Electro-hydraulic servo valve

An electro-hydraulic servo valve and valve core technology, applied in the field of servo valves, can solve the problems of poor sealing performance and poor dirt holding capacity, and achieve the effects of convenient installation, less heat generation, and low pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

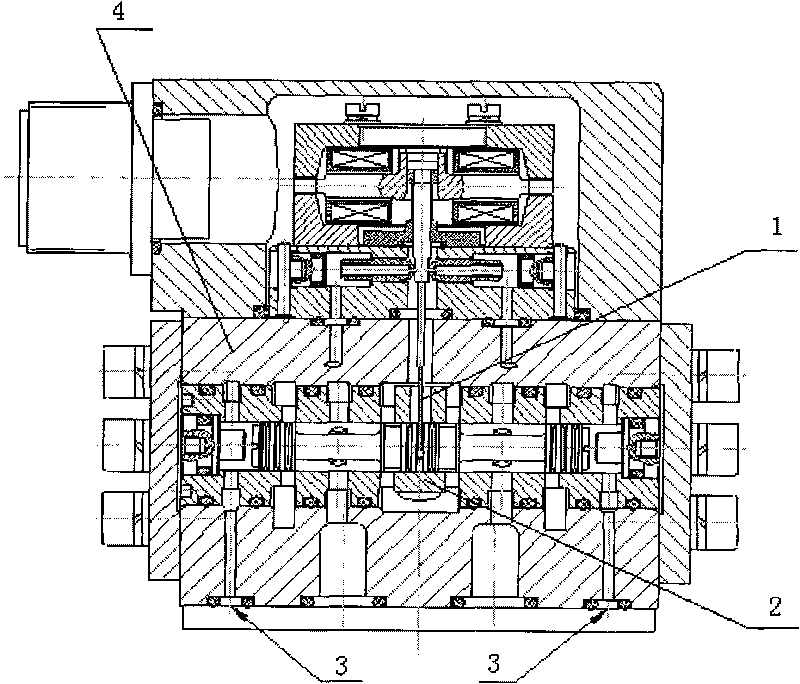

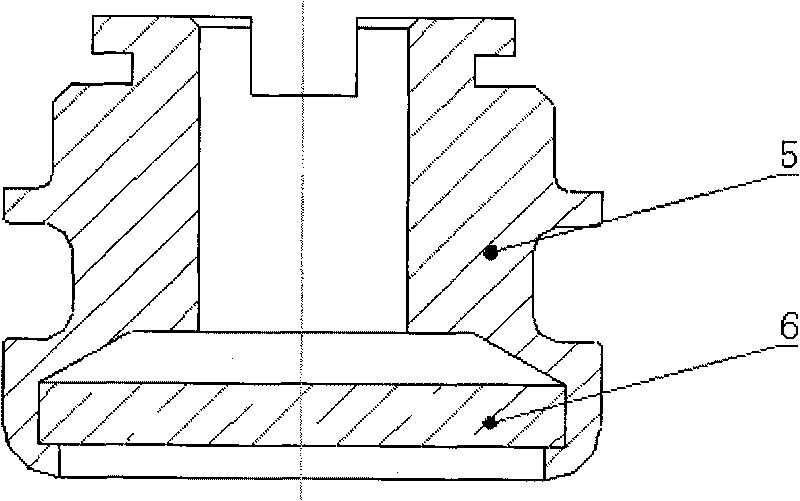

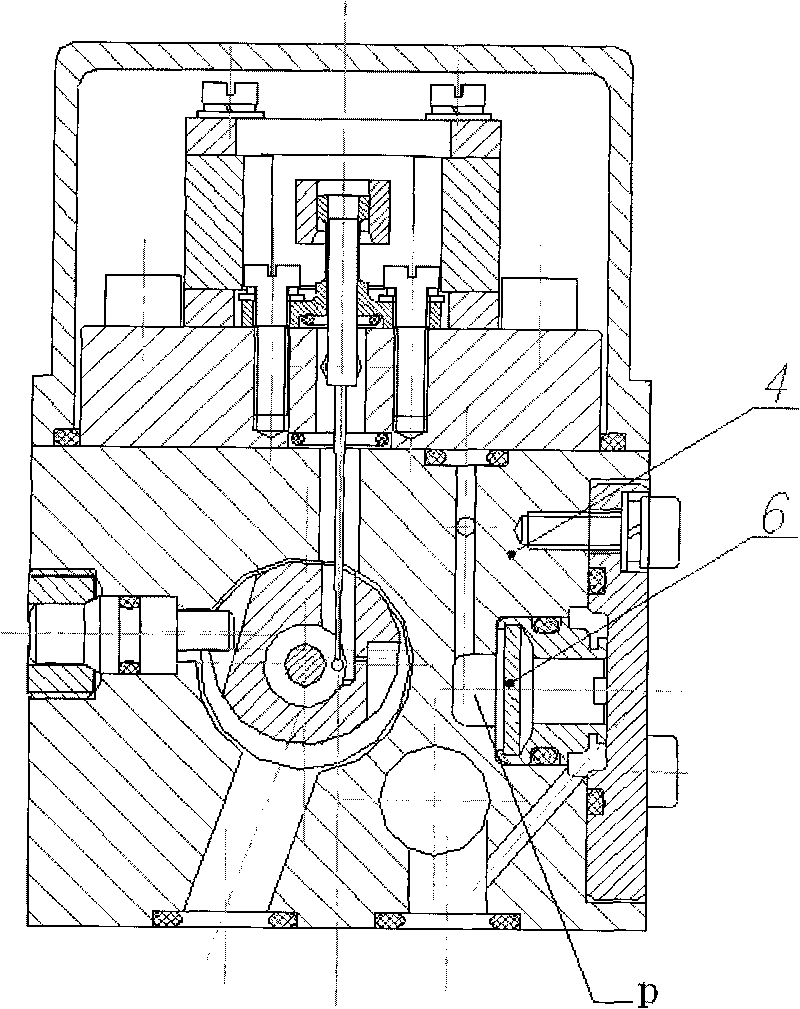

[0017] An electro-hydraulic servo valve, including a combined baffle feedback rod 1, a valve core 2, a pre-stage test hole 3, a filter housing 5 and a filter 6, the valve core 2 is located in the center of the inner cavity of the valve body 4, and the combined The type baffle feedback rod 1 runs through the middle and upper part of the valve body 4, and its lower end ball head is located at the eccentric position of the valve core 2, and the filter 6 is rolled on the lower part of the inner cavity of the filter housing 5.

[0018] The combined baffle feedback rod 1 is made of elastic alloy wire, the valve core 2 is made of tool steel, the filter housing 5 is made of brass, the filter 6 is made of stainless steel wire, and the valve body 4 is made of forged aluminum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com