Flowmeter flange dismounting device and using method

A technology for dismantling devices and flowmeters, which is applied to measuring devices, volume measurement, flange connections, etc., can solve problems such as time-consuming and labor-intensive efficiency, rusting of fixing bolts, and normal production impact, so as to reduce time-consuming and quickly disassemble , The effect of reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0034] It is worth noting that the directional words such as "up", "down", "left", "right", "front" and "rear" involved in this document are relative to the perspective of the drawings, which are only for the convenience of description and should not be construed as opposites. Limitations of technical solutions.

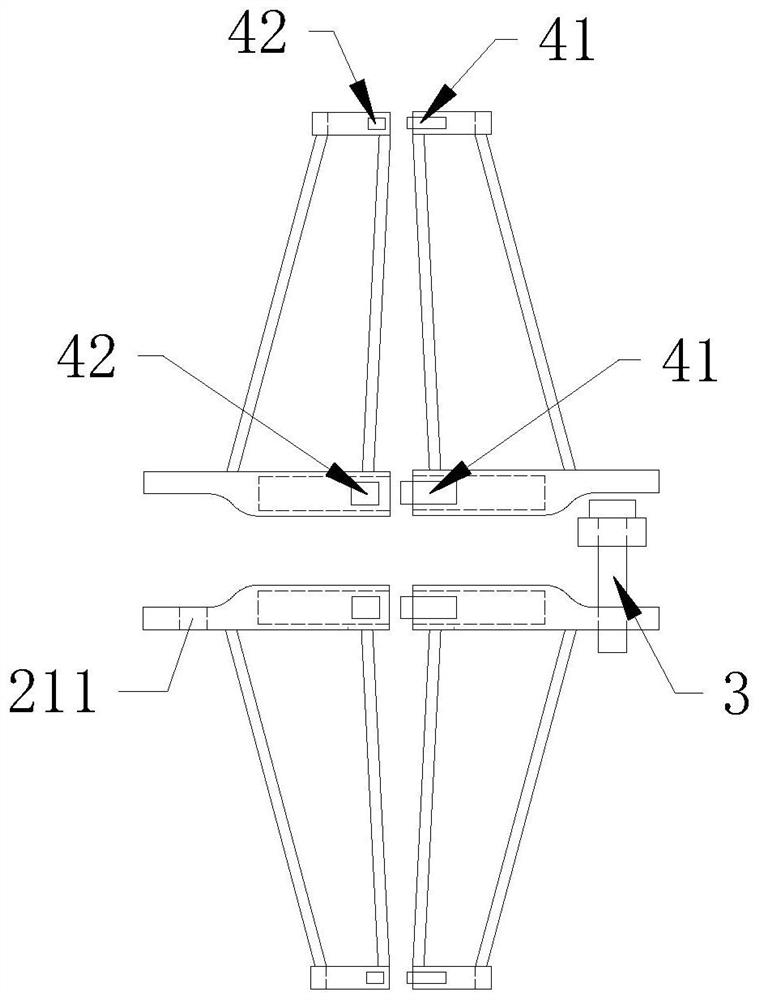

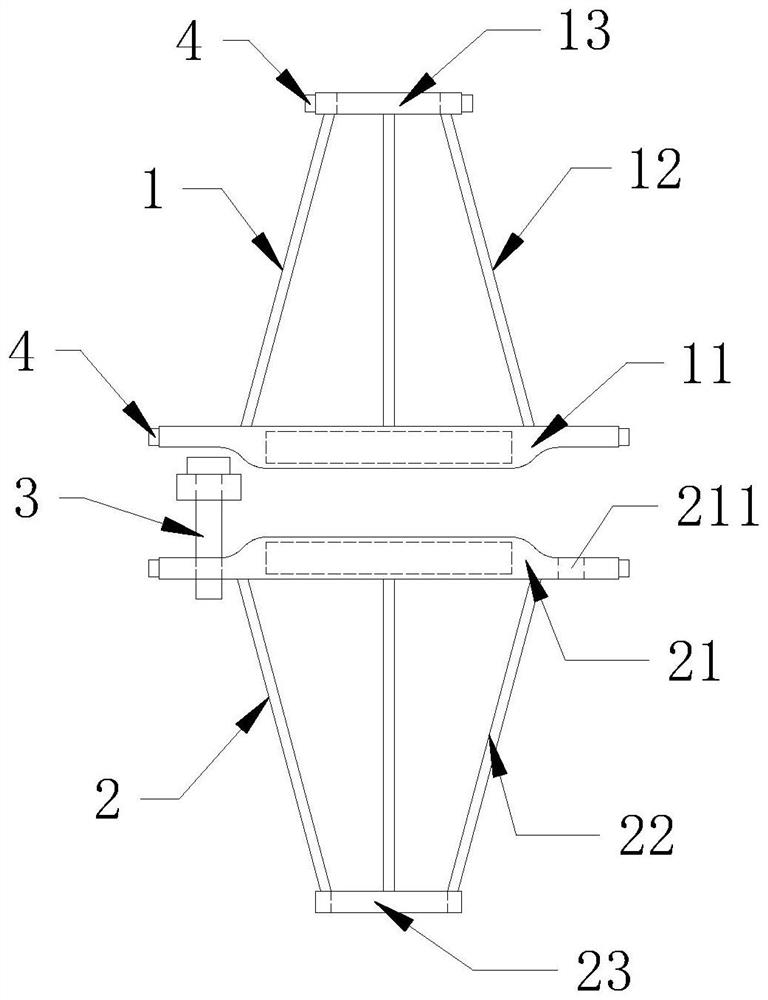

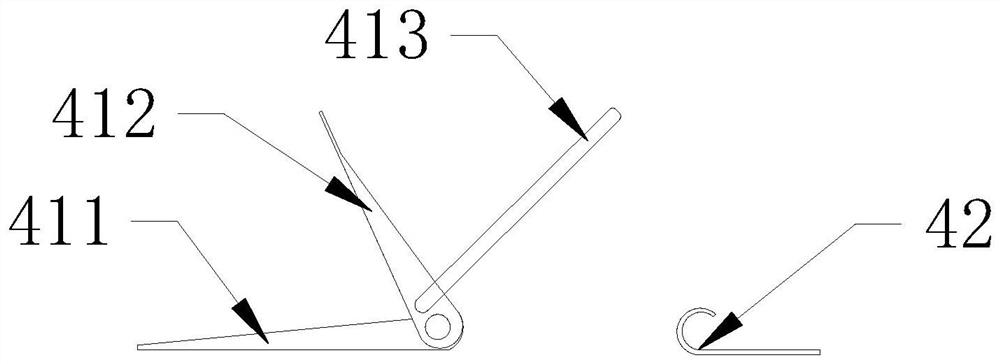

[0035] like Figure 1-4 As shown, a flowmeter flange disassembly device includes a disassembly module 3 for disassembling rusted fixing bolts, a flowmeter frame 1 installed on the flowmeter flange, and a pipeline flange frame installed on the conveying pipeline flange. 2;

[0036] The flowmeter frame 1 is composed of two symmetrical flowmeter half-frames. The flowmeter half-frame includes a flowmeter flange half-ring, a flowmeter retaining half-ring and a plurality of upper connecting rods 12. The ring forms the flowmeter flange ring 11 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com