Emulsion fine cooling system control method and control device

A technology of cooling system control and cooling control, which is applied in the direction of workpiece cooling device, temperature control, metal rolling, etc., to achieve the effect of improving yield, stable system operation and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

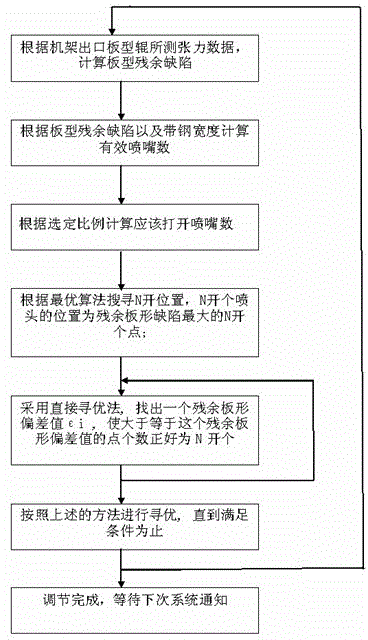

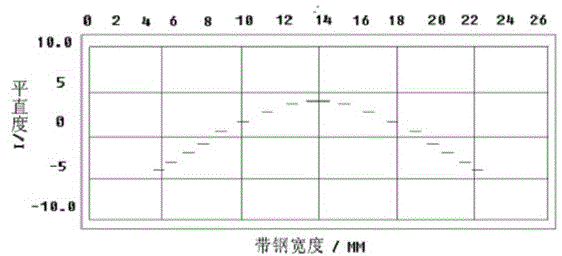

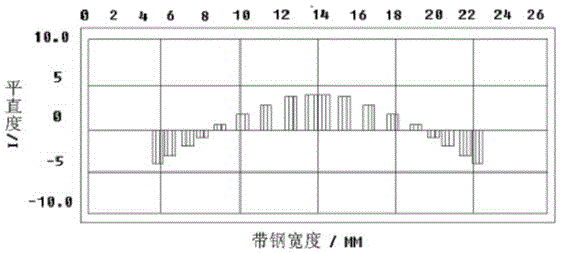

[0044] see figure 1 — image 3 , a method for controlling an emulsion fine cooling system, the method comprising the following steps: 1) calculating residual defects of the shape according to the contact tension data of the sheet and strip steel measured by the shape roller at the exit of the rack,

[0045] 2) Calculate the number of effective nozzles according to the residual defects of the plate shape and the width of the strip, and N effective = B / 52

[0046] In the formula, B is the strip width (mm), and the distance between each nozzle is 52mm,

[0047] 3) According to the selected ratio, calculate the number of nozzles that should be opened N open, N open = N effective × K1,

[0048] K1 is the selected opening ratio, generally we choose 50%. Of course, you can reset K1 as needed,

[0049] 4) Search for N positions according to the optimal algorithm, and the positions of N nozzles are the N points with the largest residual plate shape defects,

[0050] 5) Use the d...

Embodiment 2

[0063] Example 2: see Figure 4 — Figure 9, an emulsion fine cooling control device, the control device includes a detection unit, a control unit, an execution unit, and a computer control system, and the detection unit includes a plate-shaped roller (11) for detecting tension at the outlet of the rack, and the roller body is set There are 26 sections, and each section is equipped with 4 pressure sensors for detecting tension in the four directions of 0°, 90°, 180° and 270° of the circumference, a total of 104, and it will detect different tensions of different sections values are transmitted to the computer control system,

[0064] The control unit includes a profile control system 15 and a flatness control system 12, which converts and calculates the tension change signal transmitted by the profile rollers. The first wave A 1 x 4 is processed by inclination, and the second wave A 2 x 2 Processed by roll shifting and roll bending, 3 times and 4 times of high-order wave...

Embodiment 3

[0065] Example 3: see Figure 4 — Figure 9 , as an improvement of the present invention, the execution unit includes spray beam 1, liquid inlet pipe 2, air inlet pipe 3, lower work roll 4, upper work roll 5, plate and strip steel 6, tube bundle connection interface 7, nozzle A 8, B nozzle 9, C nozzle 10, pneumatic control system box 13, air source 14, upper surface control air source 16, lower surface control air source 17, emulsion frequency conversion pump 18, emulsion heater 19, piston blind end Cavity 20, built-in compressed air, emulsion medium cavity 21 in the spray beam box, injection valve body 22, injection valve fixing bolt 23, nozzle 24, injection channel 25, cavity 26 connecting the piston and the atmosphere, piston parts, all The spray beam is set as a two-chamber structure, the two-chamber spray beam 1 separates the liquid inlet pipe 2 and the air inlet pipe 3, and the cooling sections correspond to the sections of the plate shape measuring rollers, which are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com