Method for replacing sealing part of operation oil pipe utilizing tackle device

A technology for operating oil pipes and sealing parts, which is applied in the field of replacing the sealing parts of operating oil pipes with a pulley device, which can solve the problems of mechanical damage caused by slipping and falling, narrow space, heavy workload, etc., and achieves reduced workload, high flexibility, and avoidance The effect of hot work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for replacing the sealing part of the operating oil pipe by using a pulley device;

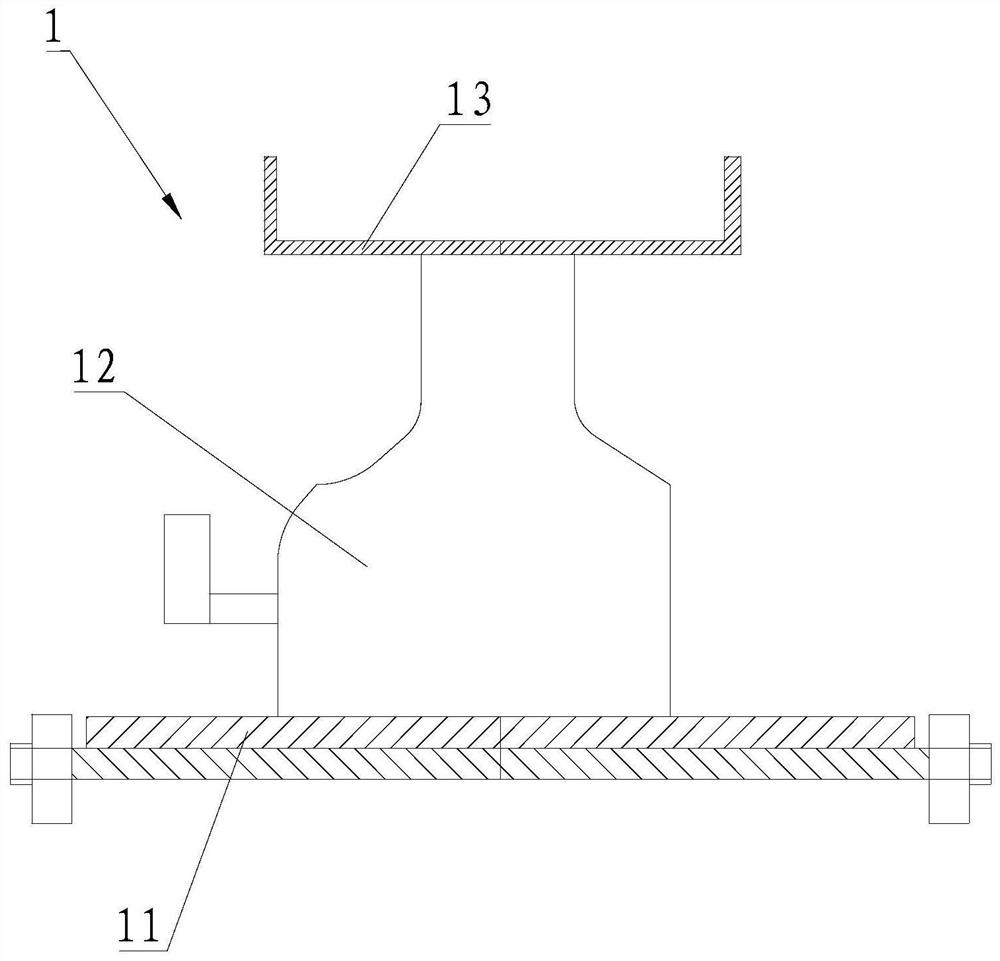

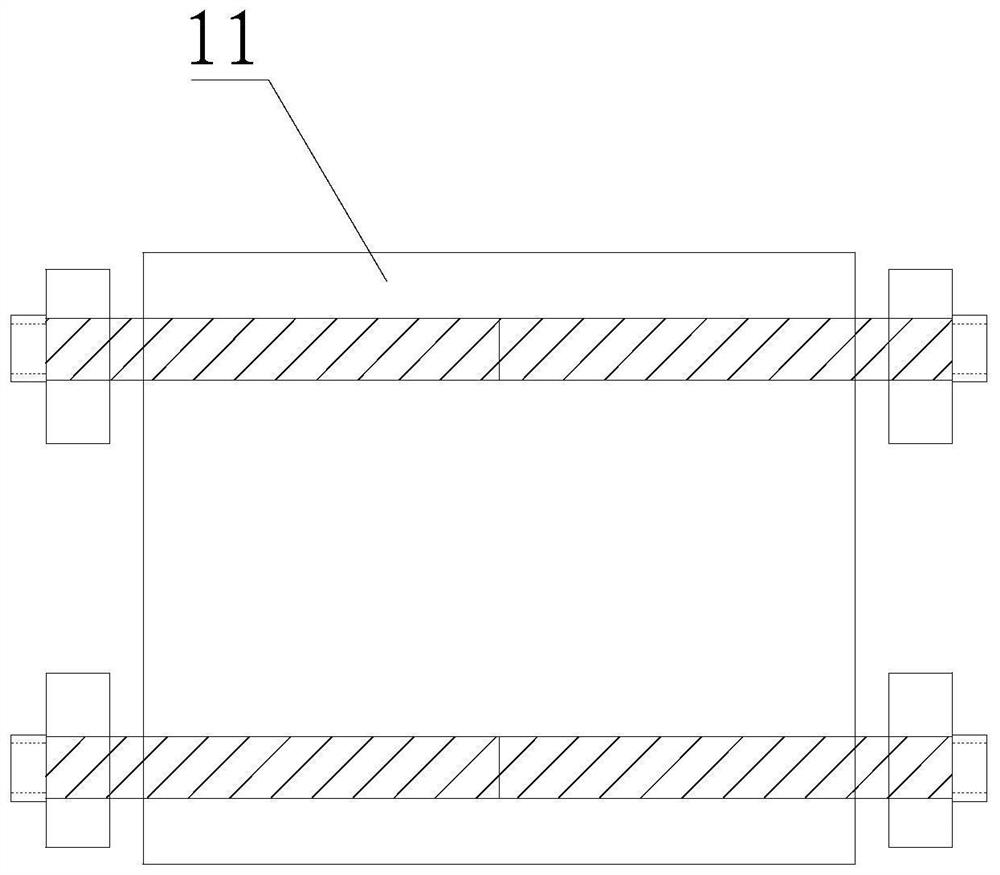

[0042] Described tackle device 1 comprises base 11, jack 12 and tray 13, and described base 11 bottom is provided with roller, and the bottom end of described jack 12 is fixedly connected on the base 11, and described tray 13 is connected to the top of jack 12 in rotation, Both sides of the tray 13 are provided with anti-fall baffles;

[0043] The roller is a bearing roller, and the bottom of the base 11 is fixedly connected with at least two axles, and the inner end of the roller is sleeved on the end of the axle and fixedly connected with the axle;

[0044] The method for replacing the sealing part of the oil pipe by using the pulley device includes the following steps:

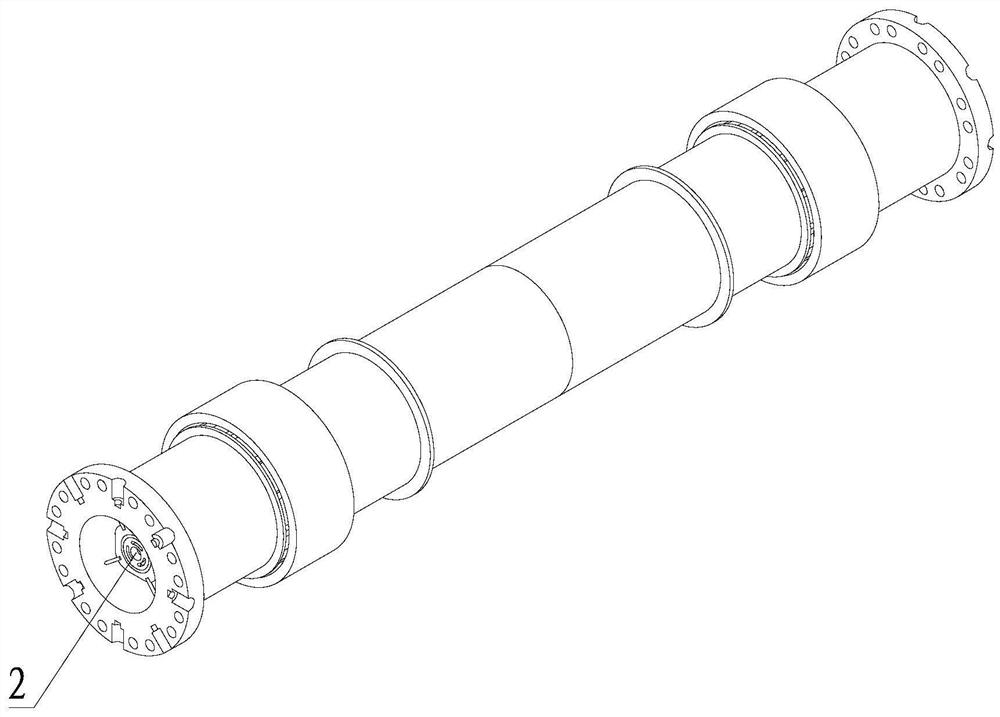

[0045] Step 1: Move the pulley device 1 to the inside of the main shaft, and make it under the operation oil pipe 2, lift the tray 13 through the jack 12, and make the tray 13 support the operation oil pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com