Imaging lens, camera module and electronic equipment

A technology of imaging lens and camera module, which is applied in the direction of optical components, optics, instruments, etc., can solve the problems of lens focal length limitation and difficult demand, and achieve the effect of shortening the lateral distance, saving space, and increasing the cost of the spacer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

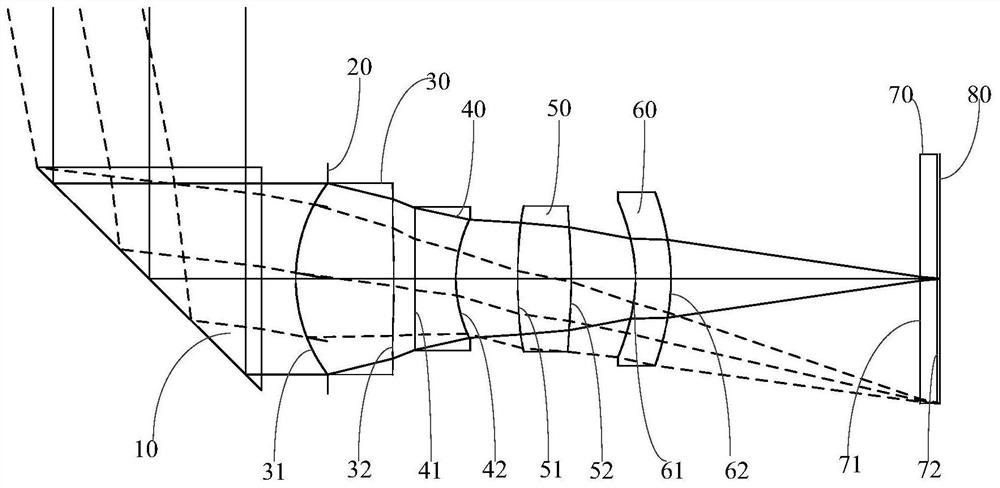

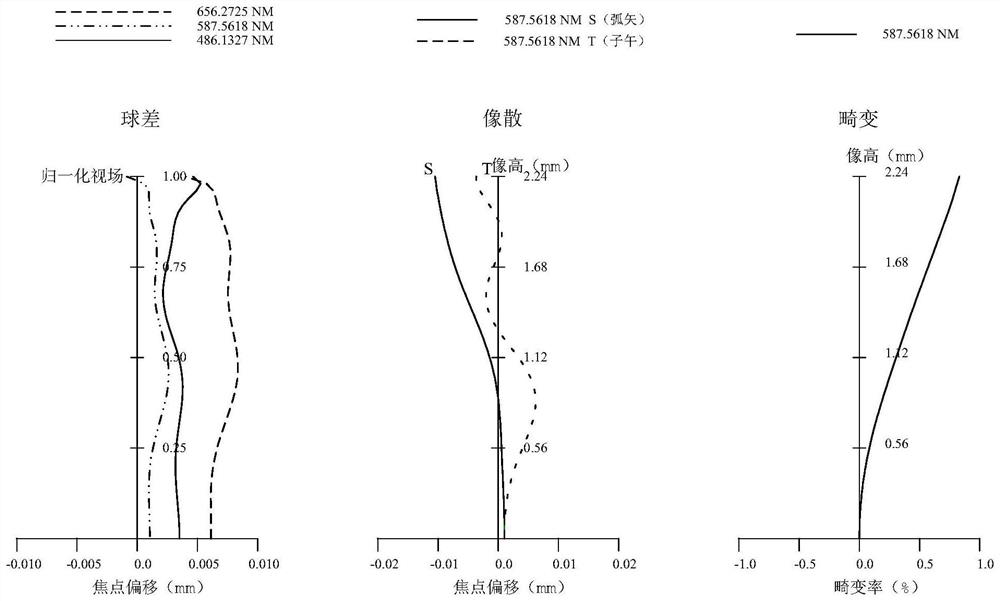

[0050] see figure 1 and figure 2 as shown, figure 1 The solid line through the lens indicates the central field of view, and the dashed line through the lens indicates the 1.0 field of view. According to Embodiment 1 of the present invention, an imaging lens is provided, and the imaging lens includes a prism 10, a first lens 30, a second lens 40, a third lens 50, and a fourth lens 60 arranged in sequence from the object side to the image side .

[0051] Wherein, the prism 10 is in the shape of a right triangle, the hypotenuse of the right triangle is set away from the first lens 30, and the two right angles of the right triangle are respectively set parallel to the optical axis and perpendicular to the optical axis, the prism 10 can make light deflection, and can form a folded periscope structure with the first lens 30, the second lens 40, the third lens 50 and the fourth lens 60, which can effectively utilize the space for installing the structure of the imaging lens and ...

Embodiment 2

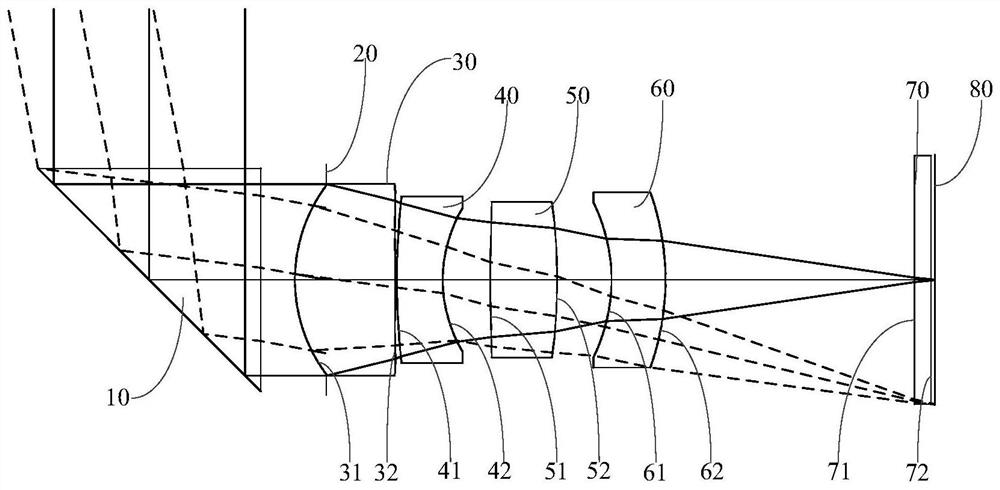

[0077] see image 3 with Figure 4 as shown, image 3 The solid line through the lens indicates the central field of view, and the dashed line through the lens indicates the 1.0 field of view. According to Embodiment 2 of the present invention, an imaging lens is provided, the structure of the imaging lens is basically the same as that in Embodiment 1, the difference is:

[0078] The object side surface 41 of the second lens 40 in this embodiment is convex at the optical axis and at the circumference.

[0079] The object side surface 51 of the third lens 50 is concave at the circumference.

[0080] The imaging lens in this embodiment satisfies the following conditional formula:

[0081] 0.4mm

[0082] 1.0

[0083] 1.51.6mm;

[0084] 2.0

[0085] 1.0mm<(T12+T23+T34)=1.866mm<3.0mm;

[0086] 0.05

[0087] 4

[0088] 5.5

[0089] Table 3 is a characterist...

Embodiment 3

[0099] see Figure 5 with Image 6 as shown, Figure 5 The solid line through the lens indicates the central field of view, and the dashed line through the lens indicates the 1.0 field of view. According to Embodiment 3 of the present invention, an imaging lens is provided, the structure of the imaging lens is basically the same as that in Embodiment 1, the difference is:

[0100] The object side surface 41 of the second lens 40 in this embodiment is convex at the optical axis and at the circumference.

[0101] The imaging lens in this embodiment satisfies the following conditional formula:

[0102] 0.4mm

[0103] 1.0

[0104] 1.51.6mm;

[0105] 2.0

[0106] 1.0mm<(T12+T23+T34)=1.448mm<3.0mm;

[0107] 0.05

[0108] 4

[0109] 5.5

[0110] Table 5 is a characteristic table of the imaging lens of this embodiment, wherein each data is obtained by using v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com