Air conditioner heat exchanger automatic pipe penetrating method and production line without pipe supplementing procedure

A heat exchanger and production line technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to improve production efficiency, inability to achieve full automation, etc., and achieve simplified, easy to implement, and shortened length of return and tray methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Such as figure 2 shown.

[0037] An automatic pipe threading method for an air-conditioning heat exchanger that does not require a pipe replenishment process, comprising the following steps:

[0038] First, transfer the stack of fins together with the pallet from the stamping station of the punch press to the pipe threading table;

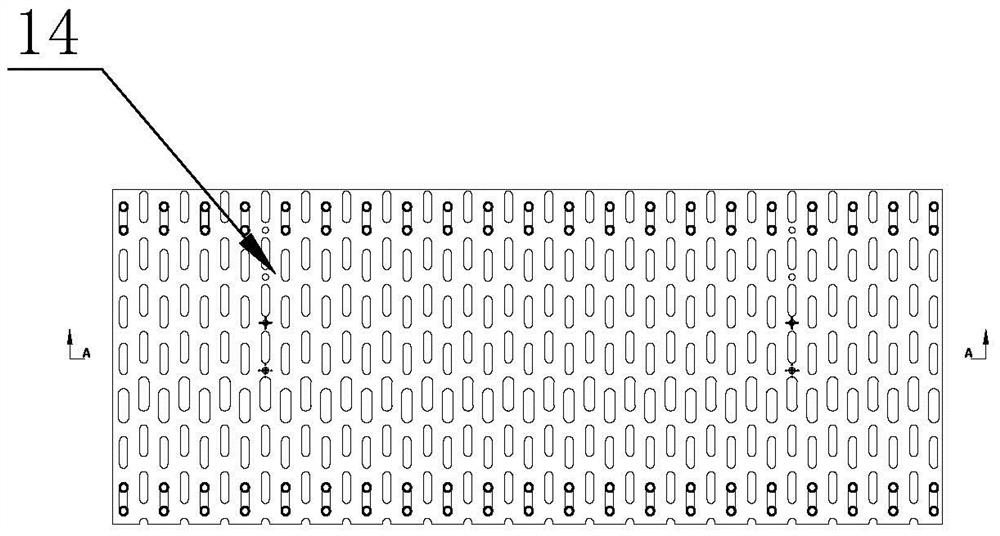

[0039] Secondly, insert a positioning pin for each row of fins, the upper end of each positioning pin is connected with the connecting plate, all positioning pins are inserted together, and a pin or a pin with a hole is installed at both ends of the connecting plate at the same time;

[0040]Third, when the stack of fins moves to the first pipe-passing station, the lifting mechanisms set on both sides of the production line rise to insert the pin holes or pins installed on the anti-lifting mechanism into the pins or belts on both sides of the positioning pin connecting plate. In the hole pin rod, the longitudinal positioning of the fin st...

Embodiment 2

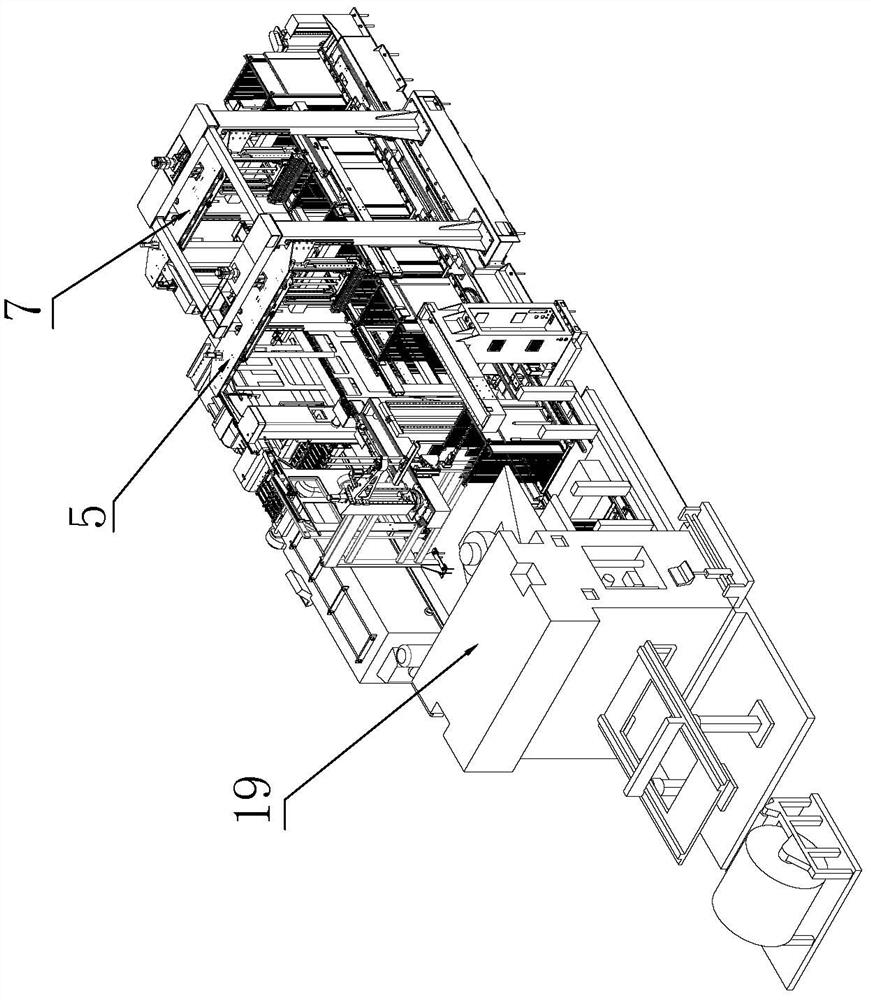

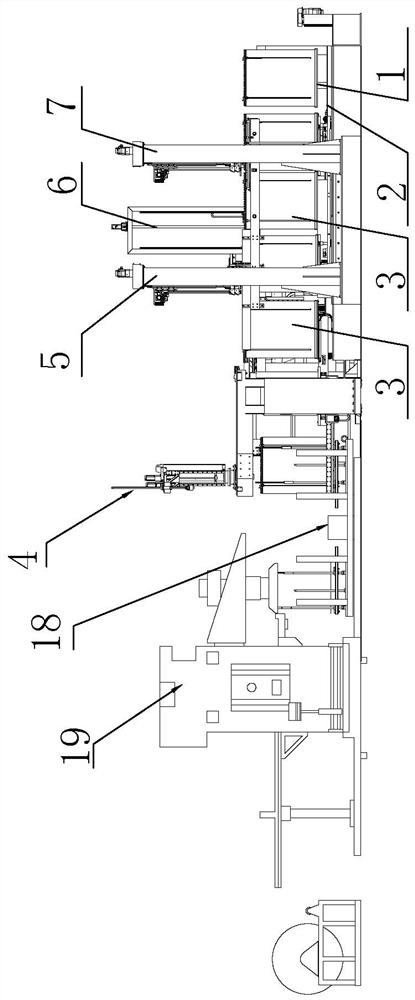

[0045] Such as Figure 1-10 shown.

[0046] An automatic pipe-piercing production line for air-conditioning heat exchangers that does not require pipe replenishment. Its three-dimensional structure is as follows: figure 1 As shown, it includes a pipe threading workbench 1. The pipe threading workbench 1 is installed on the guide rail 2 and can move according to the production rhythm under the traction of the traction mechanism. A pallet return mechanism is installed at the end of the guide rail, and the pallet return mechanism is installed on the guide rail. The lower part, in order to transport the tray from the end of the guide rail to the beginning of the guide rail, and receive the fin stack 3 on the punch press 19 after rising; the guide rail 2 is sequentially installed with a positioning pin insertion device 4, a first pipe threading device 5, a positioning Needle pulling device 6, second tube threading device 7 and tray return mechanism 8, such as figure 2 , 3 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com