Miniature integral cold air propeller

A micro-propeller technology, which is applied in jet propulsion devices, machines/engines, aerospace vehicle guides, etc., can solve the complex three-dimensional structural characteristics of pressure reducers and electronically controlled valves, and the overall design method cannot be compatible with micro-processes. Problems such as complex structure of spring type or piston type pressure reducer, to achieve the effect of reliable operation, saving installation structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

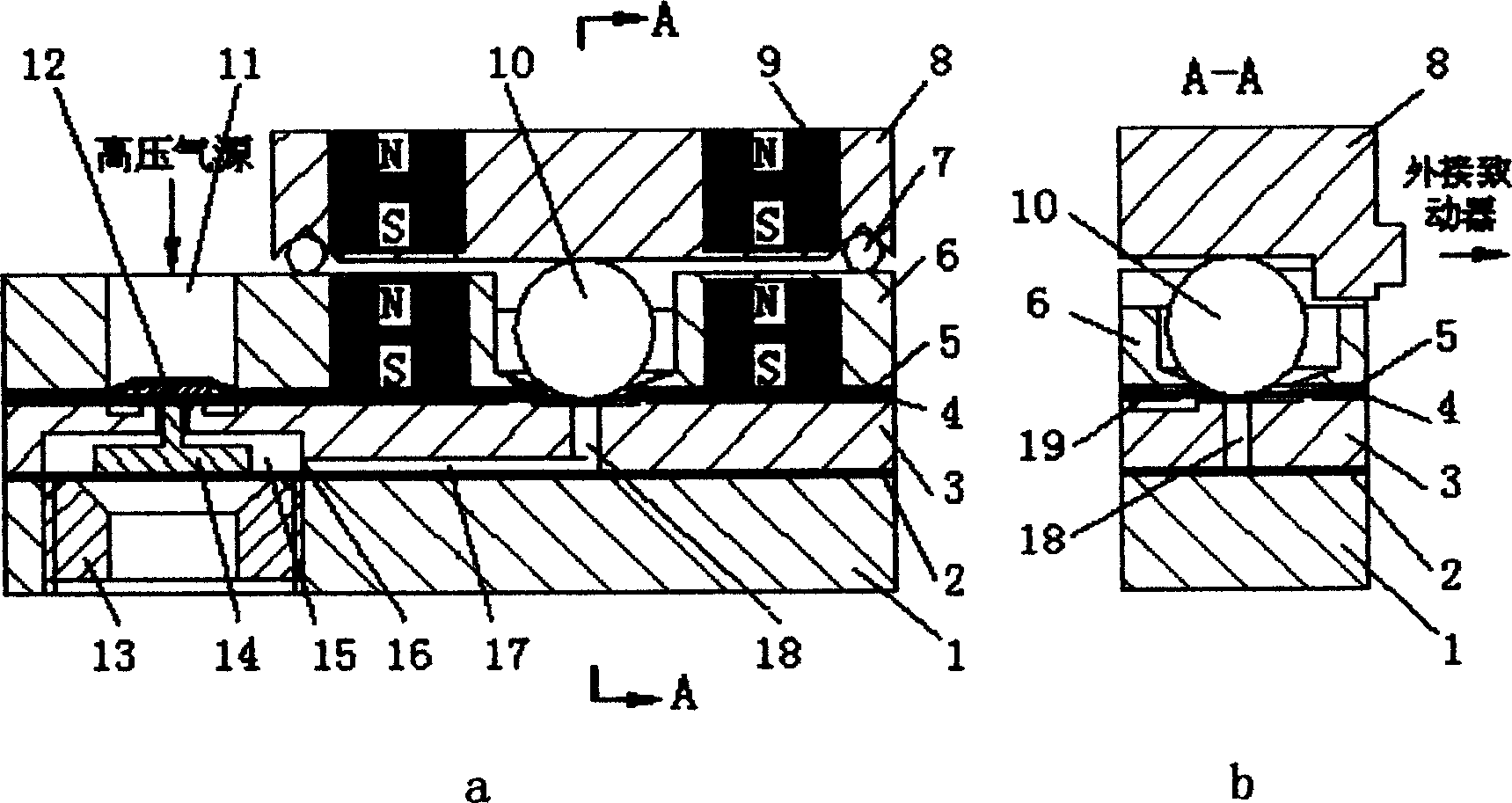

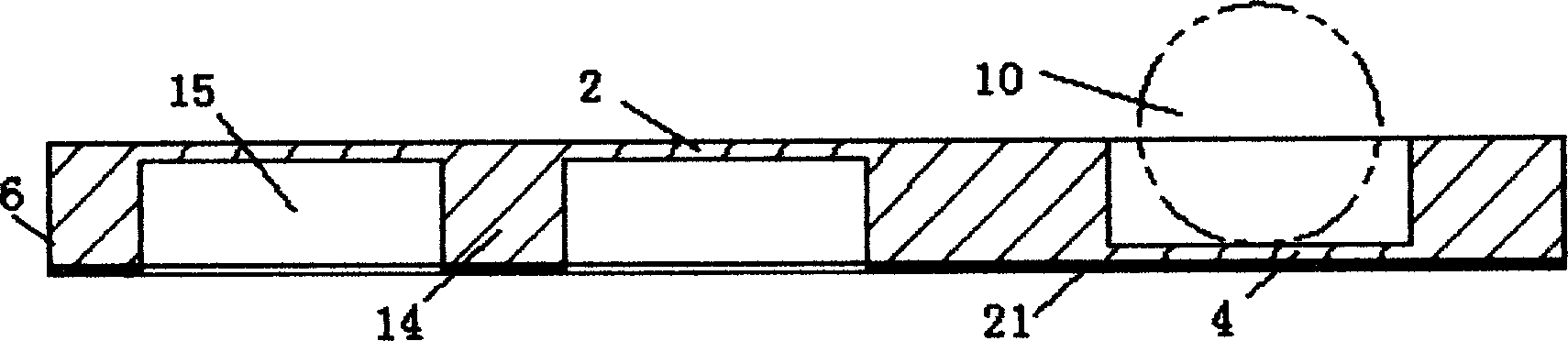

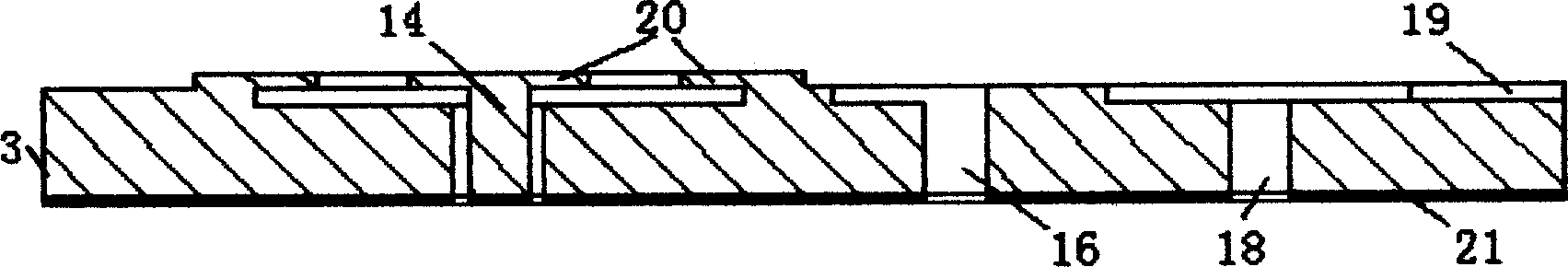

[0031]The invention is a micro-miniature integral structure cold air propeller, which is composed of a micro-miniature pressure reducer with a plane structure, a rolling ball valve core shut-off valve and a micro-miniature plane nozzle. According to the size and thrust of the designed cold air propeller, different processing and assembly techniques are required, and the corresponding structural details and characteristics are also different. figure 1 Shown is a 40mm small integrated structure cold air propeller made by precision machining technology; Figure 2 shows a 5mm miniature integrated structure cold air propeller made by planar micro technology, of which Figure 2(a) and Figure 2(b) , Figure 2(c) is a schematic diagram of its layered structure, and Figure 2(d) is its assembly diagram.

[0032] figure 1 Shown is a 40mm small integrated structure cold air thruster, the pressure reducer and the shut-off valve share the bottom plate 1, the middle plate 3, the top plate 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com