Split type upper elastic sheet structure, driving device and electronic equipment

A split-type, shrapnel technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of occupying the space of the motor and failing to effectively use the internal space of the motor, so as to increase reliability and stability and ensure the assembly process Sexuality, the effect of increasing the available space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

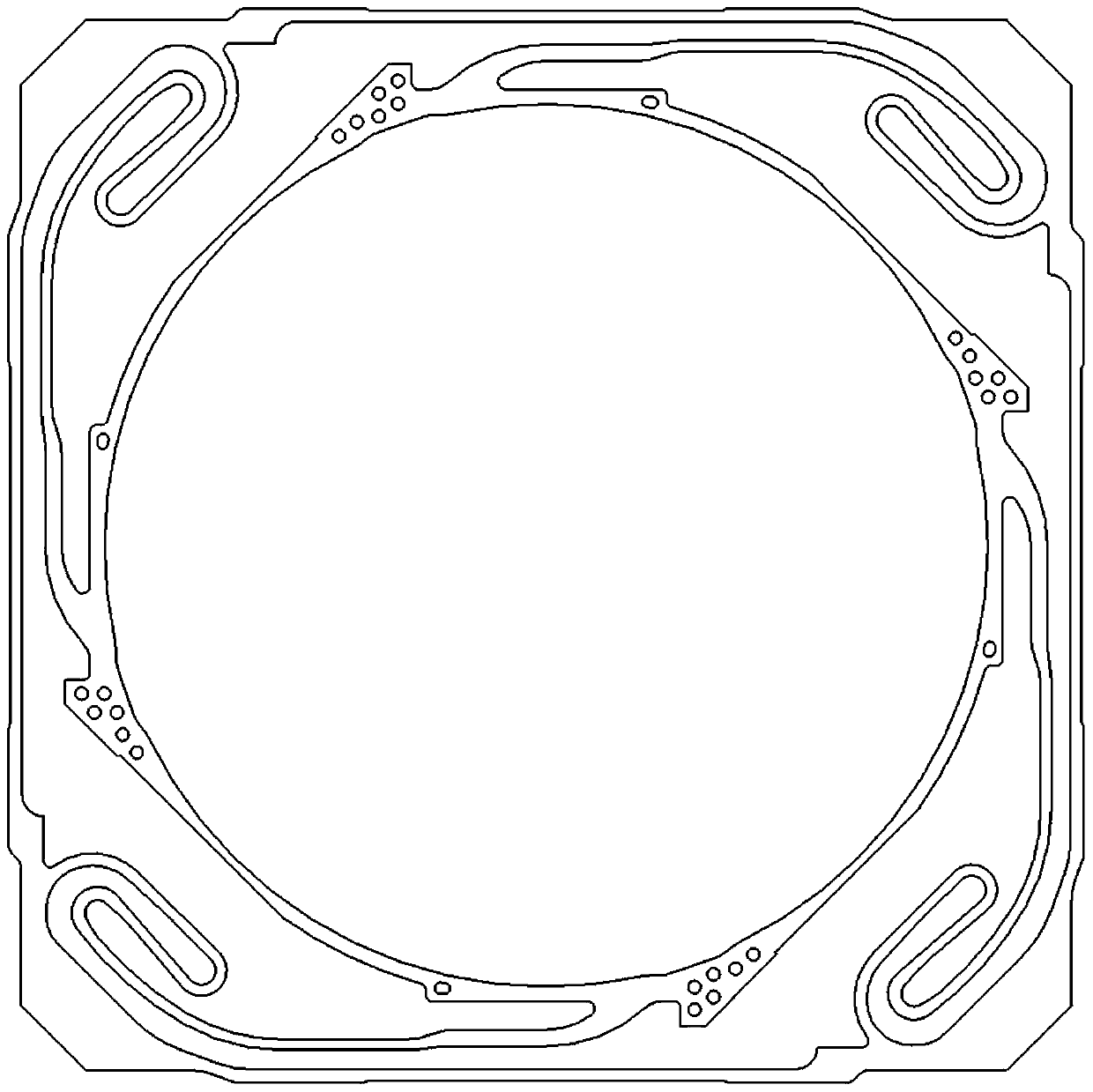

Image

Examples

Embodiment 1

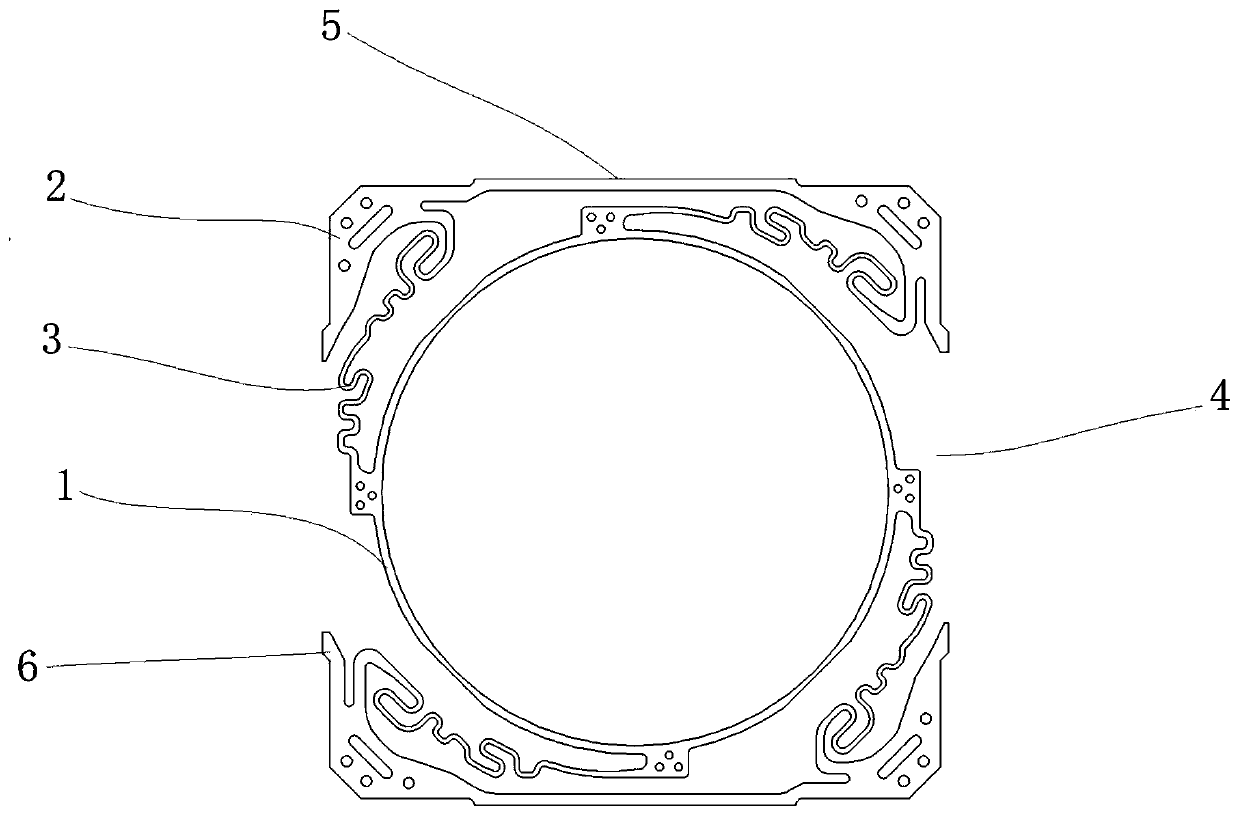

[0024] see figure 2 , in this embodiment, the fixing part (2) includes a first fixing part (21), a second fixing part (22), a third fixing part (23) and a first fixing part (23) arranged along the outside of the inner ring part (1). Four fixed parts (24);

[0025] The first fixing part (21) and the second fixing part (22) are connected through an outer frame (5), and the third fixing part (23) and the fourth fixing part (24) are connected through another outer frame (5) ; The first fixing part (21) and the fourth fixing part (24) are provided with a gap (4), and the second fixing part (22) and the third fixing part (23) are provided with another gap (4).

[0026] By adopting the above structure, this embodiment increases the available space inside the motor and increases the reliability and stability of the motor.

Embodiment 2

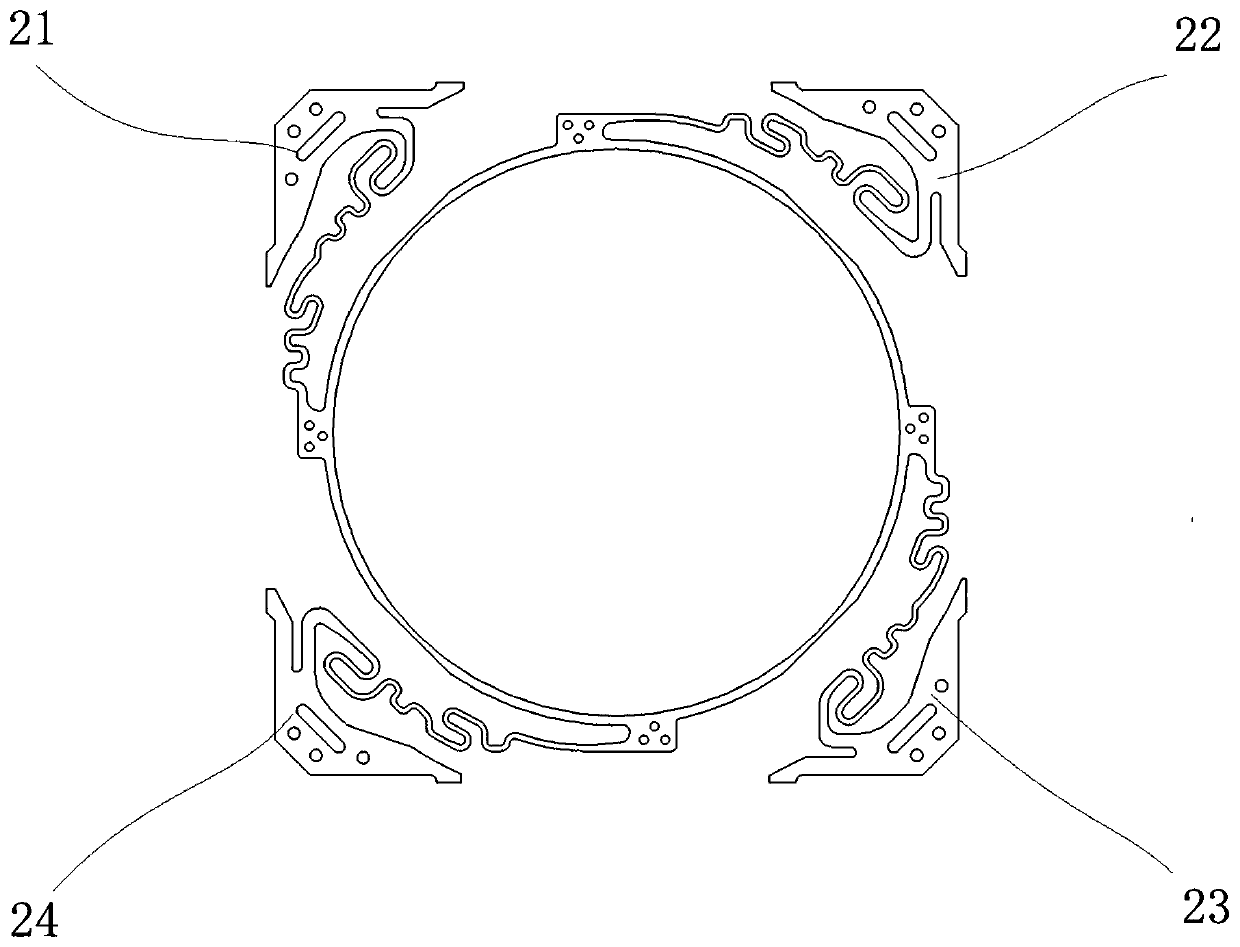

[0028] see image 3 , in this embodiment, the fixing part (2) includes a first fixing part (21), a second fixing part (22), a third fixing part (23) and a first fixing part (23) arranged along the outside of the inner ring part (1). Four fixed parts (24);

[0029] A gap (4) is provided between any adjacent fixed parts (2), and is separated into a split structure by the gap (4).

[0030] By adopting the above structure, this embodiment increases the available space inside the motor and increases the reliability and stability of the motor.

[0031] From Embodiment 1 and Embodiment 2, it can be seen that the key point of the design of this application is that there is a gap (4) between the fixing parts (2), and the gap (4) is used to separate it into an independently arranged split structure. The setting of the gap (4) is not limited to the left and right sides, the upper and lower sides, and the upper, lower, left, and right sides are separated. By ensuring the assembling manu...

Embodiment 3

[0033] A voice coil motor has a split-type upper elastic piece structure as described in Embodiment 1 or Embodiment 2. In this embodiment, other structures of the voice coil motor are the same as those of the prior art, so details are not described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com