Hydraulic cylinder with clearance sealed type deformed piston

A piston clearance and sealing technology, applied in the field of hydraulic cylinder, can solve the problems of difficult to control clearance and leakage, achieve the effect of simple structure, reduce leakage and improve frequency response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

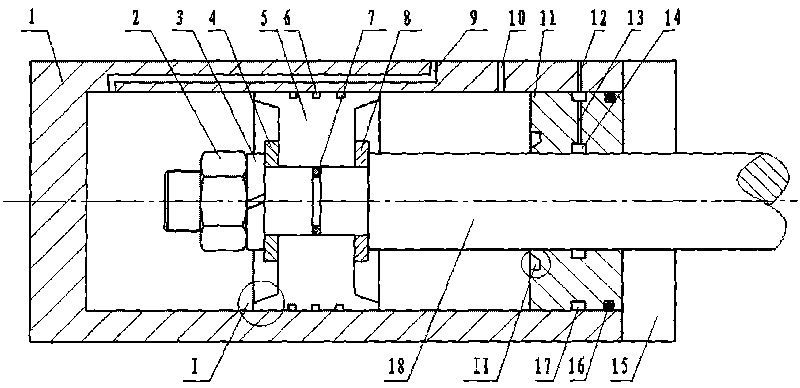

[0025] A deformation piston gap sealing hydraulic cylinder, such as figure 1 As shown, the hydraulic cylinder includes a cylinder block 1, a piston 5, a piston rod 18, a guide sleeve 11 and an end cover 15. It is characterized in that there are 3 to 5 balance grooves 6 symmetrically and evenly opened on the outer circle of the piston 5. The piston rod 18 of the piston 5 is provided with a first sealing groove 7 , and the end faces on both sides of the piston 5 are provided with annular bosses having the same outer diameter as the piston 5 .

[0026] A second sealing groove 16 is provided at the outer circumference of the guide sleeve 11, and a first oil drain groove 14 and a second oil drain groove 17 are respectively provided at the inner and outer circles of the guide sleeve 11. The first oil drain groove 14 passes through the The second oil drain channel 13 communicates with the second oil drain channel 17, the second oil drain channel 17 communicates with the first oil dra...

Embodiment 2

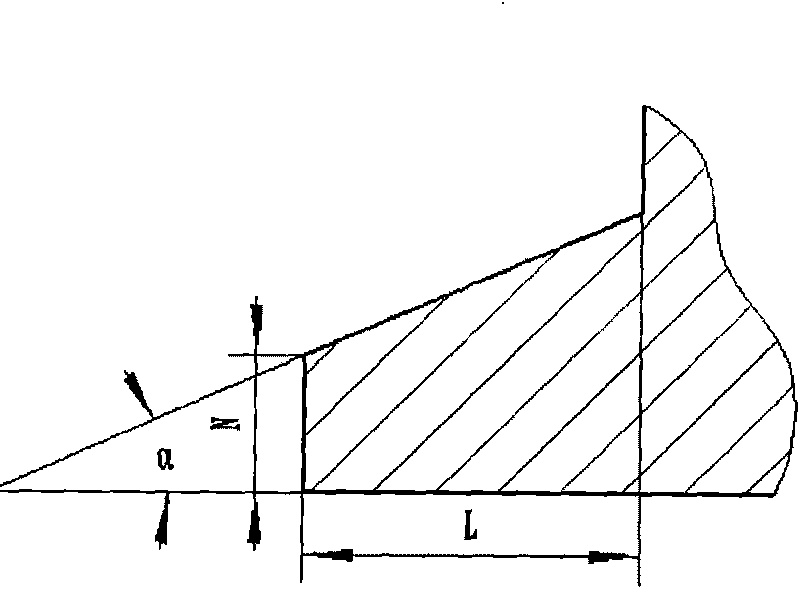

[0034] A deformation piston gap sealing hydraulic cylinder. The shape of the annular boss is as figure 2 As shown, the cross section is a right trapezoid, the included angle of the right trapezoid is α=30~35°, the height of the right trapezoid is L=8~12mm, and the length of the upper base of the right trapezoid is N=1.2~1.5mm. The annular boss is integral with the piston 5 .

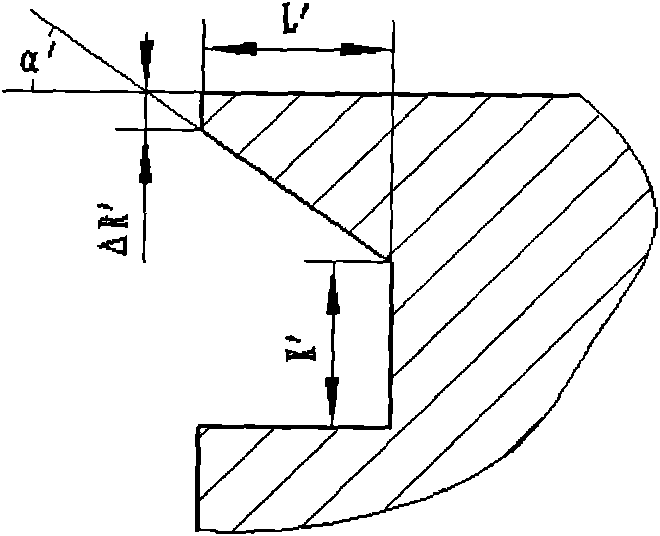

[0035] The annular groove on the inner end face of the guide sleeve 11 is as follows: image 3 As shown, the depth of the annular groove is L'=8~12mm, the bottom width of the annular groove is K'=8~10mm, the cross section of the annular groove is a right-angled trapezoid, and the included angle of the right-angled trapezoid is α'=30~35° ; The difference between the inner radius of the annular groove at the end face and the inner radius of the guide sleeve 11 is ΔR′=1.3~1.5mm;

[0036] The groove width of the balance groove 6 on the piston 5 is 0.6-0.8mm, the groove depth is 0.8-1.0mm, and the distanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Groove width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com