Blade type hydraulic motor with rocker arm structure

A hydraulic motor and vane type technology, applied in the field of vane type hydraulic motor, can solve the problems of reduced hydraulic motor efficiency, irregular gap leakage, difficult processing and assembly, etc., and achieve the effects of eliminating lag, reducing internal leakage and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

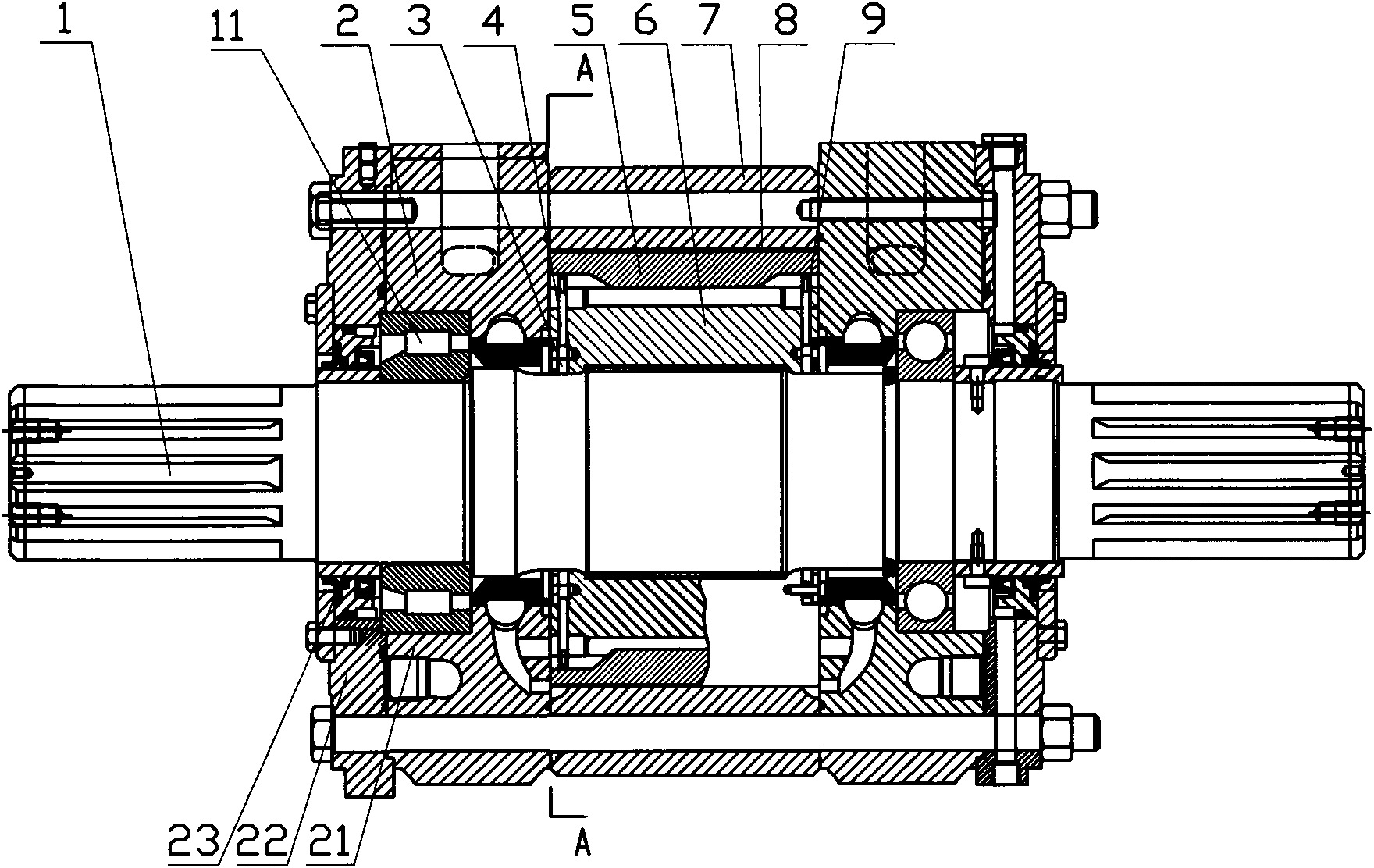

[0034] Embodiment one: if figure 1 As shown, a six-action vane hydraulic motor includes a rotating shaft 1 , a casing 2 , a rotor 6 , and a stator 7 . The housing 2 is composed of an oil distribution plate 21, an end cover 22 and a seal 23. The oil distribution plate 21 has an oil circuit and an inlet and outlet of the oil circuit, and a bearing 11 is installed between the oil distribution plate 21 and the end cover 22, and the bearing Seal 23 is also installed beside 11 to carry out leakproof and dustproof protection. End cover 22, oil distribution plate 21 and stator 7 are connected with 12 bolts. A rotor 6 is installed in the stator 7, and the rotor 6 is splined to the rotating shaft 1.

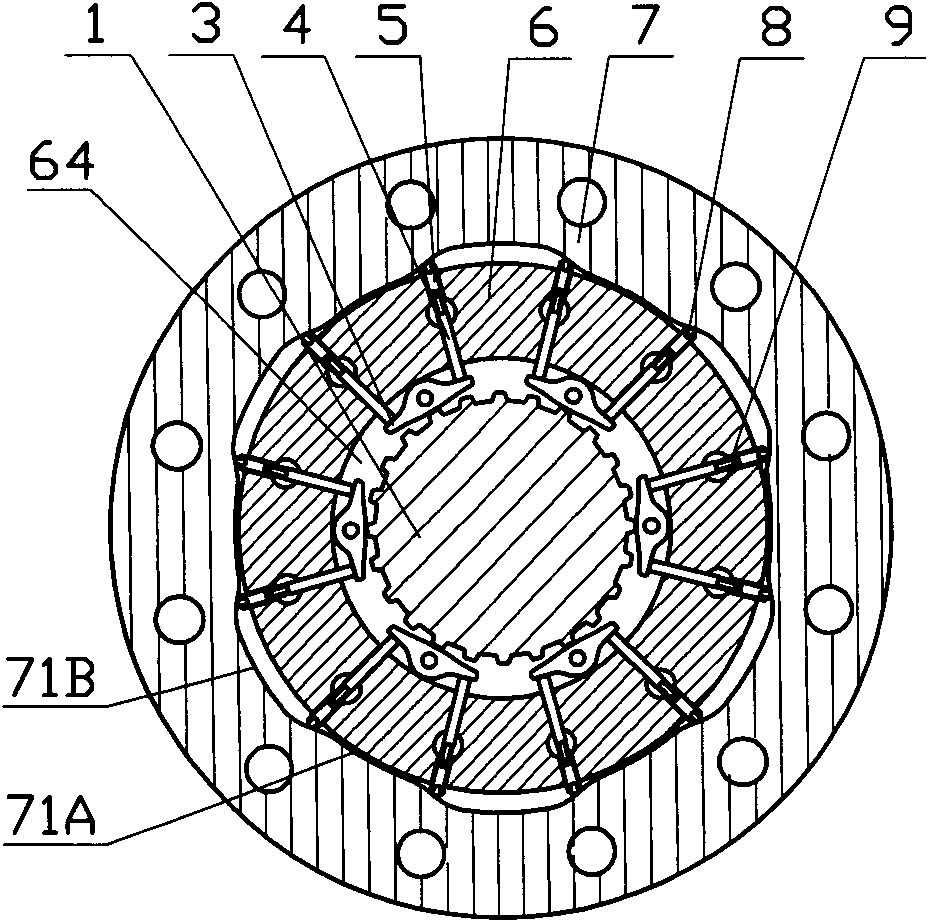

[0035] The inner surface of the stator 7 is an inner curved surface 71, and the surface of the rotor 6 has 12 blade grooves 61. Such as image 3 As shown, the cross section of the vane slot is U-shaped, and the vane 5 is installed. There is a through hole 62 communicating with it on bo...

Embodiment 2

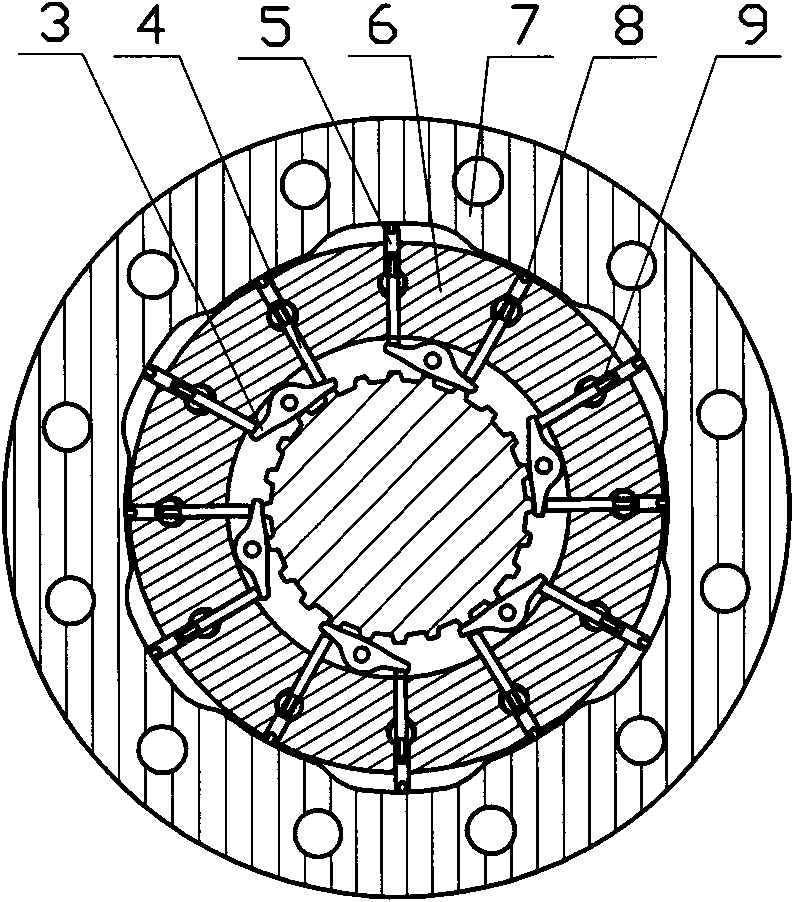

[0043] Embodiment 2: In order to further increase the torque of the hydraulic motor and improve the performance of the hydraulic motor, especially the stability of the low-speed operation, the number of blades on the rotor can be doubled. Such as Figure 5 , Image 6 As shown, in addition to being the same as the first embodiment, the circular groove 64 of the rotor 6 is directly connected with a set of rocker beams 3 (6 on one side and 12 in total) with pin shafts on the circular groove 64 of the rotor 6; Connect an annular backing plate 65 with screws on the circular groove 64, and the bottom surface of the annular backing plate 65 and the circular groove 64 on the rotor is parallel, and a set of rocker beam 3 ′ is installed on the 65 inner sides of the annular backing plate. Correspondingly, the number of vane grooves 61 on the rotor 6 is doubled, and the position corresponding to the rocker beam 3' in the vane slots is provided with a through hole and a circular cavity, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com