Voltage Stabilizers for Structural Testing

A technology of voltage stabilization device and structure test, applied in the field of voltage stabilization device and structure test voltage stabilization device, can solve the problems of unstable oil pressure, unstable vertical force, increase or decrease of counterweights, etc., to ensure oil pressure. , Improve the accuracy and reduce the effect of oil pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

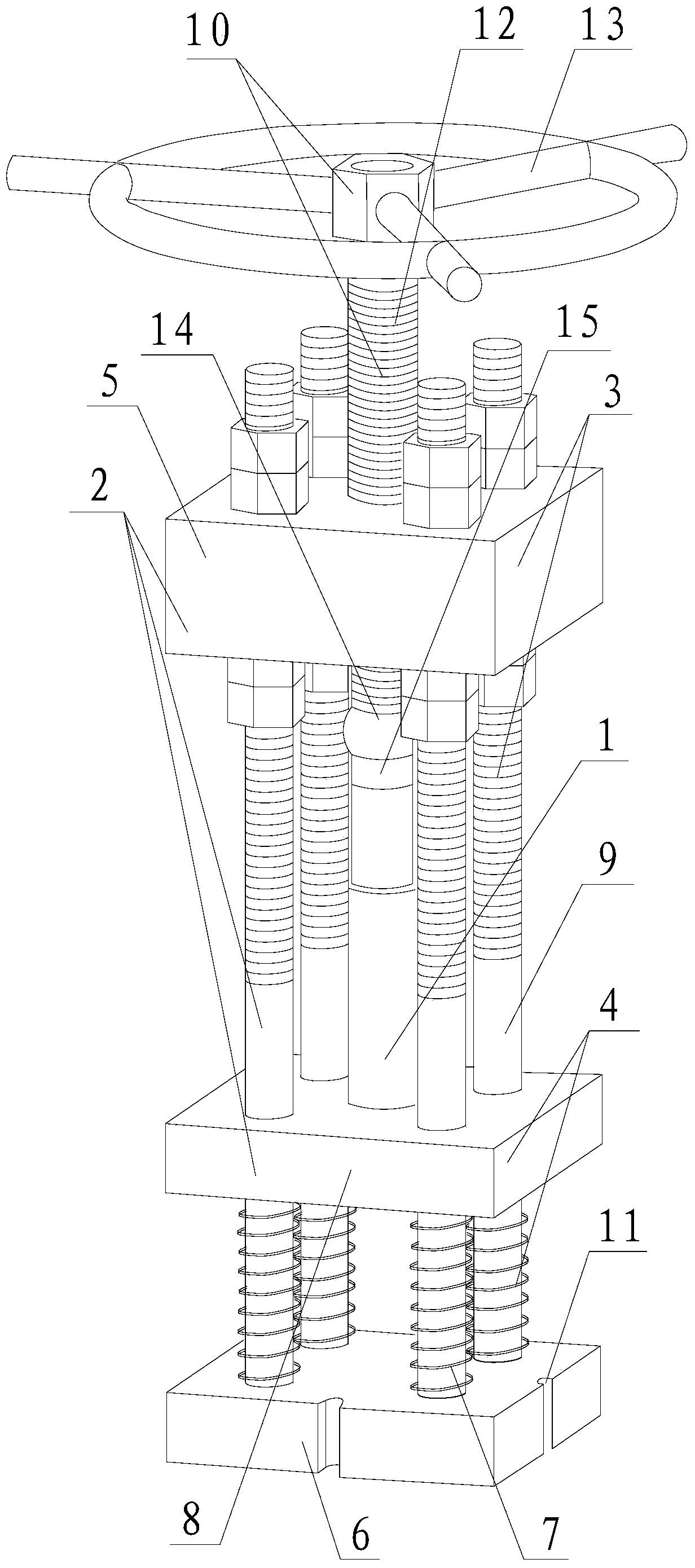

[0017] Such as figure 1 Shown is a voltage stabilizing device for structural testing provided by the present invention, which can effectively reduce the oil pressure fluctuation of the series jack hydraulic system, thereby improving the accuracy of the test results. The voltage stabilizing device includes a voltage stabilizing jack 1 connected in series on the oil circuit of the hydraulic loading system. The voltage stabilizing device also includes a set of self-balancing load system 2. The load on both ends of the stabilizing jack 1 passes through the self-balancing The load system 2 adjusts itself according to the oil pressure on the oil circuit of the hydraulic load system. The above-mentioned set of self-balancing load system 2 applies load to both ends of the stabilized jack 1 connected in series on the oil circuit of the hydraulic loading system, and the self-balancing load system 2 adjusts itself according to the oil pressure on the oil circuit of the hydraulic loading s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com