Centralized control oil replenishment system and decentralized oil replenishment method

A control system and centralized control technology, applied in control/adjustment system, liquid level control, non-electric variable control, etc., can solve problems such as low work efficiency, easy fatigue, heatstroke, and excessive oil replenishment, so as to improve work efficiency and avoid High temperature operation, the effect of ensuring the safety of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

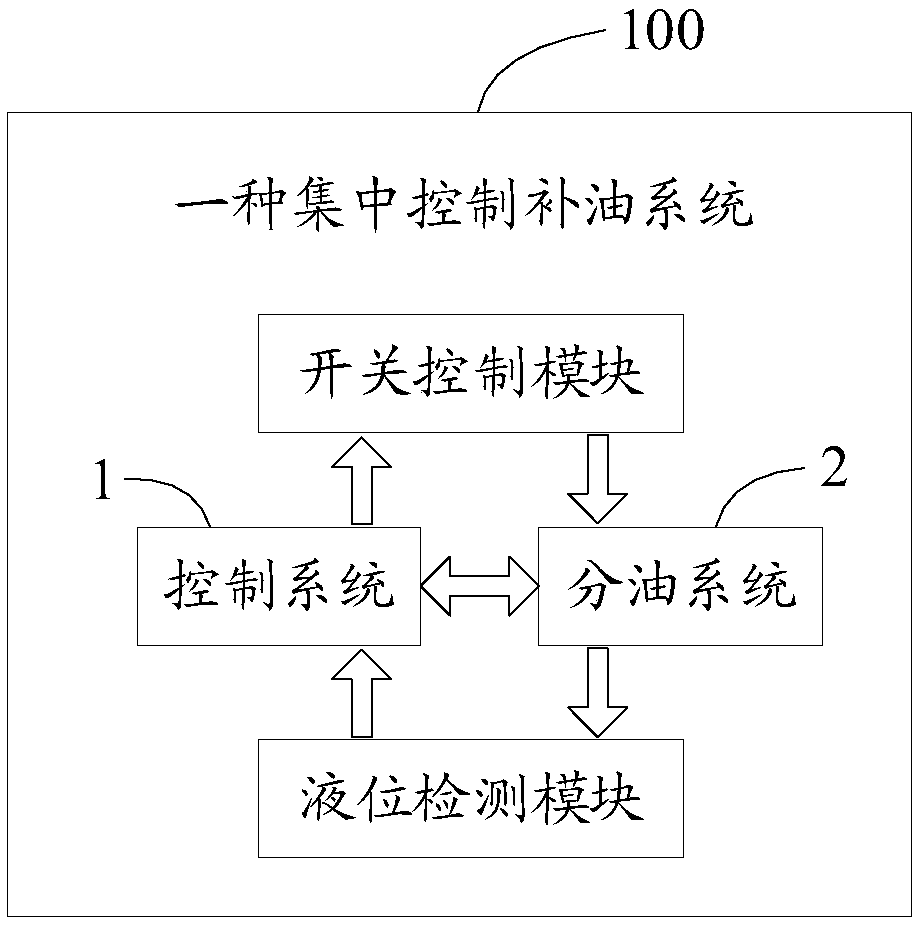

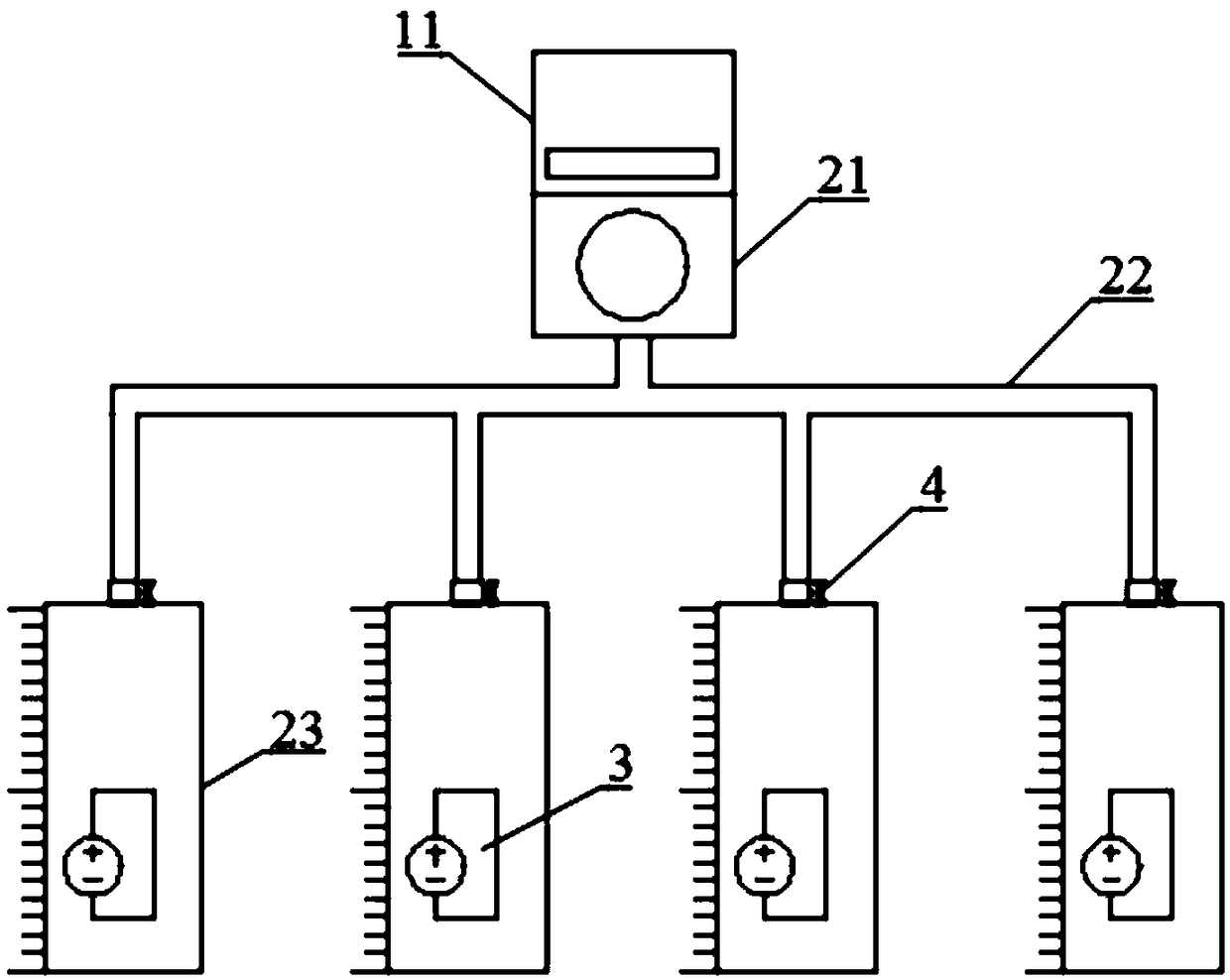

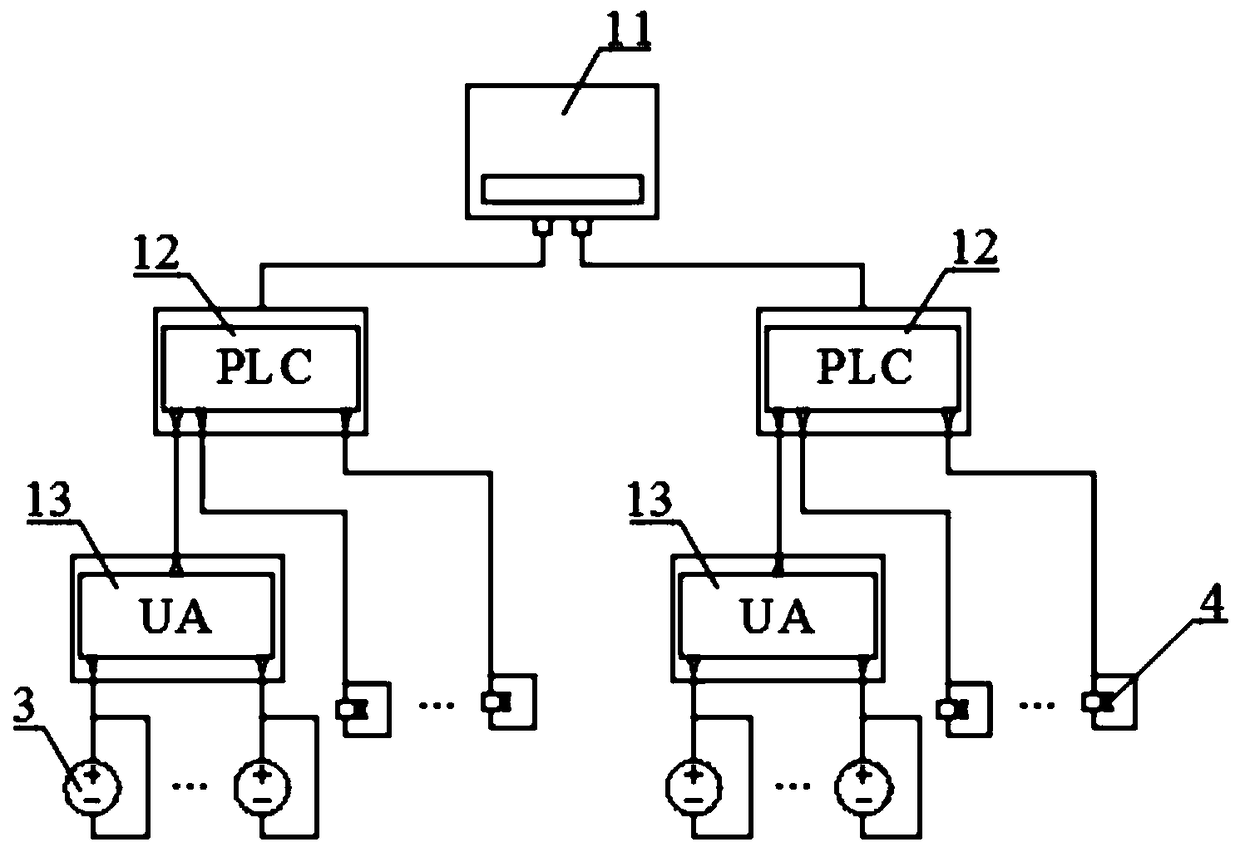

[0069] Please refer to Figure 1 to Figure 8 , Embodiment 1 of the present invention is:

[0070] A centralized control oil supply system 100, including a control system 1, an oil distribution system 2, a liquid level transmitter 3 and a solenoid valve 4, the oil distribution system 2 includes a total oil tank 21, an oil pipeline 22 and an oil distribution tank 23; the control System 1 includes a control terminal 11, a PLC control module 12 and an analog input module 13, the control terminal 11 is connected to the PLC control module 12, the PLC control module 12 is connected to the analog input module 13, and the analog input module 13 is connected to the liquid level transmitter The device 3 is connected, and the PLC control module 12 is connected with the solenoid valve 4;

[0071] Wherein, the total oil tank 21 is connected with the oil distribution tank 23 through the oil pipeline 22, the solenoid valve 4 is arranged in the oil pipeline 22, the liquid level transmitter 3 ...

Embodiment 2

[0078] Please refer to Figure 9 to Figure 10 , the second embodiment of the present invention is:

[0079] A method for dispersing and replenishing oil, comprising the steps of:

[0080] S1. The liquid level transmitter detects the oil level signal in the oil distribution tank, converts the oil level signal into a current signal, and sends the current signal to the control system, wherein, in this embodiment, the oil level signal is converted into a current signal Specifically: the oil level signal and the current signal have a linear relationship, when the oil level signal is 0 meters, the current signal is 4mA, and when the oil level signal is 2 meters, the current signal is 20mA;

[0081] S21. The analog input module receives the current signal, converts the current signal into a PLC control signal, and sends the PLC control signal to the PLC control module, wherein, in this embodiment, the conversion of the current signal into a PLC control signal is specifically: curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com