Steel structure fabricated cavity floor slab

A cavity floor, prefabricated technology, used in floors, building components, building structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

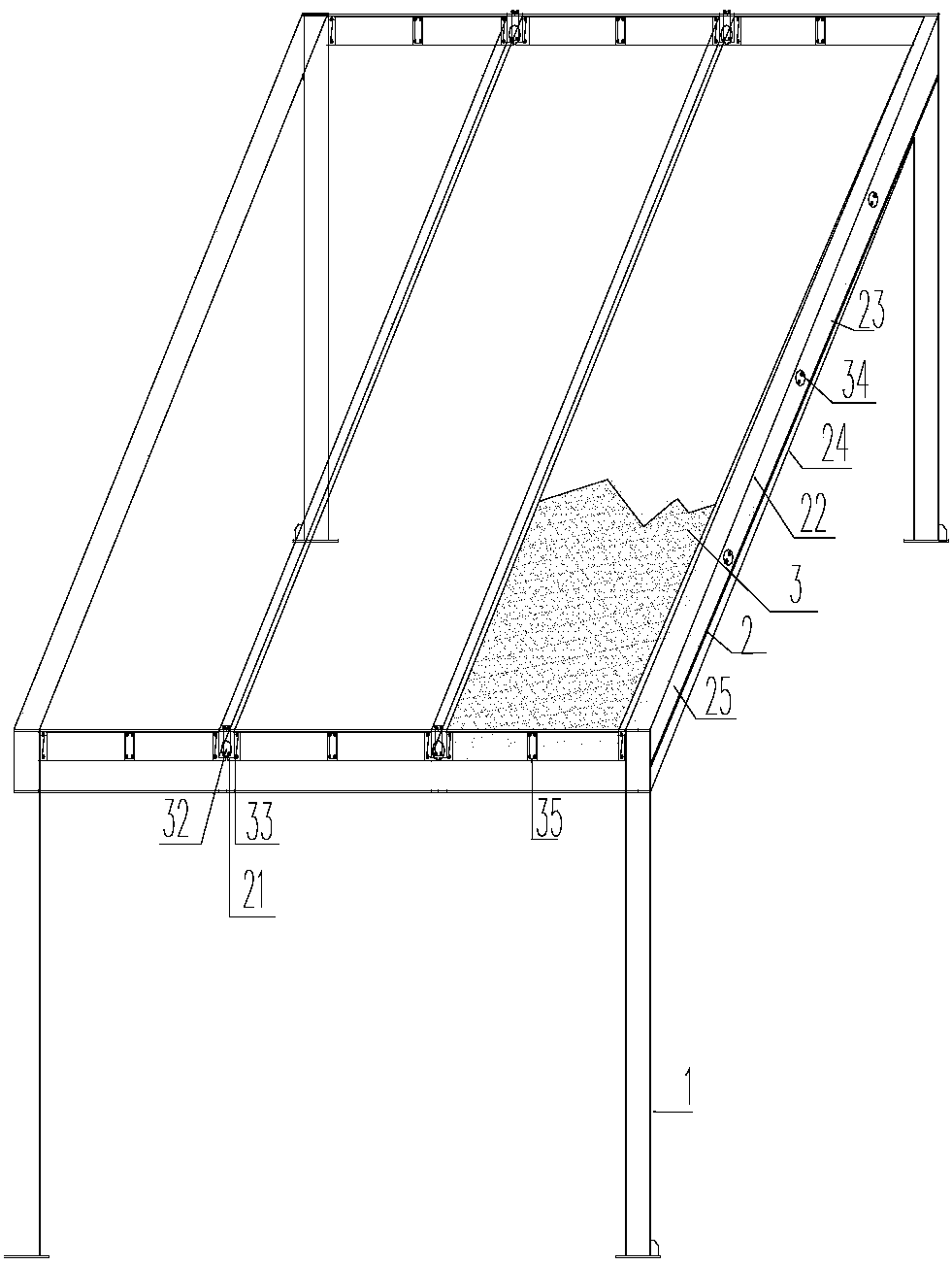

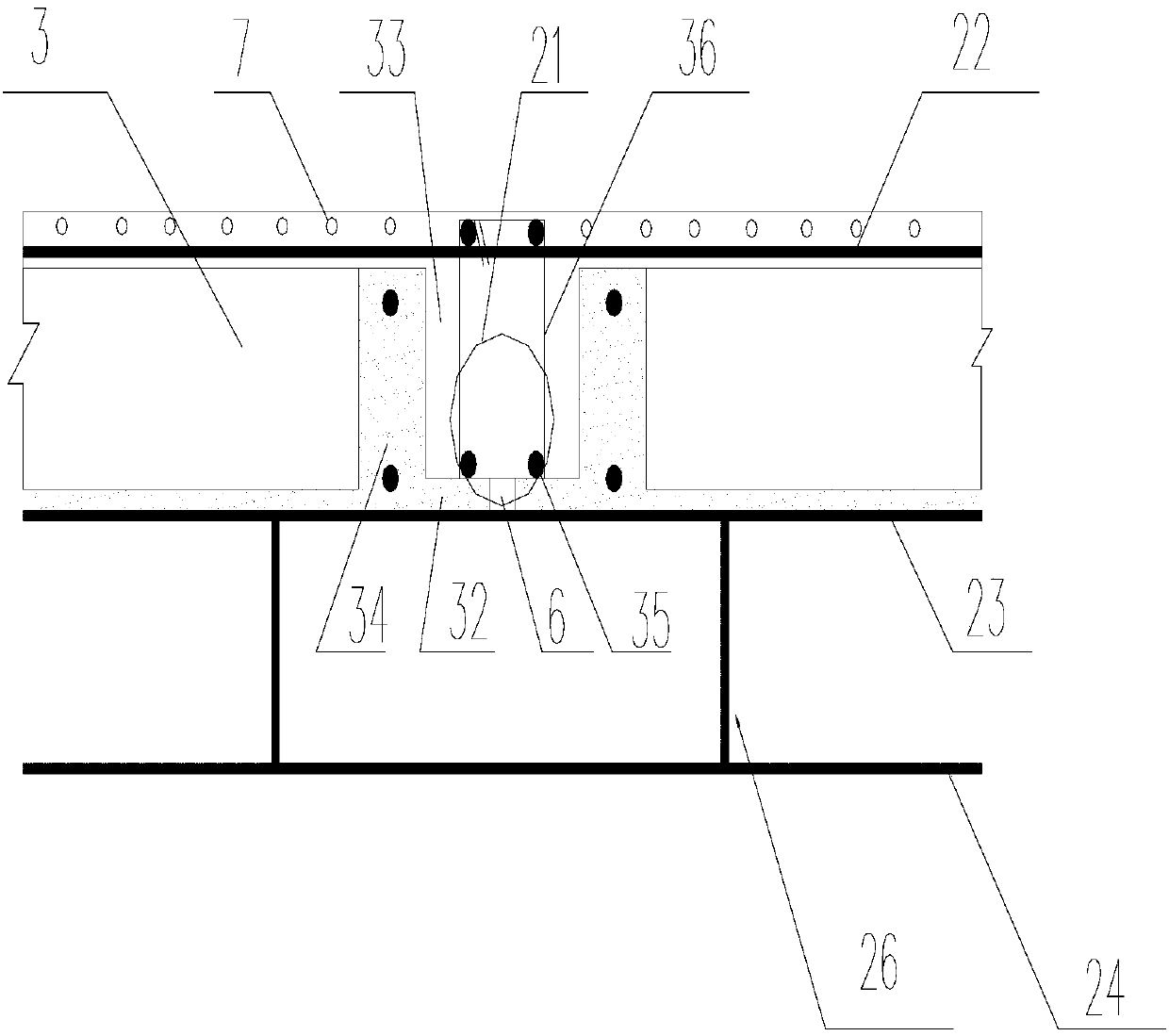

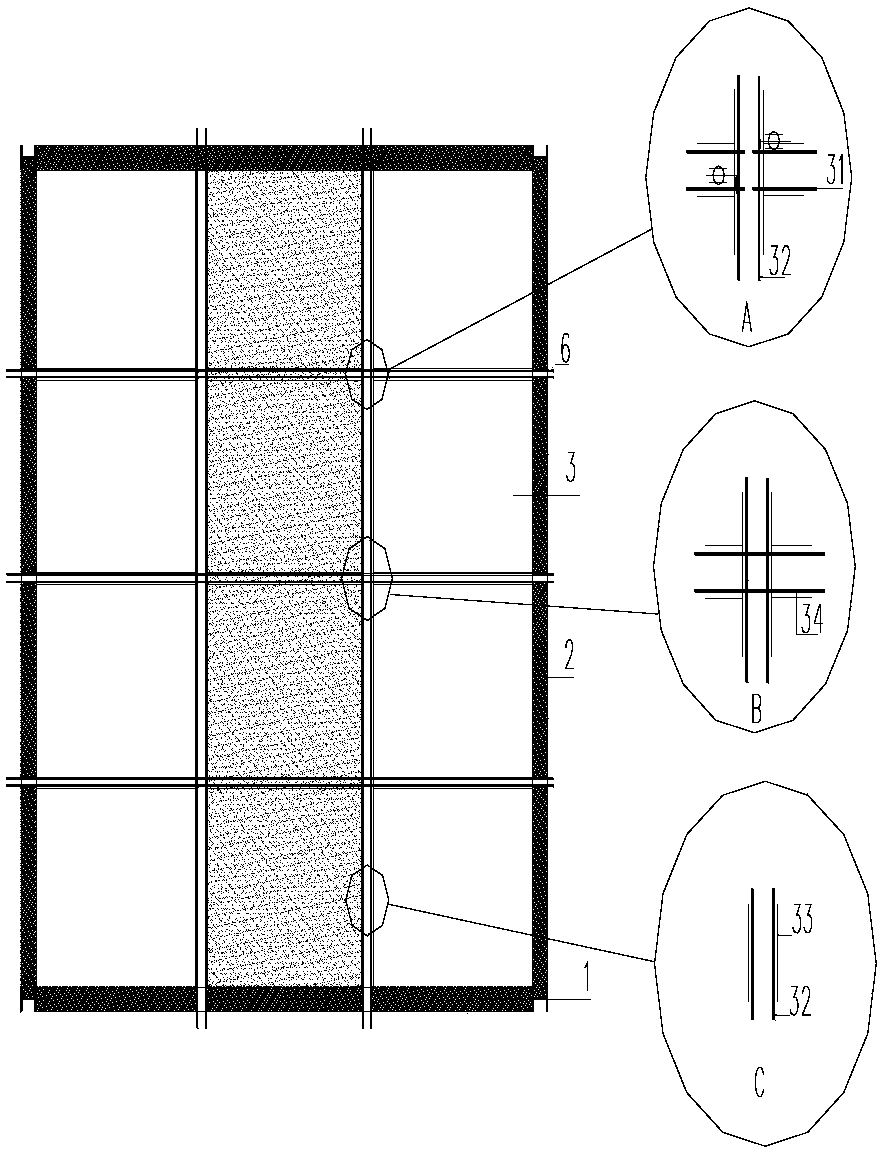

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] figure 1 It is an embodiment of a steel-concrete combined fabricated building floor structure of the present invention. When the present invention is implemented, the steel column 1, the king-shaped steel beam 2, and the cavity plate member 3 manufactured by the factory are respectively transported to the construction site; The section steel column 1 and the king-shaped steel beam 2 are installed on the foundation column piers, and the external wall panels of the enclosure structure can be inlaid in the H-shaped steel column at the same time; the lifting cavity plate member 3 is assembled on the king-shaped steel beam 2 Supports are provided between the flange plate 22 and the middle flange plate 23, and between the lower flange plate 24 and the middle flange plate 23; the L-shaped concrete 32 of the two adjacent cavity plate members 3 are convexly joined to form a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com