A Bypass Valve Realizing Segmented Overflow

A valve and overflow technology, which is applied in the direction of controlling the pressure of lubricant, can solve the problems of lubricating oil pressure fluctuations, long valve strokes, and long valve moving strokes, and achieve small lubricating oil pressure fluctuations, shortened moving strokes, and adjustment accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

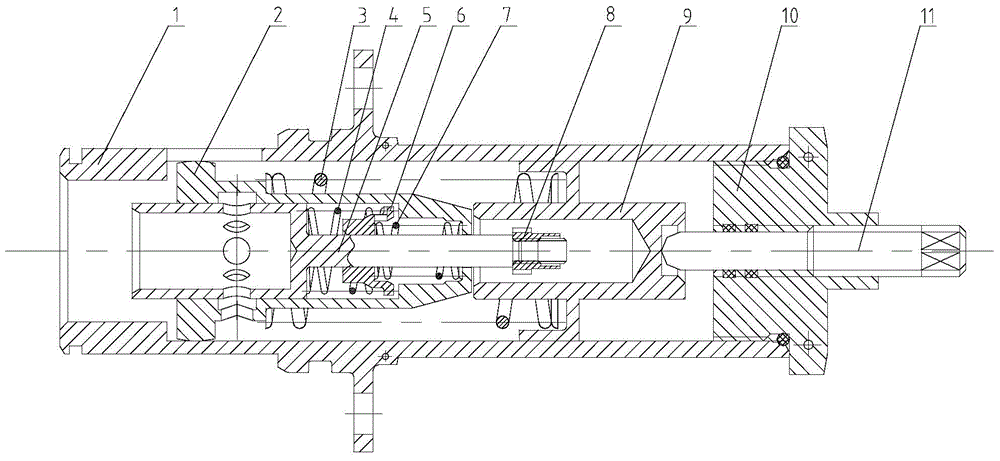

[0016] This embodiment provides a bypass valve for realizing segmental overflow, which is characterized in that: the bypass valve for realizing segmental overflow includes a housing 1, a large valve 2, a first spring 3, a second Spring 4, small valve 5, first positioning block 6, third spring 7, nut 8, second positioning block 9, locking nut 10, adjusting screw 11;

[0017] The casing 1 is connected with the lubricating oil pump group; the large valve 2 compresses the first spring 3 to move in the casing 1; the small valve 5 compresses the second spring 4, pushes the first positioning block 6, and compresses the third spring 7 in the hole of the large valve 2 Internal movement; the nut 8 is connected with the small valve 5 to prevent the small valve 5 from coming out of the large valve 2 when the lubricating oil pressure is low; the adjusting screw 11 is connected with the lock nut 10, and the lock nut 10 is connected with the housing 1, through the adjustment screw The adjust...

Embodiment 2

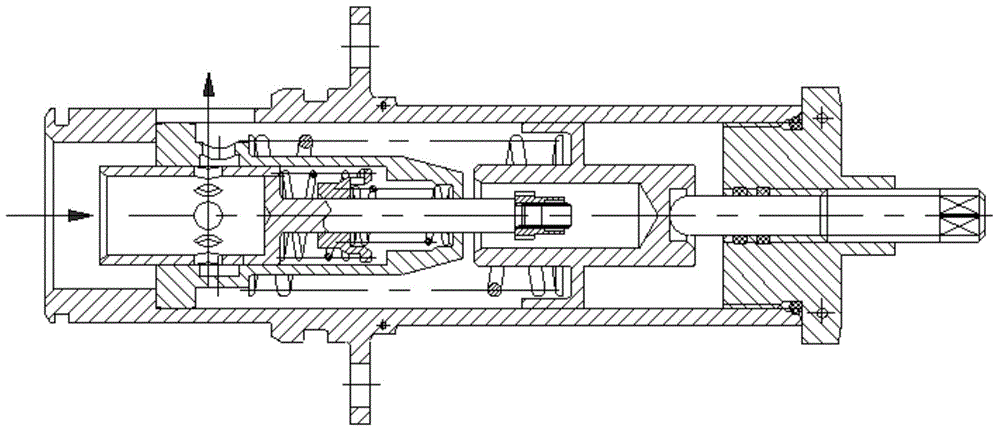

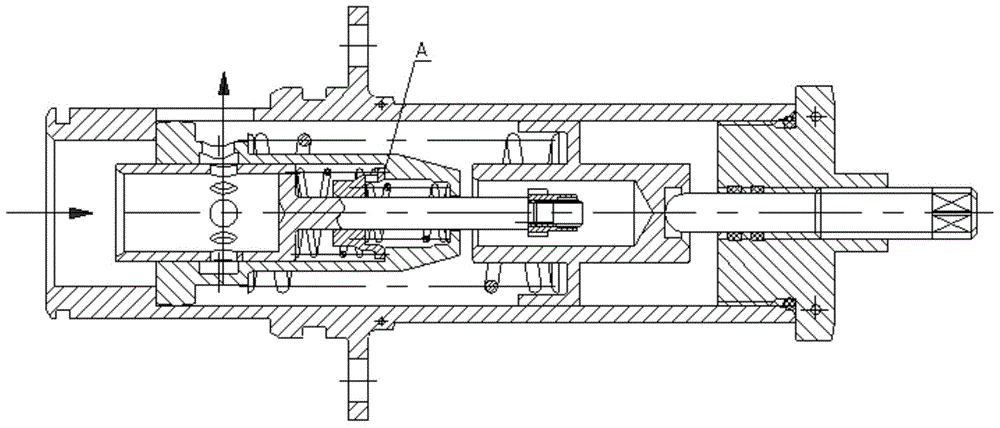

[0021] This embodiment provides a bypass valve for realizing segmental overflow, which is characterized in that: the bypass valve for realizing segmental overflow includes a housing 1, a large valve 2, a first spring 3, a second Spring 4, small valve 5, first positioning block 6, third spring 7, nut 8, second positioning block 9, locking nut 10, adjusting screw 11;

[0022] The housing 1 is connected with the lubricating oil pump group; the large valve 2 compresses the first spring 3 to move in the housing 1; the small valve 5 compresses the second spring 4, pushes the first positioning block 6, and compresses the third spring 7 in the hole of the large valve 2 Internal movement; the nut 8 is connected with the small valve 5 to prevent the small valve 5 from coming out of the large valve 2 when the lubricating oil pressure is low; the adjusting screw 11 is connected with the lock nut 10, and the lock nut 10 is connected with the housing 1, through the adjustment screw The adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com