The method of replacing the shield tail brush of the ultra-large diameter shield machine under the condition of high water pressure

A technology with super-large diameter and shield-tail brush, which is applied in earthwork drilling, underground chambers, shaft equipment, etc., can solve the problems of difficult replacement of shield-tail brush, and achieve easy, safe, stable and efficient replacement, simple and convenient construction, and ingenious design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

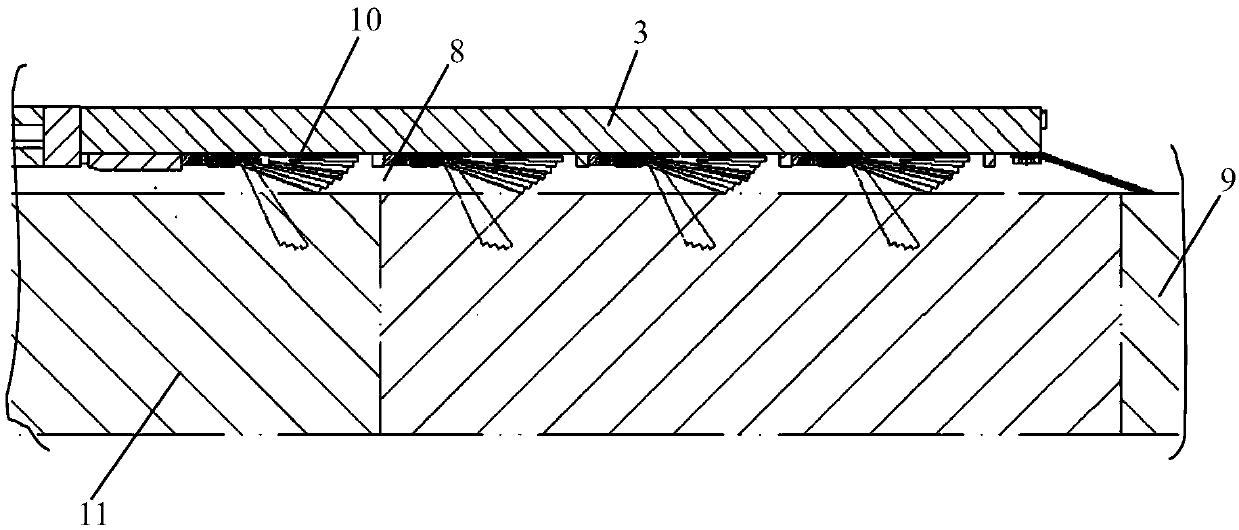

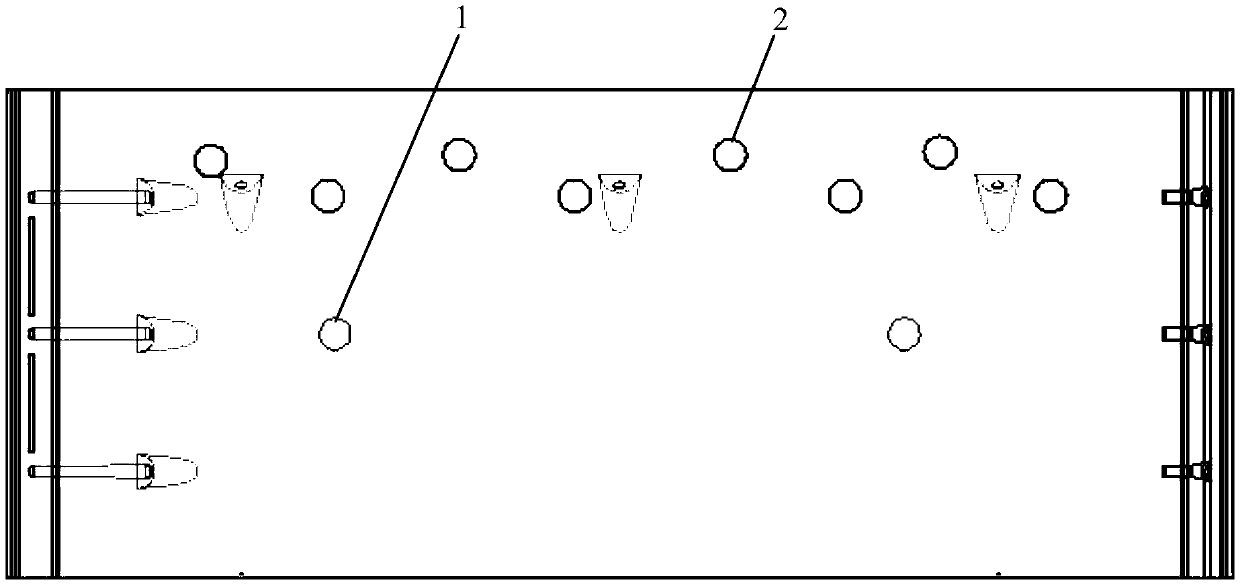

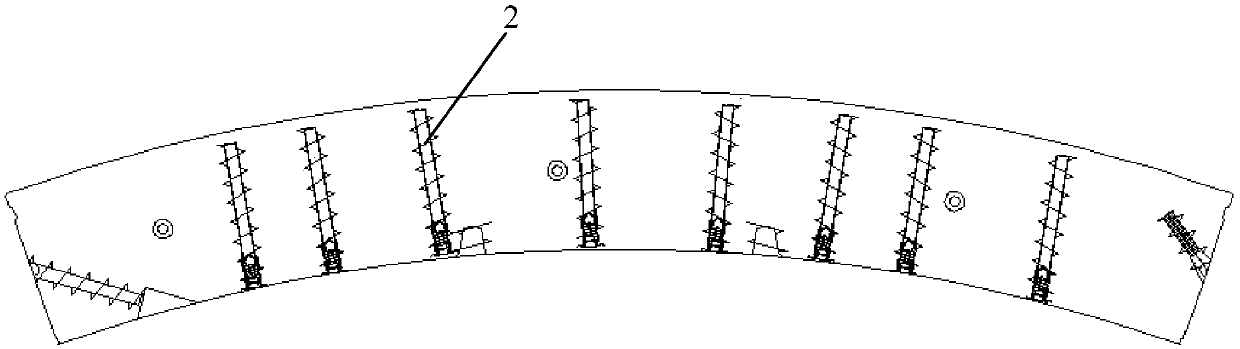

[0056] See Figure 1 to Figure 4 As shown, during the advancement of the shield tunnel, when the shield tail 3 leaks slurry or grease or the grease chamber 8 of the shield tail 3 cannot maintain the pressure, it is necessary to check whether the seal of the shield tail 3 has failed. Take immediate steps to replace the shield tail brush 10. The shield tail brush 10 here can be a shield tail wire brush.

[0057] In a specific embodiment of the present invention, the method for replacing the shield tail brush of an ultra-large diameter shield machine under high water pressure conditions of the present invention mainly has the following steps:

[0058] Step 1: Preparations before replacing the shield tail brush 10

[0059] (1) Determine the replacement position of the shield tail brush 10 when the super-large-diameter shield machine is shut do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com