Wall-mounted direct blowing type air processing set

An air handling unit, direct blowing technology, applied in the direction of heating, air conditioning system, air flow control components, etc., can solve the problem of not being able to meet the requirements of indoor environment, increase the initial investment and operation cost of equipment, and directly return to the unit through the return air outlet and other problems, to achieve the effect of simple and compact unit structure, reduce failure points and maintenance costs, and change the installation method and system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment the present invention is described in further detail:

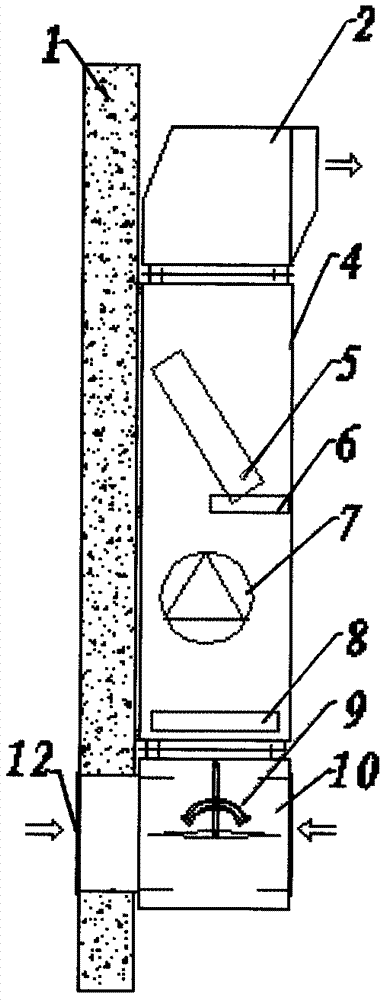

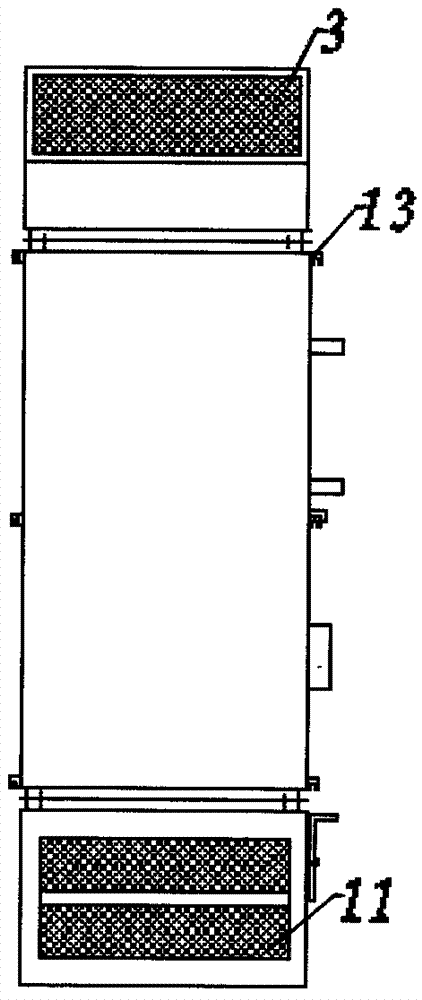

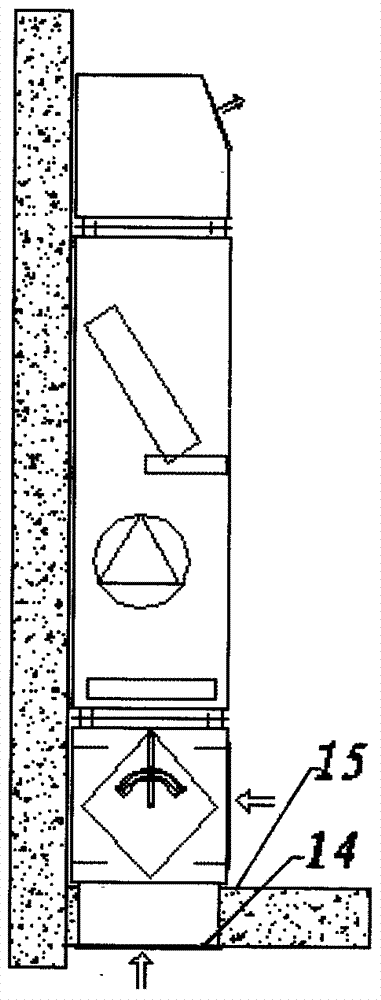

[0021] Such as Figure 1-3 As shown, a wall-mounted direct blowing air handling unit includes an air inlet device, a box body 4 and an air outlet device, and the air inlet device includes an air inlet box 10 arranged at the lower end of the box body 4 and an The tuyere regulating device 9 inside the bellows 10; the box body includes a plate type primary effect filter 8, a blower 7, a cold and hot coil 5, a water tray 6, and an installation hanger 13; the air outlet device includes a The air outlet box 2 on the body 4 upper ends. The air outlet of air outlet box 2 is provided with air supply louver tuyere 3, and the both sides and bottom of air inlet box 10 are provided with fresh air louver tuyere 12, return air louver tuyere 11, bottom louver tuyere 14.

[0022] The installation steps of this unit are as follows:

[0023] 1) Unit box installation: The user selects the unit m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com