Automobile kinetic energy conversion and recovery device

A kinetic energy conversion and vehicle technology, used in power units, pneumatic power units, vehicle components, etc., can solve the problems of short service life, large braking energy, large volume and weight of subways, etc., to improve vehicle performance, fast and stable Smooth braking and acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

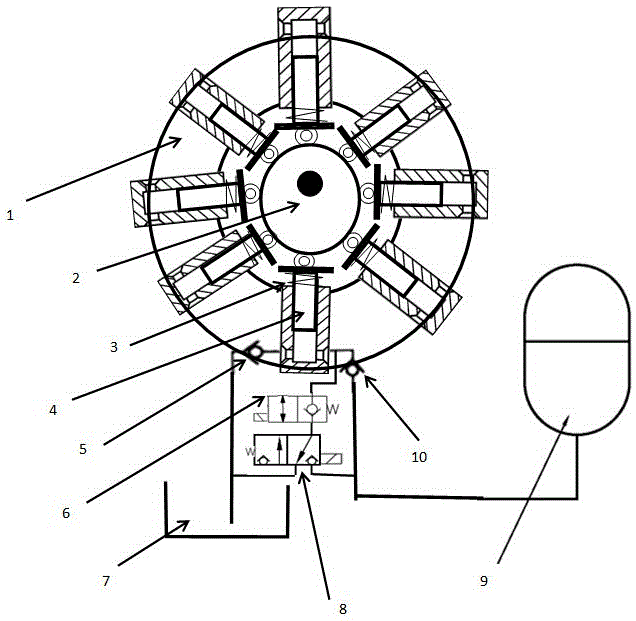

[0022] Such as figure 1 As shown: a plurality of hydraulic plungers 4 are evenly distributed in the pump body 1, and the roller 2 at the end of each plunger rod is pressed against the eccentric wheel 2 under the action of the plunger return spring 3 . Each plunger has a hydraulic circuit to control its oil suction and discharge, charging and discharging. The circuit consists of oil suction check valve 5, oil discharge check valve 10, two-position two-way electromagnetic stop valve 6, and two-position three-way electromagnetic stop valve. 8 composition. figure 1 Only the hydraulic circuit corresponding to one plunger is drawn, and the circuits of other plungers are the same.

[0023] When the vehicle starts to brake, the eccentric wheel is synchronized with the wheel shaft of the vehicle through the switch of the clutch to drive the eccentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com