Rotary-tillage, mulching and earthing machine

A technology of soil cover and rotary tiller, which is applied to agricultural machinery and implements, shovels, plows, etc., can solve the problems of restricting the development of agricultural mechanization, four-wheel tractors cannot be used for farmland operations, and cannot be used together with micro tillers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

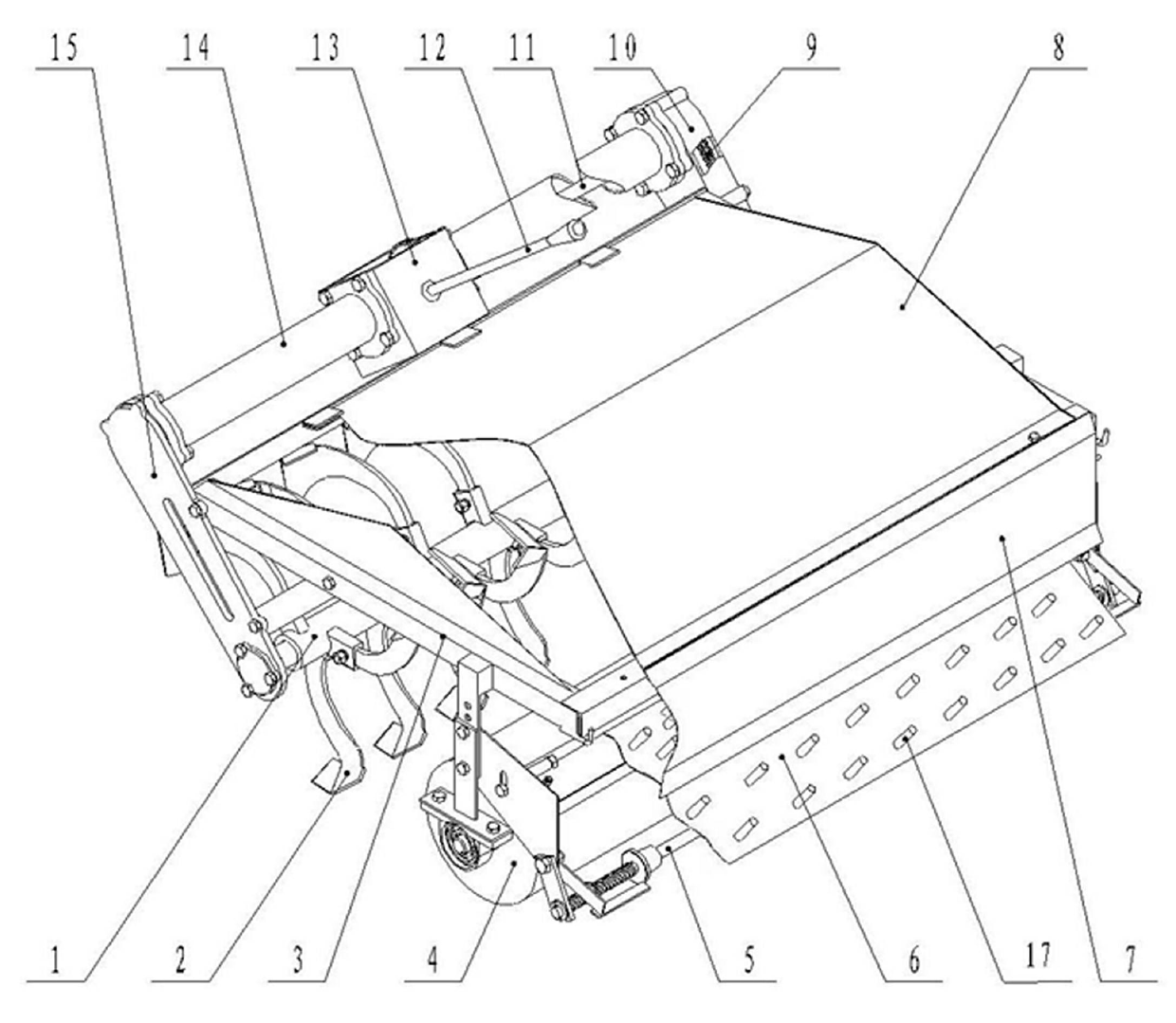

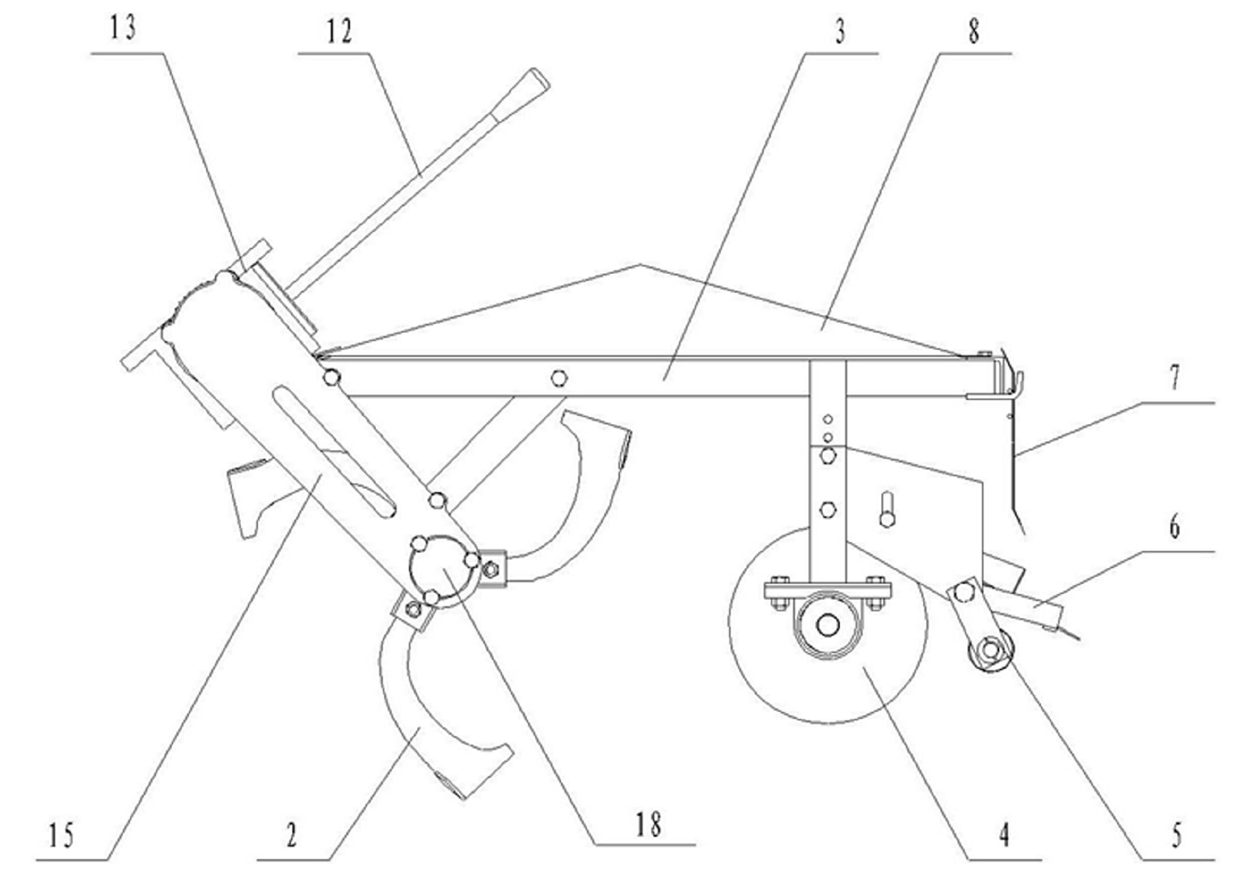

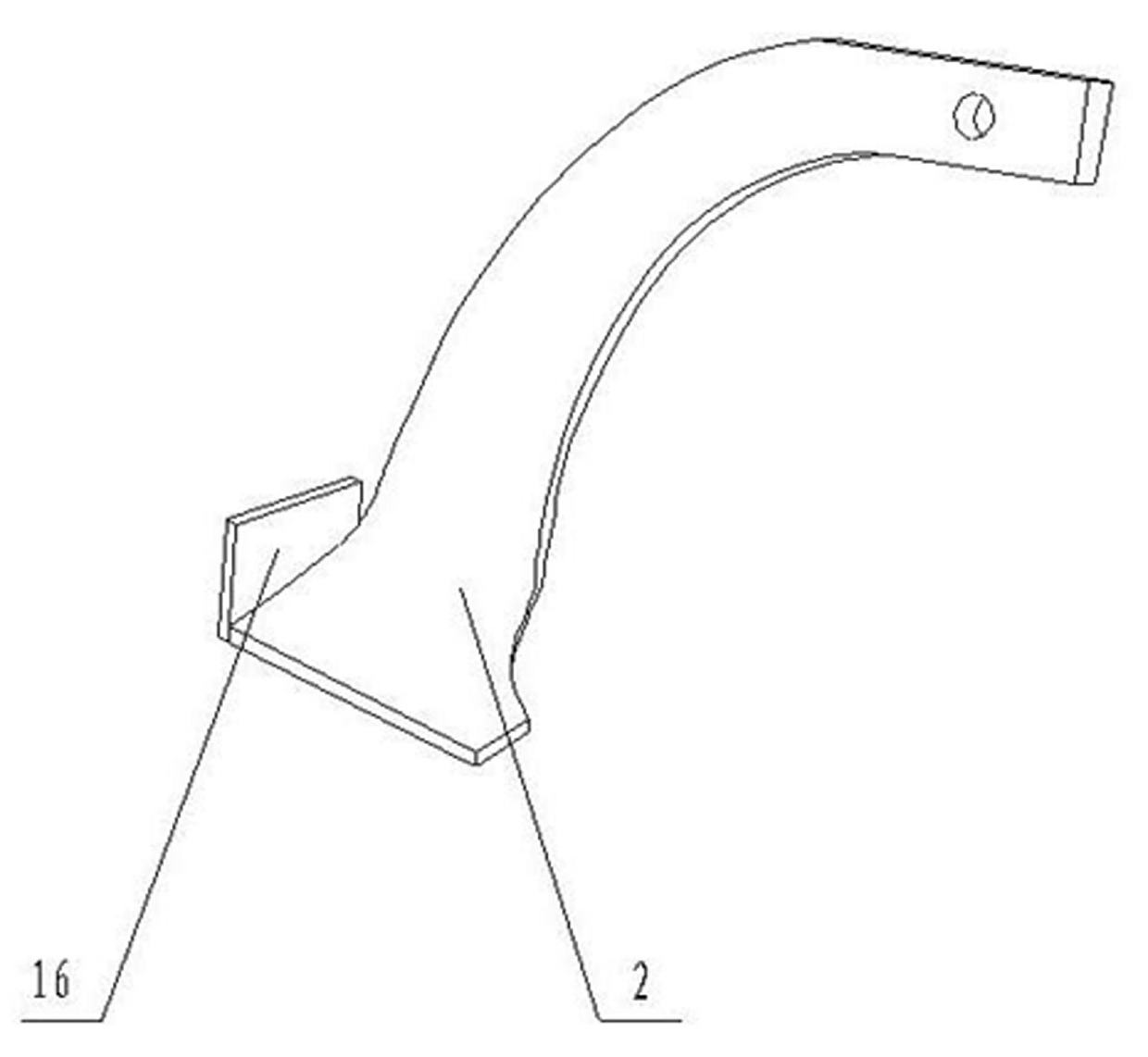

[0018] Such as figure 1 , figure 2 , image 3 As shown, a rotary tillage film-laying and soil-covering machine is mainly composed of a rotary tiller 1, a spoon-shaped rotary tiller 2, a frame 3, a shaping and pressing roller 4, a film-hanging frame 5, a soil splitter plate 6, and a soil retaining adjustment Plate 7, protective cover 8, chain 9, right connecting plate 10, transmission shaft 11, clutch lever 12, gear box 13, connecting sleeve 14 and left connecting frame 15 etc. are made up of parts. Rotary cultivator 1 is installed on the front bottom of frame 3 by left connecting frame 15 and right connecting frame 10. Rotary cultivator 1 is made up of rotary cultivator shaft 18 and spoon-shaped rotary cultivator 2, several spoon-shaped rotary cultivators 2 are arranged on rotary cultivator shaft 18, and spoon-shaped rotary cultivator 2 is broken in exist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com