An oil circuit pressure control device and control method thereof

A pressure control and oil circuit technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve problems such as inflexible design space, easy to generate noise, large oil pressure fluctuations, etc., achieve low noise, reduce pollution emissions, The effect of small oil pressure fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

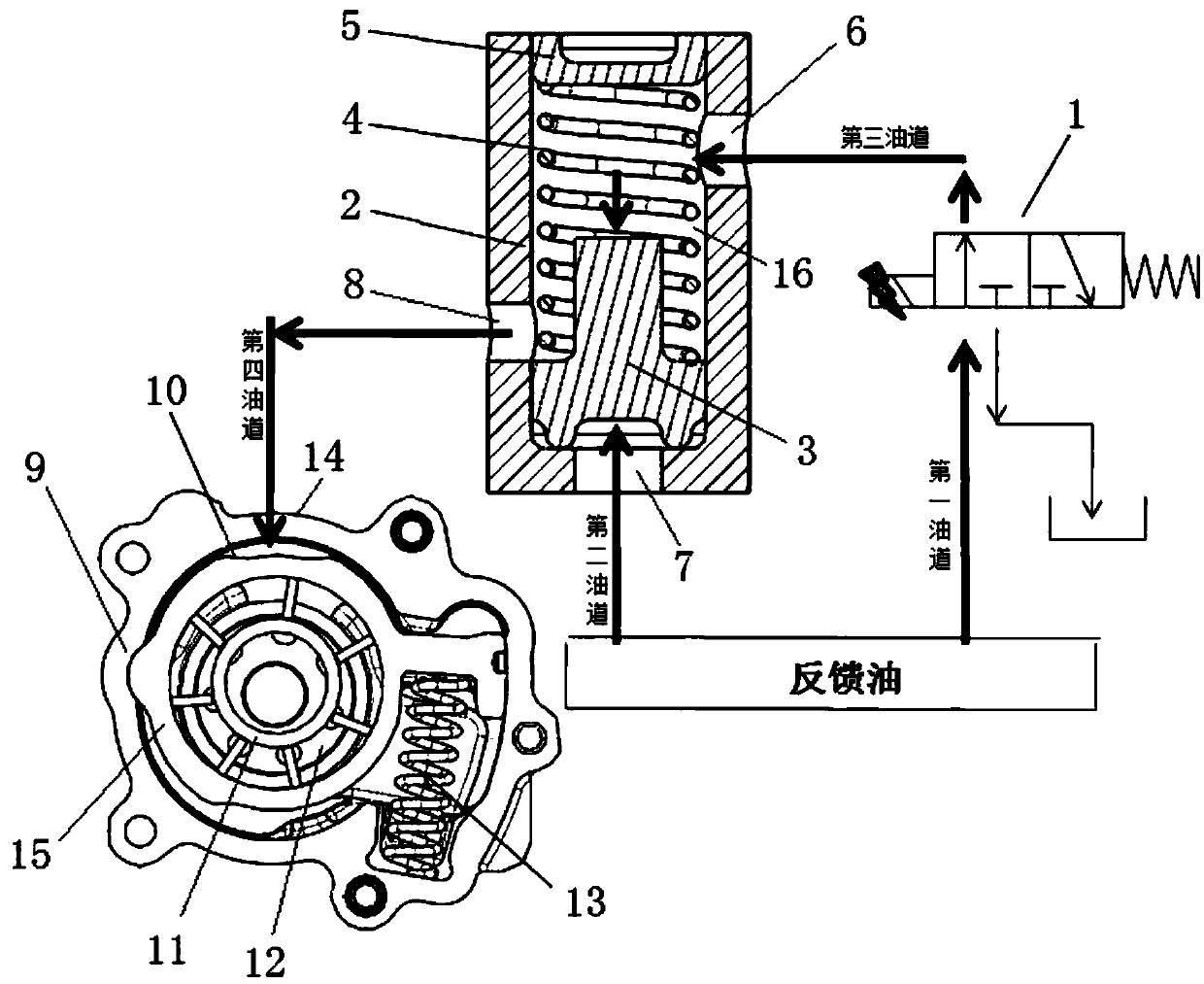

[0066] See figure 1 , figure 2 , an oil circuit pressure control device provided by the present invention includes an engine, a solenoid valve 1, a variable displacement pump, and an oil pump.

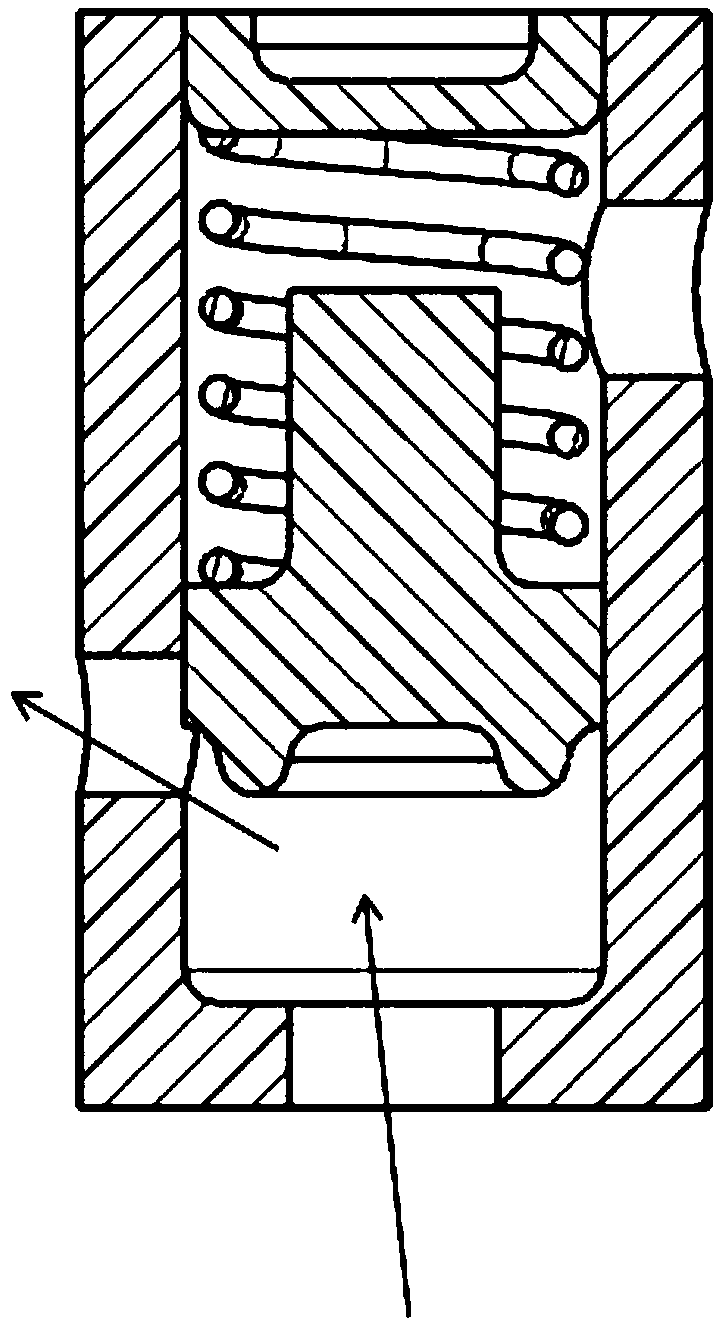

[0067] The oil pump comprises an oil pump housing 2, a bottom piston 3, a first spring 4, and a top piston 5, and the bottom piston 3 and the top piston 5 have the same maximum cross-sectional area. Three oil holes are provided on the oil pump housing 2 , namely a first oil hole 6 , a second oil hole 7 and a third oil hole 8 .

[0068] The bottom piston 3, the first spring 4 and the top piston 5 are located in the oil pump housing 2, the first spring 4 is installed between the bottom piston 3 and the top piston 5, and a spring is formed between the bottom piston 3, the top piston 5 and the oil pump housing 2 Cavity 16.

[0069] The variable displacement pump includes a casing 9 , a pump control ring 15 , a vane ring 11 , a vane pump rotor 12 , a second spring 13 , and a fourth oil ...

Embodiment 2

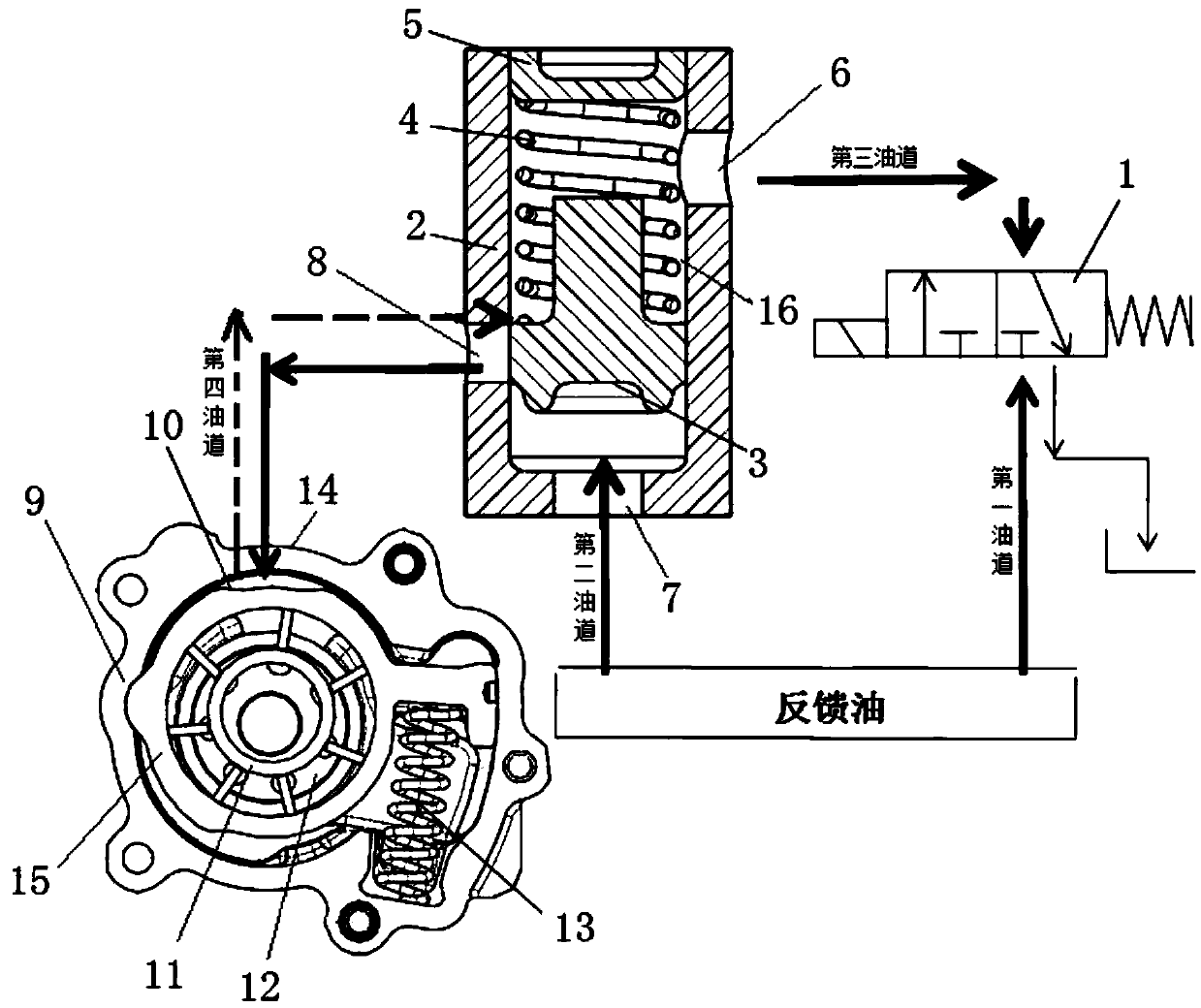

[0084] See image 3 , Figure 4 , an oil circuit pressure control device provided by the present invention includes an engine, a solenoid valve 1, a variable displacement pump, and an oil pump.

[0085] The oil pump comprises an oil pump housing 2, a bottom piston 3, a first spring 4, and a top piston 5, and the bottom piston 3 and the top piston 5 have the same maximum cross-sectional area. Three oil holes are arranged on the oil pump casing 2, which are respectively the first oil hole 6, the second oil hole 7, the third oil hole 8, and the oil pump outlet.

[0086] The bottom piston 3, the first spring 4, and the top piston 5 are located in the oil pump housing 2, the bottom piston 3 is installed below the top piston 5, the first spring 4 is installed below the bottom piston 3, the bottom piston 3 and the oil pump housing 2 A spring cavity 16 is formed therebetween.

[0087] The variable displacement pump includes a casing 9, a pump control ring 15, a vane ring 11, a vane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com