Manufacturing method of cobalt-chromium-molybdenum alloy spherical powder

A cobalt-chromium-molybdenum alloy and spherical powder technology, which is applied in the field of preparation of cobalt-chromium-molybdenum alloy raw material powder, can solve the problems of low yield and high energy consumption, achieve uniform alloy composition, avoid high-temperature operation, and reduce production energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of cobalt-chromium-molybdenum alloy spherical powder, comprising the following steps:

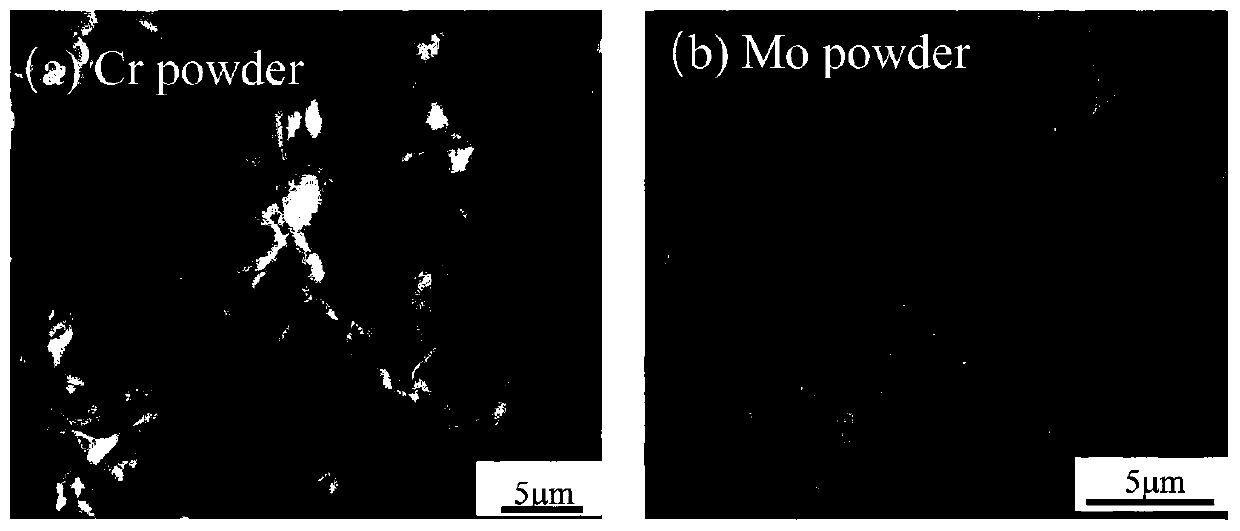

[0035] (1) 20g polyurethane, 63g cobalt metal powder, 30g chromium metal powder and 7g molybdenum metal powder are fully mixed in absolute ethanol to obtain a mixed slurry;

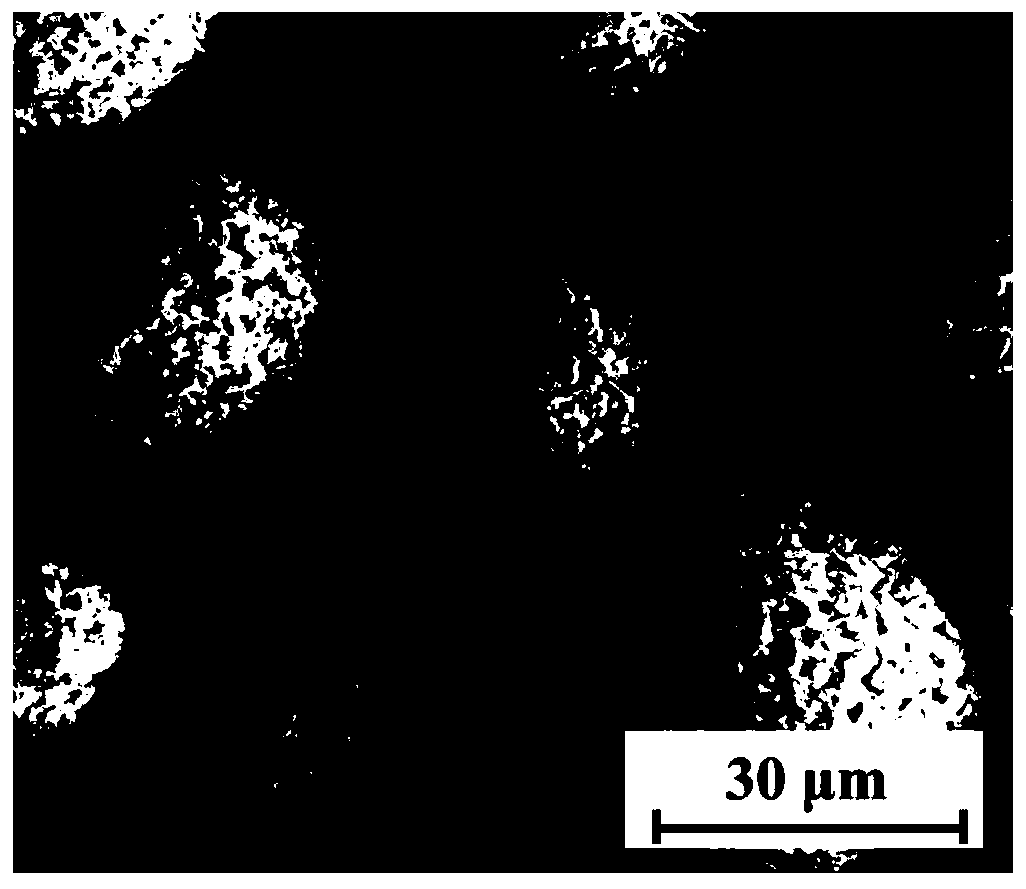

[0036] (2) the mixed slurry that step (1) obtains is transferred in the container, is sent in the atmosphere spray drier by peristaltic pump, and spray drying atmosphere is nitrogen (N 2 ), the flow rate of the slurry is 5L / min, and the inlet temperature is 180°C, and pelletizing is carried out to obtain primary spherical particles;

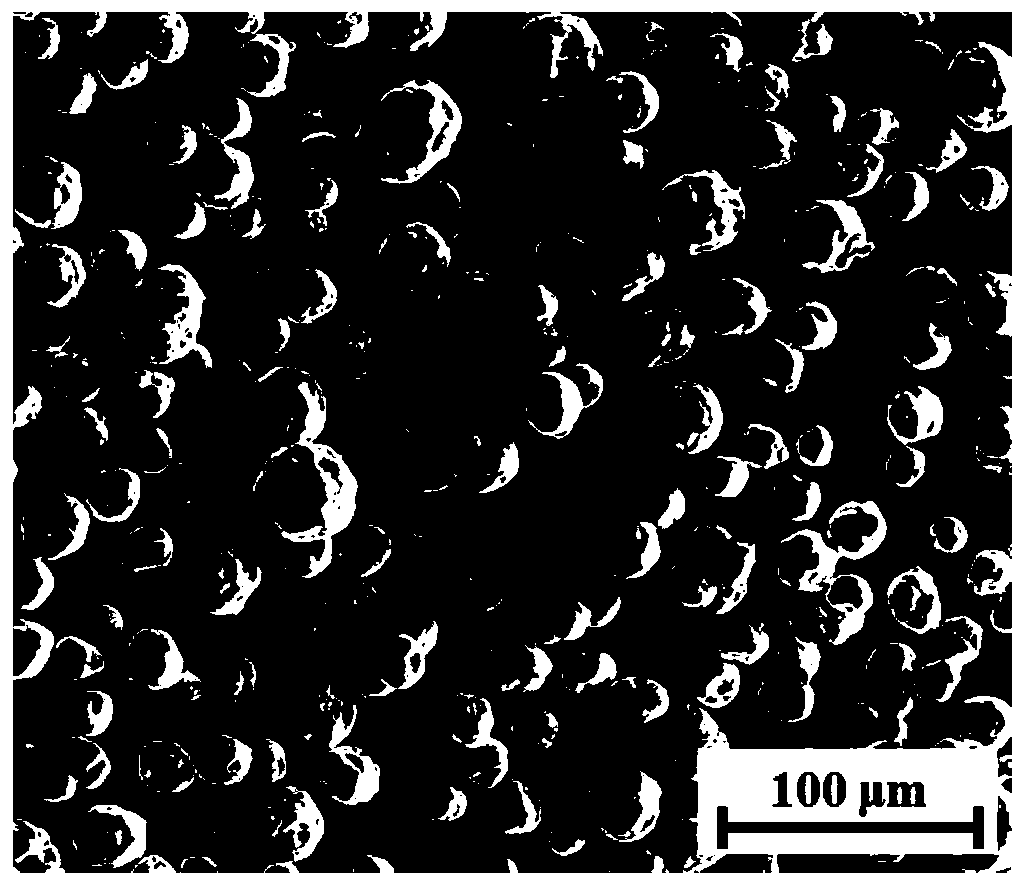

[0037] (3) The primary spherical particles obtained in step (2) are transferred to a 150ml crucible, put into an atmosphere reaction furnace for thermal degreasing, the thermal degreasing atmosphere is argon (Ar), the reaction temperature is 400°C, and the reaction time is 5h, Obtain spherical metal particles;

Embodiment 2

[0044] A preparation method of cobalt-chromium-molybdenum alloy spherical powder, comprising the following steps:

[0045] (1) 10g polystyrene, 30g cobalt metal powder, 30g chromium metal powder and 30g molybdenum metal powder are fully mixed in absolute ethanol to obtain a mixed slurry;

[0046] (2) the mixed slurry that step (1) obtains is transferred in the container, is sent in the atmosphere spray drier by peristaltic pump, and spray drying atmosphere is nitrogen (N 2 ), the flow rate of the slurry is 50L / min, and the inlet temperature is 200°C, and pelletizing is carried out to obtain primary spherical particles;

[0047] (3) The primary spherical particles obtained in step (2) are transferred to a 150ml crucible, put into an atmosphere reaction furnace for thermal degreasing, the thermal degreasing atmosphere is argon (Ar), the reaction temperature is 600°C, and the reaction time is 3h, Obtain spherical metal particles;

Embodiment 3

[0055] A preparation method of cobalt-chromium-molybdenum alloy spherical powder, comprising the following steps:

[0056] (1) 30g polyacrylate, 50g cobalt metal powder, 25g chromium metal powder and 25g molybdenum metal powder are fully mixed in absolute ethanol to obtain a mixed slurry;

[0057] (2) the mixed slurry that step (1) obtains is transferred in the container, is sent in the atmosphere spray drier by peristaltic pump, and spray drying atmosphere is nitrogen (N 2 ), the flow rate of the slurry is 20L / min, and the inlet temperature is 160°C, and pelletizing is carried out to obtain primary spherical particles;

[0058] (3) The primary spherical particles obtained in step (2) are transferred to a 150ml crucible, put into an atmosphere reaction furnace for thermal degreasing, the thermal degreasing atmosphere is argon (Ar), the reaction temperature is 500°C, and the reaction time is 5h, Obtain spherical metal particles;

[0059] (4) Add 100g of calcium oxide (CaO) to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com