Oil-gas pipeline pit defect repairing method

A pit defect and repair method technology, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of B-type sleeve repair methods, heavy repair methods, and high repair prices, and reduce the cost of pipelines. Repair cost, guaranteed pipeline operation, and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

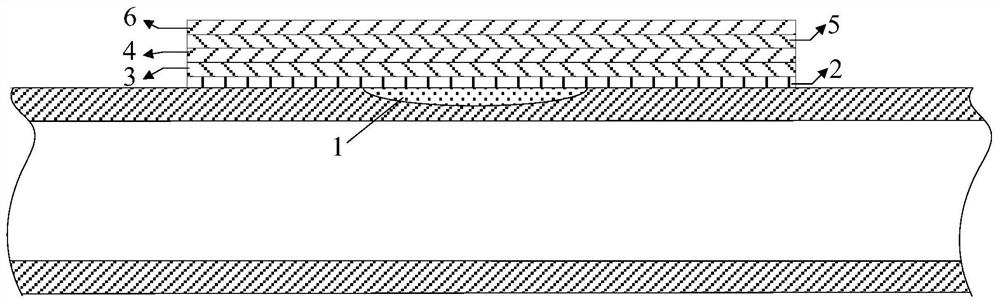

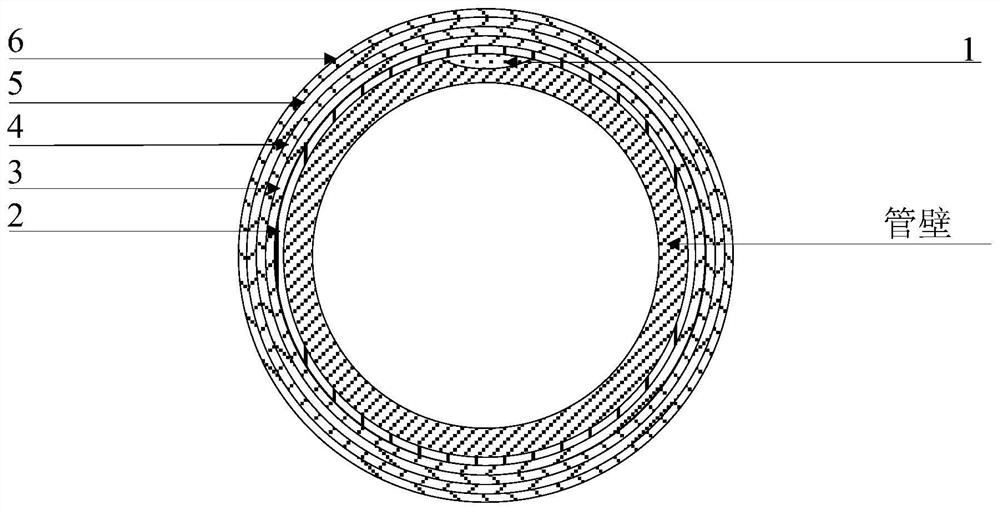

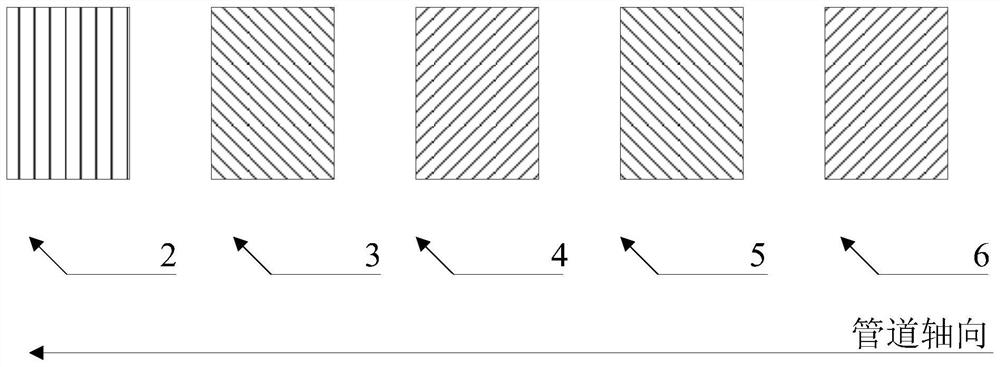

[0036] The invention discloses a method for repairing pit defects of oil and gas pipelines, which uses various composite materials to fill and wind the pipeline to repair the pit defects of the pipeline, provides theoretical guidance for the design of repairing the pits of oil and gas pipelines, optimizes the repair method of pipelines, and repairs oil and gas It is of great significance to improve the safety of pipeline operation.

[0037] A method for repairing pit defects of oil and gas pipelines according to the invention uses a variety of composite materials for repairing, avoids hot work compared with sleeve repairing, and is lighter while ensuring safe operation of the pipeline; compared with other carbon fiber repairing methods Compared with this design, the use of aramid cloth reduce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com