A method for binding planar small-size sputtering targets used in testing machines

A sputtering target and small-sized technology, which is applied in sputtering coating, metal material coating process, vacuum evaporation coating, etc., can solve the problem that the flatness of the target cannot meet the requirements of use, the deformation of the back plate is heated, and the binding Temperature increase and other issues, to achieve the effect of low cost, high failure temperature, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] A method for binding a planar small-size sputtering target used in a testing machine, comprising the following steps:

[0054] Step 1: Pretreatment of copper backplane 1 and target embryo 4:

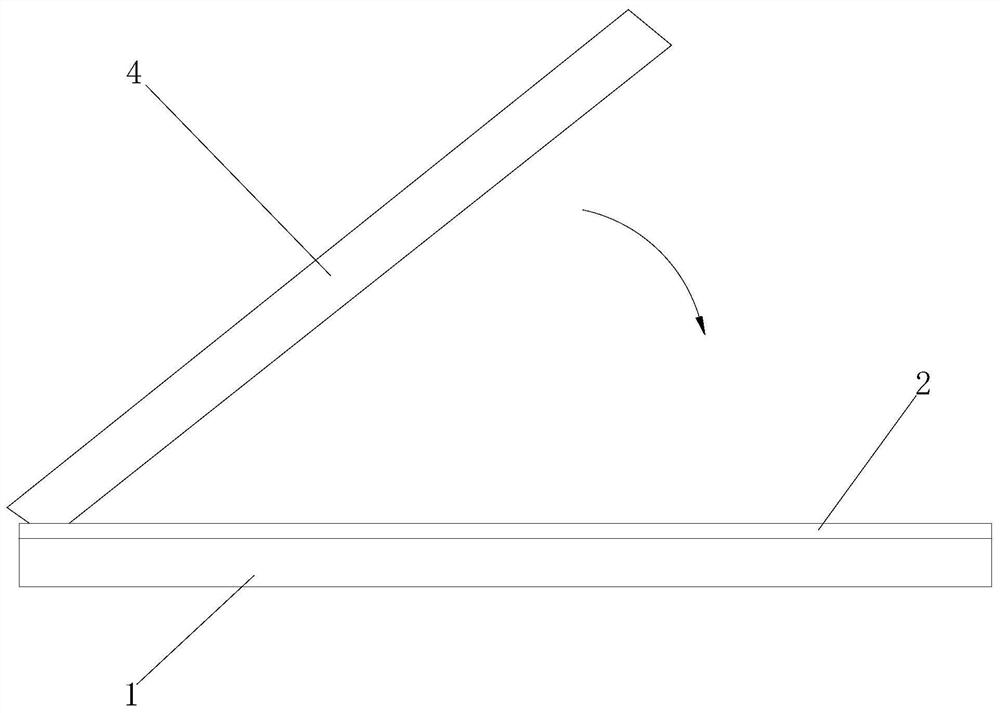

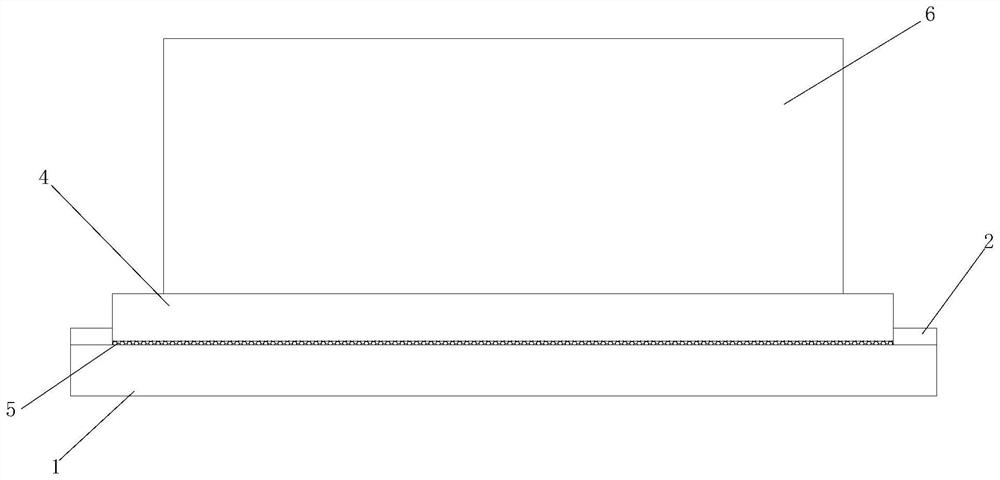

[0055] a) Sandblasting on the binding surface: sandblasting the binding surfaces of the copper backplane 1 and the target embryo 4 respectively, sandblasting conditions: compressed air 5kg, sand type: 16# white corundum, area: the binding surface of the target embryo Full area, roughness: Ra3.2-12.5; remove scale, improve the surface roughness of the target, increase the contact area between the high temperature glue and the copper backplane 1 and the target blank 4, which is beneficial to improve the bonding force;

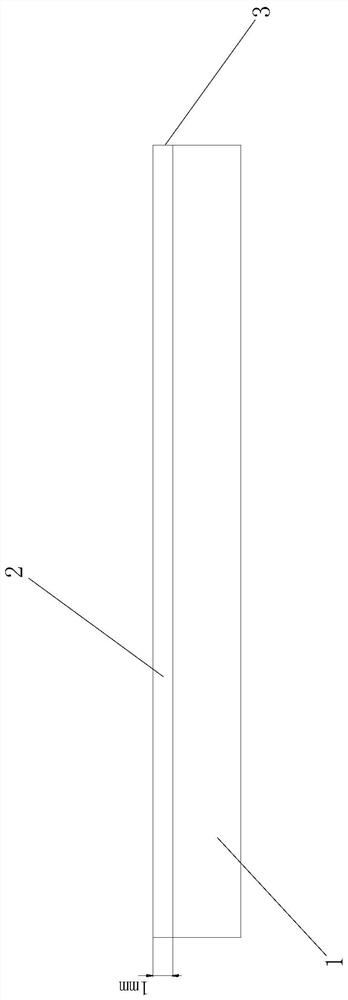

[0056] b) A groove with a depth of more than 1 mm is surrounded by adhesive tape 3 around the binding surface of the copper backplane 1, so that the copper backplane 1 and the adhesive tape 3 form a glue pool 2 after binding, and the high-temperature glue will not fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com