Automatic drying system of underwater robot

An underwater robot and drying system technology, applied in underwater operation equipment, chemical instruments and methods, ships, etc., can solve the problems of limited absorption, inconvenient operation, etc., achieve good drying, solve the difficulty of replacement, and quickly The effect of changing the desiccant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with specific embodiments. The following examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

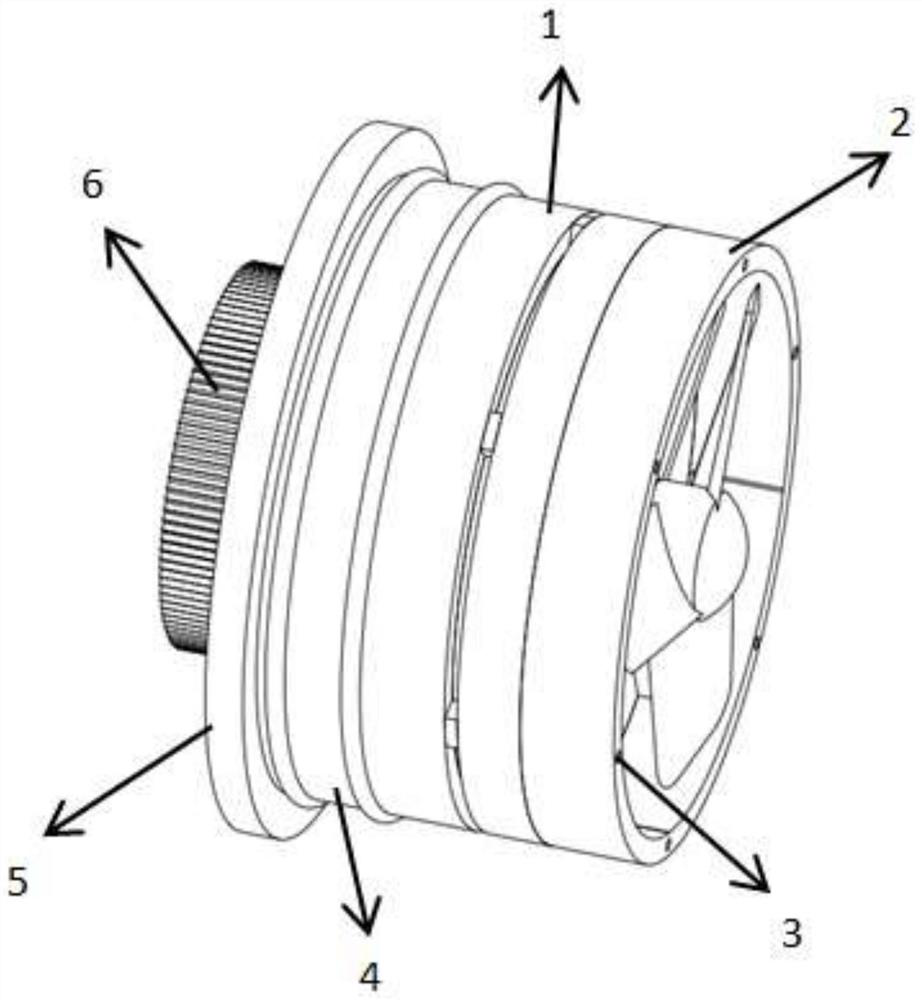

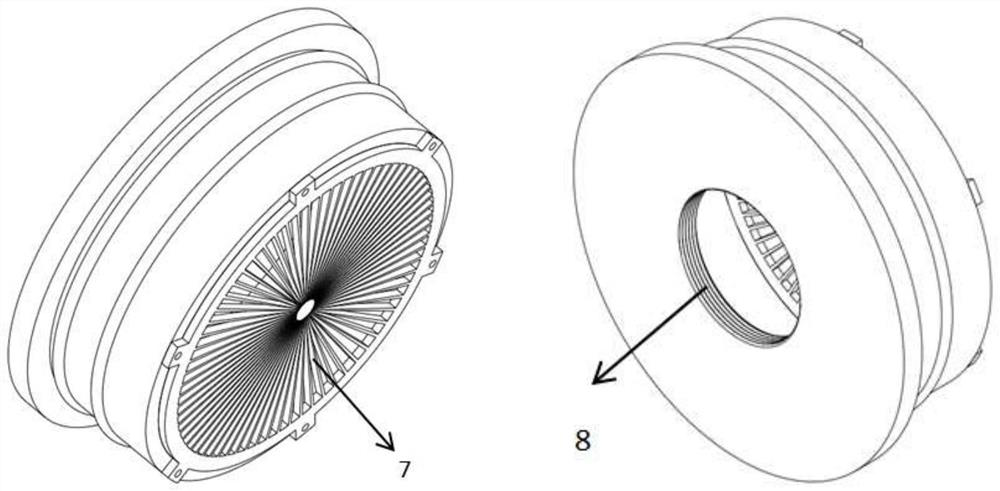

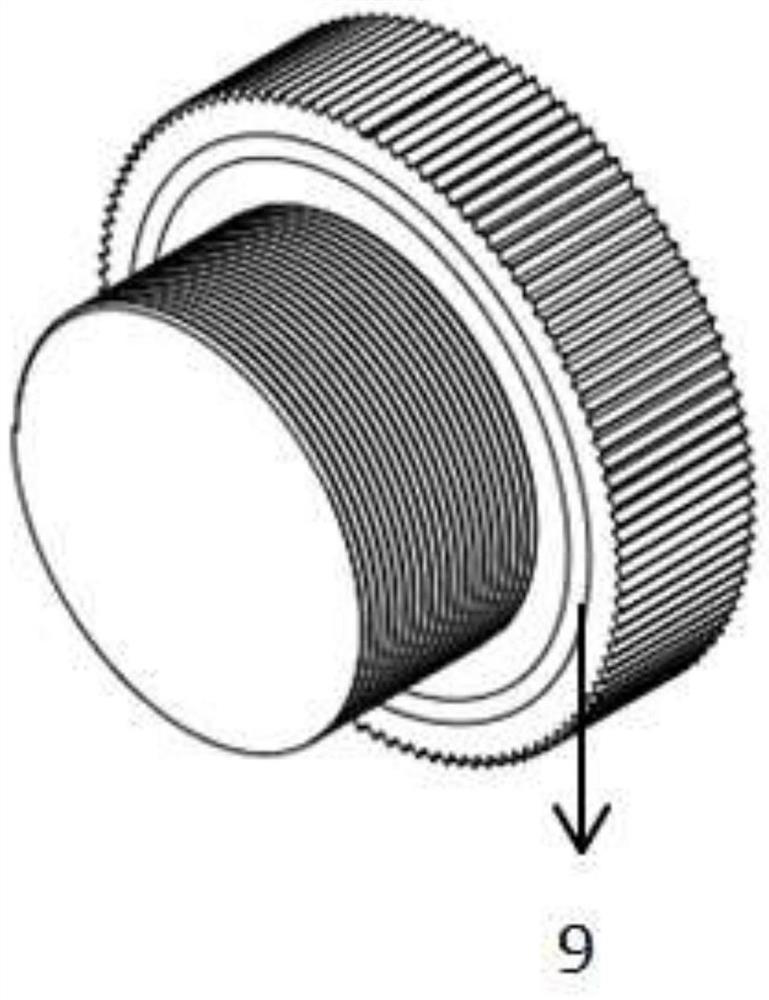

[0027] An automatic drying system for an underwater robot, comprising a heating layer 1, an AC layer 2, a drying layer 4, a partition 5, and waterproof screws; the AC layer 2, the heating layer 1, and the drying layer 4 are sequentially sealed and connected The interior is connected to form a long cylindrical sealing cover on one side of the underwater robot's airtight cabin. The order from outside to inside the cabin is drying layer 4, heating layer 1 and communication layer 2;

[0028] A propeller 14 and a DC motor are installed in the AC layer 2, the propeller 14 is connected to the DC motor, the DC motor is connected to the host computer, and the host computer controls the forward and reverse rotation of the propeller 14 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com