Piston hinge-type variable-displacement vane pump

A variable displacement vane pump, articulated technology, applied in rotary piston pumps, rotary piston machines, pumps, etc., can solve the problems of large internal frictional resistance, insignificant fuel saving effect, inflexible space layout, etc. Small internal friction resistance, easy to three-level variable, small effect of cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

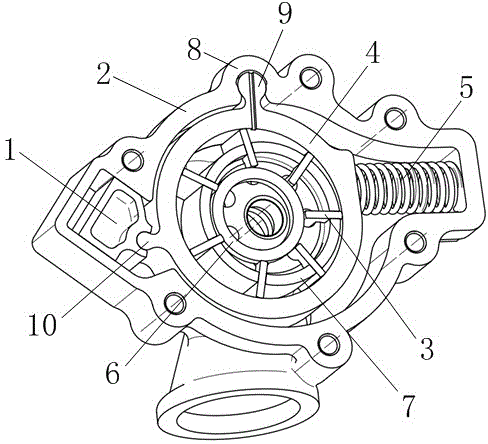

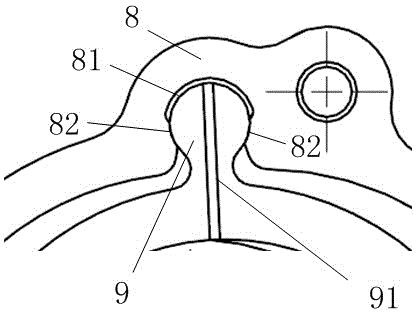

[0080] Such as Figures 1 to 5 As shown, the first embodiment of the present invention provides a piston articulated variable displacement vane pump comprising two control chambers. Here, the pump housing 2 contains a pump chamber with an inlet and an outlet. A pump cover (not shown in the figure) covers the pump casing 2 . The pump control ring 4 moves in the pump chamber to adjust the capacity of the oil pump. The vane pump rotor 7 is rotatably arranged in the pump control ring 4 , and the rotation axis of the vane pump rotor 7 deviates from the center of the pump control ring 4 . The vane ring 6 is rotatably arranged in the vane pump rotor 7 , and the vane ring 6 rotates around the center of the vane pump rotor 7 . Seven blades 3 (not limited to seven, can also be other numbers), slidably pass through the vane pump rotor 7 respectively, the inner ends of the blades 3 abut against the outer surface of the blade ring 6, and the outer end abuts the inner surface of the pum...

no. 2 example

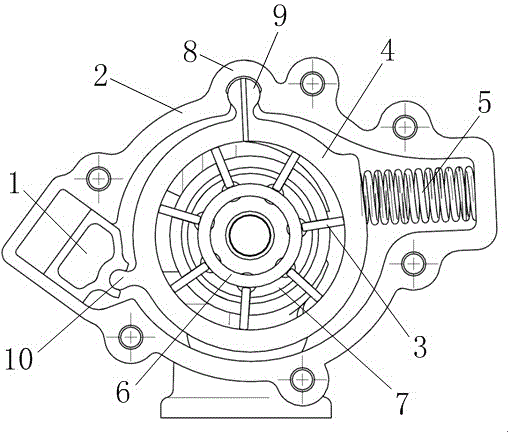

[0091] Such as Figures 6 to 11 As shown, the second embodiment of the present invention provides a piston articulated variable displacement vane pump, which is different from the first embodiment in that the second embodiment can contain at most three control chambers. Here, the pump housing 2 contains a pump chamber with an inlet and an outlet. A pump cover (not shown in the figure) covers the pump casing 2 . The pump control ring 4 moves in the pump chamber to adjust the capacity of the oil pump. The vane pump rotor 7 is rotatably arranged in the pump control ring 4 , and the rotation axis of the vane pump rotor 7 deviates from the center of the pump control ring 4 . The vane ring 6 is rotatably arranged in the vane pump rotor 7 , and the vane ring 6 rotates around the center of the vane pump rotor 7 . Seven blades 3 (not limited to seven, can also be other numbers), slidably pass through the vane pump rotor 7 respectively, the inner ends of the blades 3 abut against the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com