An overflow device and fluidization equipment with the device

An overflow device and fluidization technology, which is applied in the field of overflow device of fluidized bed and multi-stage fluidized bed, can solve problems such as overflow pipe instability and overflow pipe failure to work normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

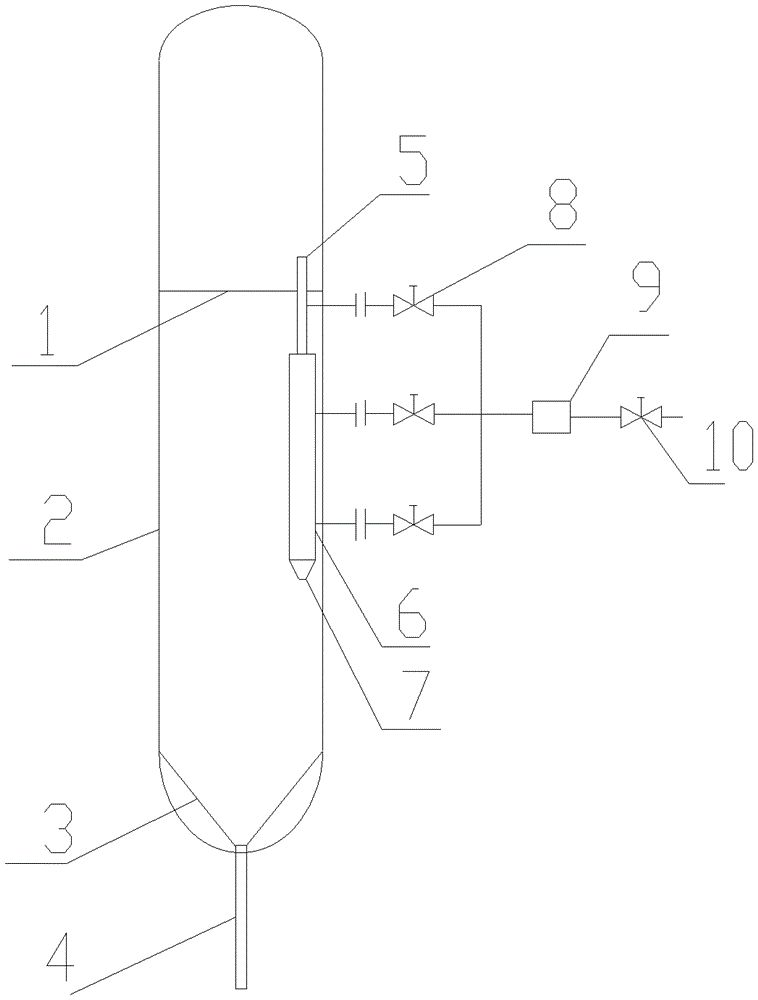

[0029] like figure 1 As shown, in one embodiment of the present invention, the overflow device of the present invention can be installed in the internal overflow multi-stage fluidization equipment. The multi-stage fluidization equipment includes a horizontal distribution plate 1 , a gasifier body 2 , a conical distribution plate 3 and a central pipe 4 .

[0030] The overflow device of the present invention is a vertical overflow device used in fluidization equipment, and the overflow device is a hollow tubular body in a longitudinal shape, and the hollow tubular body has an upper inlet (as shown in reference numeral 5 ) and the lower end outlet (as shown by reference numeral 7), wherein: on a length above the lower end outlet 7 of the overflow device, the internal cross section of the overflow device is larger than the internal cross section of the upper end inlet 5, And larger than the inner cross section of the outlet 7 at the lower end, thus, the length of the overflow dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com