Semi-automatic corrugated beam guardrail board mounting machine and working method thereof

A wave-beam guardrail and panel installation machine technology, applied in road safety devices, roads, roads, etc., can solve the problems of high labor intensity and low efficiency, and achieve the effects of saving labor, changing installation methods, and liberating labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

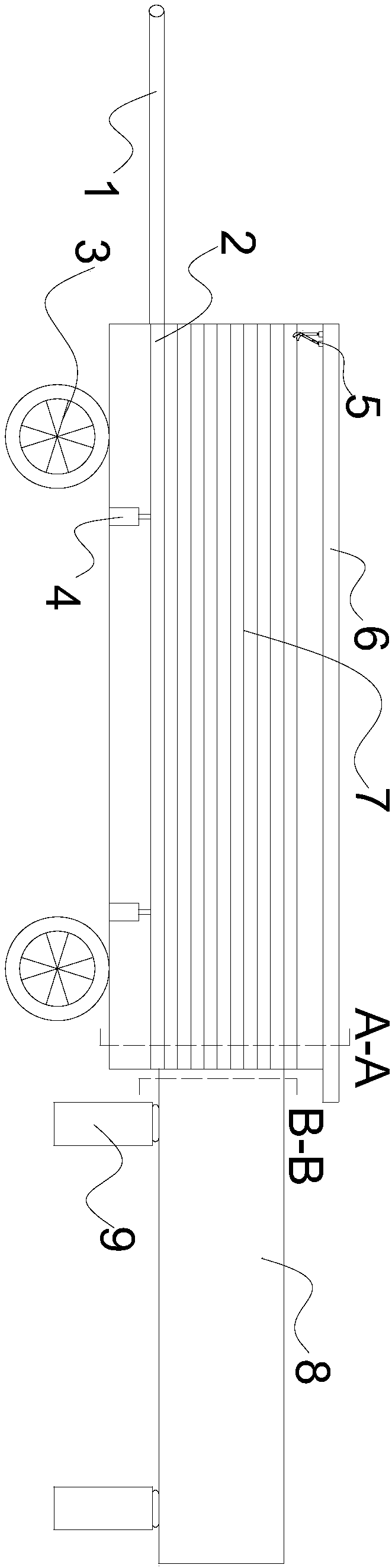

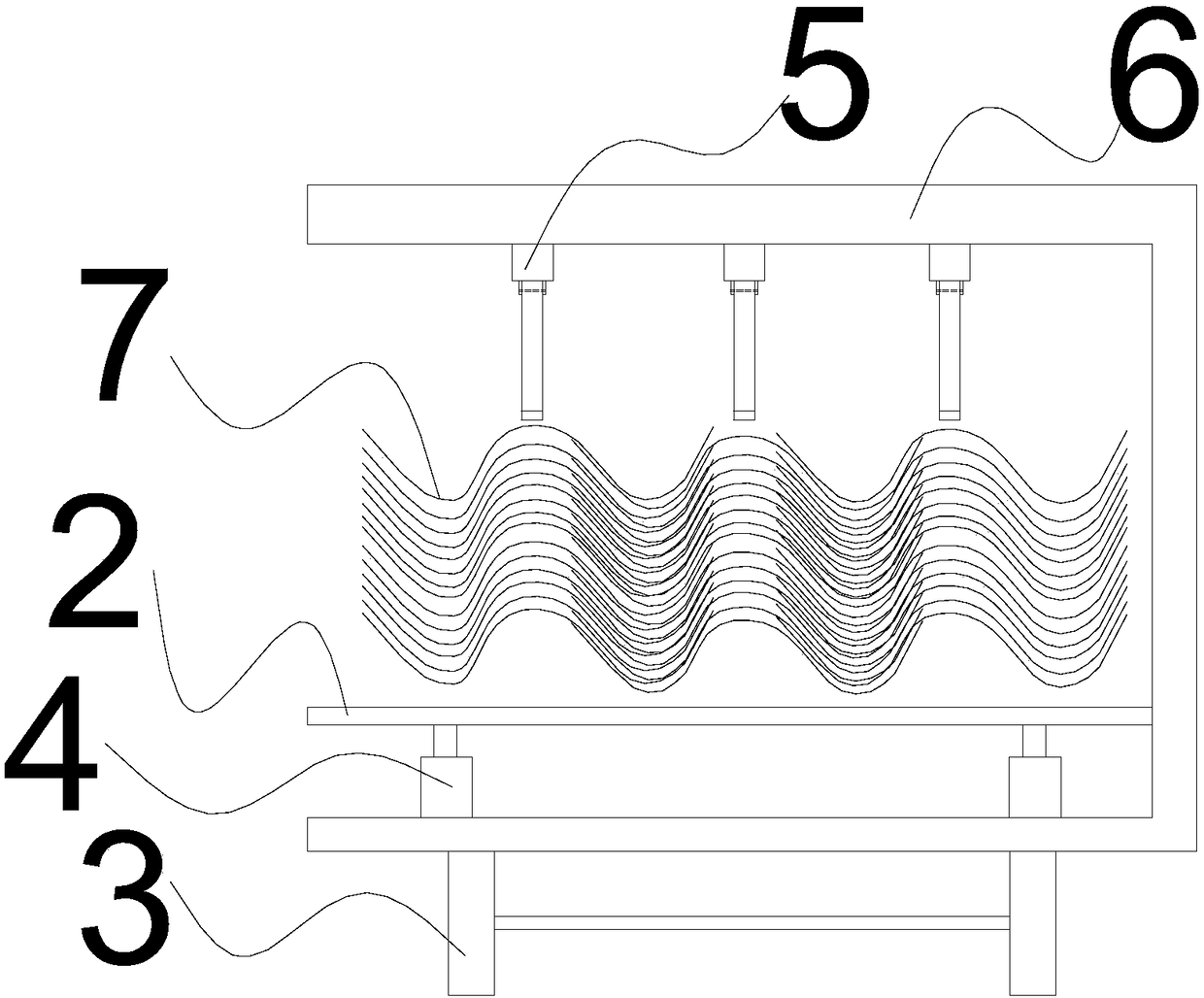

[0026] Referring to the accompanying drawings, a semi-automatic wave beam guardrail panel installation machine is characterized in that it includes a traveling mechanism; and a traction rod 1 is fixed at the front end of the traveling mechanism, and the traveling mechanism is a carriage with two sets of wheels 3 connected under the floor The bottom plate of the compartment is divided into two parts, the first part is the wave beam guardrail plate accommodation area, the second part is the wave beam guardrail plate transmission area; the hydraulic cylinder 4 is fixed in the wave beam guardrail plate accommodation area, and the output shaft of the hydraulic cylinder 4 A support plate 2 is fixed on the top, and a top cover 6 is arranged above the support plate 2. Three tracks are installed on the lower surface of the top cover 6, and a hook 5 is connected to each track. The described hook is "J" Hook; the motor provides the power for the movement of the hook 5 in the track. A chai...

Embodiment 2

[0028] The difference with Embodiment 1 is that in the track of the top cover, a lead screw is installed, and a hook is installed on the lead screw, and the hook can be connected to a nut that is threaded with the lead screw; the rotation of the lead screw drives the nut to move linearly; The ball screw transmission mechanism is adopted; the motor drives the screw to rotate to drive the hook to reciprocate.

Embodiment 3

[0030] The present invention also provides a working method of the semi-automatic corrugated beam guardrail panel installation machine, comprising the following steps:

[0031] Step 1: Install the tow bar 1 on the body of other power mechanism; reach the installation position;

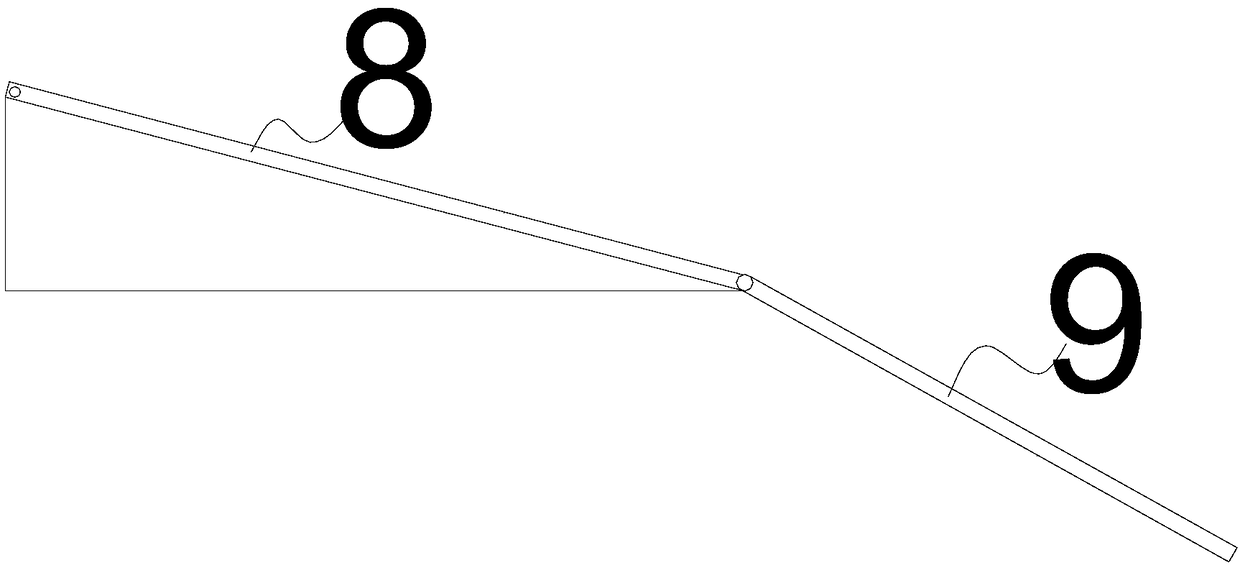

[0032] Step 2: The action of the motor drives the hook 5 corresponding to the uppermost wave beam guardrail panel 7 to move in the direction of the conveyor belt 8. During the movement, the head of the hook 5 enters the installation hole at the end of the wave beam guardrail panel 7, thereby driving the wave beam guardrail The plate 7 moves; after the corrugated beam guardrail plate 7 arrives on the conveyor belt 8, the hook 5 returns to its position, and in the process of returning to the position, it breaks away from the installation hole;

[0033] Step: 3: After the corrugated beam guardrail 7 reaches the conveyor belt 8 completely, the movement of the conveyor belt 8 drives the corrugated beam guar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com