Coiled tubing suspension device, coiled tubing wellhead mandrel type suspension structure and method

A suspension device and coiled tubing technology, used in earth-moving drilling, wellbore/well components, sealing/packaging, etc., can solve problems such as unfavorable normal operation of workers, inability to close the main valve of the wellhead, and increase the height of the wellhead, etc. The effect of avoiding restoration costs and hot work, being suitable for widespread use, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

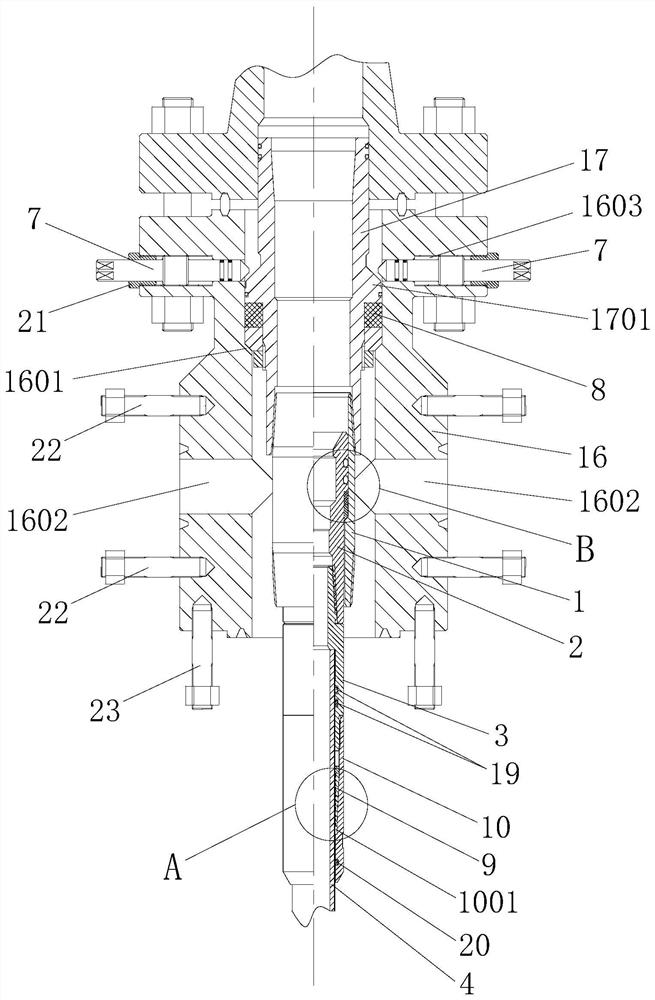

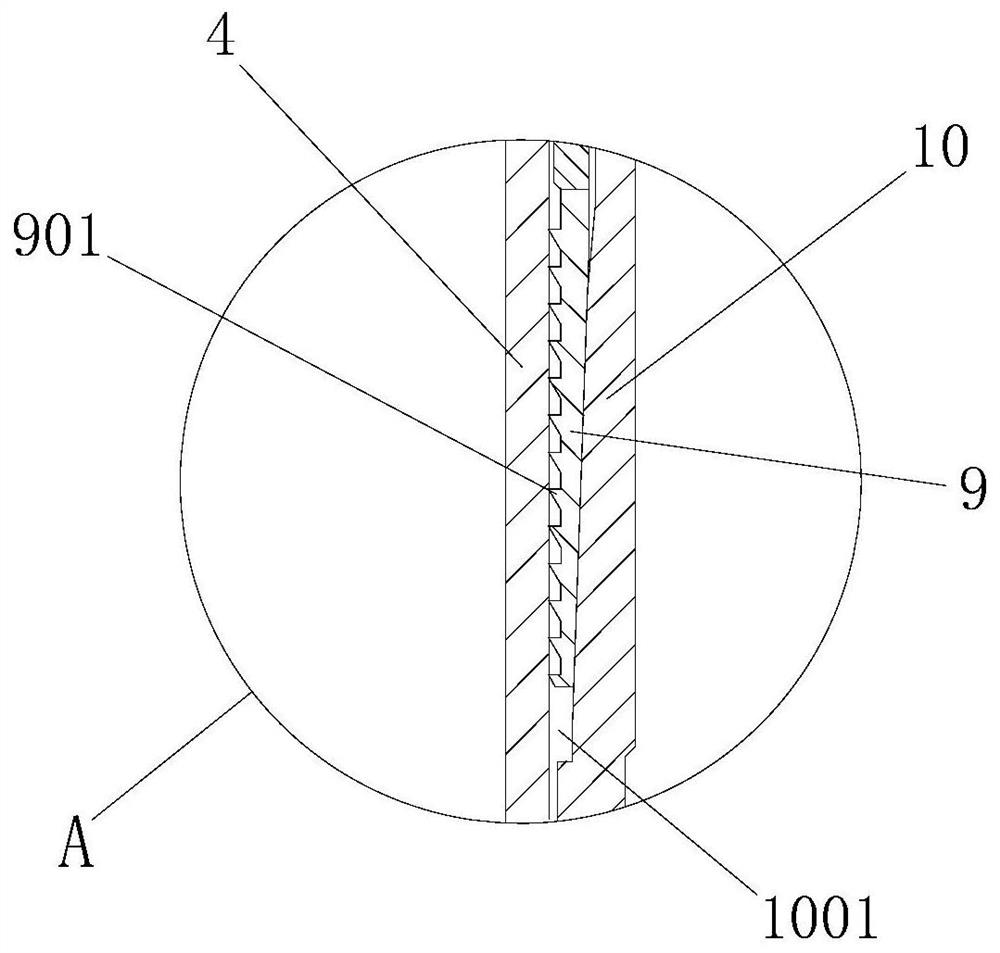

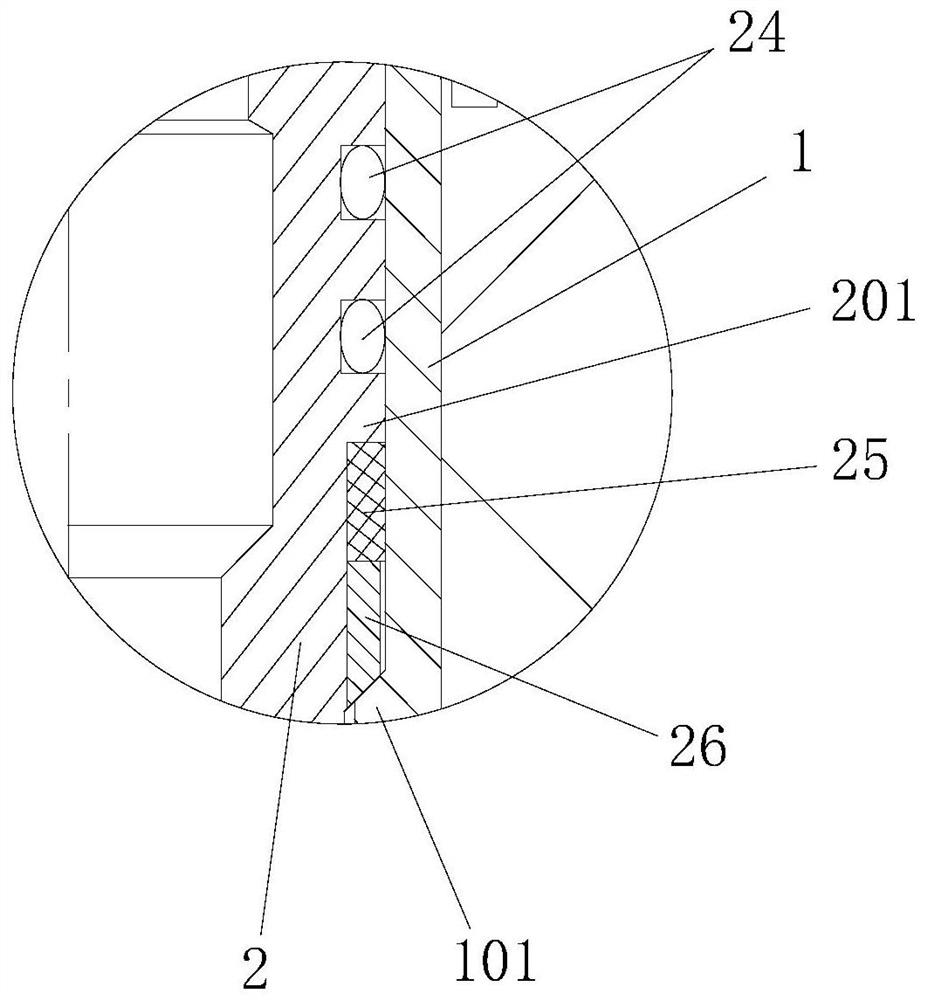

[0074] like Figure 1 to 3 , Figure 5 As shown, the present invention provides a continuous tube suspension, which is disposed at the wellhead, and the top of the continuous tube suspension is connected to the wellhead, which is connected to the continuous tube 4. The continuous tube suspension includes a tubing head 16, a tubing 17, a heavy load connector 3, and a lower joint 10. The tubing head 16 is a vertical arrangement of a cylindrical structure, and the tube hanging 17 is disposed inside the tubing head 16, the tube hanging 17, the overload connector 3 and the lower joint 10 are arranged in the upper to the lower order, and the bottom portion of the tube hanging 17 is connected between the top of the heavy load connector 3 or the bottom and overload connection of the tube hanging 17. A hanging short section 1 and the seat short section 2 are connected between the top to bottom, and the bottom of the heavy-load connector 3 is connected, and the overload connector 3 and the lo...

Embodiment 2

[0094] like Figure 4 , Image 6 As shown, the present invention provides a continuous tube well port core shaft-shaped suspension structure including injection head 11, a spray assembly 27, a wellhead main valve 15, and a continuous tube suspension device, injection Head 11, spray assembly 27, wellhead main valve 15 and the above-described continuous tube suspension device are all disposed above the wellhead. Among them: The bottom portion of the continuous tube suspension device is fixed at the wellhead, and the continuous tube 4 connected to the continuous tube suspension is incorporated into the well-in-well preset position, and the bottom of the main valve 15 of the wellhead is connected to the top of the continuous pipe suspension device, the main opening The top portion of the valve 15 is connected to the bottom of the spray assembly 27, and the top portion of the spray assembly 27 is connected to the bottom of the injection head 11.

[0095] In an alternative embodiment of t...

Embodiment 3

[0101] like Figure 1 to 6 As shown, the present invention provides a continuous tube well port core shaft suspension method including the following steps:

[0102] Step S1: The injection head 11, the spray assembly 27, the well port main valve 15, and the tubing head 16 are connected in the wellhead, and the main valve 15 opens the joint main valve to the continuous pipe 4 into the well preset position, continuous tube 4 is fixed at the well.

[0103] Step S2: Start the spray assembly 27 to seal to the ring air between the continuous pipe 4 and the wellhead;

[0104] Step S3: The overload connector 3 is connected at the top end of the continuous tube 4, and the feed tool is installed at the bottom of the injection head 11;

[0105] Step S4: Turn off the spray assembly 27, slow down the continuous tube 4 by the injection head 11 and the feed tool, and secure the top end of the continuous tube 4 in the tubing head 16;

[0106] Step S5: The end 11 is submitted to remove the feed tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com