Hacksaw frame

A technology of hacksaw and rack head, which is applied in the field of hand tools and can solve the problem of single working mode of hacksaw rack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings of the description.

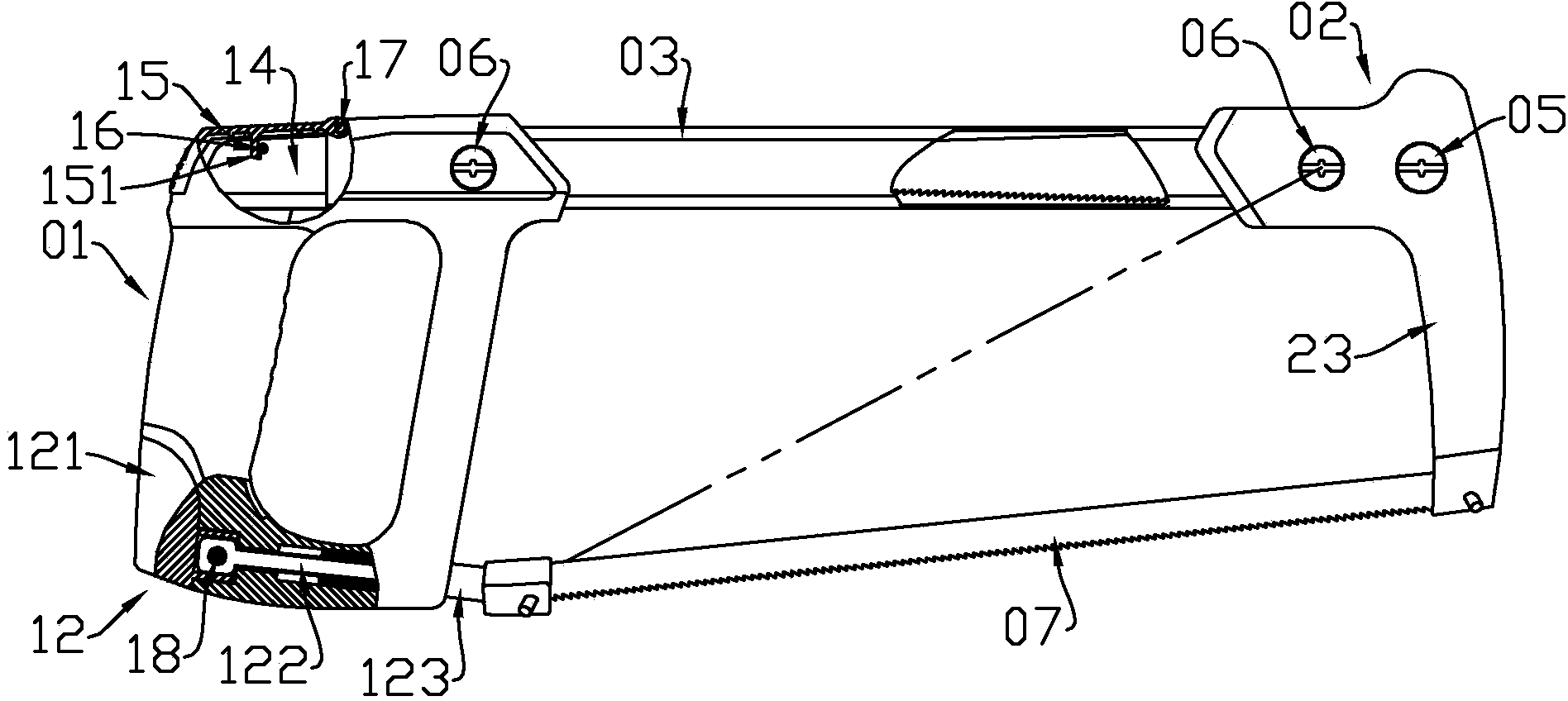

[0041] Hacksaw frame of the present invention, as figure 1 shown, which includes:

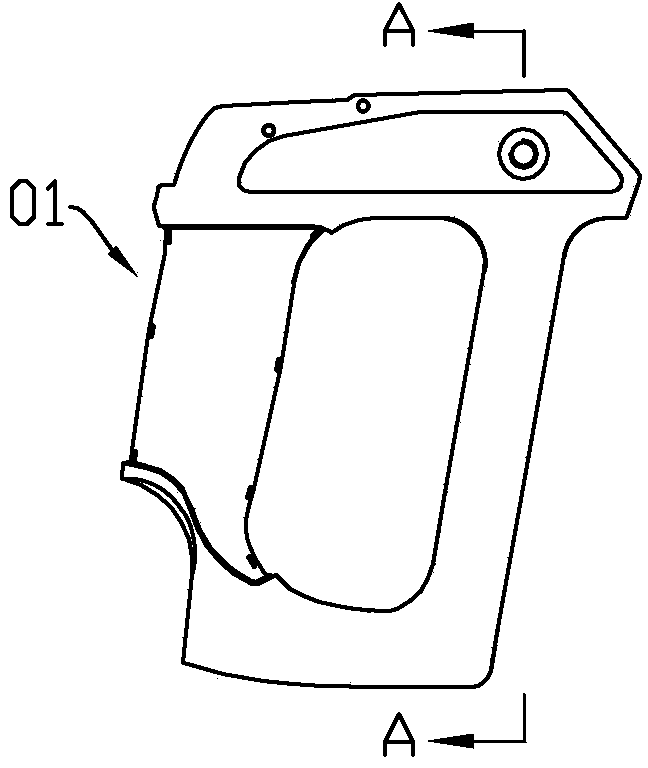

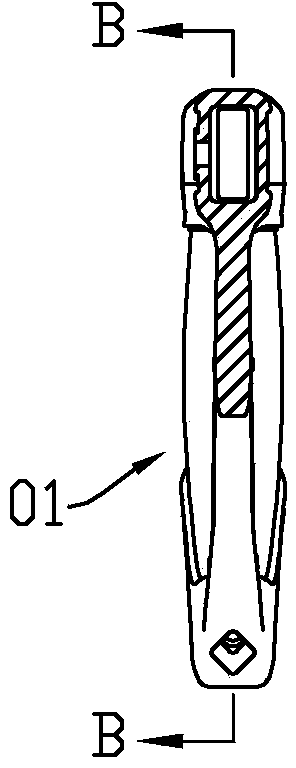

[0042] Figure 2-4 As shown in the handle 01, its upper part has an insertion hole 11 facing forward, and its lower part has a tensioning assembly 12;

[0043] Figure 9-13 The rack head 02 shown has a rearward jack 21 on its upper part and a hanging column 22 on its lower part;

[0044] Figure 14-15 The shown bow beam 03 is tubular and forms an accommodating cavity 31 inside, and its two ends are respectively inserted into the jack 11 on the handle 01 and the jack 21 on the frame head 02. Therefore, when the hacksaw blade 07 is assembled on the hanging After the column 22 and the tensioning assembly 12 are tightened by the tensioning assembly 12, a stable structure is formed and can work.

[0045] As a further improvement and supplement to the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com