Bridge crane diving platform structure and its installation process

A technology of diving platform and installation technology, which is applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of unguaranteed quality of the diving platform, complicated installation process, high production cost, etc., and achieves simple structure, avoids hot work, and saves The effect of equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

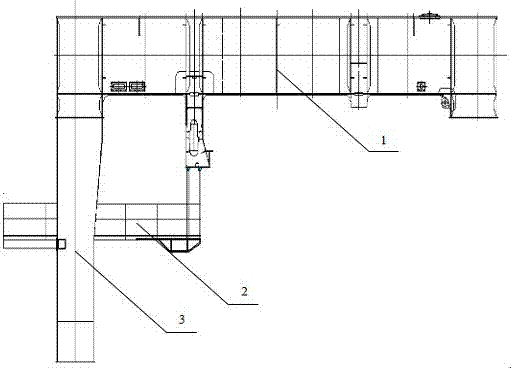

[0019] Such as figure 1 As shown, the diving platform 2 is a common auxiliary platform in the ladder platform of the bridge crane. The driver's cab of the trolley is connected, and the rest of the time this platform is like a diving platform, which is outside the ladder platform structure, so it is called diving platform 2. The whole diving platform 2 is composed of three parts: diving platform anti-hanging, diving platform truss and platform.

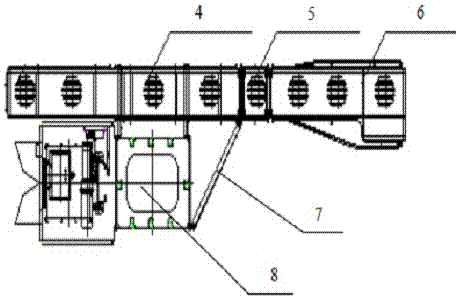

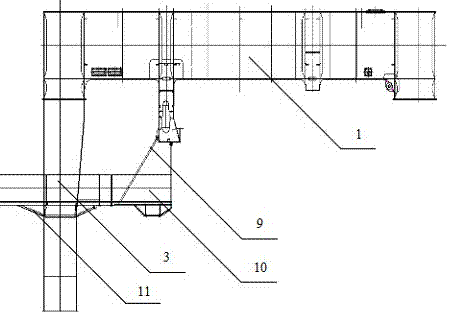

[0020] Such as figure 2 , image 3 As shown, the improved diving platform 10 includes a component one 4, a component two 5 and a component three 6 which are assembled with each other in sequence. A support rod 7 is arranged between them, and the support rod 7 is obliquely supported between the component one and the column 3, and one end of the component one 4 is fixedly connected with a connecting piece, and is connected with one end of the component two 5 by bolts, and the component two 5 Railing segment 2 is arranged on the top;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com