Annular kiln with movable flat top

A mobile and wheel kiln technology, applied in the field of kilns for firing bricks and tiles, can solve the problems of reduced production efficiency, inconvenient operation, low cooling efficiency, etc., to improve sintering yield, easy temperature control, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

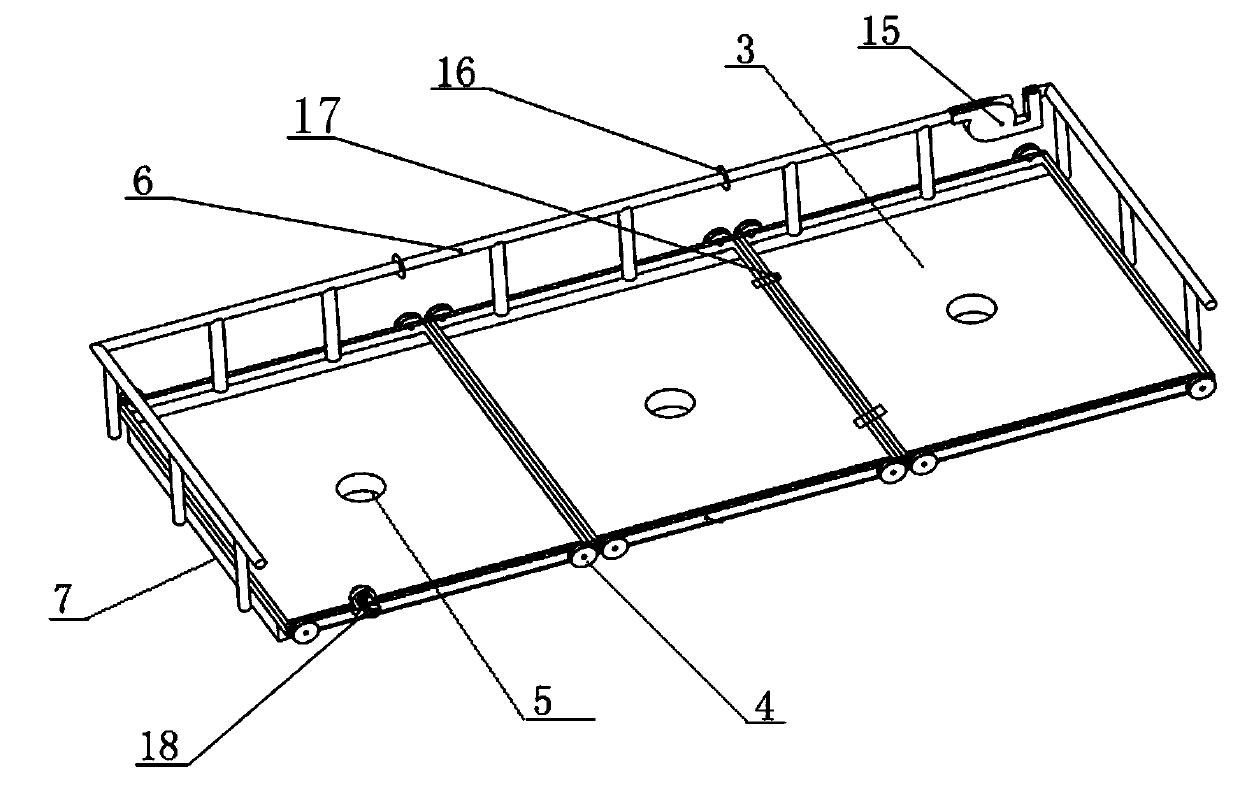

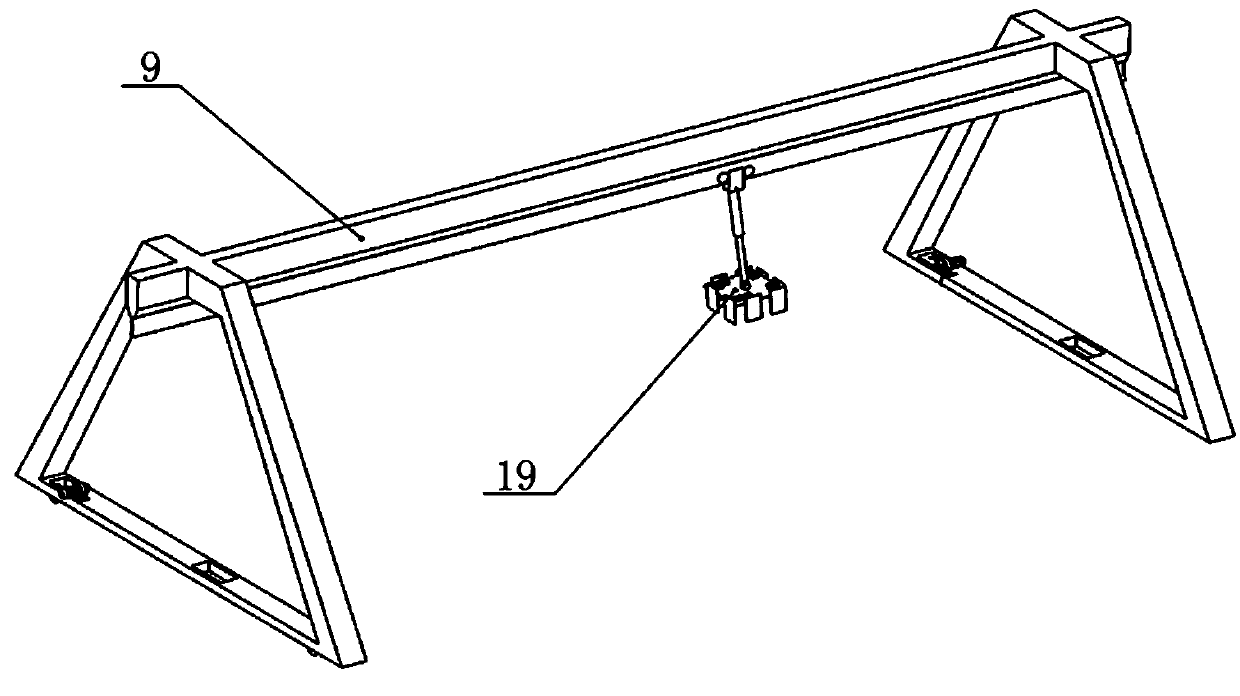

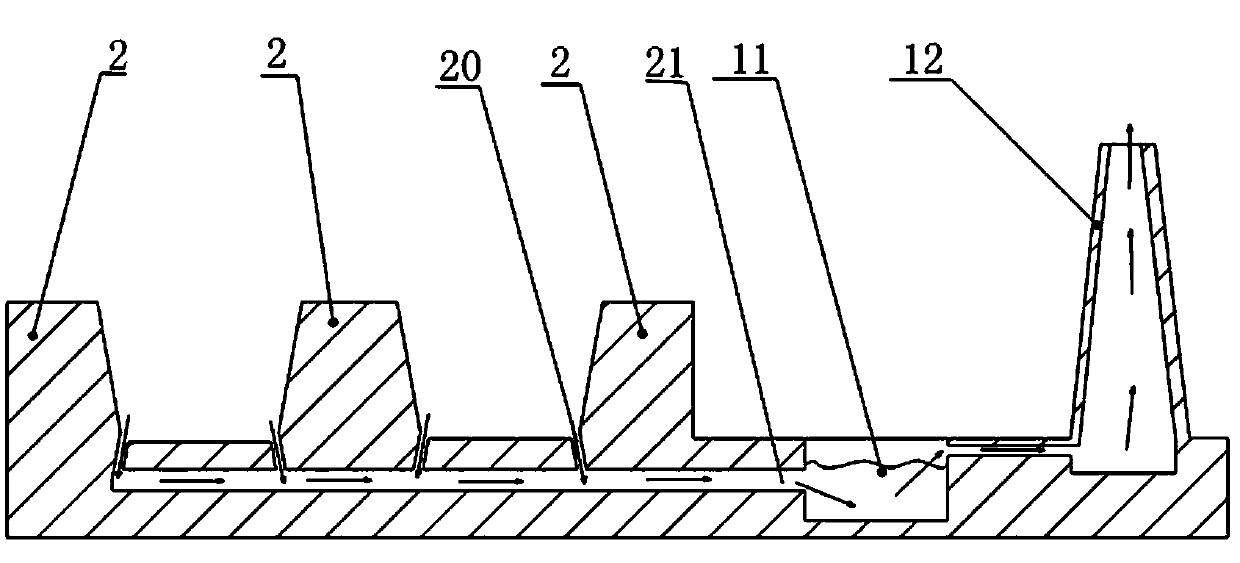

[0034] refer to figure 1 , 2 , a mobile flat-roofed wheel kiln, including a kiln body 1, a kiln roof 3 and kiln walls 2 on both sides. The inner section of the kiln body 1 is an inverted trapezoid to avoid the collapse of the kiln body 1. The kiln roof 3 is movable. Flat roof, which is composed of a plurality of overlapping steel structure frames that can be detachably connected, each steel structure frame is provided with a roller 4, and the roller 4 is matched with the first track 8 set on the upper end of the kiln wall 2; the moving kiln roof 3 The lower end surface is provided with an insulating layer 7, and the kiln roof 3 is provided with a hot gas recovery pipeline 6. An observation hole 5 is arranged in the middle of each steel structure frame of the movable kiln roof 3 .

[0035] A plurality of mobile kiln roofs 3 are detachably connected by a quick connection device 17, and the hot gas recovery pipeline 6 is connected with an exhaust fan 15, which is integrated wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com