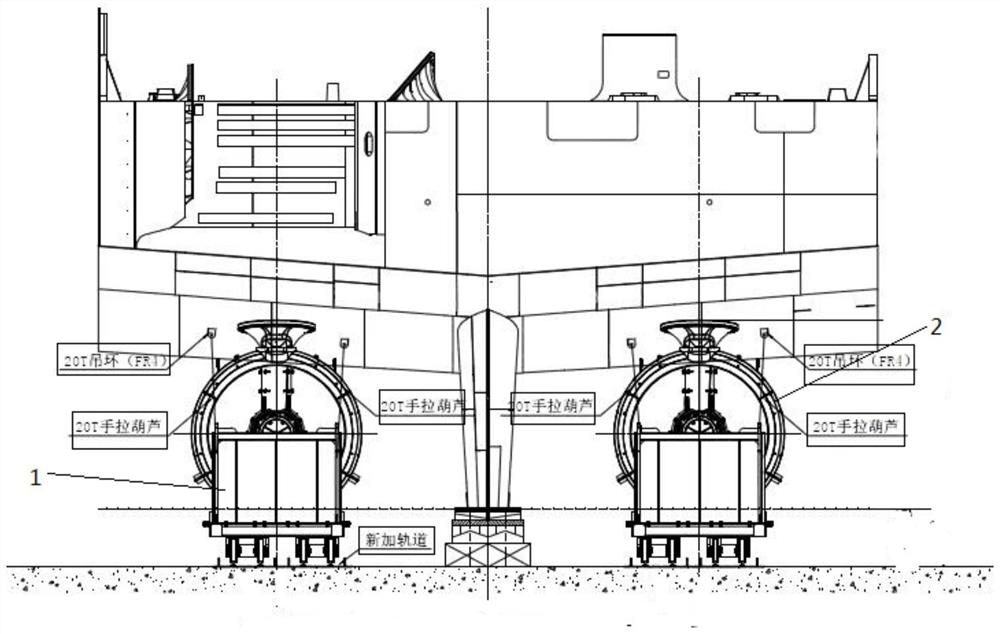

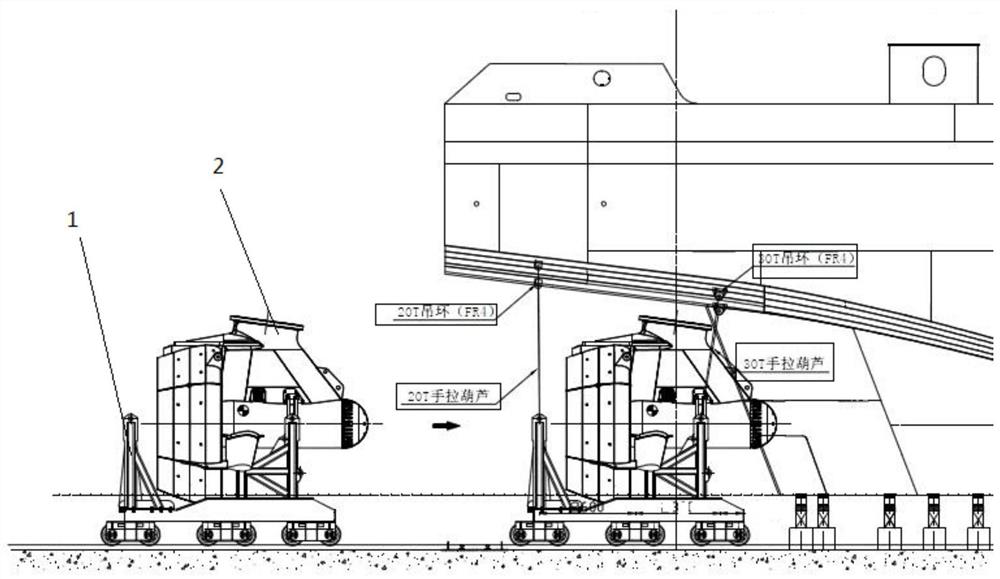

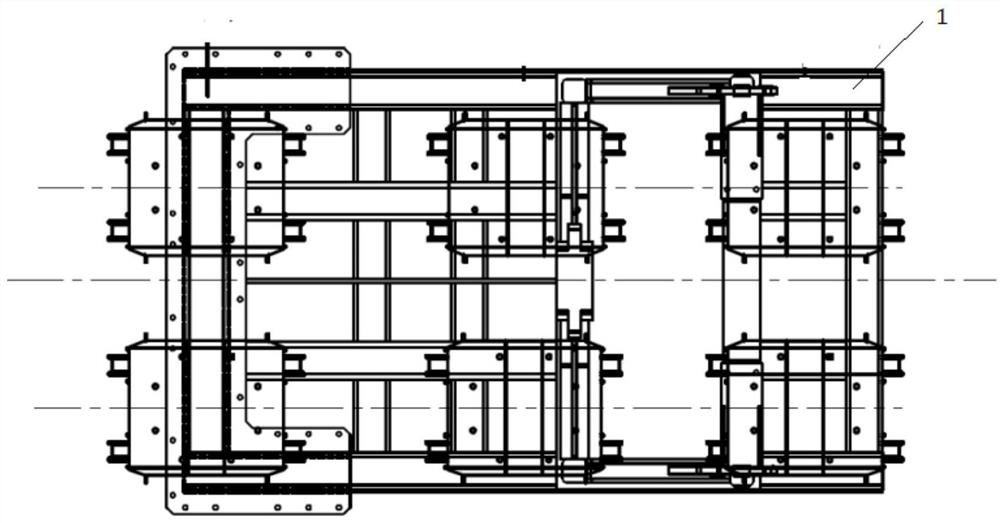

Engineering ship full-rotation main thruster installation process

An installation process and full rotation technology, applied in the direction of ships, etc., can solve the problems of heavy non-routine installation and high main thruster height, and achieve the effect of ensuring construction quality and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] The installation process of the full-slewing main thruster of an engineering ship of the present invention is characterized by including the following steps:

[0063] Step 1: Make a suitable main thruster base, which includes a flange and a cylindrical web;

[0064] Step 2: Install the main booster base:

[0065] (1) Before the flange is hoisted, use the sample punch to make the cross center line on the flange panel, and at the same time make the bottom cross center line punch point on the round pass of the flange. Spot weld an angle steel at each of the upper and lower flange ports, find the upper and lower center points on the angle steel according to the punching point, and drill holes on the punching point;

[0066] (2) Draw the ground sample line. According to the theoretical data, draw the center line of the upper flange plate and the cross center line of the lower cylinder on the berth. If the hull shell has not been drilled at this stage, simple openings can be made in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com