Transversely-arranged double-power-source vehicle driving assembly

A vehicle-driven, dual-power source technology, applied in hybrid vehicles, motor vehicles, power plants, etc., can solve the problems of being unable to use compact vehicles, unable to adapt to complex road conditions, and powertrain with a single speed ratio transmission , to make up for the lack of driving force of the whole vehicle, to achieve the effect of flexible transmission form and power input mode, and to improve the driving force of the whole vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

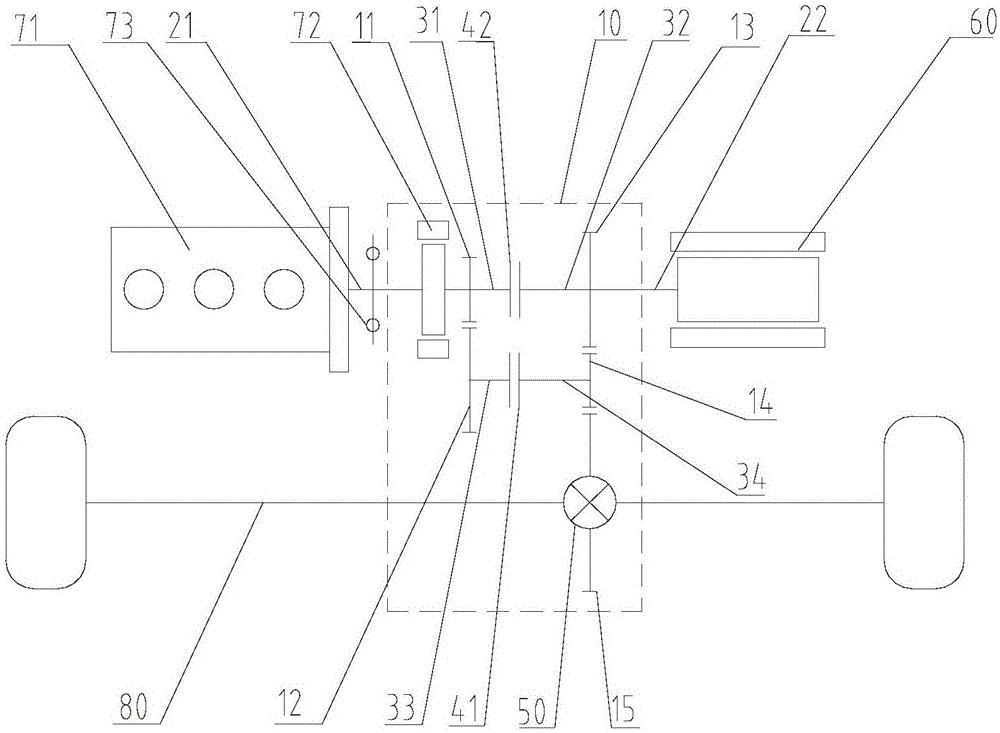

[0050] Embodiment 1 of the present invention provides a vehicle drive assembly with horizontal dual power sources, which is connected to the axle shaft, such as figure 1 As shown, the vehicle drive assembly includes a first power source, a second power source and an automatic transmission. The automatic transmission is provided with a first input shaft 21 and a second input shaft 22. The power source is connected to the two input shafts respectively. The first The power source is connected to the first input shaft 21, and the second power source is connected to the second input shaft 22; a differential is arranged at the joint between the automatic transmission and the axle shaft;

[0051] In the automatic transmission, a first intermediate shaft 31 is arranged coaxially with the first input shaft 21, and a second intermediate shaft 32 is arranged coaxially with the first intermediate shaft 31;

[0052] A second input shaft 22 is arranged in the direction coaxial with the seco...

Embodiment 2

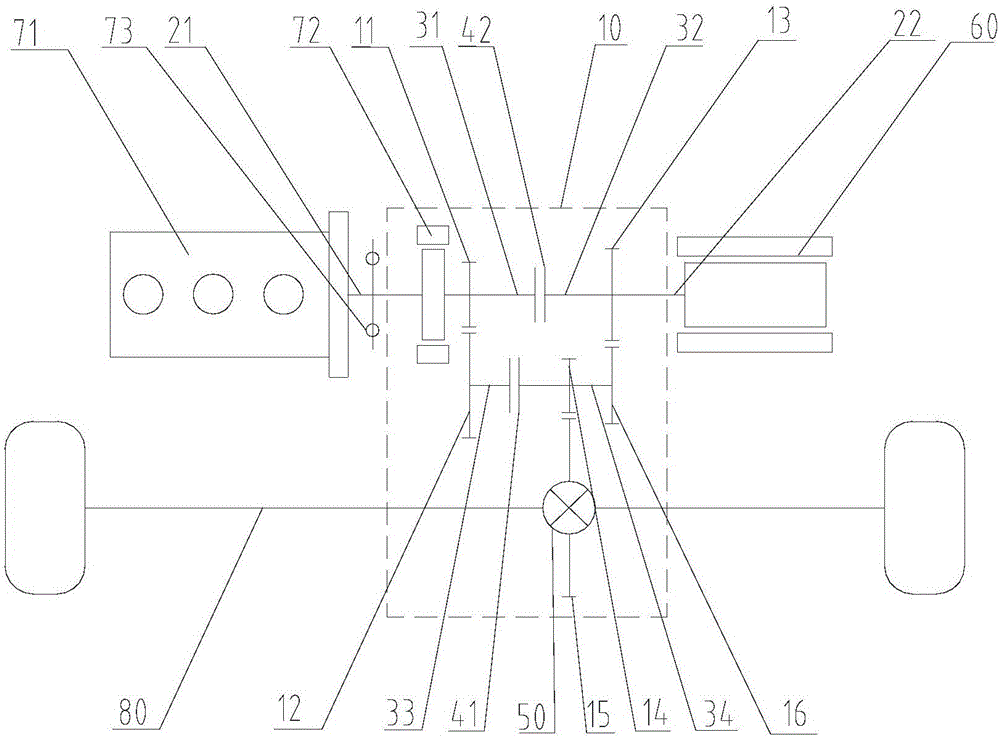

[0078] Embodiment 2 of the present invention is an improvement made on the basis of Embodiment 1. The difference between Embodiment 2 of the present invention and Embodiment 1 is that, as figure 2 As shown, the fourth intermediate shaft 34 is also provided with a sixth gear 16; the sixth gear 16 is engaged with the third gear 13 on the second intermediate shaft 32; the fourth gear 14 is only engaged with the fifth gear 15 for transmission.

[0079] Setting the third gear 13 and the sixth gear 16 mesh transmission ratio is i5;

[0080] When the first clutch 41 is engaged and the second clutch 42 is disconnected, the gear ratio of the automatic transmission is i1×i3; the first power source sequentially passes through the first input shaft 21, the first intermediate shaft 31, the first gear 11, the second The gear 12 , the third countershaft 33 , the first clutch 41 , the fourth countershaft 34 , the fourth gear 14 , the fifth gear 15 and the differential 50 transmit power to th...

Embodiment 3

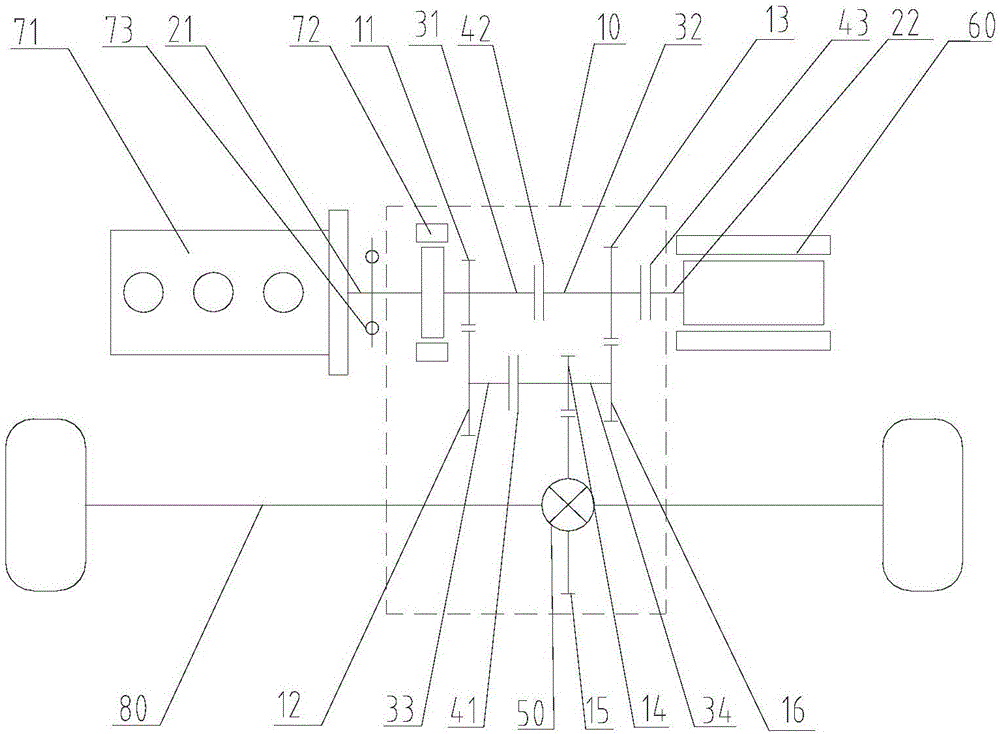

[0086] Embodiment 3 of the present invention is a change made on the basis of Embodiment 2. The difference between Embodiment 3 and Embodiment 2 is that, as image 3 As shown, the second input shaft 22 and the second intermediate shaft 32 are two independent shafts, and a third clutch 43 is provided between the second input shaft 22 and the second intermediate shaft 32 .

[0087] When the second power source motor 60 is used as an auxiliary power source, when starting the second power source motor 60, the third clutch 43 needs to be combined; when the second power source motor 60 is closed, the third clutch 43 can be disconnected, and now the motor 60 will Without idling with the running of the whole vehicle, the driving of the whole vehicle will not be restricted by the maximum rotating speed of the electric motor 60 and the moment of inertia of the rotor.

[0088] Other contents of Embodiment 3 of the present invention are the same as Embodiment 2, and will not be described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com