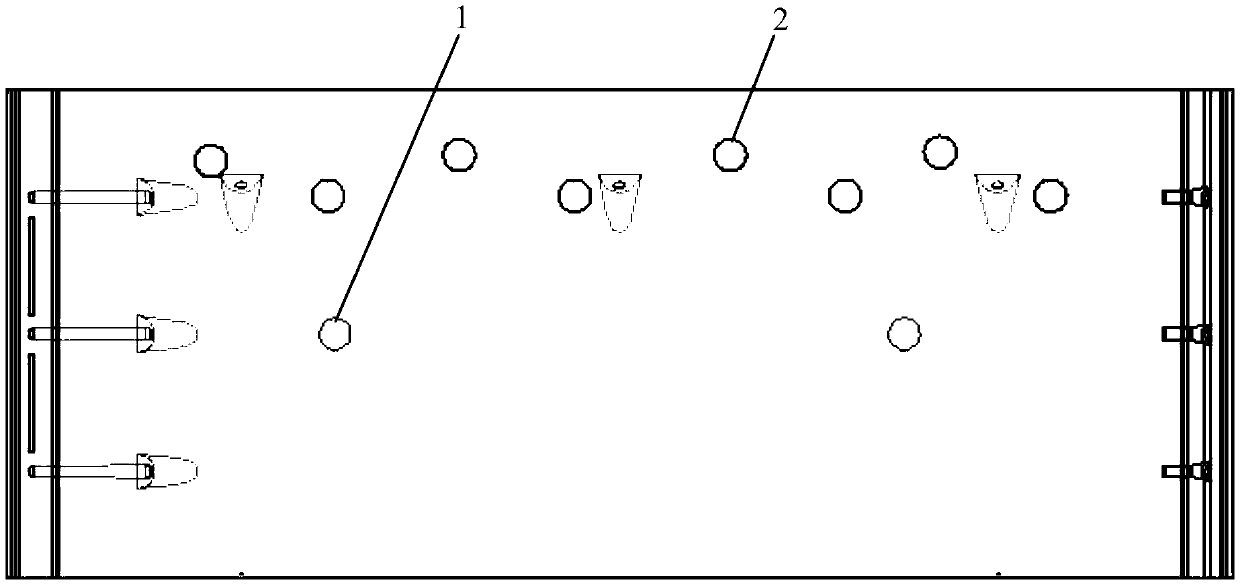

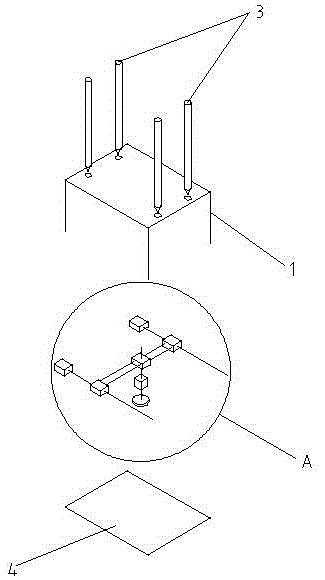

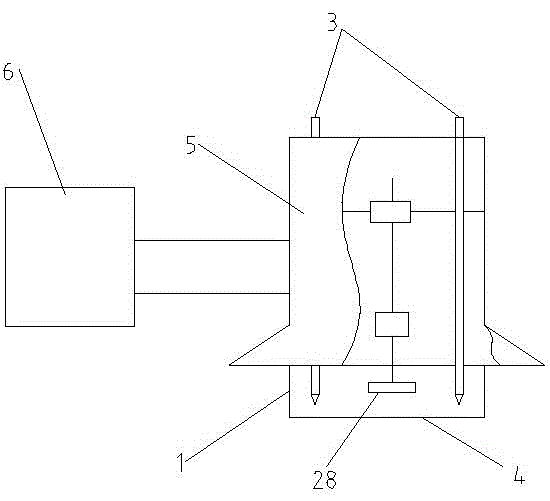

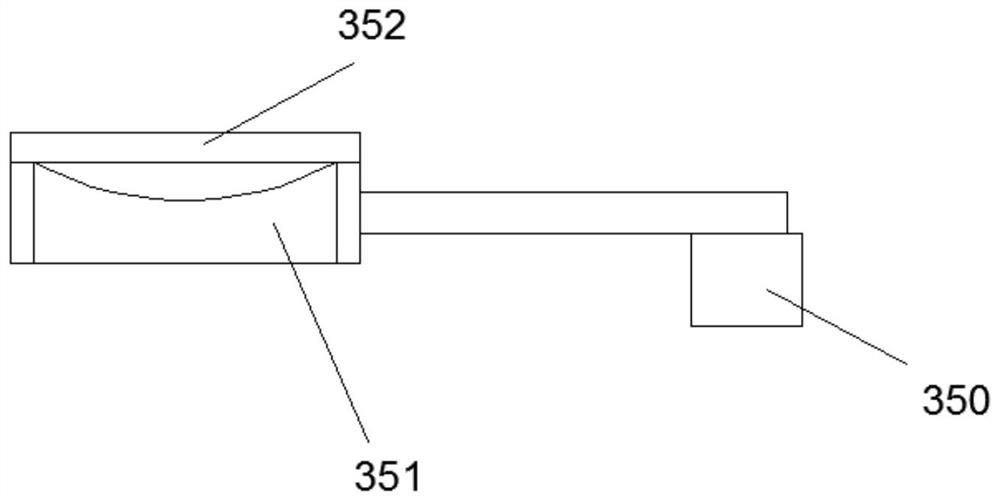

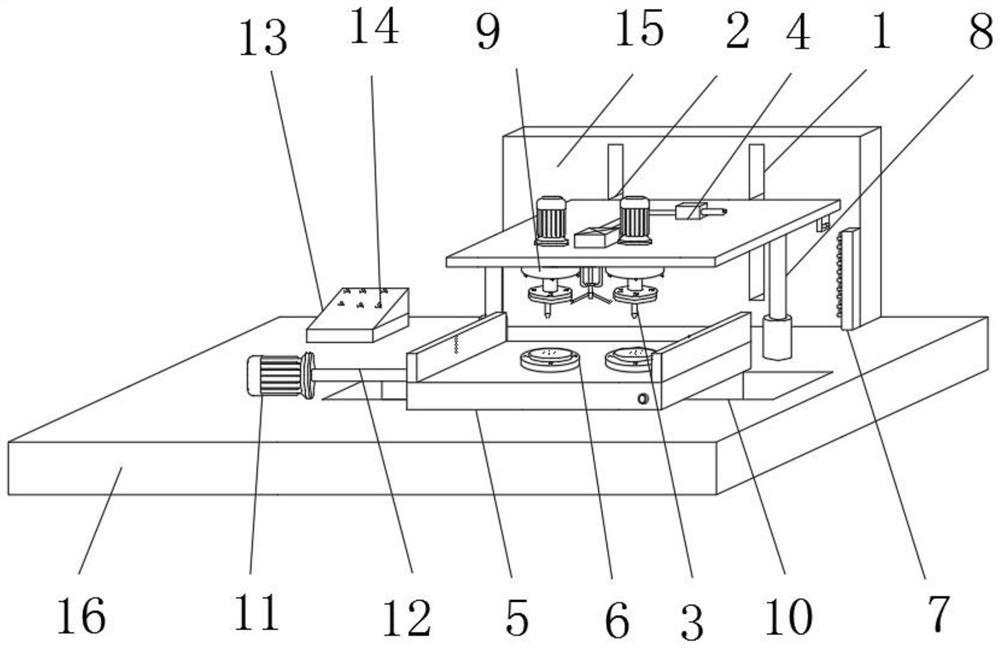

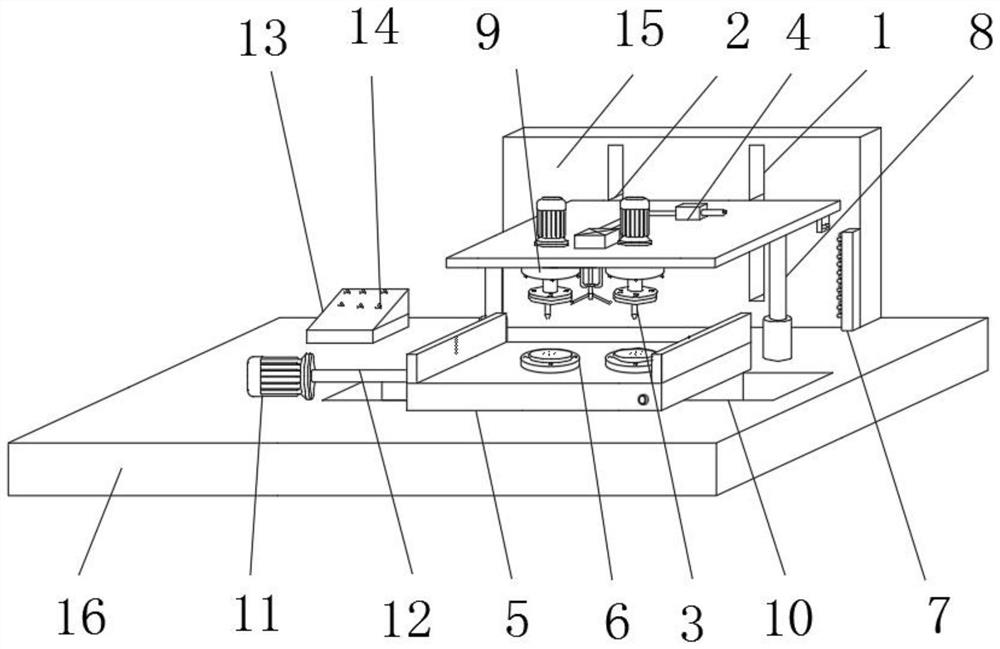

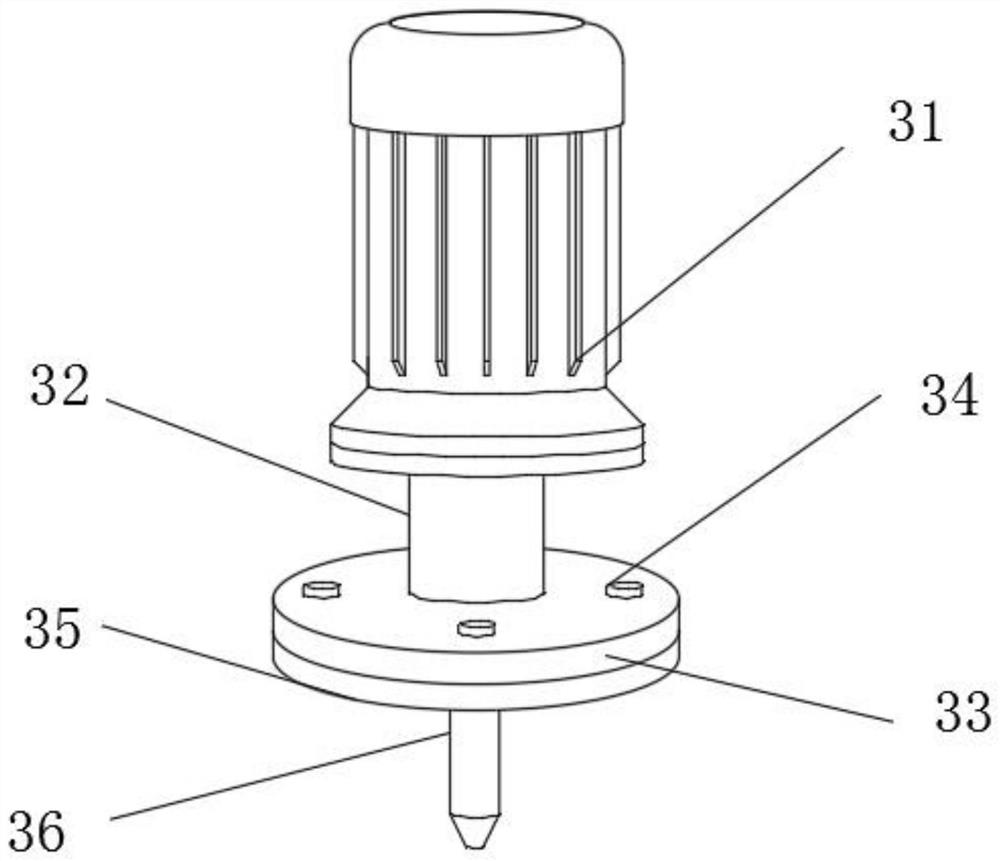

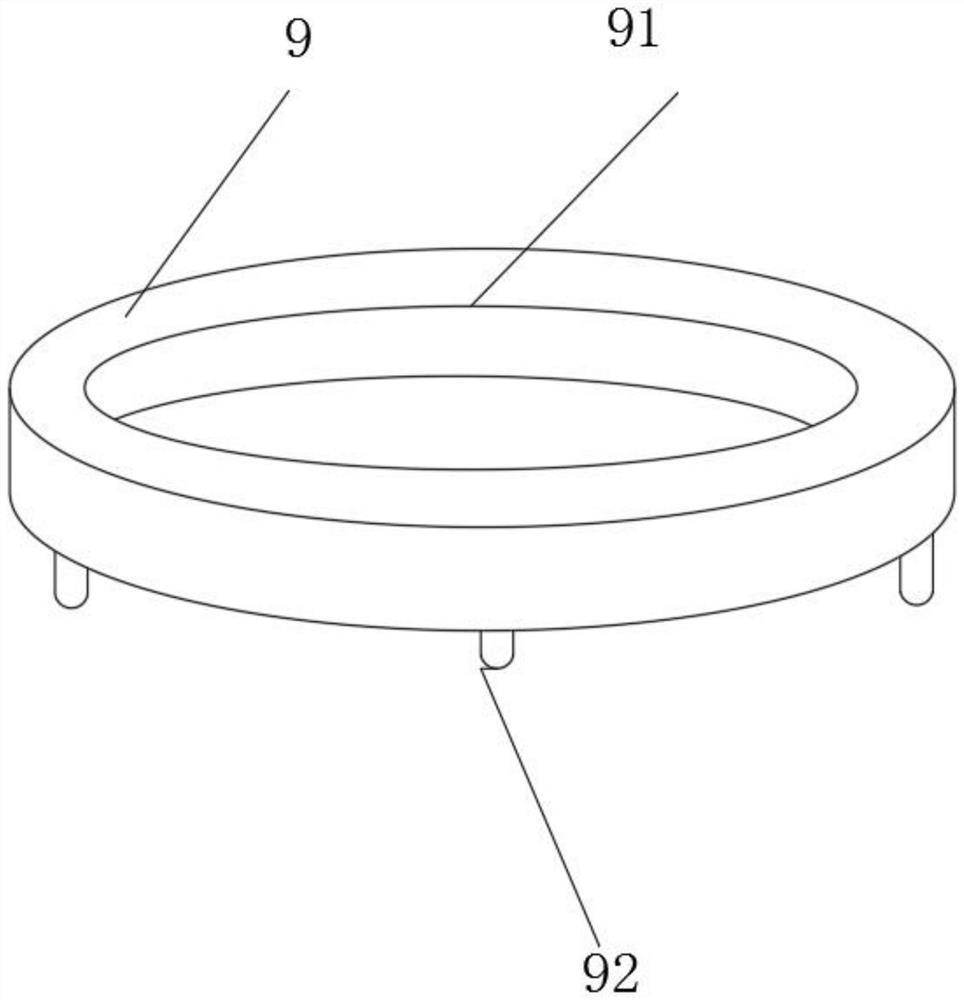

Repairing device for solar battery assembly

InactiveCN104465880AAvoid hot workImprove work efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSolar battery

The invention discloses a solar battery assembly device and belongs to the technical field of solar battery assemblies. The repairing device comprises a support, a base and a control device. The support is provided with an X-direction mobile mechanism, the X-direction mobile mechanism is provided with a Y-direction mobile mechanism, and the moving direction of the X-direction mobile mechanism and the moving direction of the Y-direction mobile mechanism are perpendicular to each other and parallel to the ground. The Y-direction mobile mechanism is provided with a Z-direction mobile mechanism, the moving direction of the Z-direction mobile mechanism is perpendicular to the ground, and the Z-direction mobile mechanism is provided with a rubber grinding head driven by a motor. The X-direction mobile mechanism, the Y-direction mobile mechanism, the Z-direction mobile mechanism and the rubber grinding head are all controlled by the control device to move. The support is further provided with an assembly fixing device. According to the repairing device, a traditional manual work mode is changed, the health of workers is guaranteed, the repairing quality and efficiency of the assembly are improved, and therefore the repairing device is quite practical.

Owner:HENGSHUI YINGLI NEW ENERGY

Pipe cold straightening device

The invention discloses a pipe cold straightening device. The pipe cold straightening device comprises a treadle-type air-driven hydraulic pump, a single-acting hydraulic cylinder, a pipe cold straightening base, an upper pressing block, a steel pipe and hooks. The hooks are arranged at the positions, close to the two ends, of the lower side of the pipe cold straightening base separately. The steel pipe is hung on the hooks. The single-acting hydraulic cylinder is fixed to the middle part of the pipe cold straightening base. A piston rod of the single-acting hydraulic cylinder penetrates out of the lower side of the pipe cold straightening base. The upper pressing block is fixed to the tail end of the piston rod and used for pressing a deformation area of the steel pipe. The single-actinghydraulic cylinder is connected to the treadle-type air-driven hydraulic pump through a pipeline in a sealed mode. The pipe cold straightening device is simple in structural design, portable, capableof being moved easily, suitable for correcting and straightening pipes of different pipe diameters, easy to operate, high in efficiency, capable of improving the work environment of workers, good in correcting and straightening quality and capable of relieving labor intensity of the workers.

Owner:住重福惠动力机械有限公司

Method of making building block using architectural garbage

InactiveCN100999100AAvoid pollutionSave raw materialsMixing operation control apparatusCeramic shaping apparatusMechanical propertyEnergy consumption

Owner:夏立成

A segmented electric heating oven for drying polyacrylamide and its use method

ActiveCN113432409BIncrease profitEffective temperature controlDrying gas arrangementsDrying chambers/containersEngineeringFan blade

The invention relates to a segmented electric heating oven for drying polyacrylamide and its use method, and relates to the technical field of chemical equipment. The furnace seat and the furnace body are connected by a furnace bottom plate, and the first-stage heating zone, the second-stage heating zone and the third-stage heating zone There are heating tubes inside and installed in the furnace body from bottom to top. The heating tubes in each section of the heating zone are respectively controlled by the linkage control of the first-stage detection part, the second-stage detection part and the third-stage detection part; the feeding auger device is installed in the furnace One side of the furnace body; the external fan separator is horizontally installed on one side of the furnace body through flanges and gaskets, the external fan separator is located under the feeding auger device, the main stirring fan is erected outside the furnace body, and the output end of the main stirring fan rotates The blowing fan blade is connected, and the blowing fan blade is located in the furnace body and directly below the external fan separator. The invention has segmental heating, which can effectively control the temperature of the slow-sum stage before the material is released from the furnace, so that the drying effect of the material is better. advantage.

Owner:山东蓝湾新材料有限公司

A method for binding planar small-size sputtering targets used in testing machines

ActiveCN110629171BAvoid hot workReduce labor intensityVacuum evaporation coatingSputtering coatingStructural engineeringSilicone Elastomers

The invention relates to a method for binding a plane small-size sputtering target used in a testing machine, comprising the following steps: Step 1: Pretreatment of the copper back plate and the target blank: respectively binding the copper back plate and the target blank Sandblasting; Step 2: Preparation of high-temperature adhesive: Stir the two-component silicone elastomer; Step 3: Binding treatment: Select the binding layer, and evenly coat the prepared high-temperature adhesive on the copper backplane and the target embryo Lay the binding layer on the copper backboard that has been coated with high-temperature glue; put the glue-coated side of the target blank down so that the target blank and the copper backplane are completely bonded; solidify the high-temperature glue, That is, the target binding operation is completed. The invention avoids the high-temperature operation of the binding process and reduces labor intensity; binding under low temperature conditions avoids the deformation of the copper back plate and meets the flatness requirements of the target material; the high-temperature glue failure temperature of the binding material is high, which meets the binding requirements of the target material on the high melting point Requirements for fixed layers; simple operation, high efficiency and low cost compared with ordinary binding technology.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

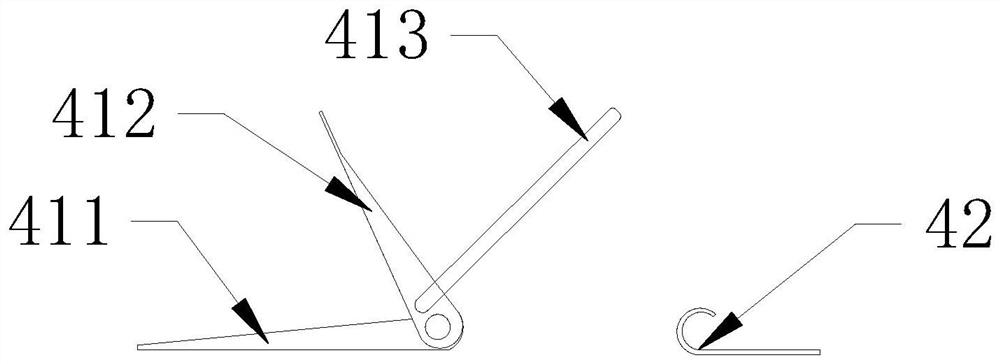

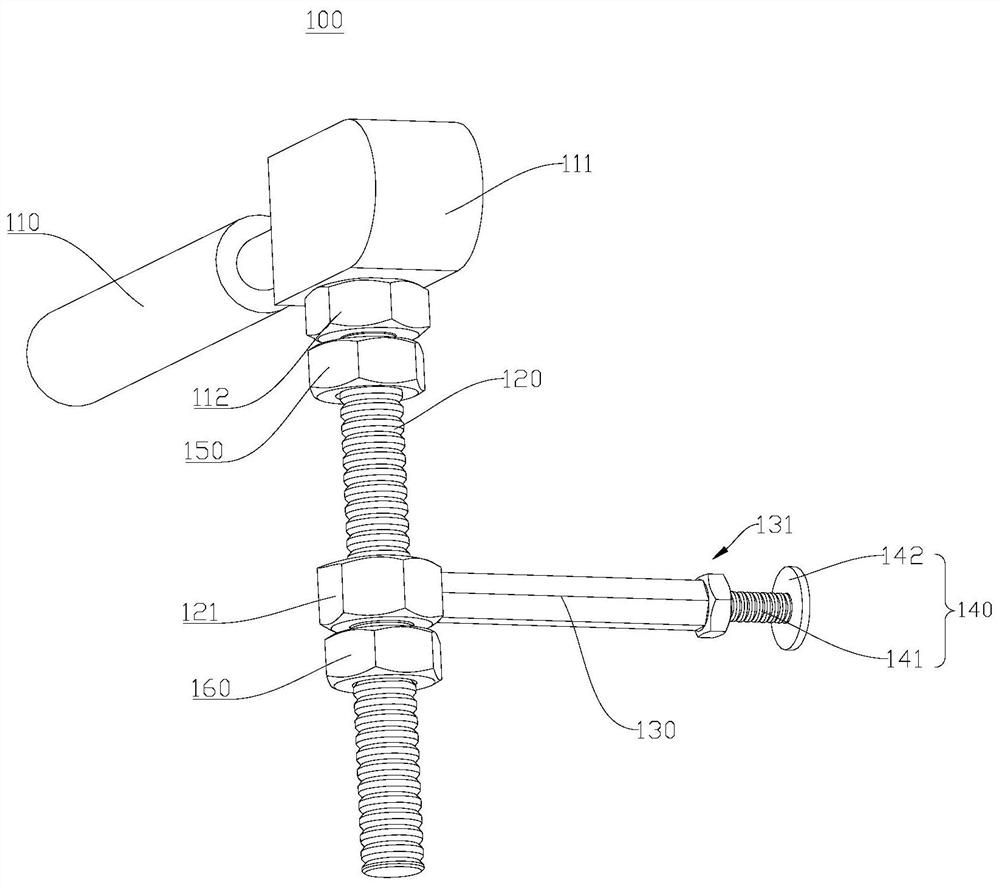

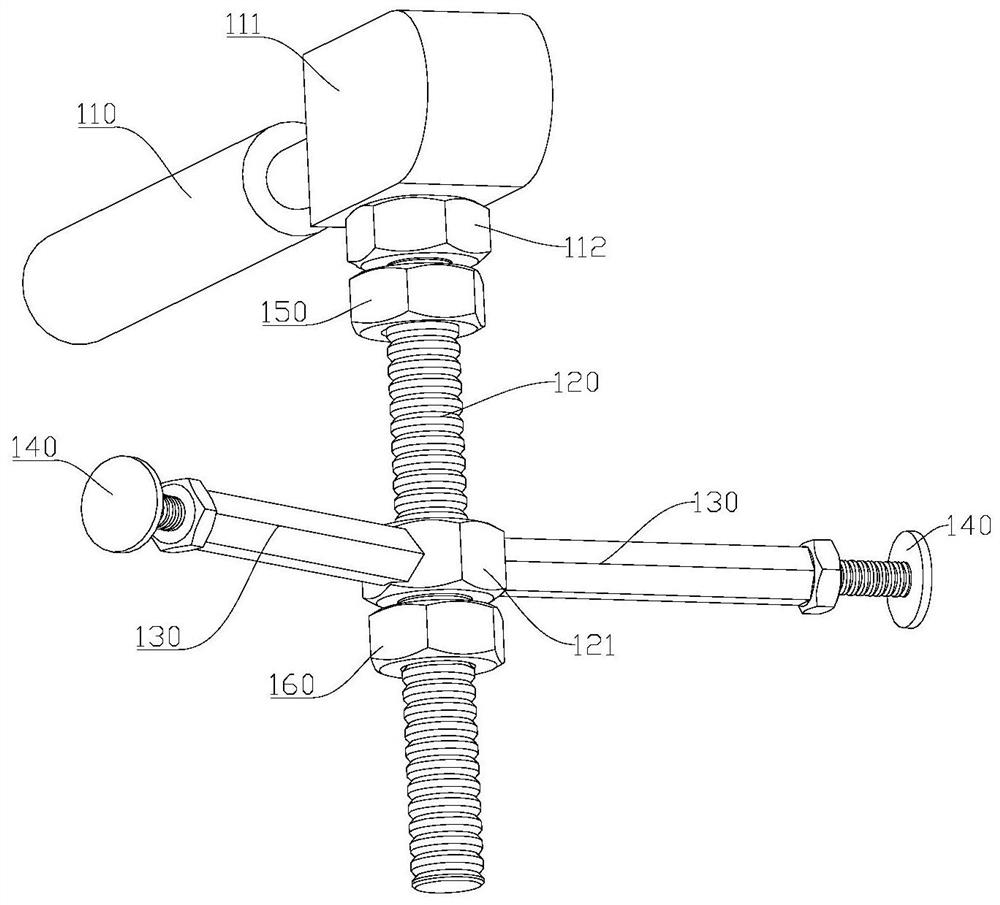

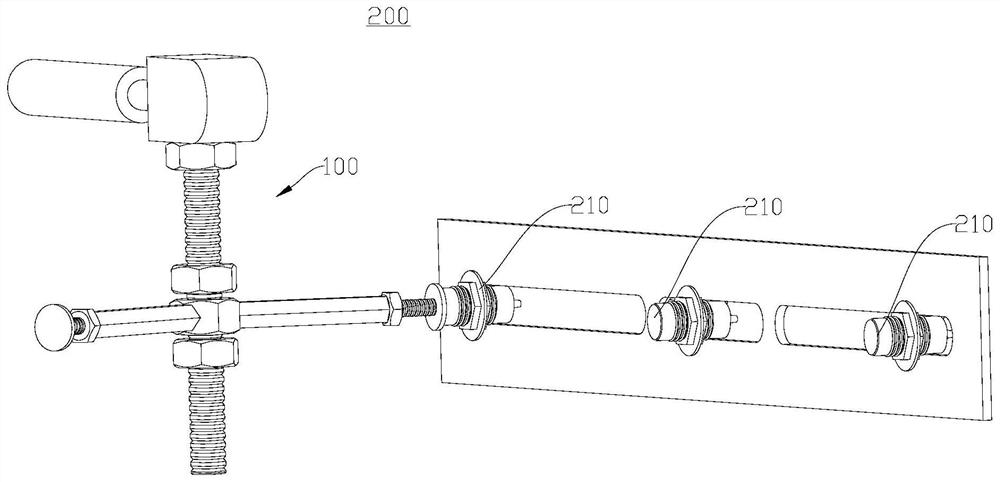

Flowmeter flange dismounting device and using method

PendingCN114526386AEnsure personal safetyAvoid hot workFlanged jointsVolume meteringSteel millIndustrial engineering

The invention relates to a flowmeter flange dismounting device which comprises a dismounting module used for dismounting rusted fixing bolts, a flowmeter frame installed on a flowmeter flange and a pipeline flange frame installed on a conveying pipeline flange, and pipeline flowmeters used in a steel plant are different in size and form. However, most pipelines are connected through flanges, but fixing bolts of the flanges are prone to corrosion and rusting due to the fact that the field environment is severe, and when the pipeline flow meters need to be maintained or replaced due to faults, the flanges of the pipeline flow meters and the fixing bolts of the pipeline flanges cannot be disassembled normally due to rusting. In the prior art, a rusty fixing bolt in a flange needs to be fused through air welding, but the field environment belongs to a gas area, large potential safety hazards exist in fire operation, the efficiency of manually disassembling the rusty fixing bolt is low, and production of enterprises can be greatly influenced. Therefore, a device capable of guaranteeing safety and rapidly disassembling the rusted fixing bolt needs to be developed.

Owner:GUANGDONG GUANGDONG SHAOGANG ENG TECH

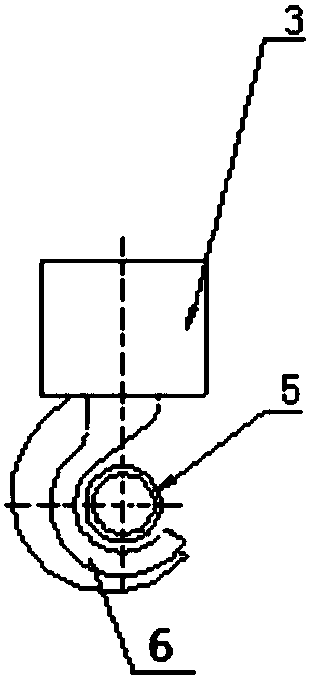

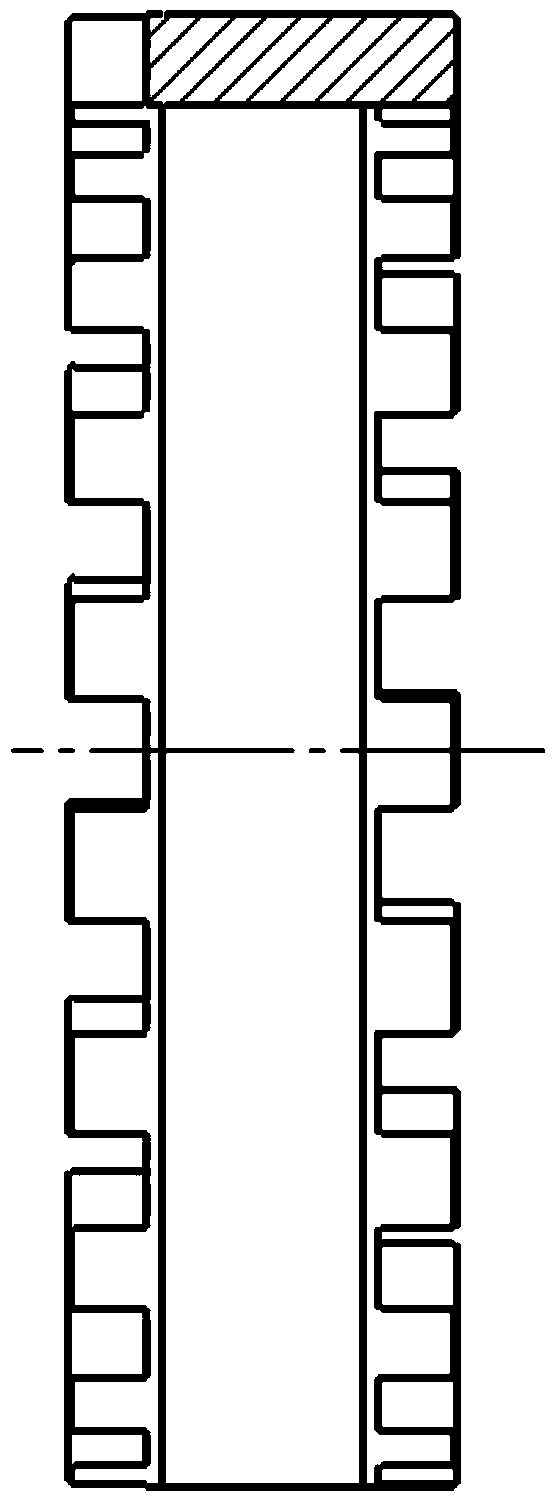

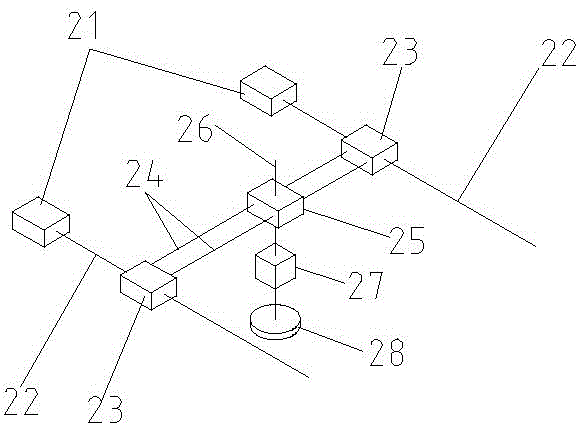

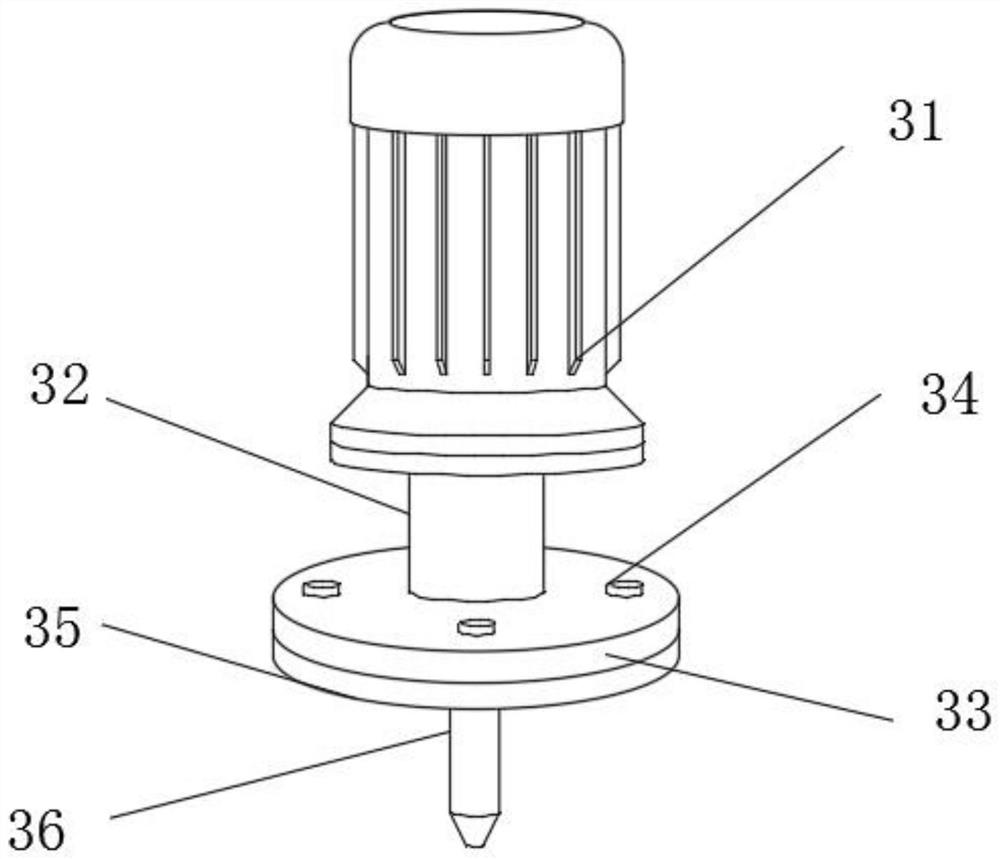

A branch well angle difference adjustment tool and its angle difference adjustment method

ActiveCN105443063BImprove torsion resistanceHigh precisionBorehole/well accessoriesDrilling machines and methodsAngular degreesUltimate tensile strength

The invention relates to the technical field of drilling and completion of a multilateral well, in particular to a multilateral well angular difference adjustment tool and an angular difference adjustment method thereof. The multilateral well angular difference adjustment tool comprises three reversing sleeves. The circumference of two ends of each reversing sleeve is processed with 20 splines or end face teeth at an equal angle. The angular difference exists between a center line of the concave portion of the female end of the reversing sleeve and a center line of the convex portion corresponding to the male end in the counter-clockwise direction. The reversing sleeve can be designed to be 5 angular differences, namely, 0 degree, 1 degree, 2 degrees, 5 degrees and 10 degrees. According to the multilateral well angular difference adjustment tool, the anti-twisting property of a whole tubular column of the multilateral well is improved after the angular difference adjustment, the adjustment precision of the angular differences and the strength are high, the multilateral well angular difference adjustment tool is simple and convenient to operate, hot work of well site welding is avoided, and risks in the construction processes of the multilateral well are reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

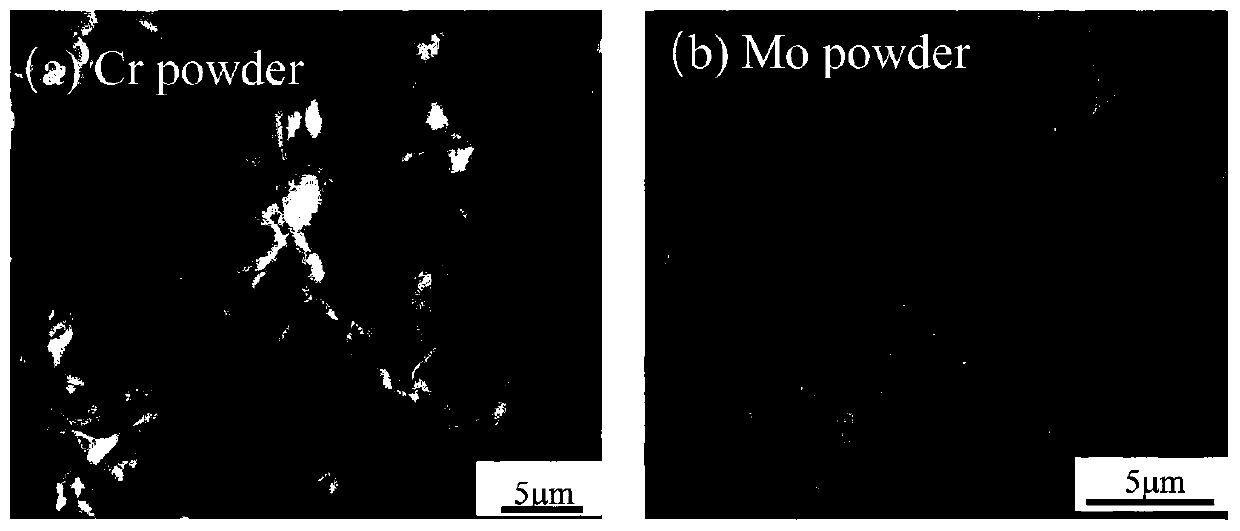

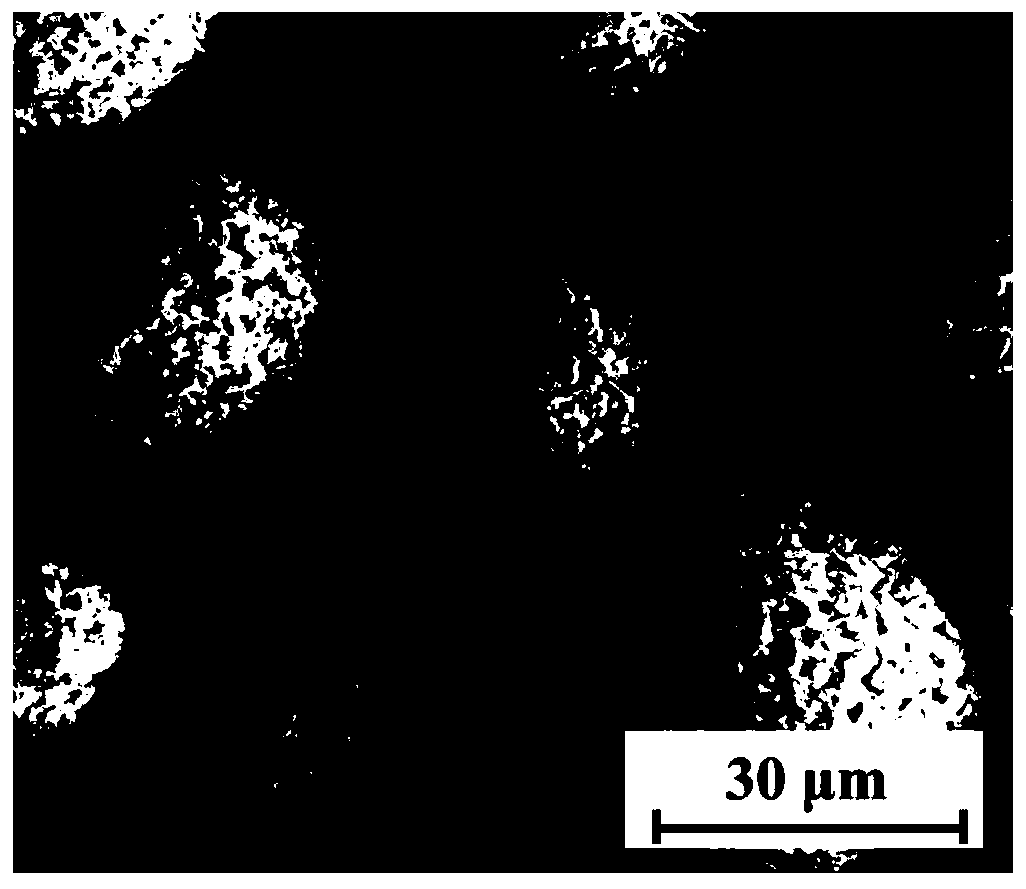

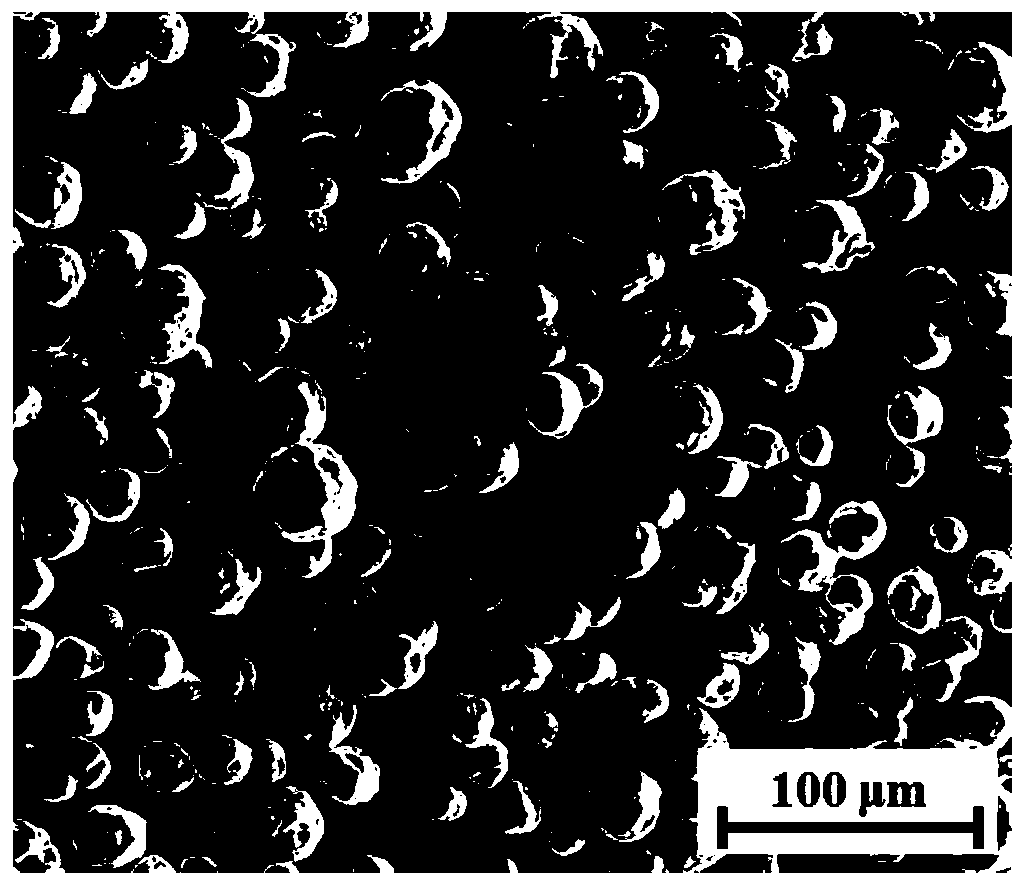

Manufacturing method of cobalt-chromium-molybdenum alloy spherical powder

PendingCN110666181AOvercome the problem of composition segregationUniform compositionTransportation and packagingMetal-working apparatusCobalt metalMetal particle

The invention discloses a manufacturing method of cobalt-chromium-molybdenum alloy spherical powder. The manufacturing method comprises the steps of 1, fully mixing a thermoplastic binder, cobalt metal powder, chromium metal powder and molybdenum metal powder in a solvent to obtain mixed slurry; 2, transferring the mixed slurry into an air spray dryer for pelletizing to obtain primary spherical particles; 3, carrying out thermal degreasing on the primary spherical particles to obtain spherical metal particles; 4, adding calcium oxide into the spherical metal particles, and mixing to obtain a mixture; and 5, sintering the mixture, and washing, filtering, drying and grinding the sintered product to obtain the cobalt-chromium-molybdenum alloy spherical powder. In the manufacturing method, theproduct is segregation-free after being subjected to sintering purification, the oxygen content can be controlled to be less than 0.2% by weight, the particle size is less than 75 micrometers, and the powder keeps good spherical morphology at last.

Owner:CENT SOUTH UNIV

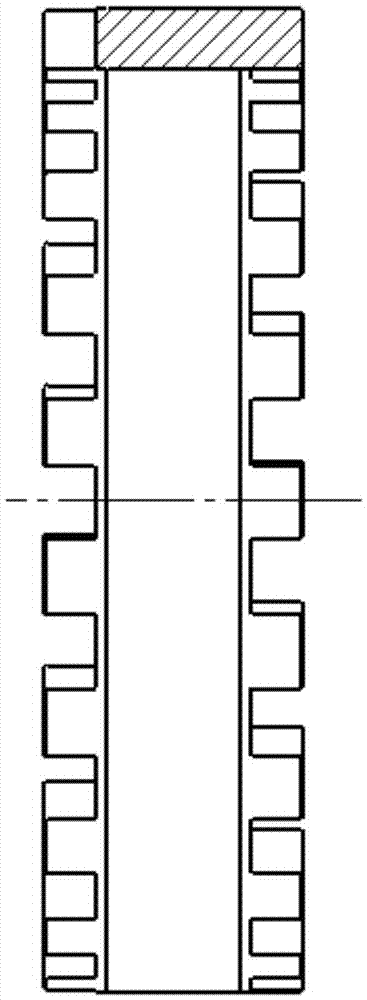

Multilateral well angular difference adjustment tool and angular difference adjustment method thereof

ActiveCN105443063AImprove torsion resistanceHigh precisionBorehole/well accessoriesDrilling machines and methodsAngular degreesUltimate tensile strength

The invention relates to the technical field of drilling and completion of a multilateral well, in particular to a multilateral well angular difference adjustment tool and an angular difference adjustment method thereof. The multilateral well angular difference adjustment tool comprises three reversing sleeves. The circumference of two ends of each reversing sleeve is processed with 20 splines or end face teeth at an equal angle. The angular difference exists between a center line of the concave portion of the female end of the reversing sleeve and a center line of the convex portion corresponding to the male end in the counter-clockwise direction. The reversing sleeve can be designed to be 5 angular differences, namely, 0 degree, 1 degree, 2 degrees, 5 degrees and 10 degrees. According to the multilateral well angular difference adjustment tool, the anti-twisting property of a whole tubular column of the multilateral well is improved after the angular difference adjustment, the adjustment precision of the angular differences and the strength are high, the multilateral well angular difference adjustment tool is simple and convenient to operate, hot work of well site welding is avoided, and risks in the construction processes of the multilateral well are reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

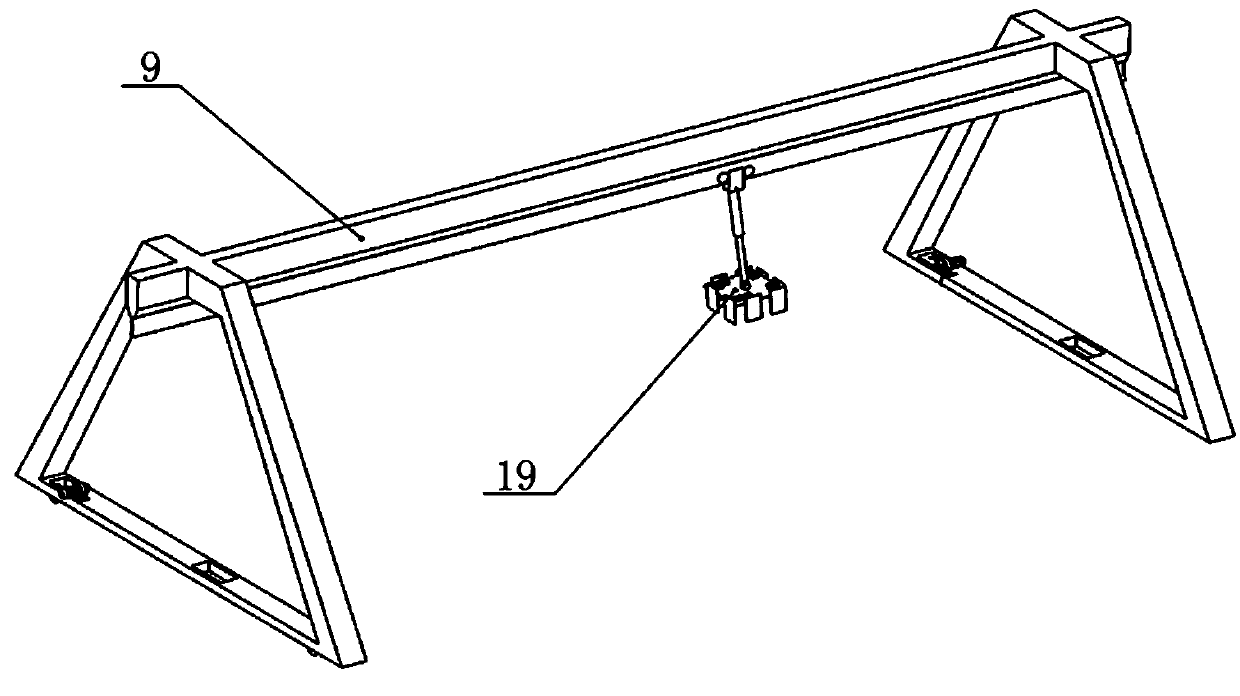

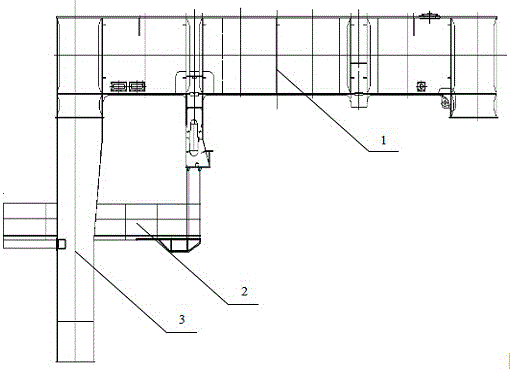

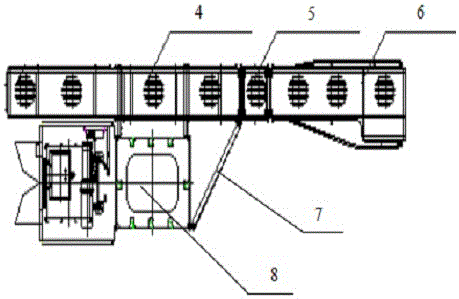

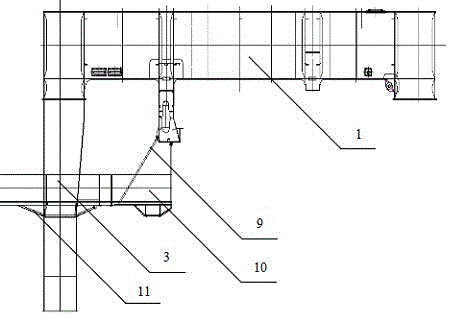

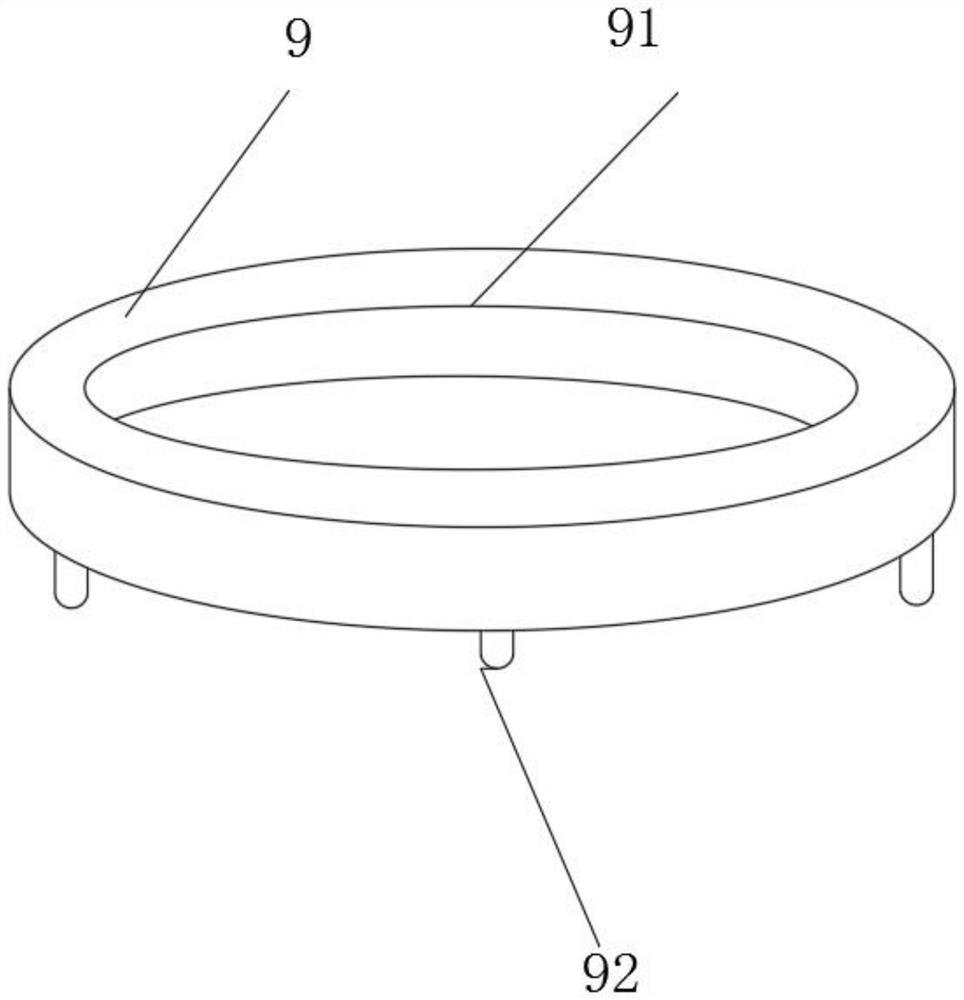

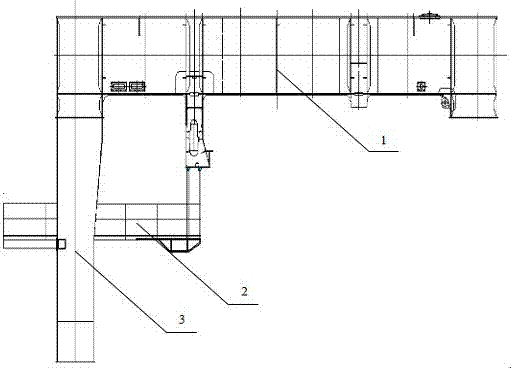

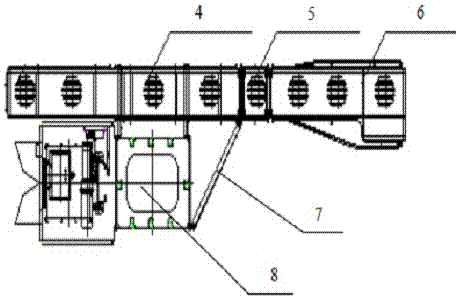

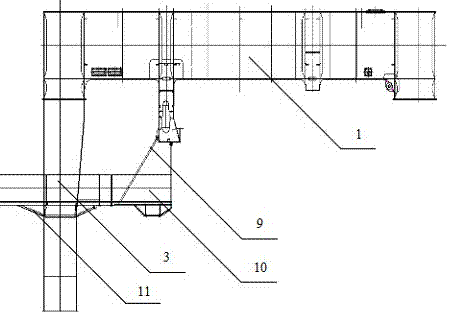

Bridge crane diving platform structure and mounting process thereof

ActiveCN106081903ASimple structureEasy to installLoad-engaging elementsLarge sizeMechanical engineering

The invention relates to a bridge crane diving platform structure and a mounting process thereof. The bridge crane diving platform structure comprises a first assembly, a second assembly and a third assembly which are assembled in sequence from the front to the back. The mounting process of the first assembly comprises the step that when a left side door frame and a right side door frame are assembled, the first assembly is mounted to the right position. A mounting process of the third assembly comprises the steps that when a front girder is lifted to an eight-meter jig frame, a diving platform truss is located and mounted with the center line of a landside upper cross beam as the baseline; and the height of the third assembly is adjusted, and it is guaranteed that a cab is level with the third assembly. A mounting process of the second assembly comprises the steps that after the door frames, the front girder and a rear girder are assembled, the second assembly is preassembled; then the first assembly, the second assembly and the third assembly are bound with coir ropes; diving platform lower support bolts are loosened; the height of the first assembly is adjusted so that the first assembly can be aligned with the third assembly; and then the second assembly is connected to the first assembly and the third assembly properly. The bridge crane diving platform structure and the mounting process thereof have the beneficial effects that an improved diving platform is simple in structure and convenient to mount; fire work is effectively avoided; and the second assembly which is finally mounted is small, and large-size hoisting equipment such as vehicles is not needed to be used when bolts are screwed, so that equipment cost is saved.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

Method for replacing sealing part of operation oil pipe utilizing tackle device

PendingCN112648126AImprove replacement efficiencyImprove convenienceHydro energy generationMachines/enginesWater turbineControl engineering

The invention relates to the technical field of water turbines, in particular to a method for replacing a sealing part of an operation oil pipe utilizing a tackle device. The method involves the tackle device, wherein the tackle device comprises a base, a jack and a supporting plate; and rolling wheels are arranged at the bottom of the base, the bottom end of the jack is fixedly connected to the base, and the supporting plate is connected to the top end of the jack. The method for replacing the sealing part of the operation oil pipe utilizing the tackle device has the beneficial effects that extra welding of angle steel is not needed in the replacement process of the sealing part, so that the replacement efficiency of the sealing part is greatly improved, the workload of operators is reduced, fire operation is effectively avoided, and the operation safety is improved; and the tackle device is high in flexibility, the weight of the operation oil pipe can be stably borne, and the position of the operation oil pipe can be adjusted in the vertical direction and the axial direction, so that convenience in the replacement process of the sealing part is improved.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +1

The method of replacing the shield tail brush of the ultra-large diameter shield machine under the condition of high water pressure

ActiveCN107035378BEasy to replace, safe, stable and efficientSolve the difficulty of replacementUnderground chambersTunnel liningEngineeringSlurry

The invention provides a replacing method of shield tail brushes of a super-large-diameter shield machine under a high water pressure condition. In the propelling process of last ring pipe pieces before shutdown, in addition to the last ring pipe piece before shutdown, gaps between a shield tail and the pipe pieces is filled with elastic water absorbing materials or elastic waterproof materials; in the propelling process of the last ring pipe pieces before shutdown, ordinary grease is injected into a grease cavity of the shield tail brushes in a pressure mode, and the other grease cavities of other shield tail brushes of the super-large-diameter shield machine are injected with waterproof grease in a pressure mode; in the replacement position, a mud tank of the super-large-diameter shield machine is subjected to new slurry replacement; and in the replacement position, a shield shell hoop of the super-large-diameter shield machine is injected with filling slurry body in a pressure mode. Preferably, the shield tail brushes are detachable. According to the replacing method of the shield tail brushes of the super-large-diameter shield machine under the high water pressure condition, replacement of the shield tail brushes under the high water pressure condition is easy, safe, stable and efficient, the problem that replacement of the shield tail brushes of the super-large-diameter shield machine under the high water pressure condition is difficult can be solved, design is ingenious, construction is simple, convenient, safe and efficient, and large-scale application and promotion is adaptable.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

Hydraulic cylinder, coke oven gas exchanger and use method of coke oven gas exchanger

ActiveCN111852985AReduce riskImprove efficiencyFluid-pressure actuatorsCoke oven detailsHydraulic cylinderThermodynamics

The invention relates to the field of iron and steel smelting, in particular to a hydraulic cylinder, a coke oven gas exchanger and a use method of coke oven gas exchanger. A connecting piece, a firstguide rail, at least one second guide rail, and induction blocks are arranged on a cylinder head of a hydraulic cylinder body. The first guide rail is detachably connected to the connecting piece. The second guide rails are connected to the first guide rail, and the second guide rails are movably connected to the first guide rail. The induction blocks are installed at the free ends of the secondguide rails and movably connected to the second guide rails. When a hydraulic cylinder of the coke oven gas exchanger is replaced, the induction blocks are adjusted to be in contact with a proximity switch only after the hydraulic cylinder is installed on site, so that the efficiency of overhaul operation is greatly improved, and fire operation is avoided.

Owner:SGIS SONGSHAN CO LTD

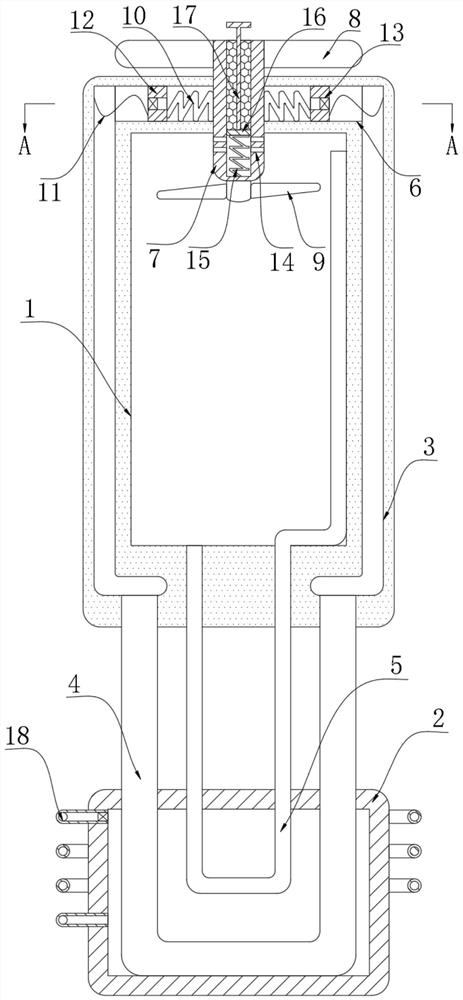

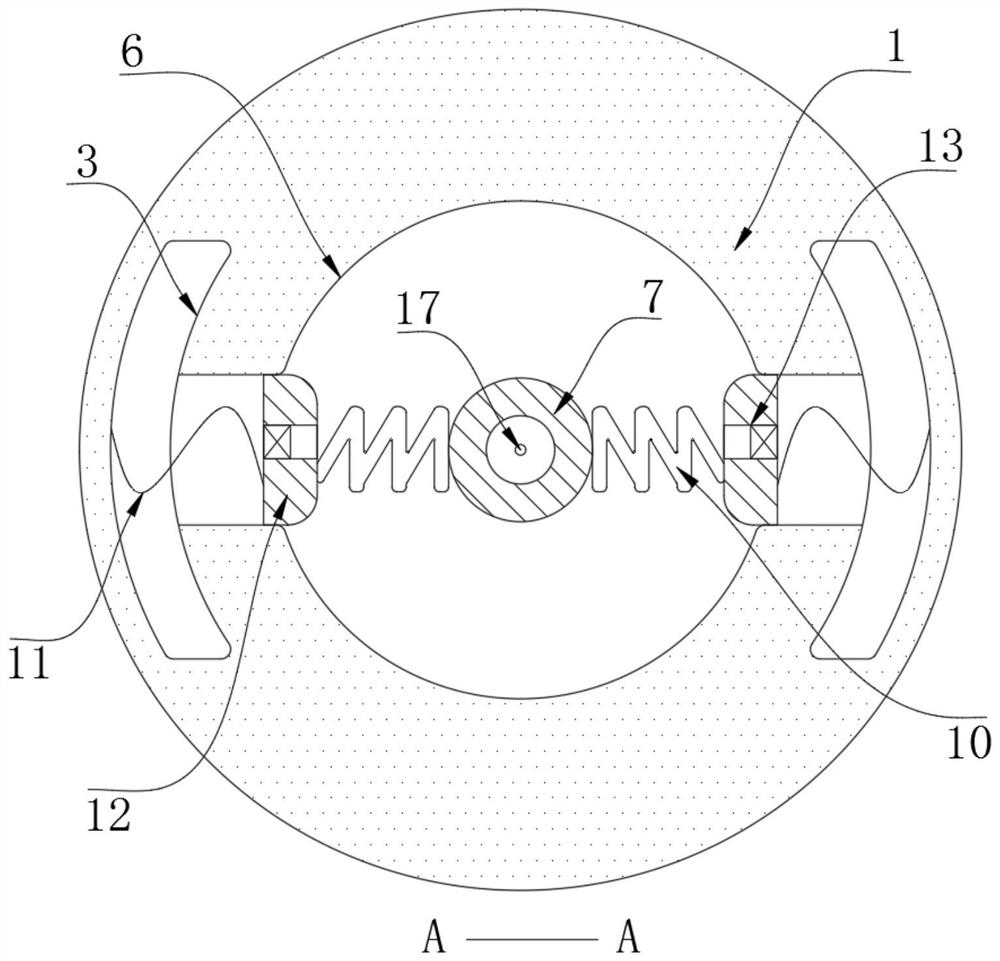

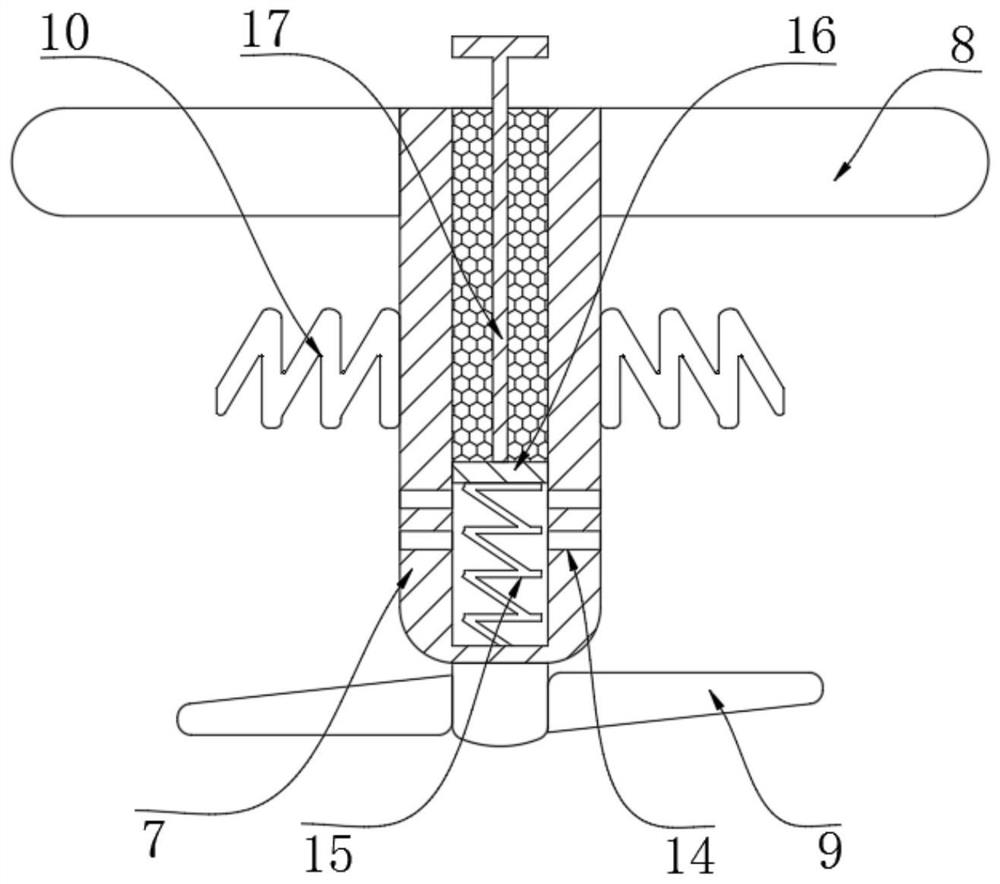

Special electrical cabinet suitable for complex environment

ActiveCN112164994APrevent risingAvoid hot workSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsPhysicsEngineering

The invention discloses a special electrical cabinet suitable for a complex environment, which comprises a box body and an insulation box buried underground. Two symmetrically arranged heat storage grooves are formed in the side wall of the box body, and a U-shaped heat exchange tube communicated with the two heat storage grooves is inserted into the inner wall of the insulation box in a penetrating manner. A similar-U-shaped airflow pipe communicating with the interior of the box body is inserted into the inner wall of the insulation box in a penetrating mode, a pumping groove is formed in the top of the box body, a rotating cylinder is rotatably connected to the top of the box body in a penetrating mode, and rotating blades are fixed to the upper portion of the rotating cylinder. The electrical cabinet has the advantages that the insulation box is arranged and buried under the ground, so that the internal temperature of the insulation box is relatively stable, the heat storage grooveis formed, a good heat insulation effect can be achieved, meanwhile, water flow in the heat storage groove flows, absorbed heat is continuously discharged, the low temperature of the heat storage groove is guaranteed, and therefore rising of the internal temperature of the box body is avoided; and normal work of components in the box body in an effective temperature is ensured.

Owner:莱芜钢铁双山陶土福利加工有限公司

Solar cell module rework device

InactiveCN104465880BAvoid hot workImprove work efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingSolar batterySolar energy

The invention discloses a solar battery assembly device and belongs to the technical field of solar battery assemblies. The repairing device comprises a support, a base and a control device. The support is provided with an X-direction mobile mechanism, the X-direction mobile mechanism is provided with a Y-direction mobile mechanism, and the moving direction of the X-direction mobile mechanism and the moving direction of the Y-direction mobile mechanism are perpendicular to each other and parallel to the ground. The Y-direction mobile mechanism is provided with a Z-direction mobile mechanism, the moving direction of the Z-direction mobile mechanism is perpendicular to the ground, and the Z-direction mobile mechanism is provided with a rubber grinding head driven by a motor. The X-direction mobile mechanism, the Y-direction mobile mechanism, the Z-direction mobile mechanism and the rubber grinding head are all controlled by the control device to move. The support is further provided with an assembly fixing device. According to the repairing device, a traditional manual work mode is changed, the health of workers is guaranteed, the repairing quality and efficiency of the assembly are improved, and therefore the repairing device is quite practical.

Owner:HENGSHUI YINGLI NEW ENERGY

A kind of forging equipment of gas burner head assembly

InactiveCN108889896BReduce work intensityAvoid hot workForging press detailsHandling devicesEngineeringHeating furnace

Owner:JIANGXI KEMING COPPER IND CO LTD

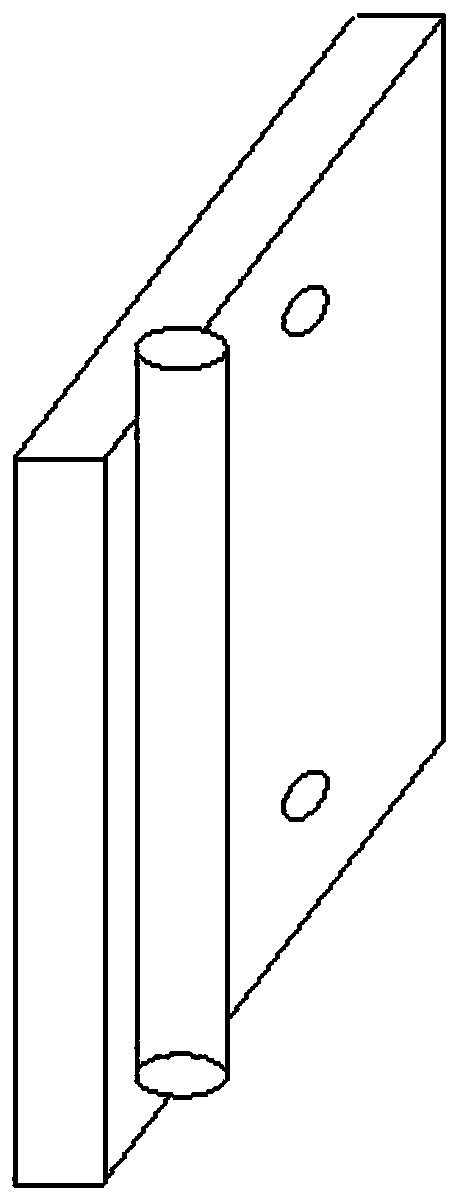

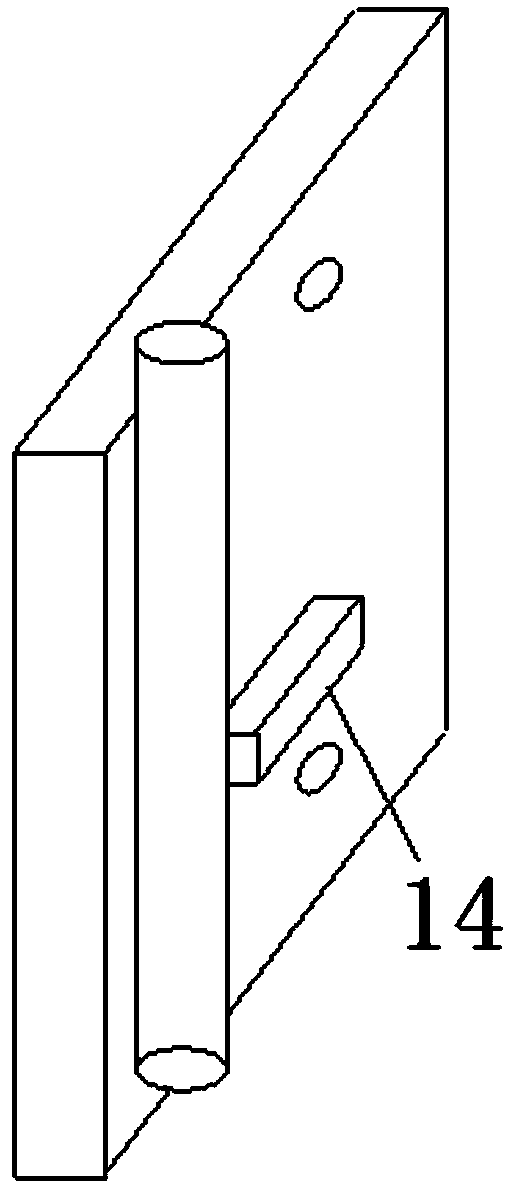

Support corbel structure and using method thereof

The invention discloses a support corbel structure and a using method thereof. The support corbel structure comprises a corbel base and a corbel supporting frame, wherein the structure also comprisesa pressing plate and a limiting and adjusting mechanism used for adjusting clamping force between the corbel base and the pressing plate; the corbel supporting frame is connected with one side away from the pressing plate of the corbel base. Compared with the conventional method, the damage to steel structure stand column bodies can be avoided; the fire operation is avoided, so that the occurrenceof fire can be effectively prevented; through the mounting method, a large amount of labor cost can be reduced; the removably assembled corbel structure is firm to mount and easy to operate, and is economical and practical.

Owner:ANHUI ZHONGDIAN XINGFA & XINLONG TECH CO LTD

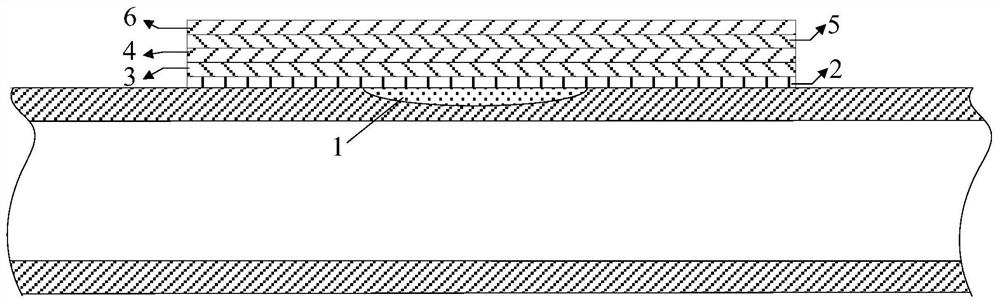

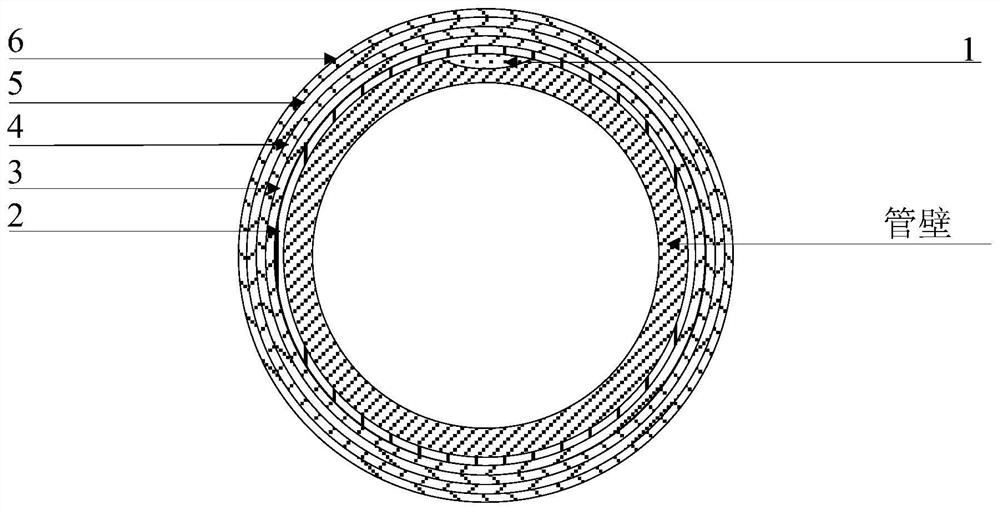

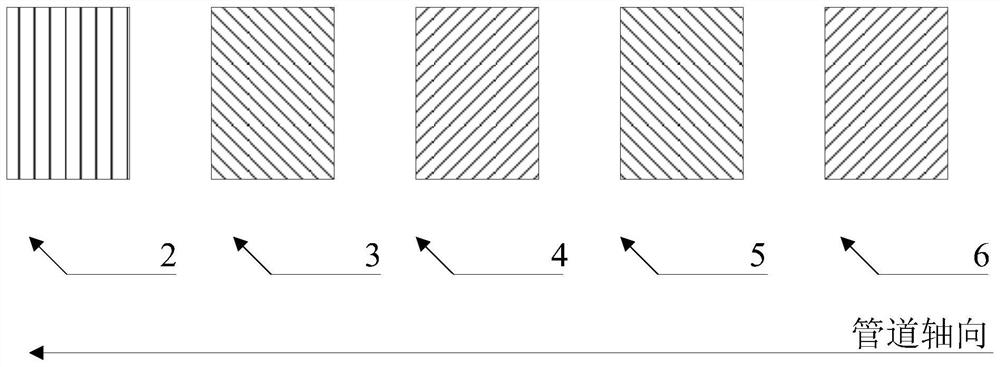

Oil-gas pipeline pit defect repairing method

The invention provides an oil-gas pipeline pit defect repairing method. The oil-gas pipeline pit defect repairing method has the advantages of being reasonable in design, easy in operation, free of fire, low in cost and good in repairing effect. The method comprises the following steps that 1, the outer surface of a pipeline pit is pretreated, an anti-corrosion layer is removed, and cleaning and drying are carried out; 2, the pipeline pit is coated with polyurethane, and repairing is carried out until the surface of the defect part is flat; 3, aramid fiber cloth is wound around the pipeline pit filled with the polyurethane; 4, a plurality of layers of carbon fiber cloth is wound around the surface of the aramid fiber cloth layer by layer in a staggered mode; and 5, after the carbon fiber cloth on the outermost layer is bonded, the surface of the pipeline is ground and cleaned for anti-corrosion treatment to complete pipeline pit defect repairing. According to the method for repairing the defect of the pipeline pit by filling and winding the pipeline with various composite materials, theoretical guidance is provided for concave repairing design of an oil-gas pipeline, and the methodhas important significance in optimizing the pipeline repairing method, repairing the defect of the oil-gas pipeline and improving the operation safety of the pipeline.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

High-precision drilling machine for workpiece machining

PendingCN114799259AAchieve high precision machiningAccurate drillingMeasurement/indication equipmentsPositioning apparatusNumerical controlEngineering

The high-precision drilling machine comprises a bottom plate, a driving part is fixedly connected to the rear portion of the upper end of the bottom plate, a cooling device and two drilling devices penetrate through the front portion of the driving part, an executing part is fixedly installed at the upper end of the bottom plate, and a second sliding groove is formed in the middle of the upper end of the bottom plate; a first air cylinder is fixedly mounted on the left portion of the upper end of the bottom plate, a first push rod is fixedly mounted at the output end of the first air cylinder, a mounting part is fixedly connected to the right end of the first push rod, two machining tables are fixedly mounted in the middle of the mounting part, and a numerical control table is fixedly mounted on the rear portion of the upper end of the bottom plate. According to the high-precision drilling machine for workpiece machining, drilling machining of different depths can be achieved, and the drilling depth is accurate; different hole diameters and different types of workpieces can be machined, and the application range of the drilling machine is widened; the cooling device can avoid high-temperature operation of the drill bit; in addition, the drilling machine is fixed through the negative pressure effect, and fixing operation is more convenient.

Owner:梁少龙

Bridge crane diving platform structure and its installation process

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

A high-precision drilling machine for workpiece machining

ActiveCN112207315BAchieve high precision machiningAccurate drillingMeasurement/indication equipmentsPositioning apparatusNumerical controlThermodynamics

The invention discloses a high-precision drilling machine for workpiece processing, comprising a bottom plate, a driving part is fixedly connected to the rear of the upper end of the bottom plate, and a cooling device and two drilling devices respectively penetrate through the front part of the driving part. The upper end of the bottom plate is fixedly installed with the actuator, the middle of the upper end of the bottom plate is provided with a No. 2 chute, the left part of the upper end of the bottom plate is fixedly installed with a No. 1 cylinder, the output end of the No. 1 cylinder is fixedly installed with a No. The right end of the push rod is fixedly connected with a mounting piece, two processing tables are fixedly installed in the middle of the mounting piece, and a numerical control table is fixedly mounted at the rear of the upper end of the bottom plate. The high-precision drilling machine for workpiece processing of the present invention can realize drilling processing of different depths, and the drilling depth is accurate; and the workpiece can be processed with different apertures and different models, thereby improving the applicable range of the drilling machine; and The cooling device can avoid the high temperature operation of the drill bit; in addition, the drilling machine is fixed by the action of negative pressure, and the fixing operation is more convenient.

Owner:YANTAI SHOUGANG DONGXING GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com