Repairing device for solar battery assembly

A technology of solar cells and components, applied in electrical components, circuits, photovoltaic power generation, etc., can solve problems such as high labor intensity, economic waste, and damage to tempered glass, and achieve the effects of ensuring work quality, improving work efficiency, and avoiding high-temperature operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

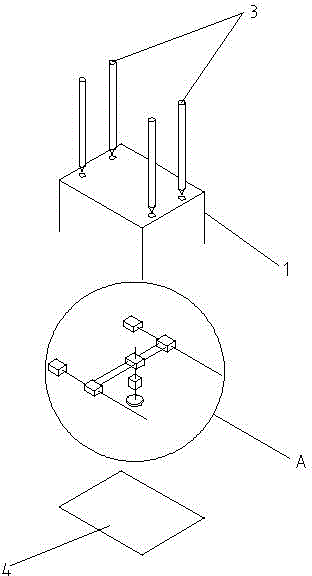

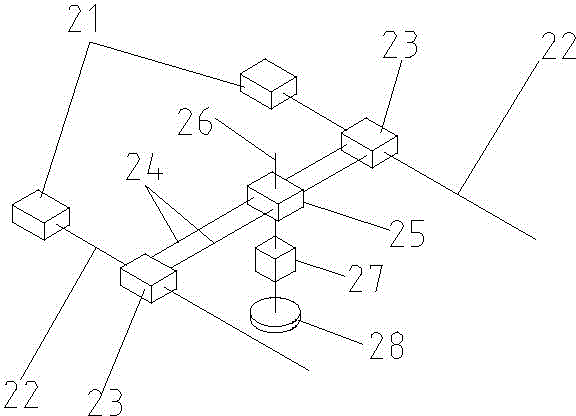

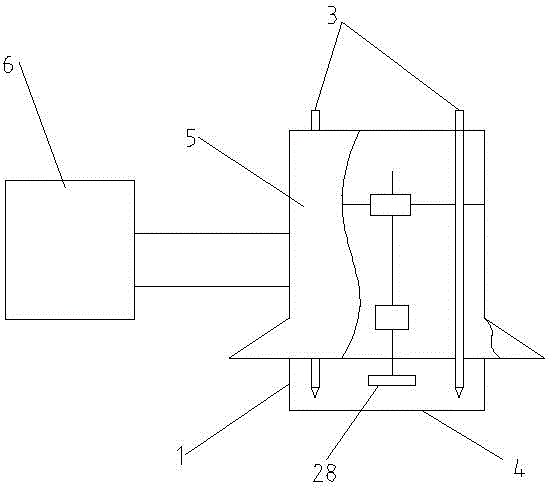

[0019] Such as figure 1 , 2 As shown in and 3, a solar cell module rework device includes a dust cover 5, a support 1, a base 4 and a control device, two first motors 21 and two first lead screws 22 are fixed on the support 1, and the second A threaded screw 22 is driven to rotate by a first motor 21, and the first threaded screw 22 is provided with two synchronously sliding first sliders 23, and two second threaded screws 24 are arranged between the two first sliders 23, The first slide block 23 is provided with a motor for driving the second lead screw 24 to rotate, the second lead screw 24 is provided with a second slide block 25, the second slide block 25 is connected with a third lead screw 26, the second slide block 25 is provided with motor to be used to drive the 3rd leading screw 26 to rotate, and the bottom of the 3rd lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com