Improved automobile clutch booster

A clutch and booster technology, applied in the direction of clutches, mechanical equipment, etc., can solve the problems of clutch booster card issuance, affecting the thrust of the large piston, affecting the assembly speed, etc., to save material costs, increase the effective area, and increase the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

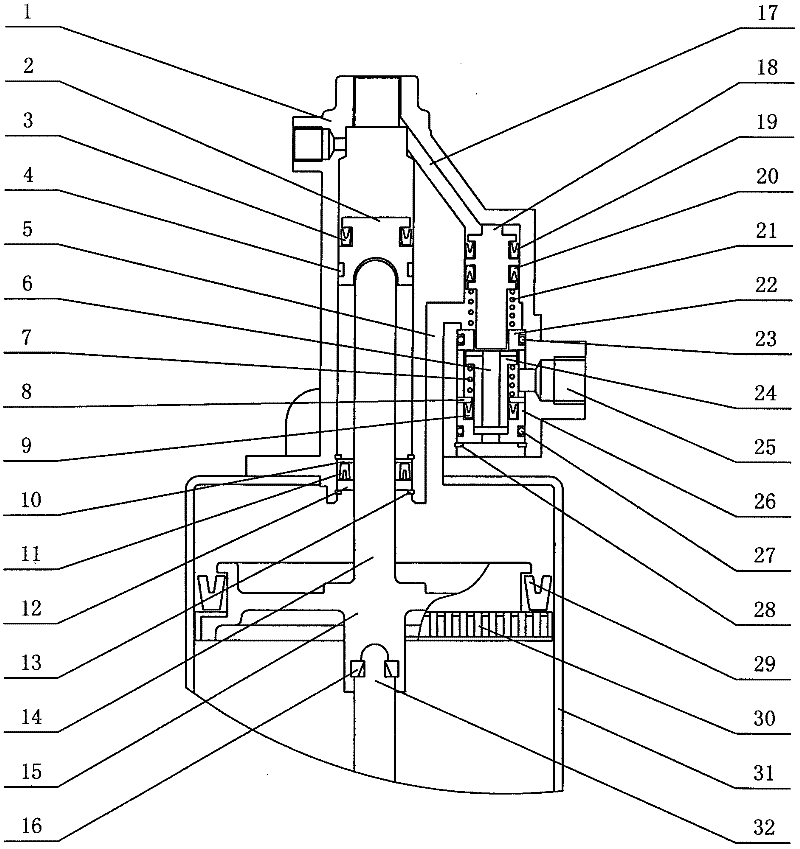

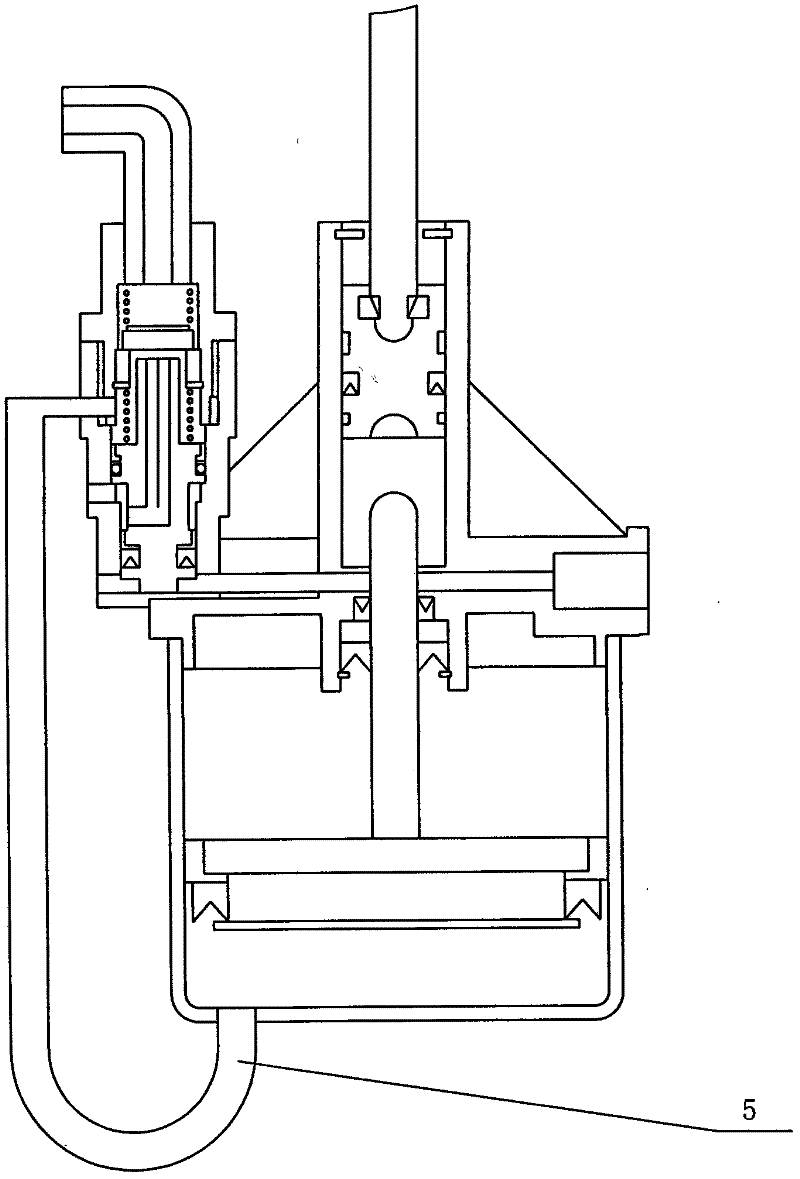

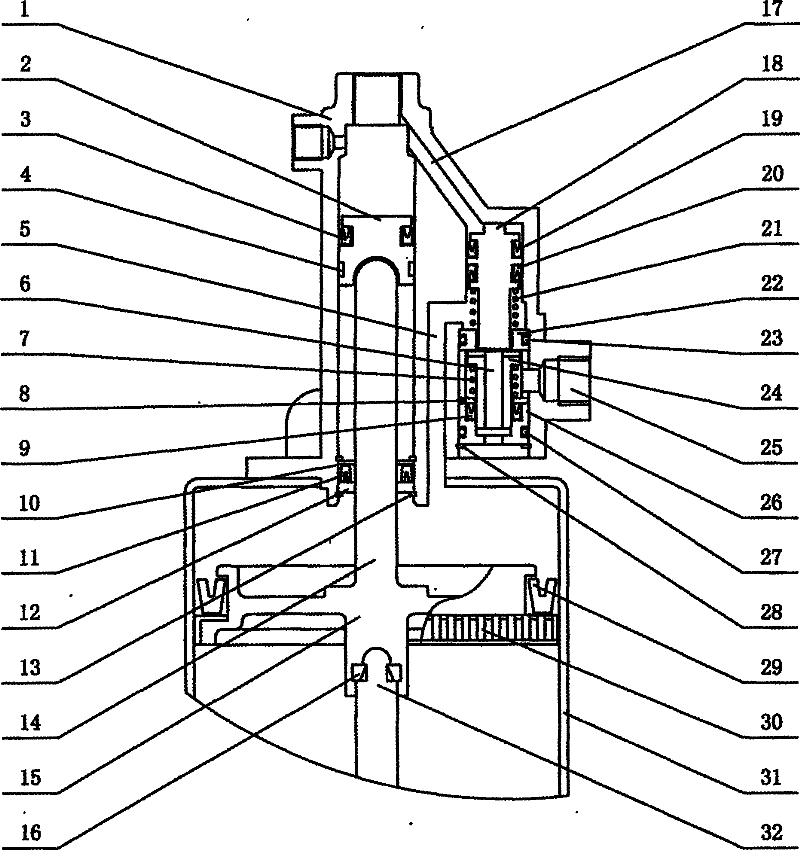

[0024] refer to figure 1 Shown, an improved automobile clutch booster. Including: body 1, oil chamber piston 2, oil chamber piston cup 3, oil chamber piston wear reducing ring 4, cylinder barrel intake and exhaust holes 5, valve plate exhaust hole 6, valve plate return spring 7, support gasket 8. Cover cover cup 9, piston rod retaining ring 10, piston rod cup 11, piston rod wear reducing ring 12, piston rod snap ring 13, piston rod 14, large piston 15, ejector rod lock sleeve 16, oil inlet hole 17. Small piston 18, small piston upper cup 19, small piston lower cup 20, small piston return spring 21, valve seat 22, valve seat O-ring 23, valve plate 24, compressed air inlet 25, blocking cover 26, Blocking cover O-ring 27, blocking cover snap ring 28, large piston cup 29, large piston cup lubricating wear-reducing ring 30, cylinder barrel 31, ejector rod 32.

[0025] The body 1 is provided with an oil chamber and an oil-air chamber. The oil chamber piston 2 is housed in the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com