Adjustable steel beam in-place mounting device

An adjustable steel girder technology, which is applied in construction, building construction, and building material processing, can solve problems such as increasing the workload and cost of processing plants or construction sites, increasing the workload of high-altitude fire contact, and affecting construction efficiency. , to achieve the effect of avoiding high-altitude cutting and hot work, facilitating batch processing and production, and improving construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

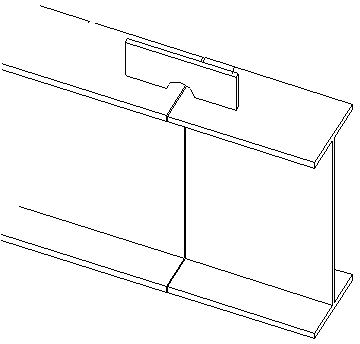

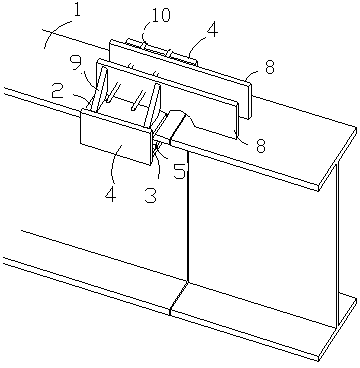

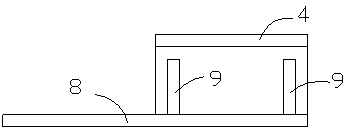

[0030] see figure 2 — Figure 5 , the present invention relates to a device for installing an adjustable steel beam, including a U-shaped jacket, an adjustment assembly, a pull bolt 10 and a seating plate 8, and the U-shaped jacket is formed by an upper splint 2 and a lower splint 3 through a vertical The plate 4 is welded, and a clamping groove that can accommodate the flange plate of the steel beam is formed between the upper splint 2 and the lower splint 3, and an adjusting bolt hole is provided on the lower splint 3; the adjusting assembly includes a backing plate 5, an adjusting Screw rod 7, adjusting nut 6, the backing plate 5 is arranged between the upper splint 2 and the lower splint 3 of the U-shaped jacket through the adjusting screw 7 and the adjusting nut 6, and the adjusting screw 7 and the backing plate 5 are welded by a perforated plug ; The seating plate 8 is a rectangular slat with a pull bolt hole, which is welded with the upper splint 2 of the U-shaped jac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com