Patents

Literature

45results about How to "Control drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

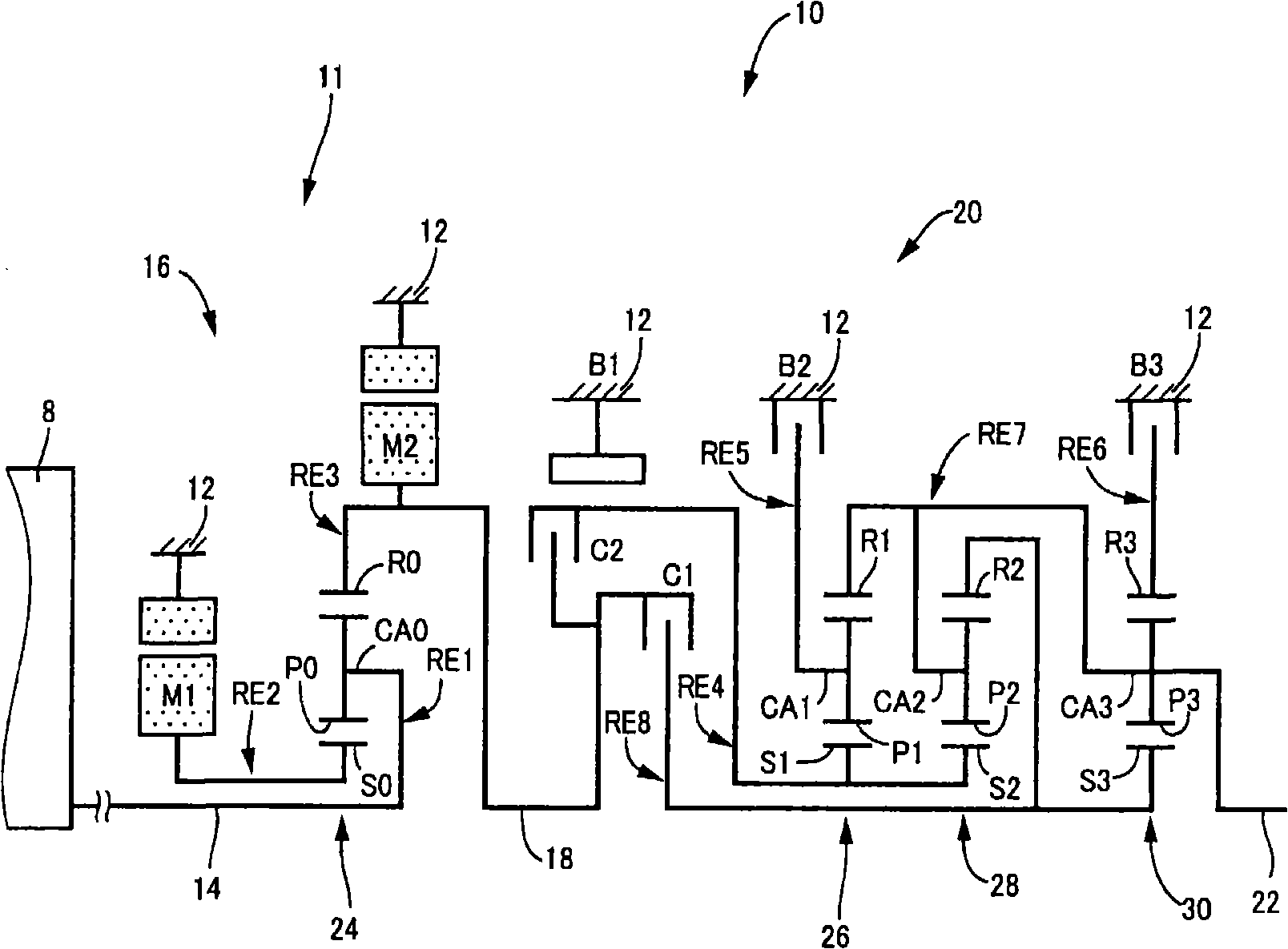

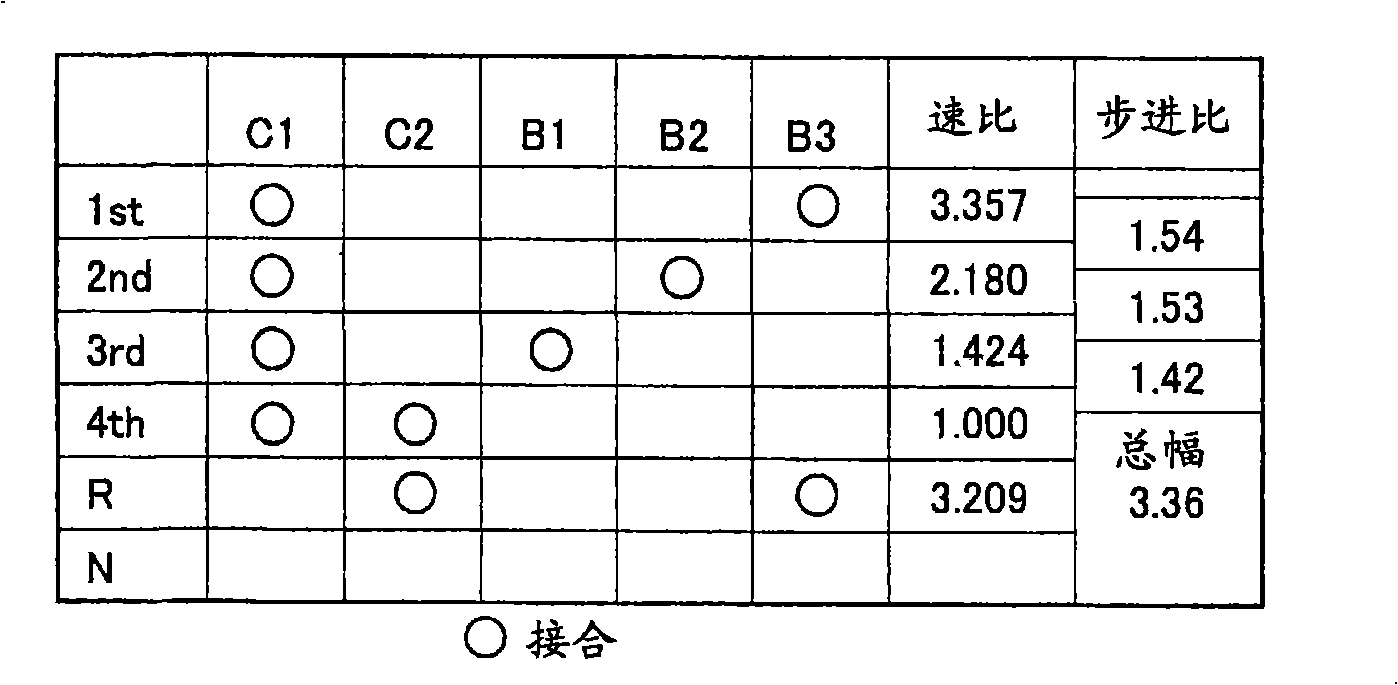

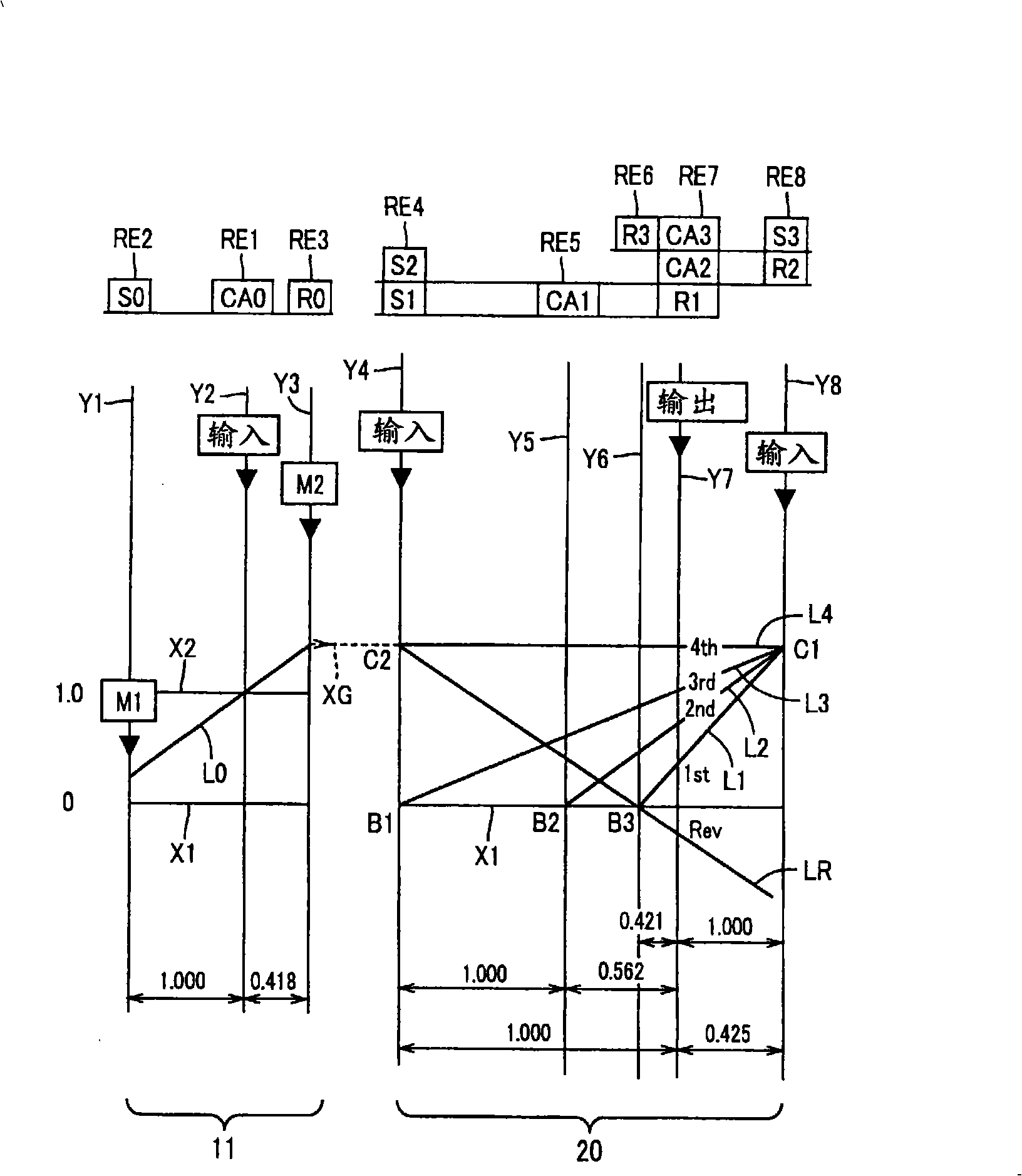

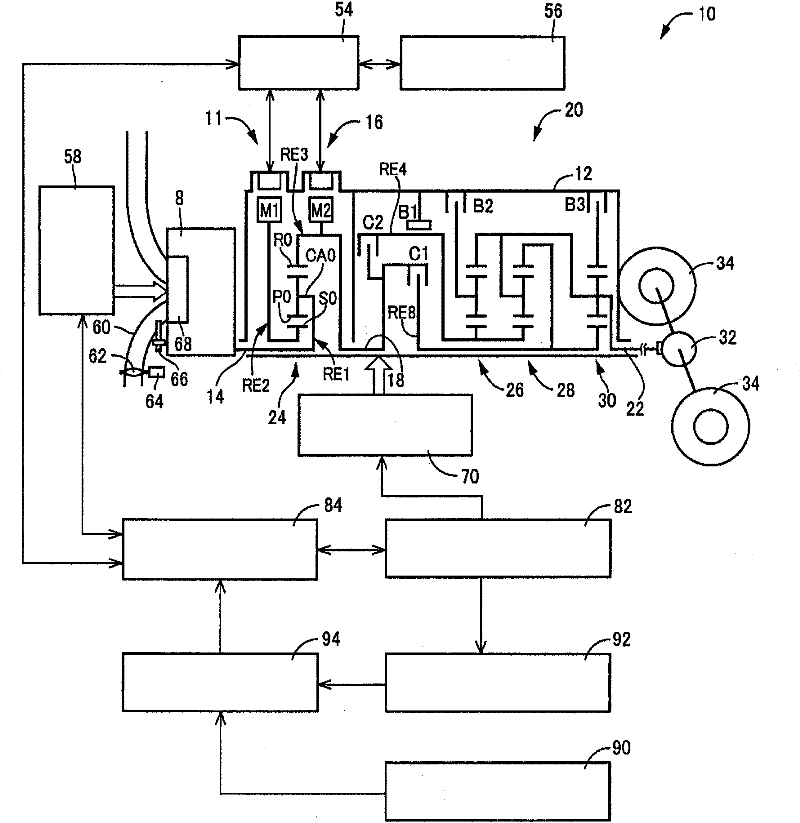

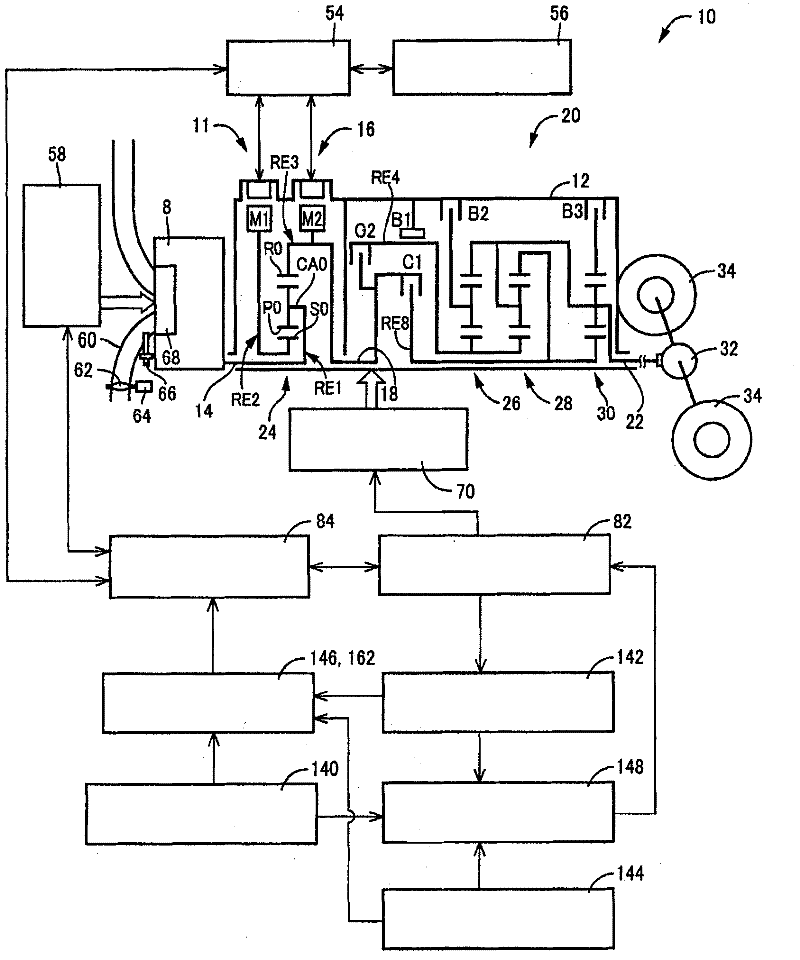

Engine start-up device for hybrid vehicle power transmitting device

ActiveCN101342902AIncrease speedGreat driving forceHybrid vehiclesElectrical controlEngineeringHybrid vehicle

Owner:TOYOTA JIDOSHA KK

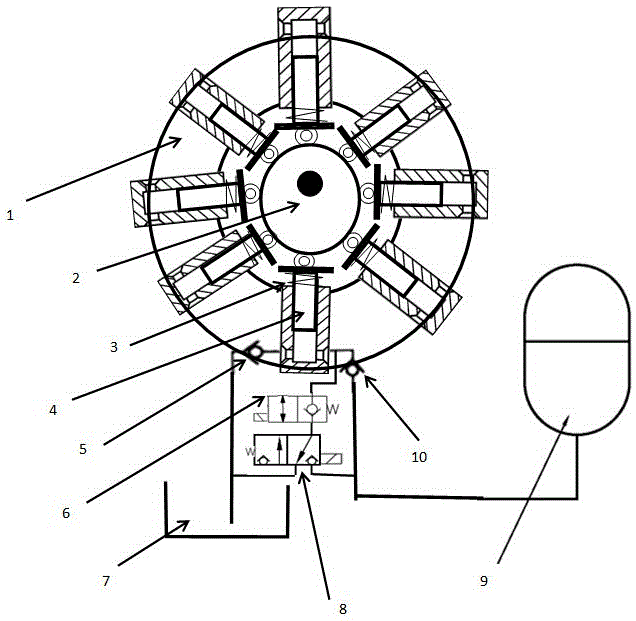

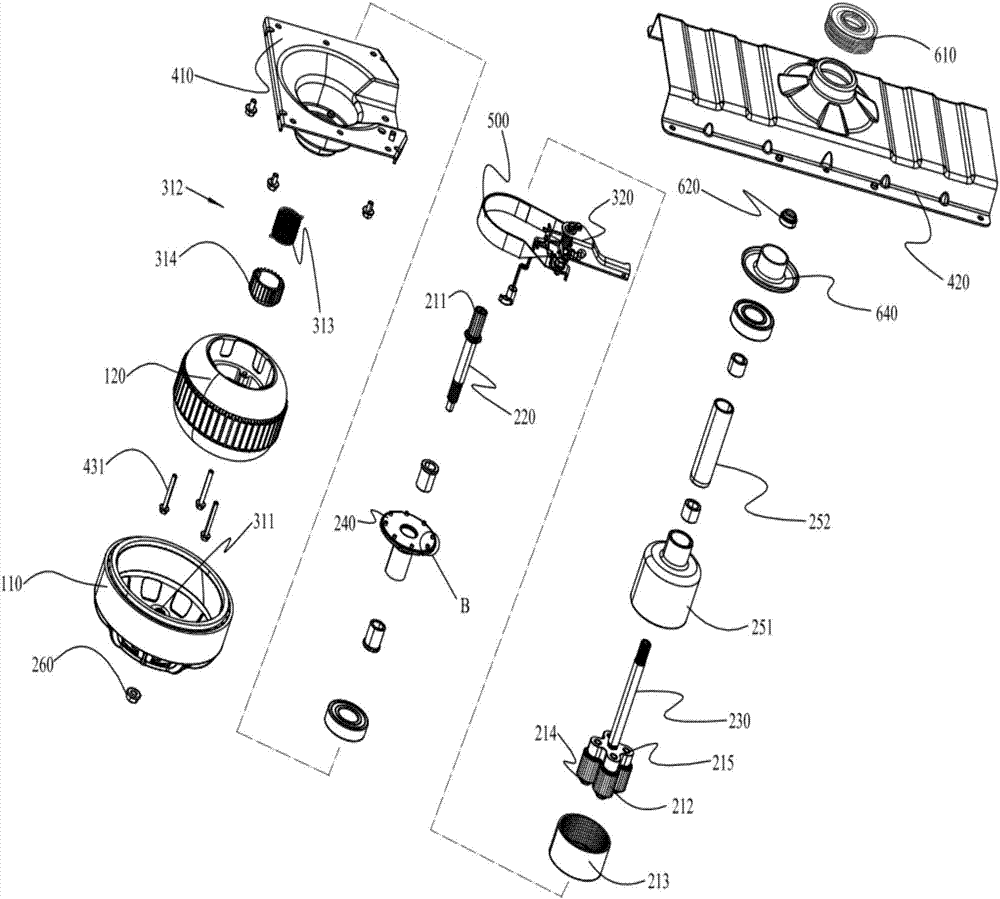

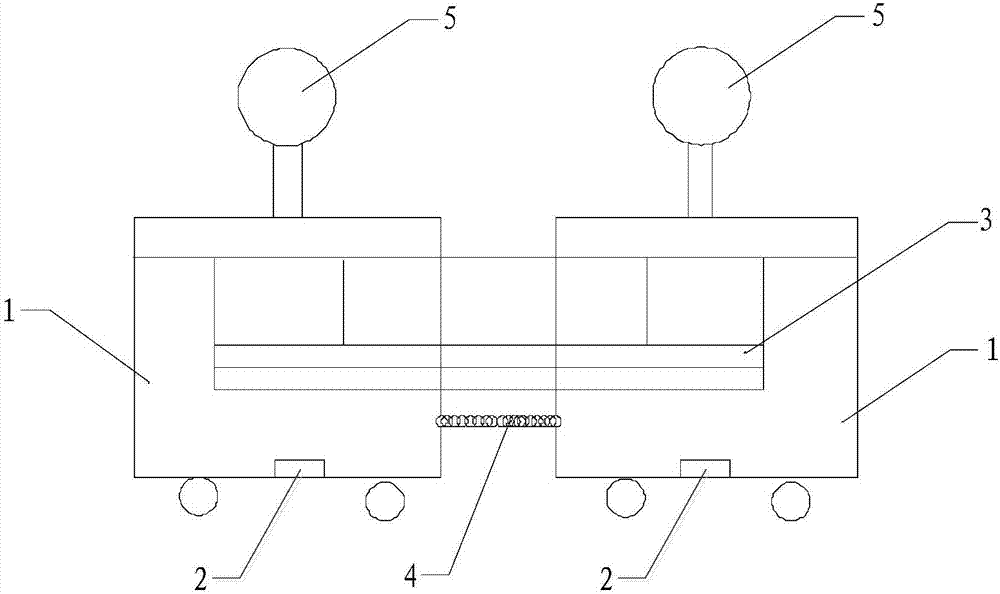

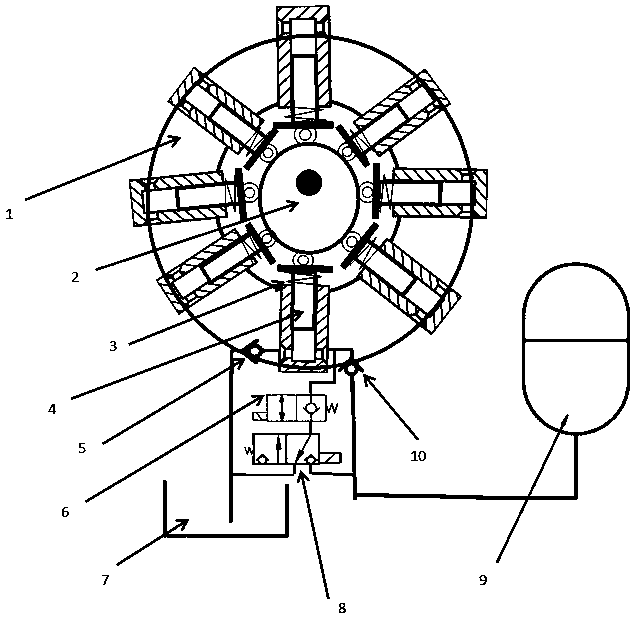

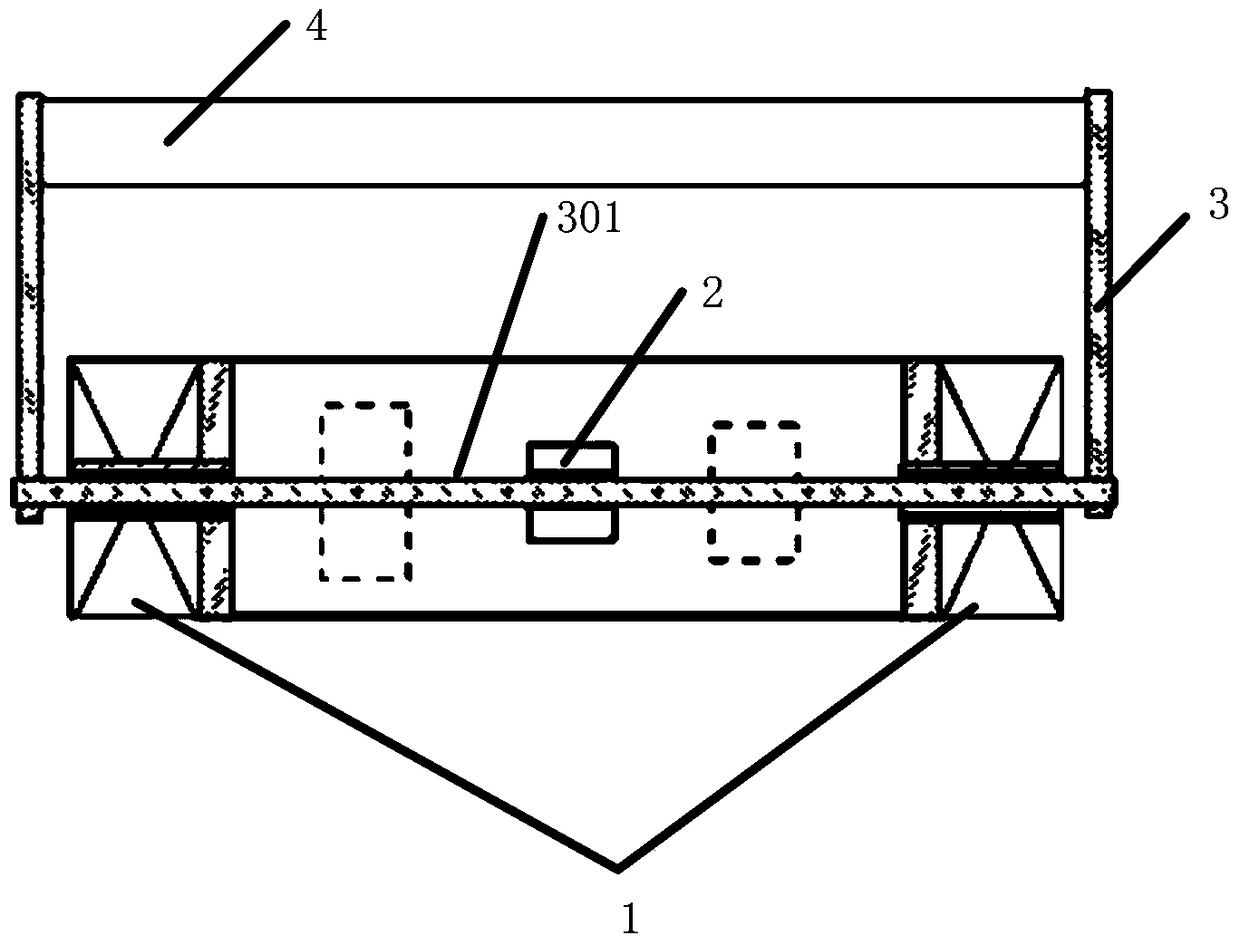

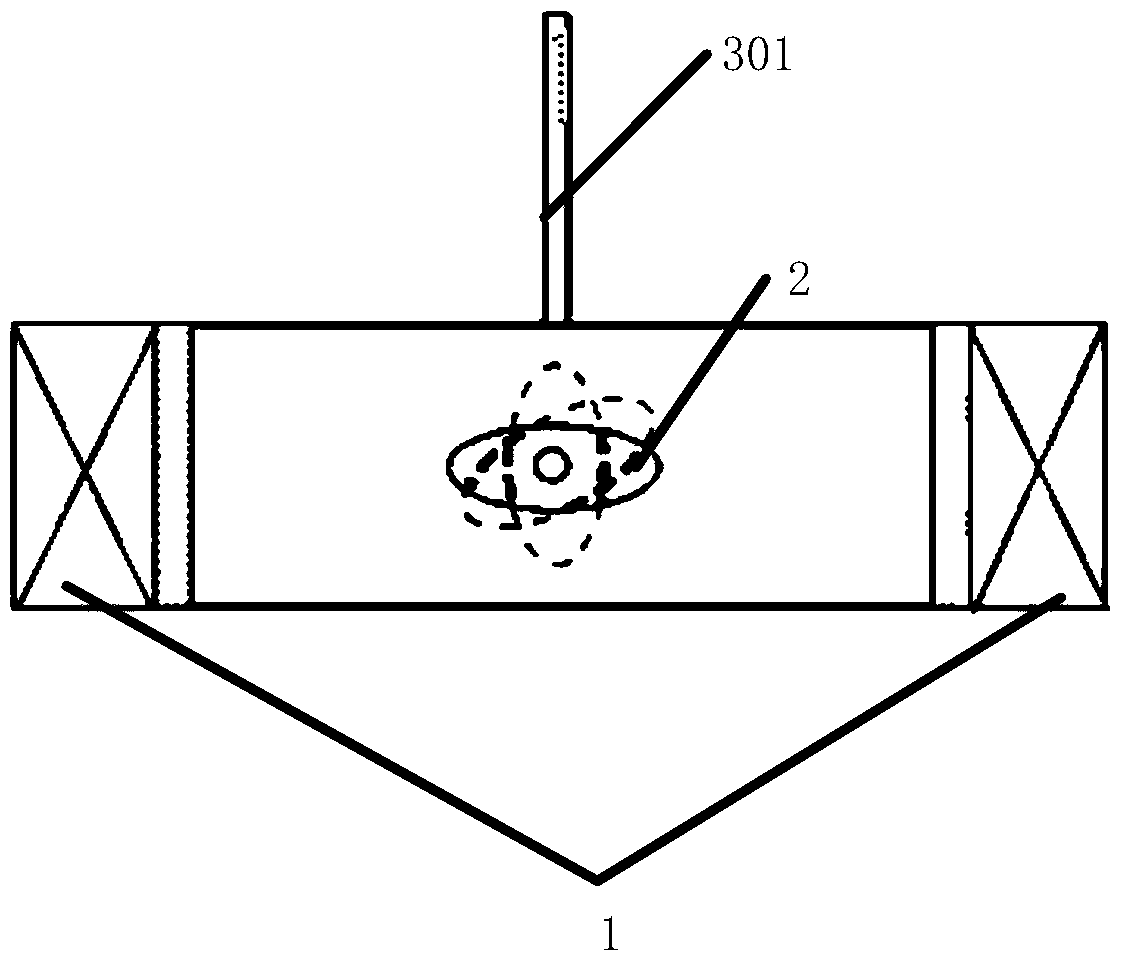

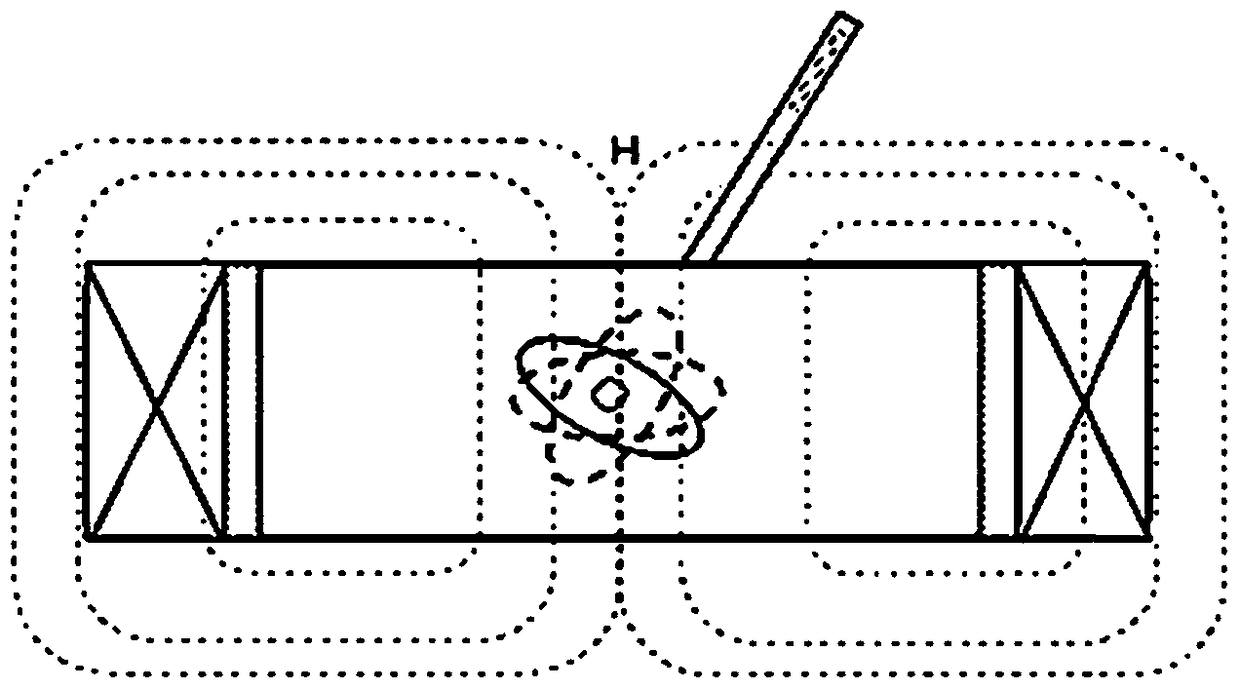

Automobile kinetic energy conversion and recovery device

ActiveCN105059274AImprove efficiencyIncrease energy densityHybrid vehiclesBraking element arrangementsHydraulic motorRadial motion

The invention discloses an automobile kinetic energy conversion and recovery device. The automobile kinetic energy conversion and recovery device is used for storing energy during subway braking and recovering kinetic energy during starting. The automobile kinetic energy conversion and recovery device mainly comprises an eccentric wheel, hydraulic plungers and a corresponding hydraulic loop. During subway braking, the eccentric wheel and an axle rotate synchronously, so that the built-in hydraulic plungers conducts reciprocating radial motion; hydraulic oil is pressed into an energy accumulator through the hydraulic plungers on the basis of the design of the corresponding hydraulic loop, and therefore kinetic energy of the automobile is converted into hydraulic energy to be stored. During subway starting, the device is used as a low-speed large-torque hydraulic motor on the basis of switching control over an electromagnetic valve to push a subway to achieve kinetic energy recovery. According to the automobile kinetic energy conversion and recovery device, the hydraulic mode is utilized for energy storage, braking energy is not converted into electric energy and is just stored as hydraulic energy, and the efficiency is much higher than that of the existing energy storage mode.

Owner:王林翔

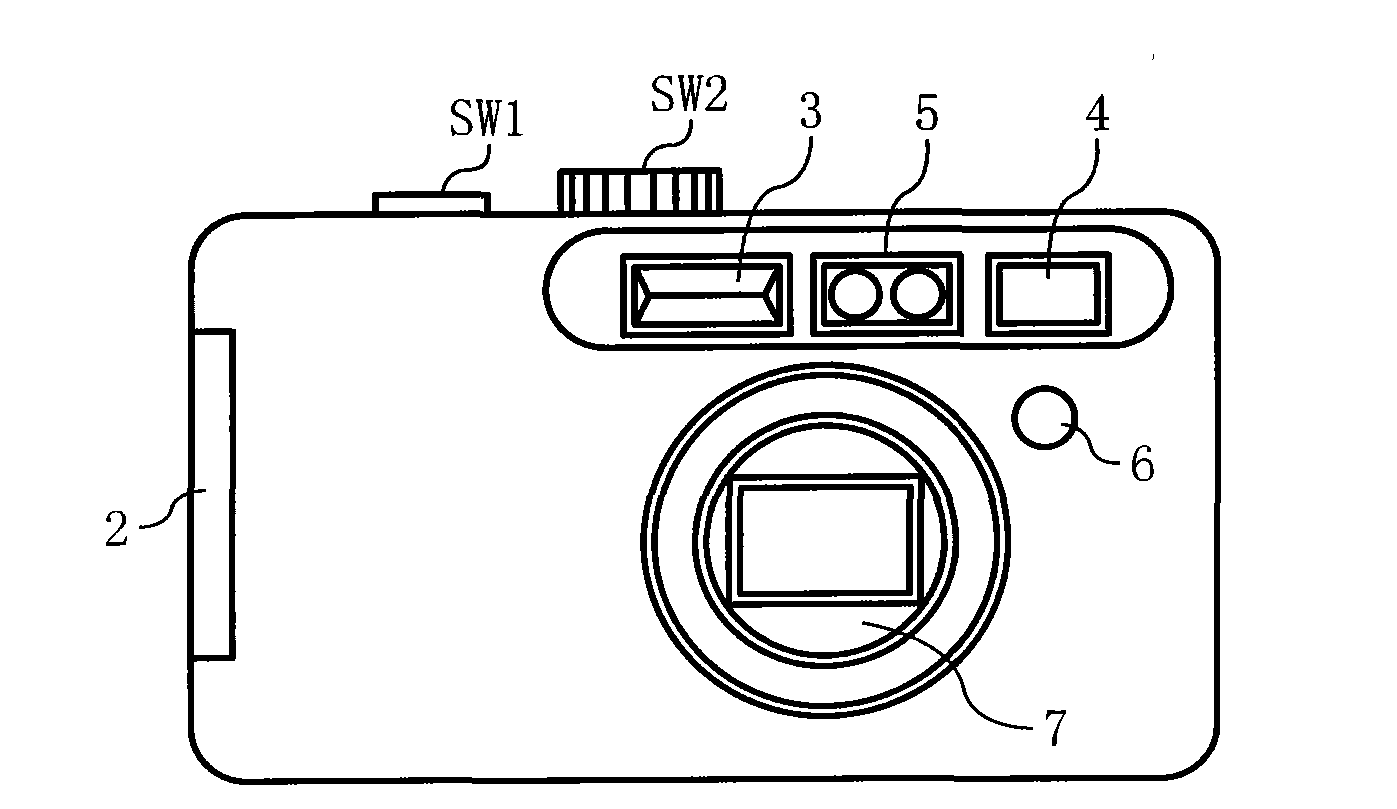

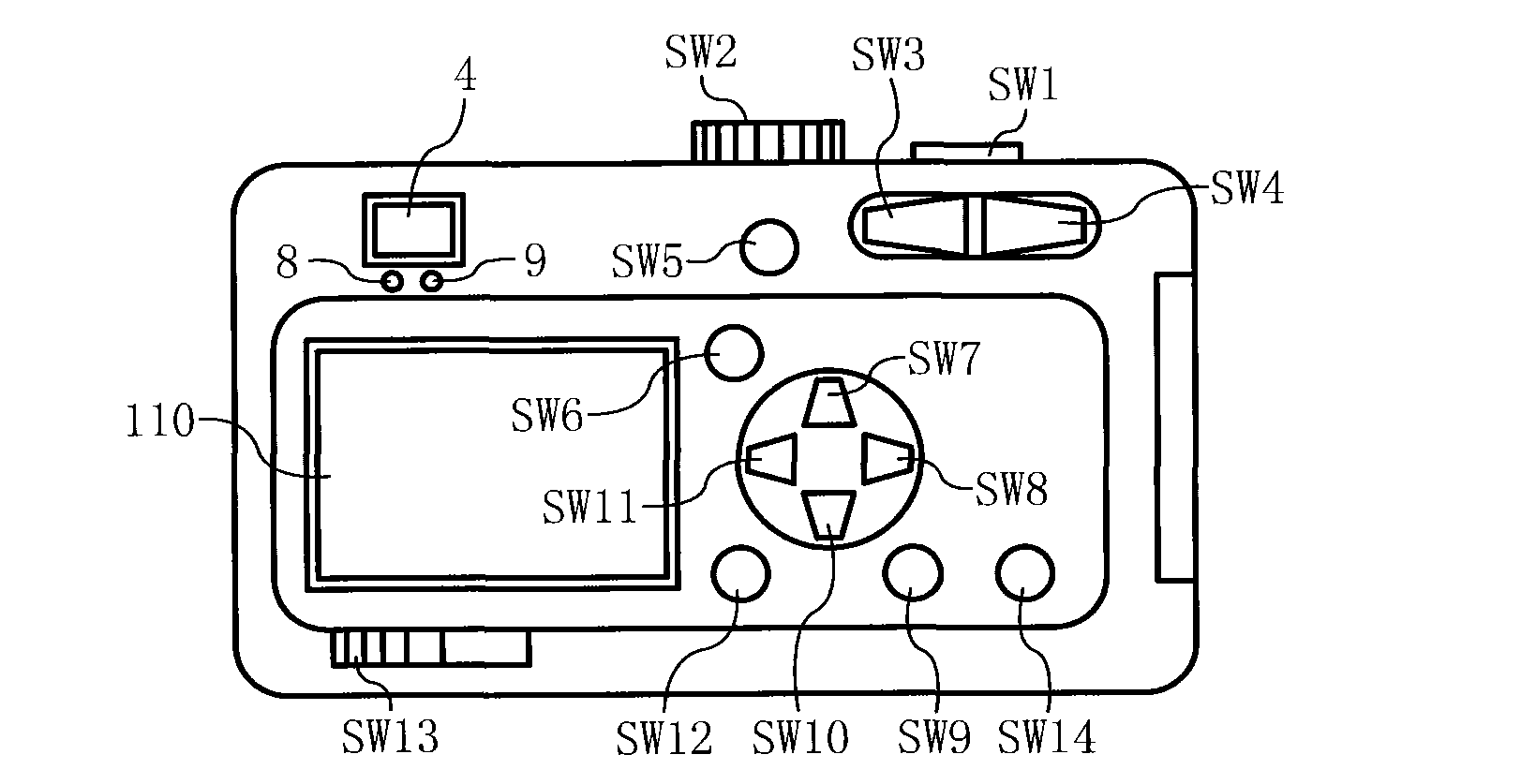

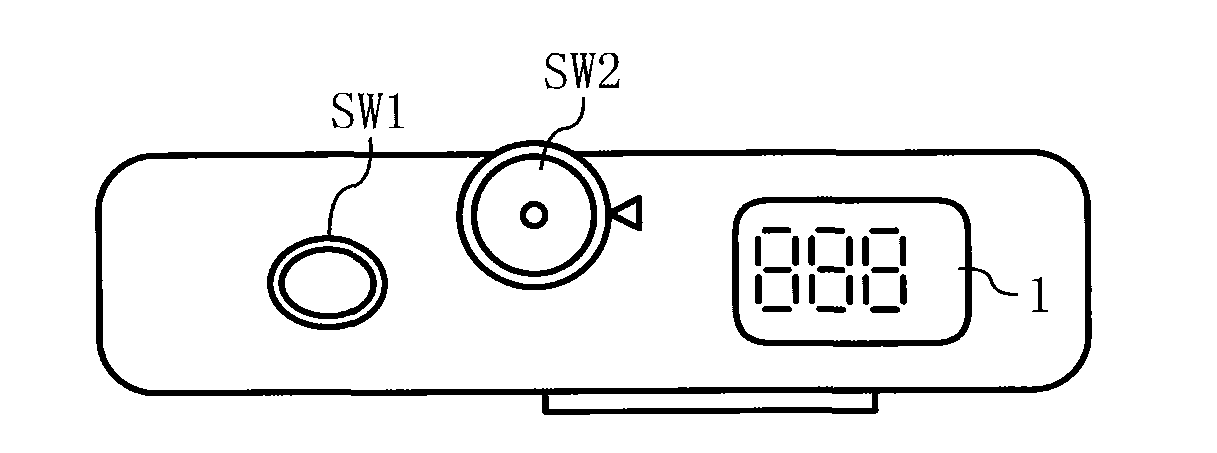

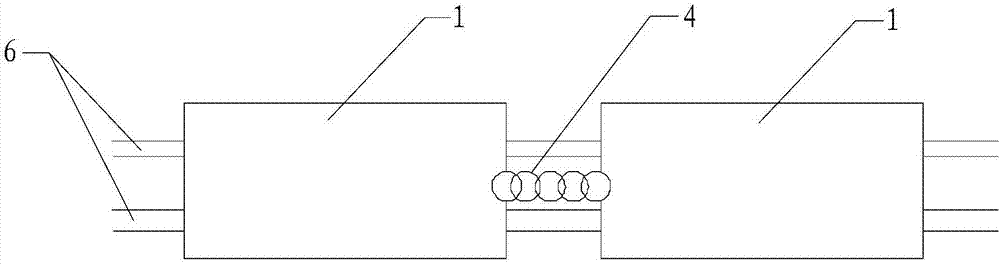

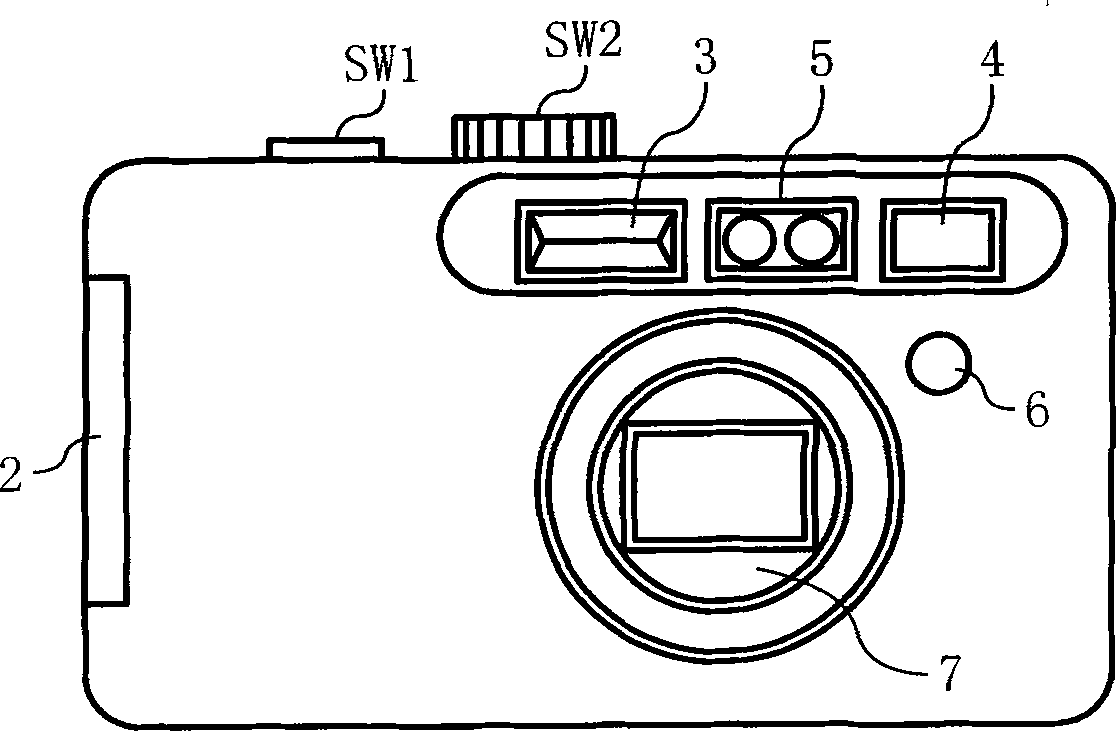

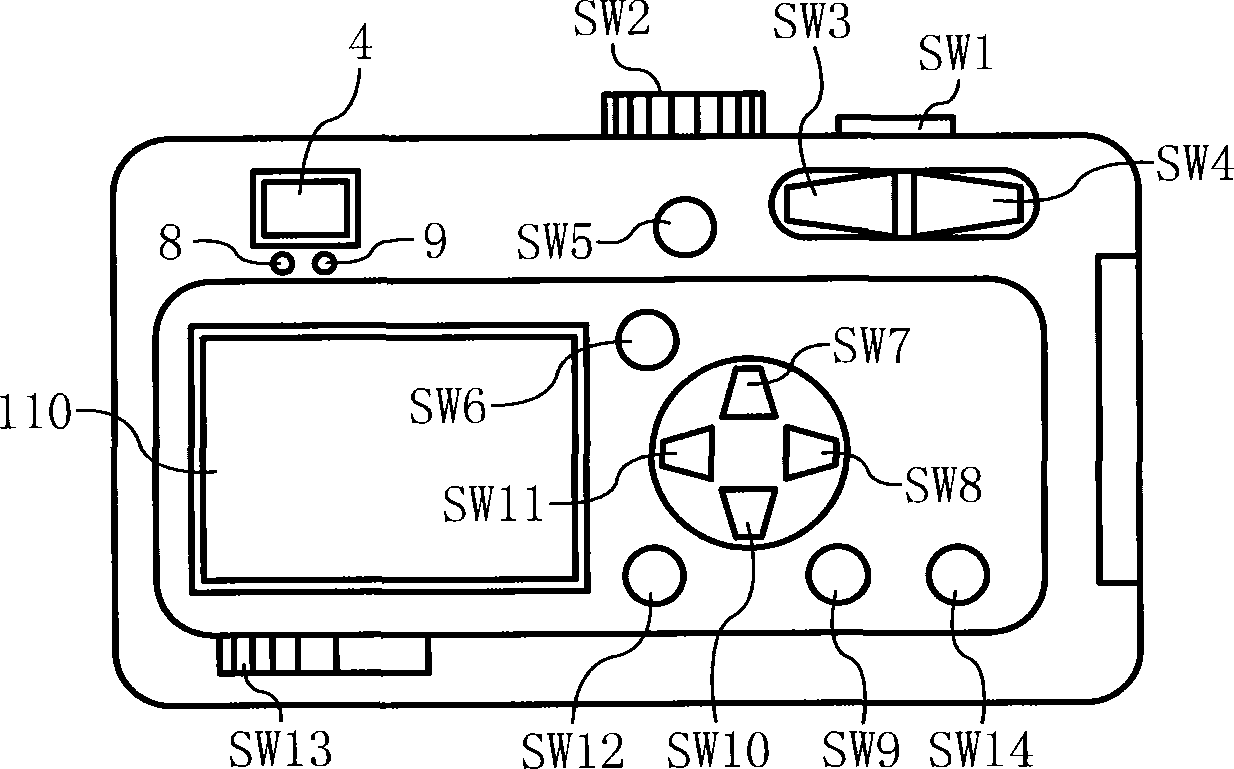

Flexible circuit board, photographing device, photographing optical device and electronic instrument thereof

InactiveCN102447825AEffectively absorb elastic reaction forceSmall footprintTelevision system detailsPrintersFlexible circuitsElectronic instrument

The present invention relates to a flexible circuit board, a photographing component with the same, a photographing optical device and electronic equipment. The flexible circuit board aims to absorb an elastic counterforce caused by bending deformation through saving space arrangement. The flexible circuit board (200) comprises an extending connection part (203) which is divided into a branched extending connection part (203b) and a main extending connection part (203a). When the branched extending connection part is folded to be overlapped with the main extending connection part, the extending connection part (203) comprises the following components: a first extending part (E1) which extends along an X-Y surface from a photographing component mounting part (201), a second extending part (E2) which extends along a Z axis, a third extending part (E3) which extends parallelly with the X-Y surface, a fourth extending part (E4) which extends reversely with the second extending part along a Z axis, and a fifth extending part (E5) which extends parallelly with the X-Y plane and has a terminal that is connected with a processing circuit connection part (202).

Owner:RICOH KK

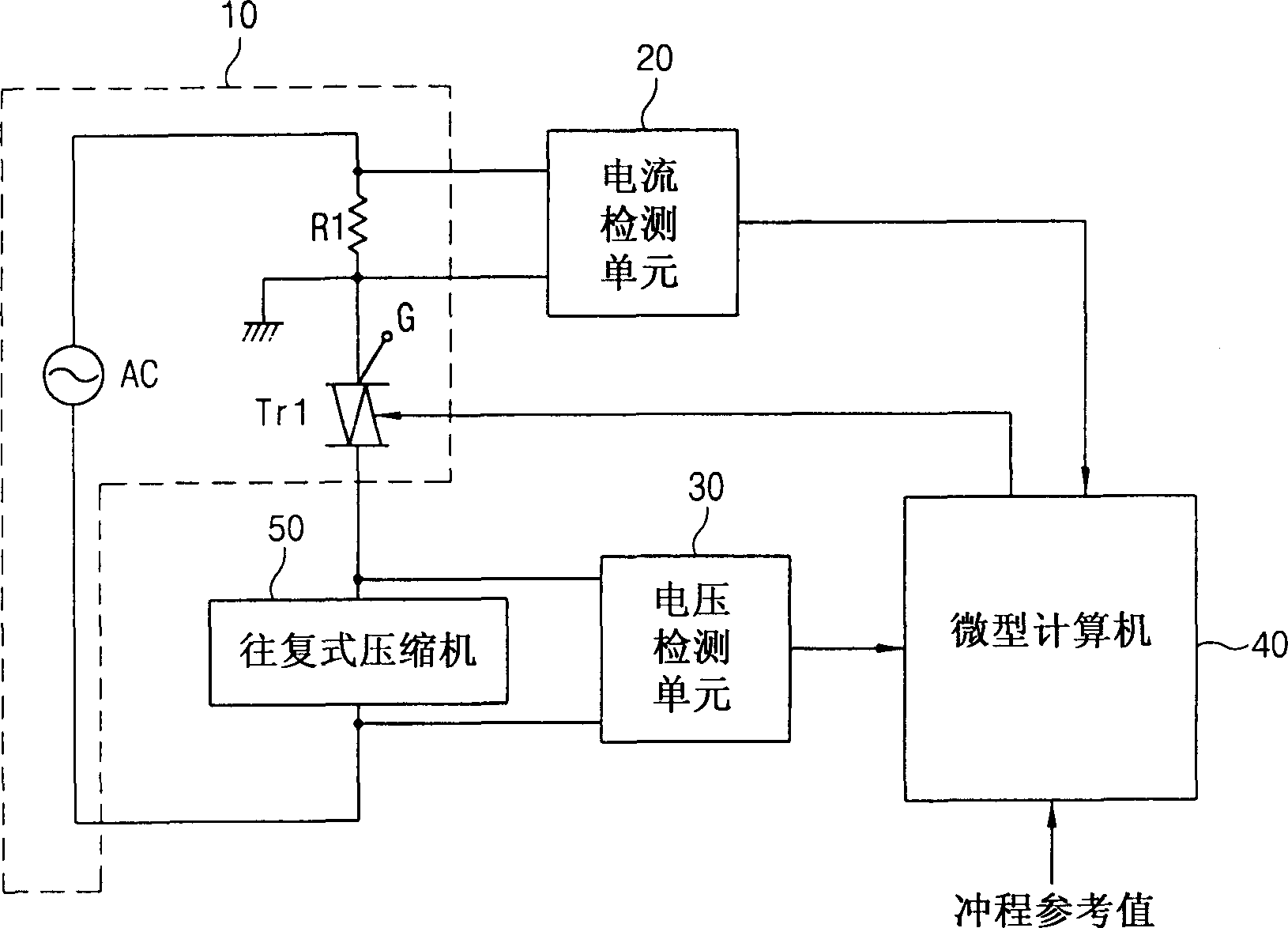

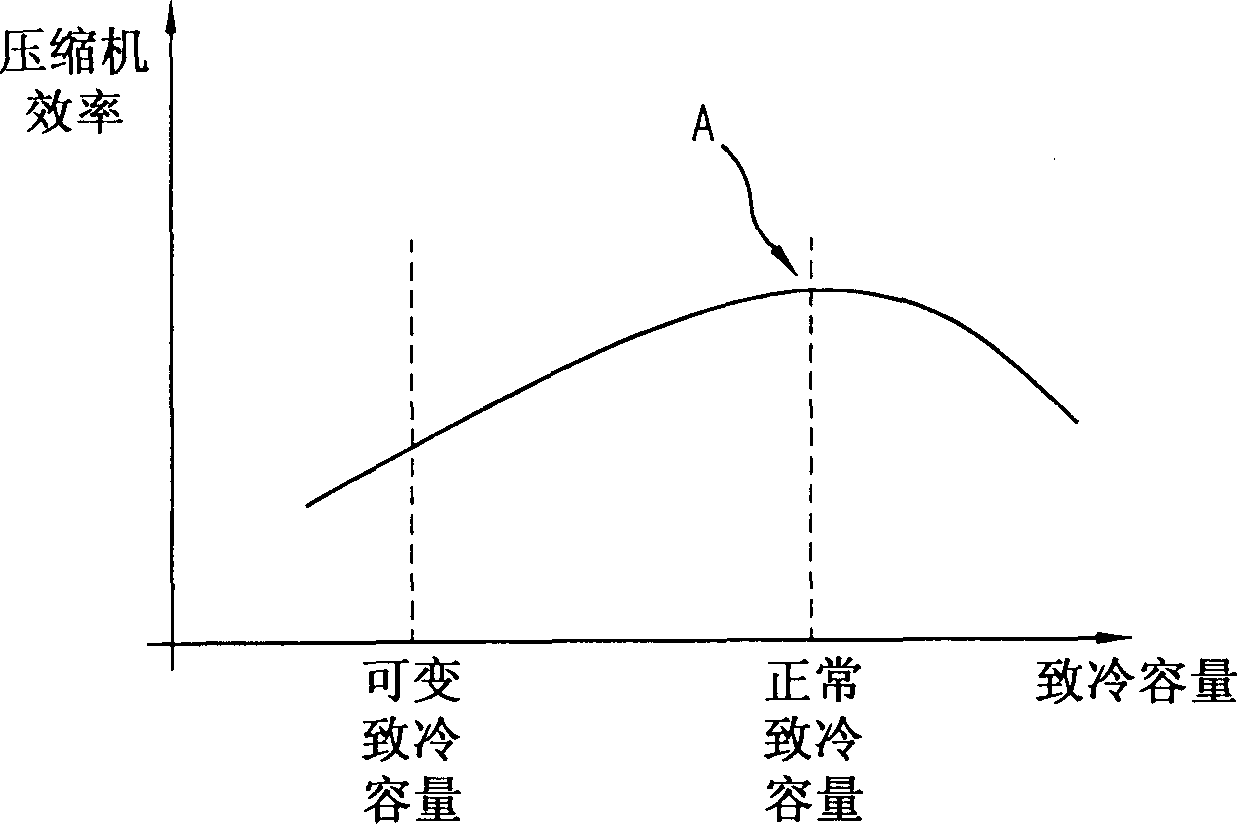

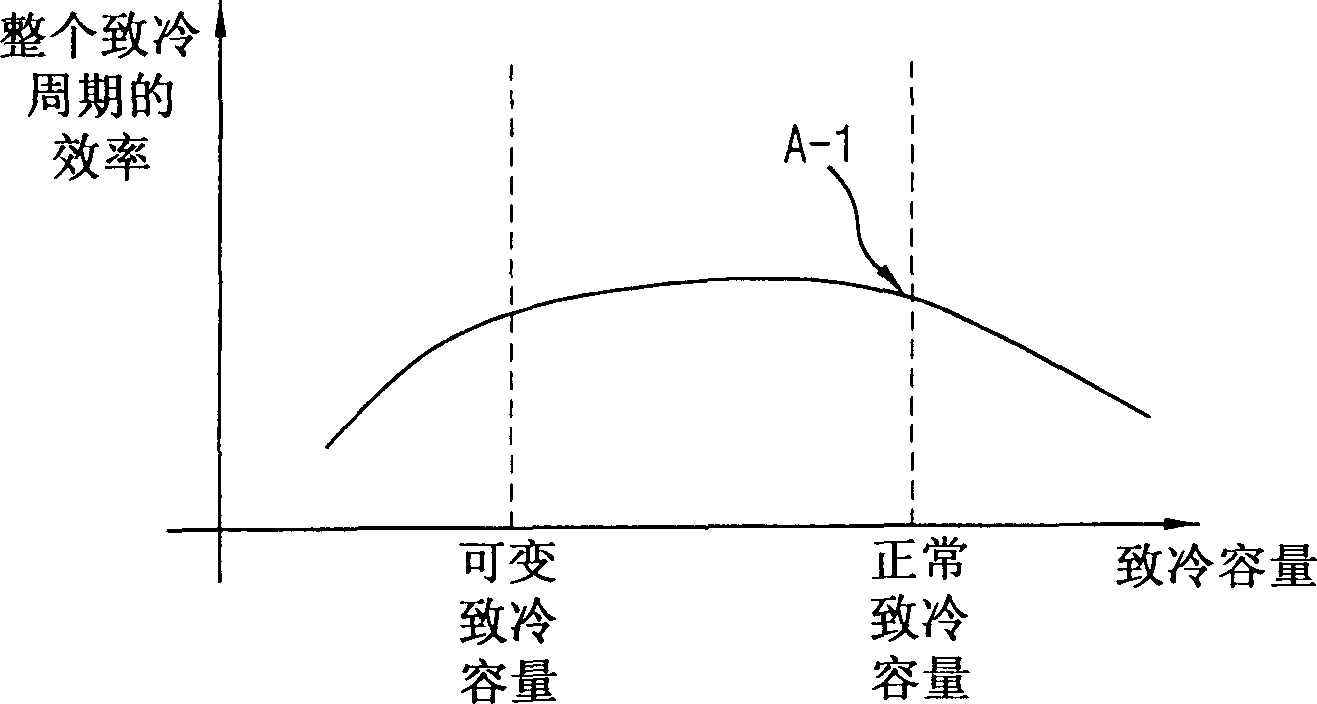

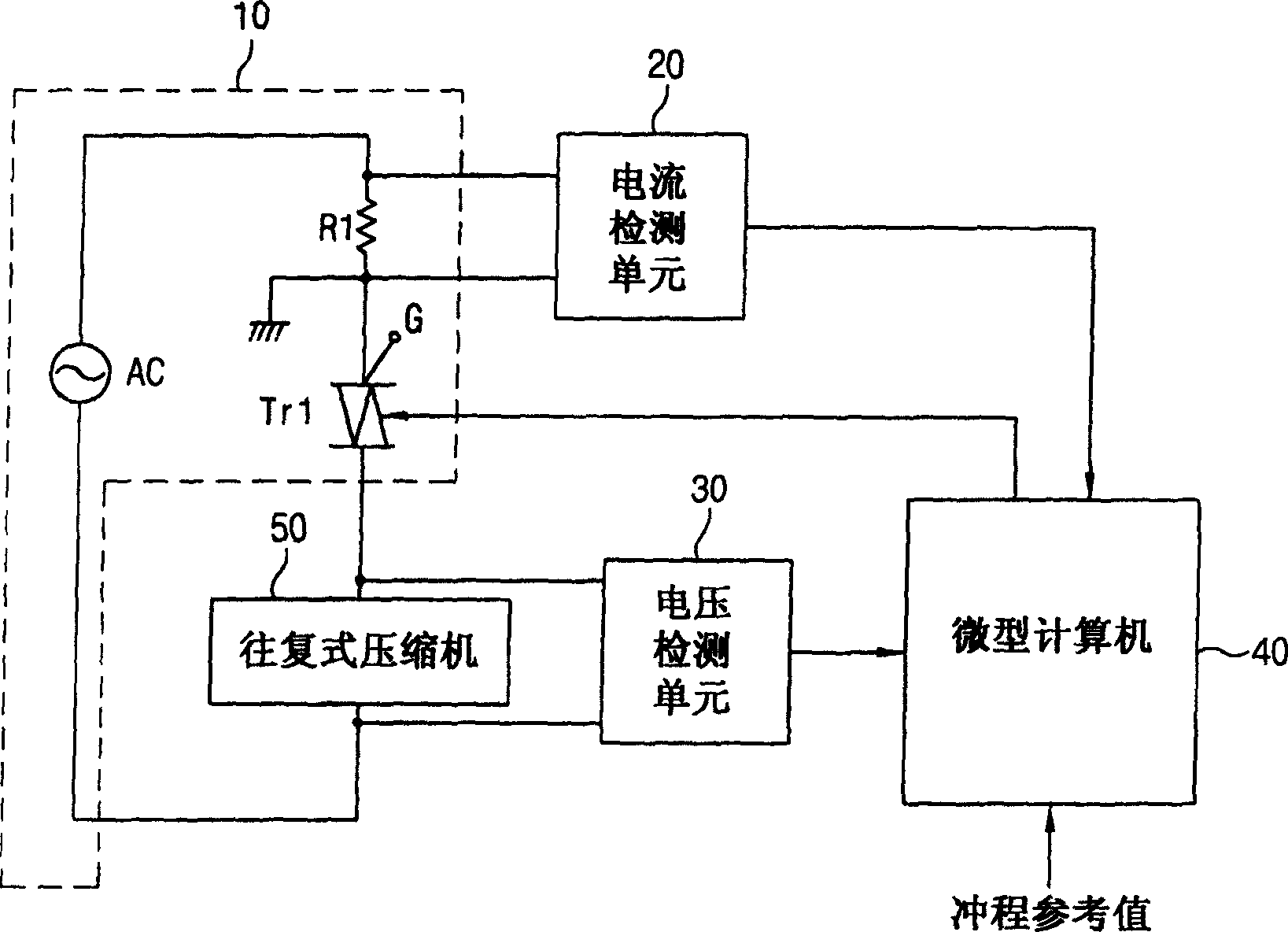

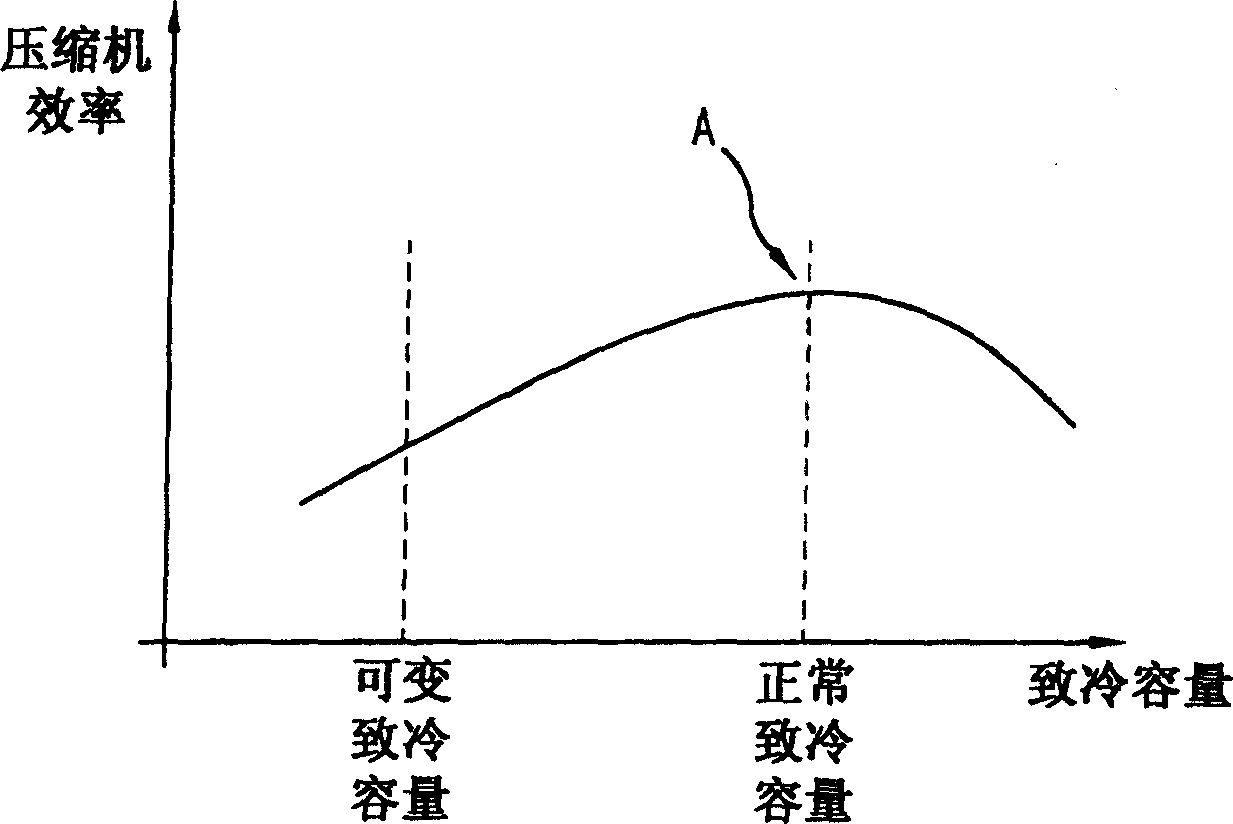

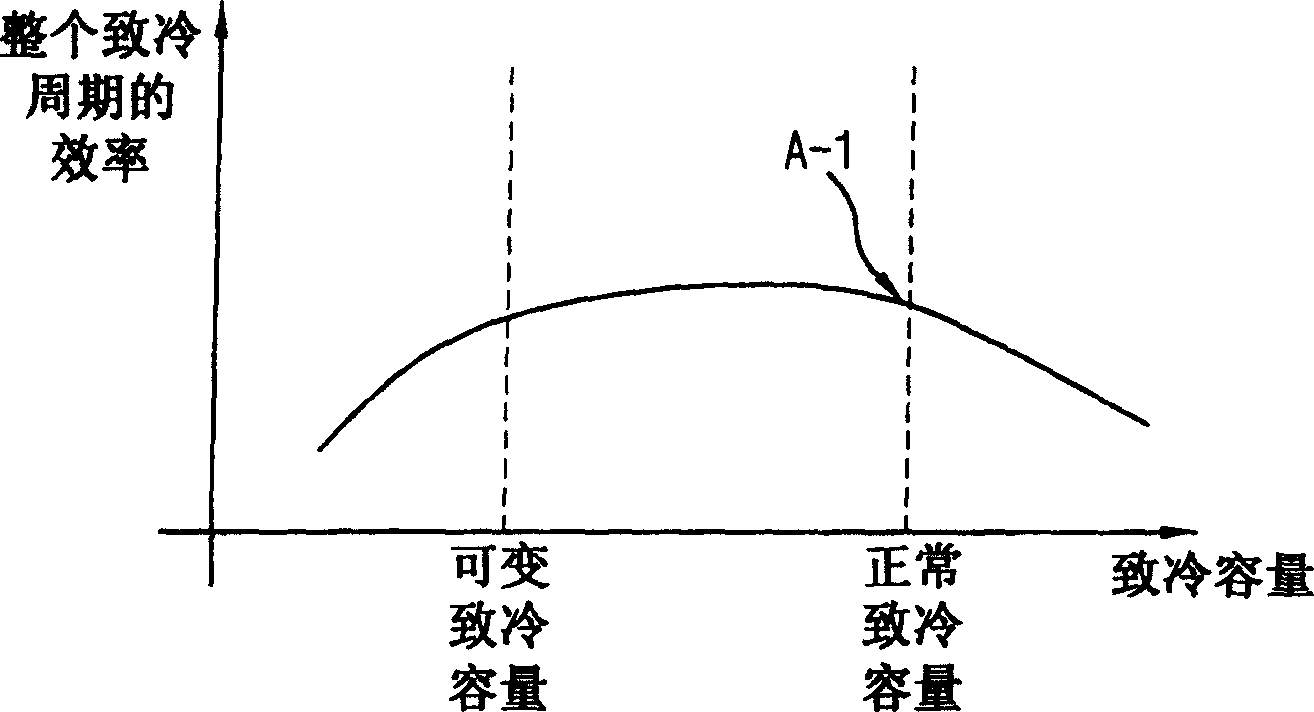

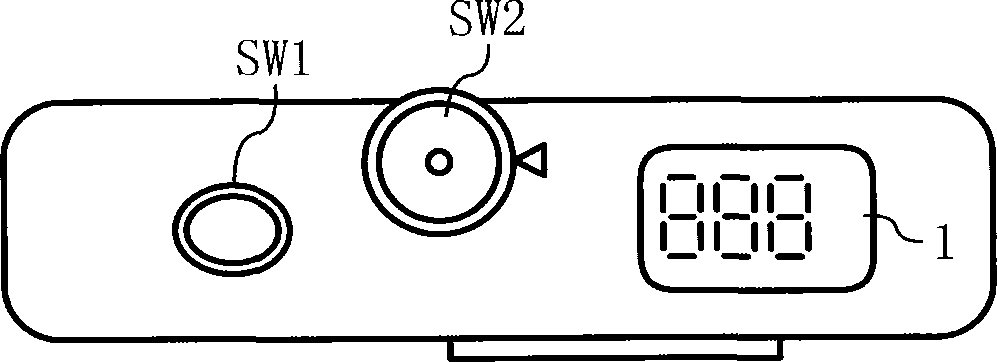

Drive controller and control method for reciprocating compressor

InactiveCN1432736AReduce cooling capacityNo re-expansion lossLighting and heating apparatusDomestic refrigeratorsMicrocomputerValue set

Disclosed is an apparatus for controlling a driving of a reciprocating compressor and a method thereof, in which a cooling capacity is decreased without a re-expansion loss by controlling a driving of a compressor used in a refrigerator by using a current offset when the cooling capacity of a refrigerator is varied. To this end, in the compressor which controls the cooling capacity by varying an inner stroke according to a stroke reference value set by a user, the apparatus comprises a storage unit for storing a current offset value corresponding to a cooling capacity variable amount; an adding unit for adding the current offset value to a current value applied to the compressor in accordance with that the cooling capacity is varied by a user; a microcomputer for generating a switching control signal corresponding to the current value added from the adding unit; and a power supply unit for controlling a driving of the compressor by applying the added current to the compressor under a dependent state on the switching control signal.

Owner:LG ELECTRONICS INC

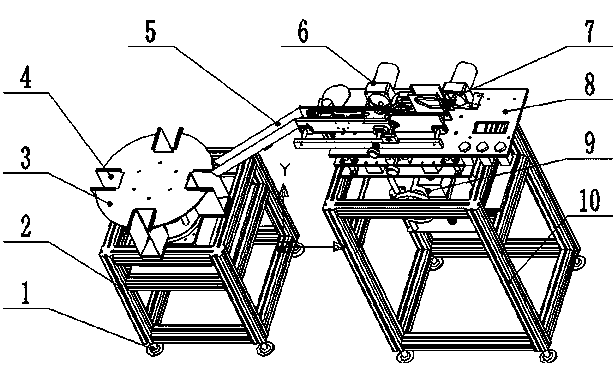

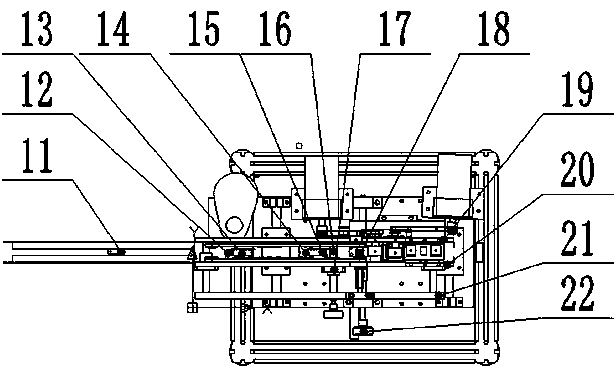

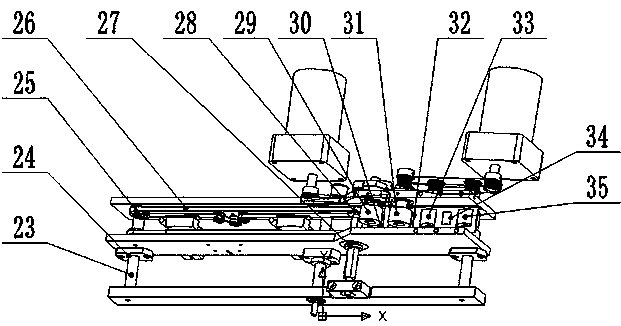

Automatic feeder for label laser marking

ActiveCN103832094AControl driveControl the speed of codingOther printing apparatusEngineeringCounter rotation

The invention discloses an automatic feeder for label laser marking. The mode that synchronous belts, shafts and friction wheels are matched is adopted. A first motor output shaft drives a first synchronous belt by a first synchronous belt pulley to rotate, drives a second synchronous belt pulley, a third synchronous belt pulley and a fourth synchronous belt pulley to rotate, and drives a first shaft, a second shaft and a third shaft to rotate; the other ends of the first shaft, the second shaft and the third shaft are provided with a first friction wheel, a second friction wheel and a third friction wheel respectively; the first friction wheel, the second friction wheel, the third friction wheel, the first shaft, the second shaft and the third shaft rotate synchronously; the upper horizontal tangent planes of the first friction wheel and the second friction wheel and the lower horizontal tangent plane of the third friction wheel are located on the same plane, and the first friction wheel, the second friction wheel and the third friction wheel rotate in the same direction; labels inside a feed hopper are directly pressed on the first friction wheel and the second friction wheel, the label at the bottommost face moves leftwards under the action of rotation of the first friction wheel and the second friction wheel and is conveyed to the third friction wheel; only one label passes under the action of reverse rotation of the third friction wheel. The automatic feeder for label laser marking can accurately control the transmission of the labels and know the errors of the system in the operation process in real time.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

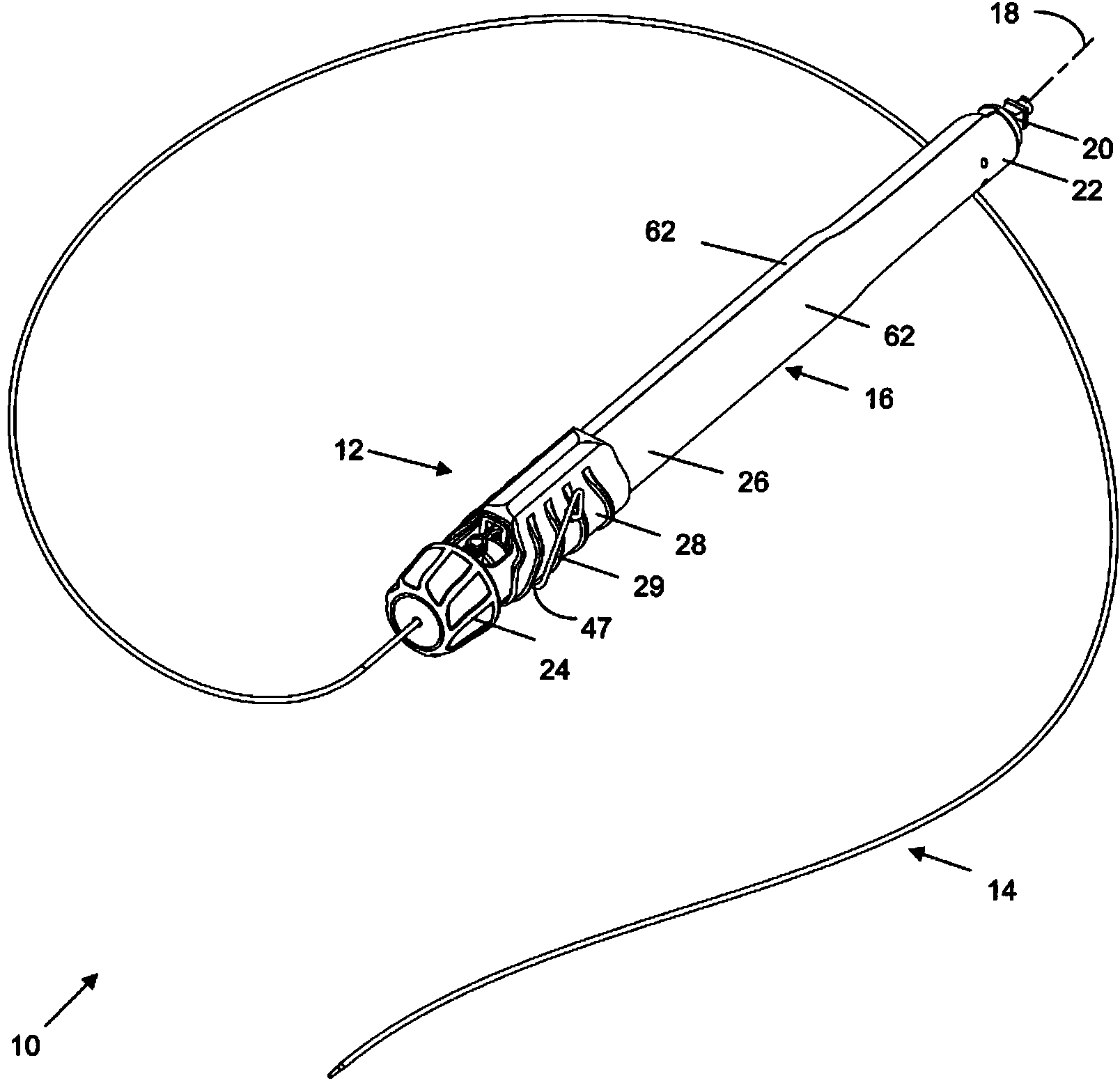

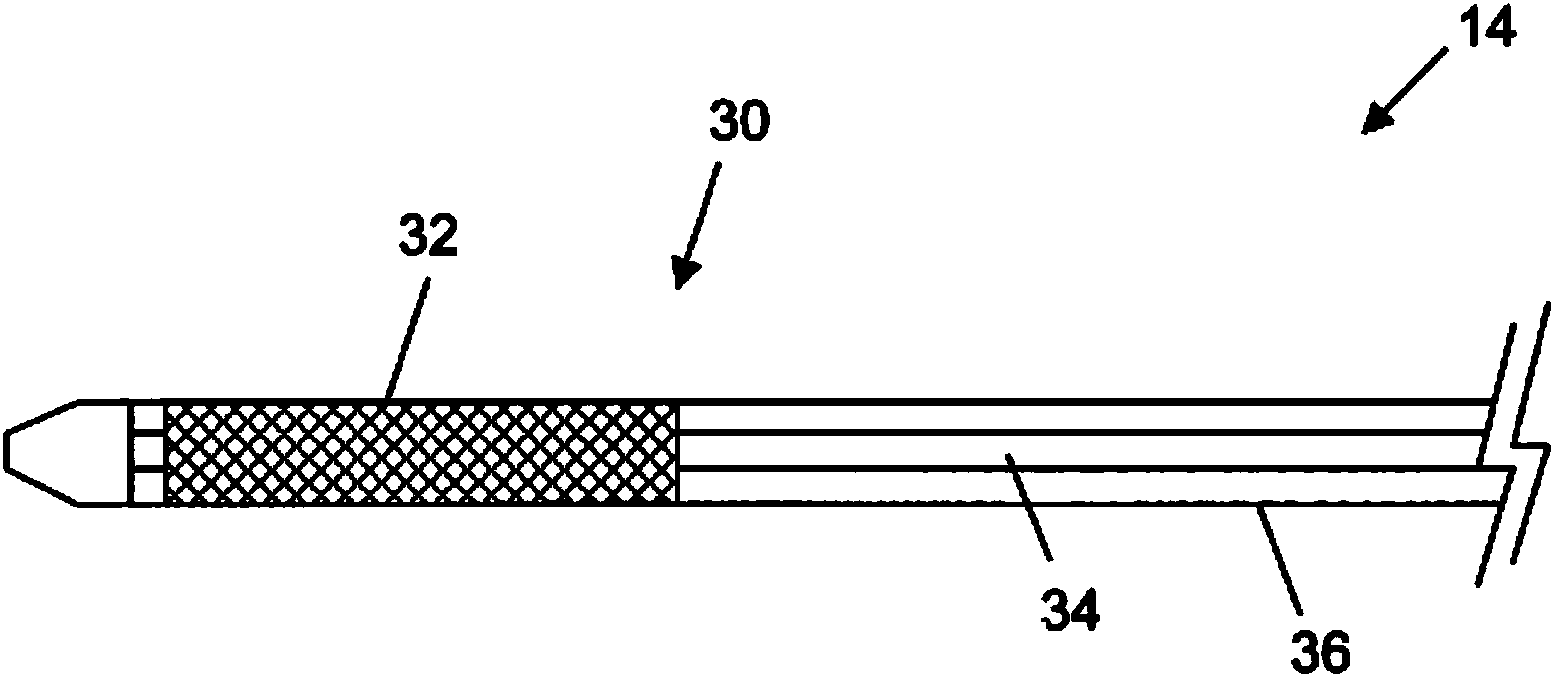

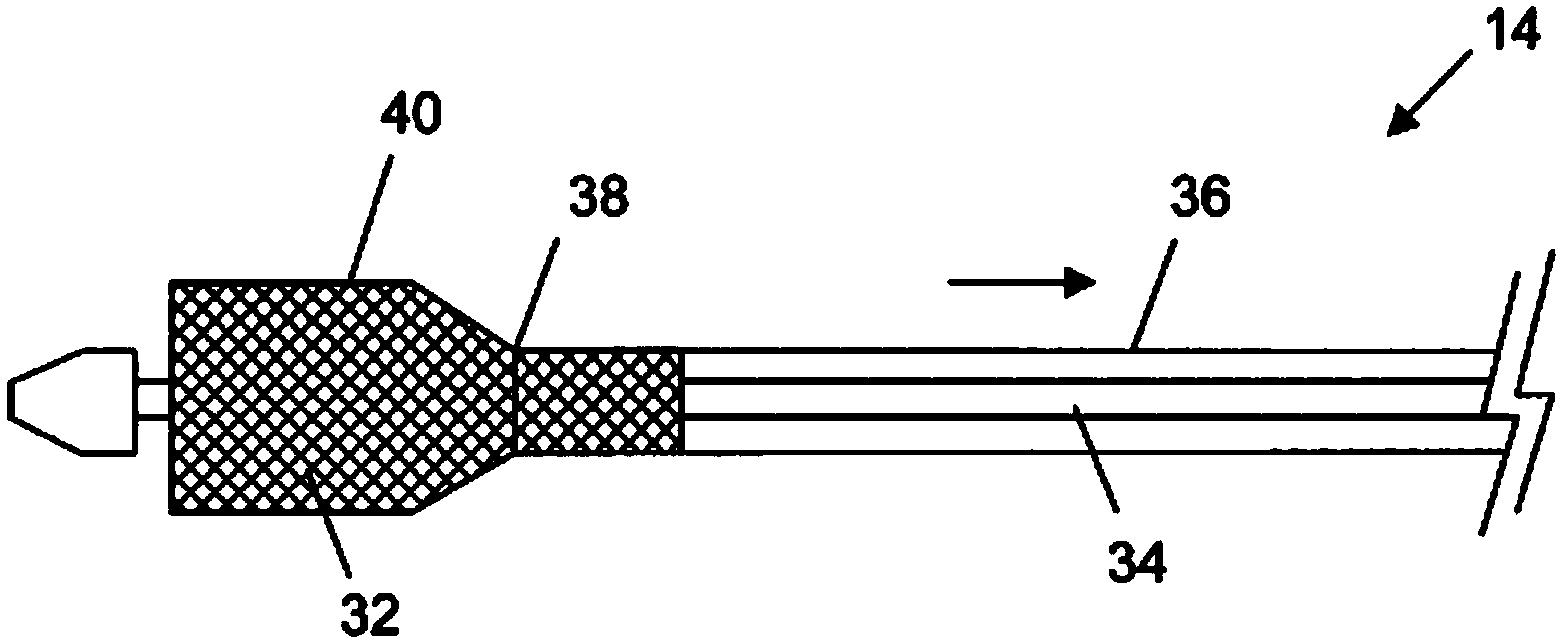

Catheter assembly with user-assisting handle

Owner:NOVOSTENT CORP

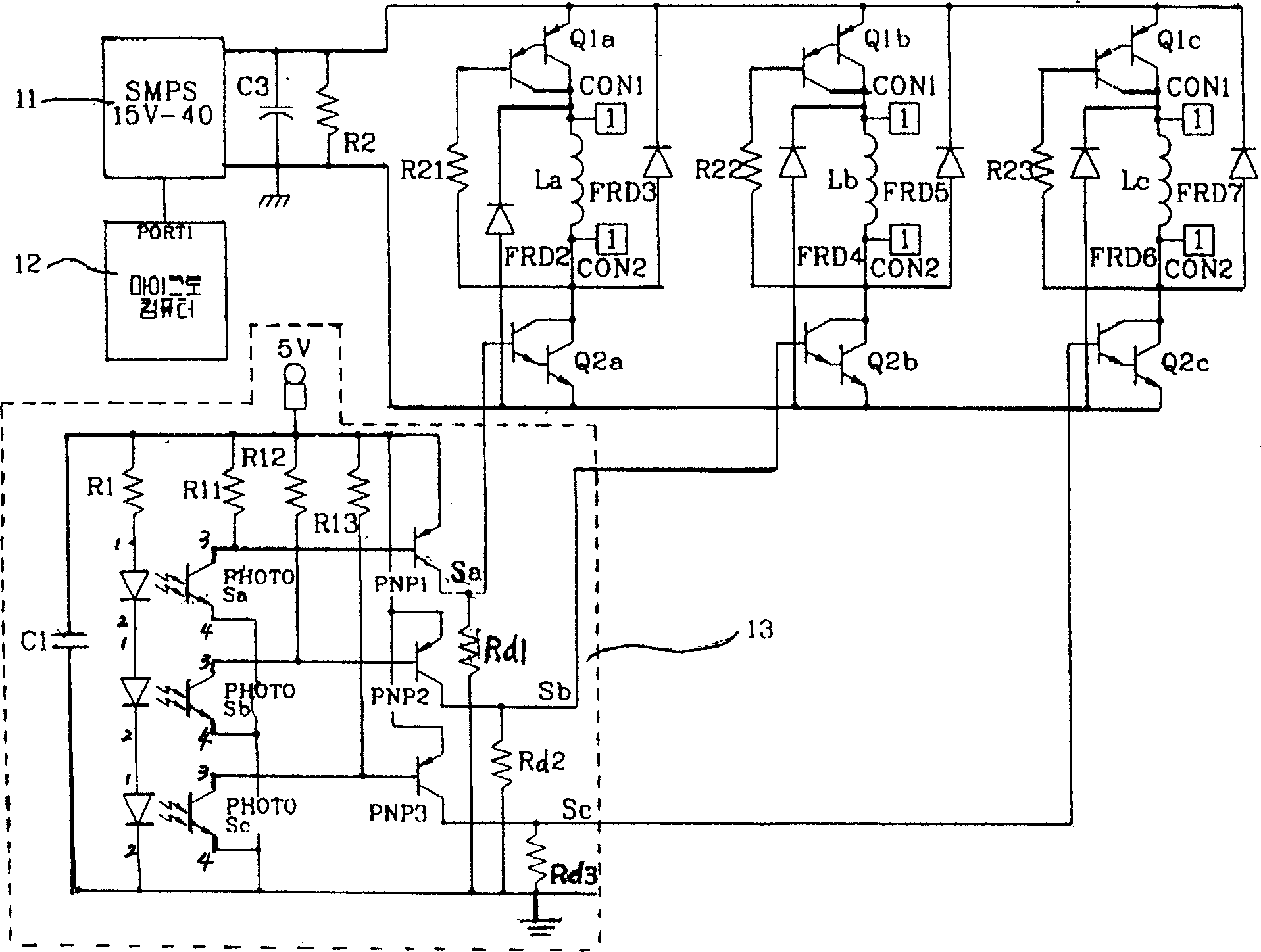

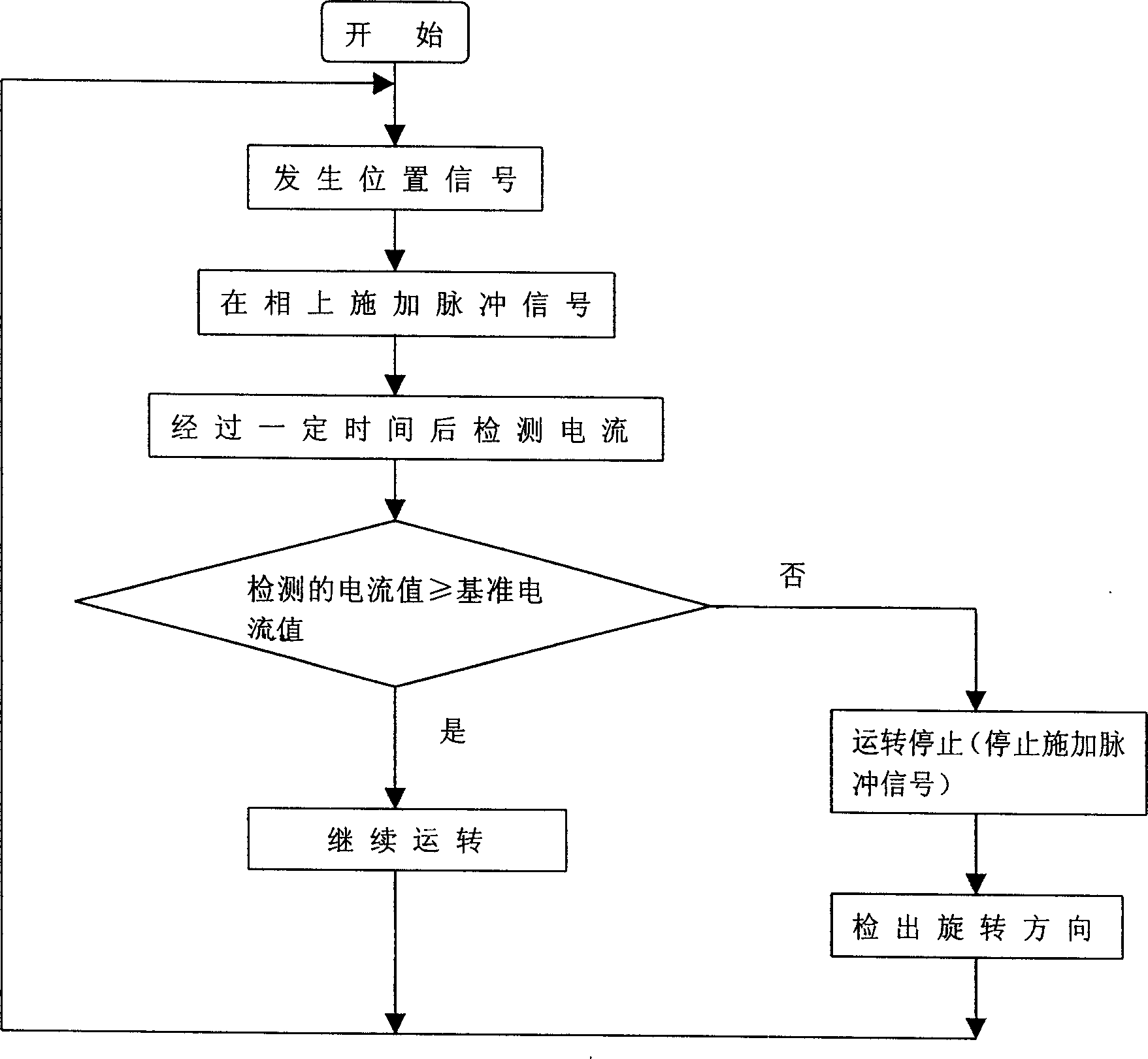

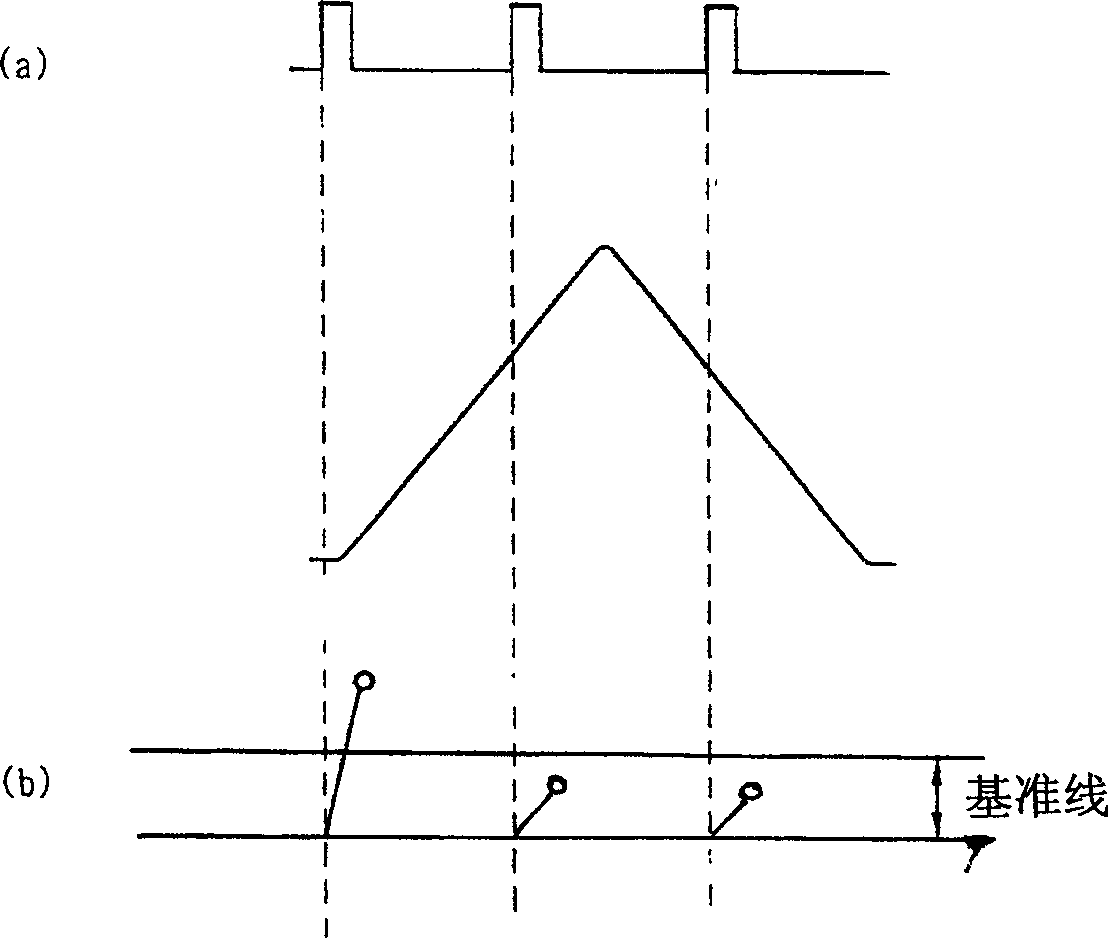

Method for detecting position signal of switch reluctance machine

The present invention relates to a method for detecting position signal of switch reluctance machine, and is characterized by that on the equipment consisting of power supply circuit, microcomputer for controlling said power supply circuit and driving circuit it utilzies a position sensor to detect the position of rotor, and adds the pulse signal related to said position on the correspondent switch device and measures the current value on the correspondent switch device after a certain time, them compares the measured current value with reference current value to obtain compared result, according to the compared result said invention can adopt the mode of properly adding pulse signal and regulating pulse current to make said electric machine normally operate.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

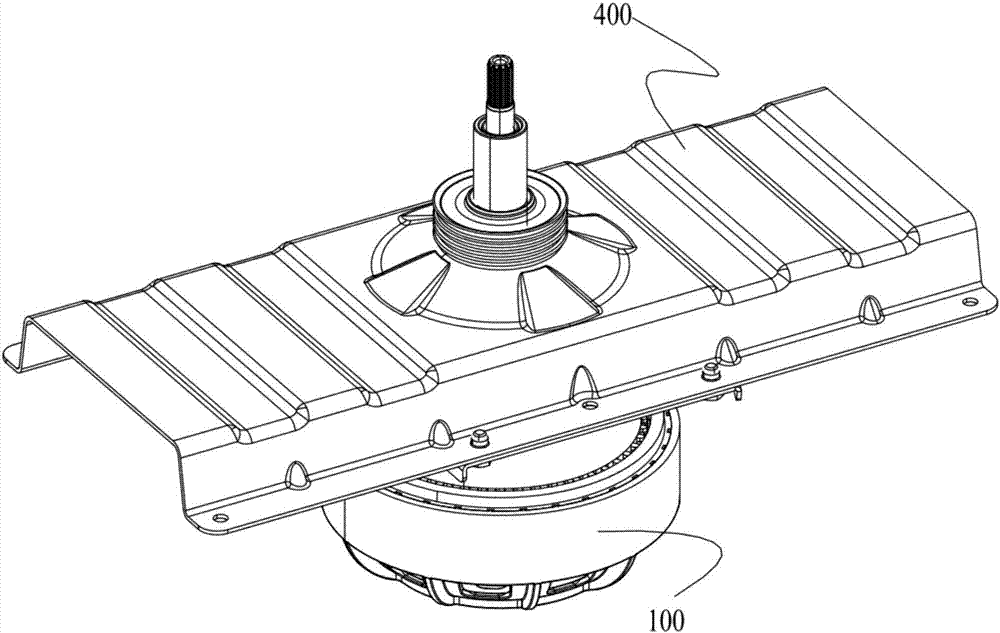

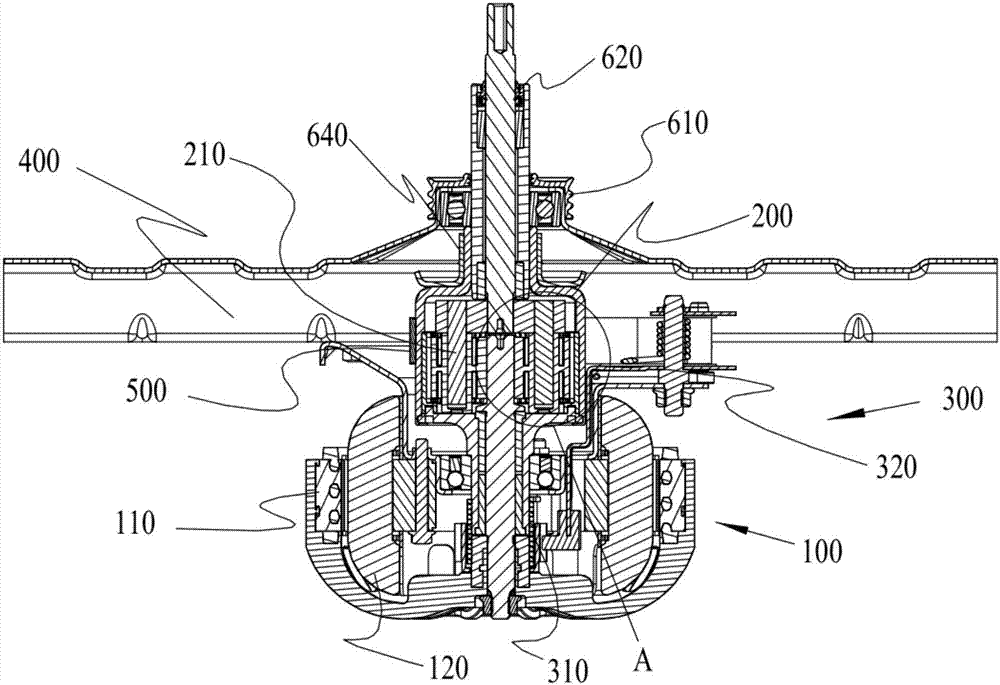

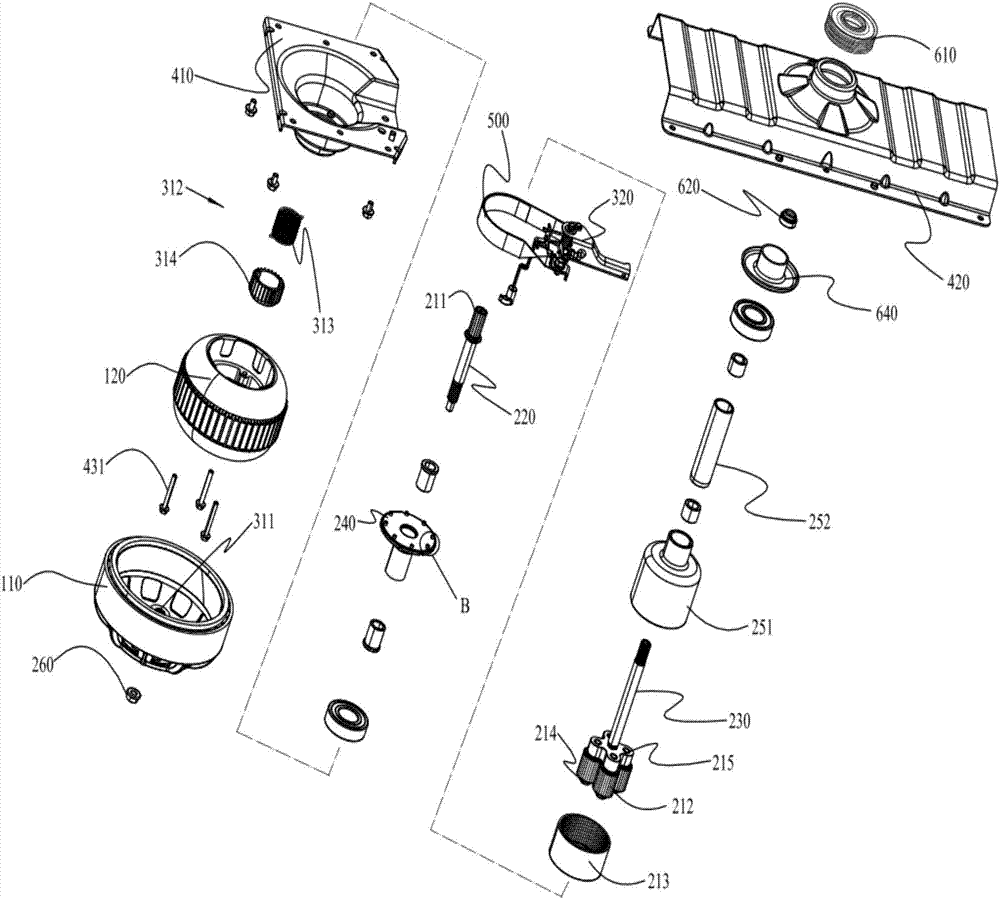

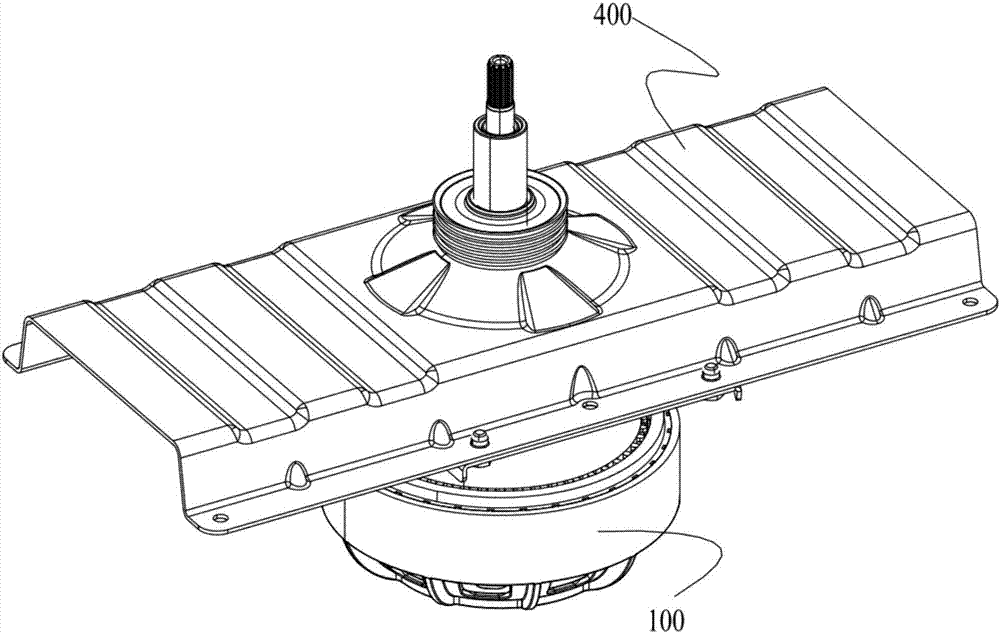

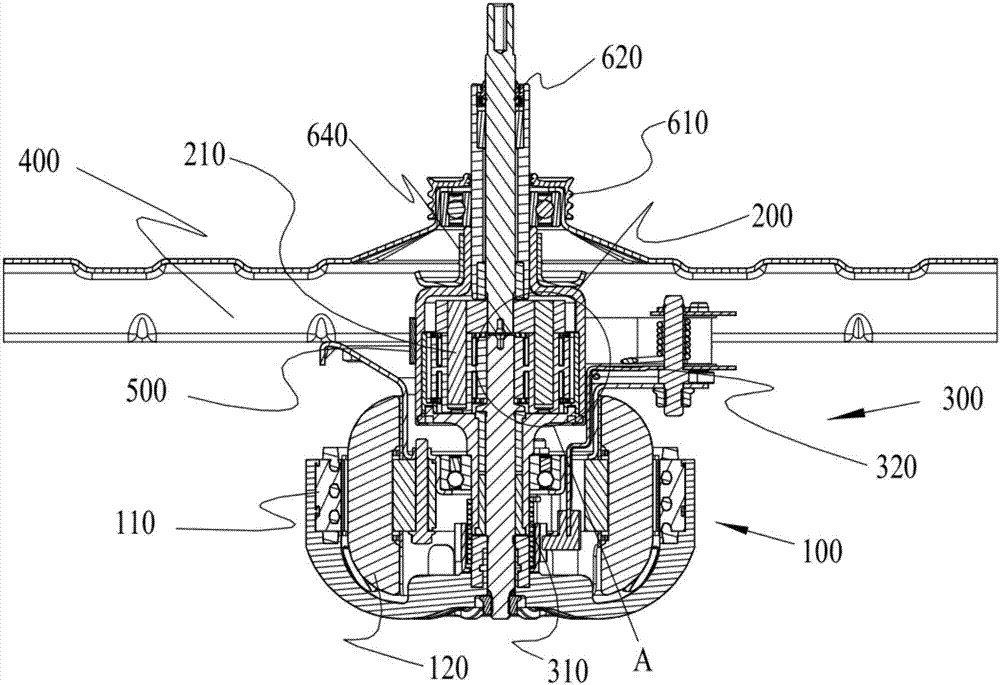

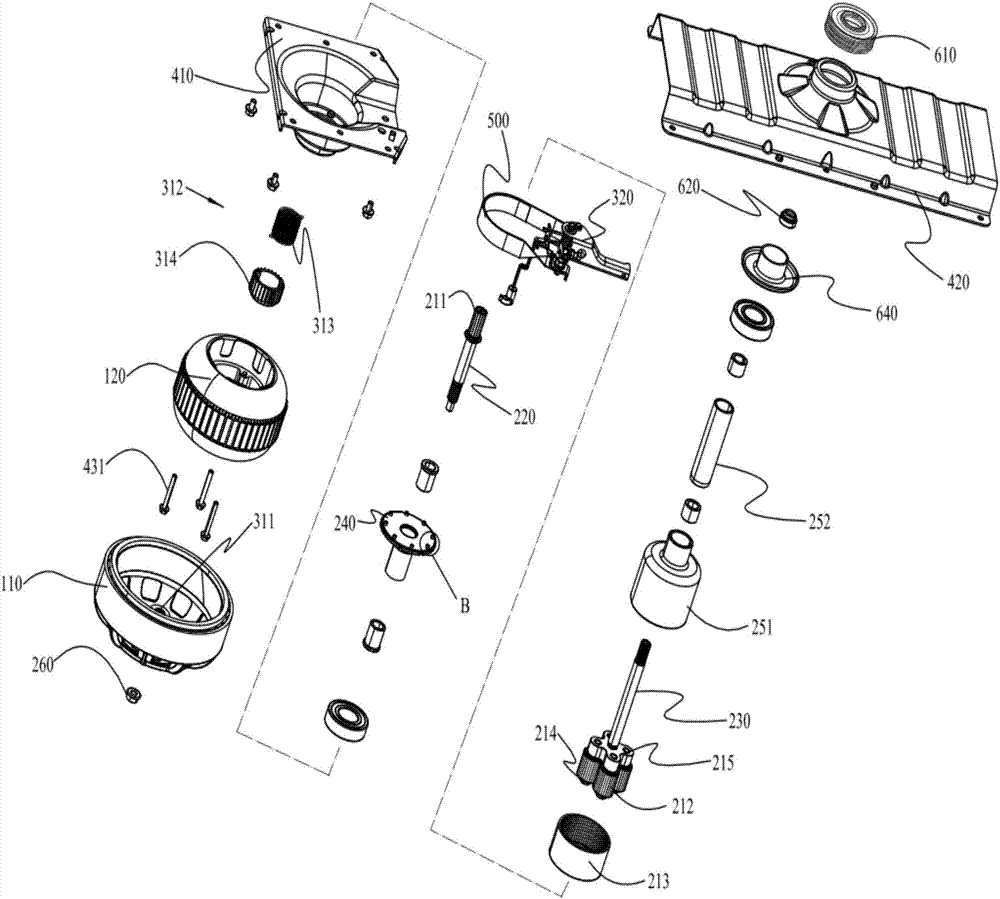

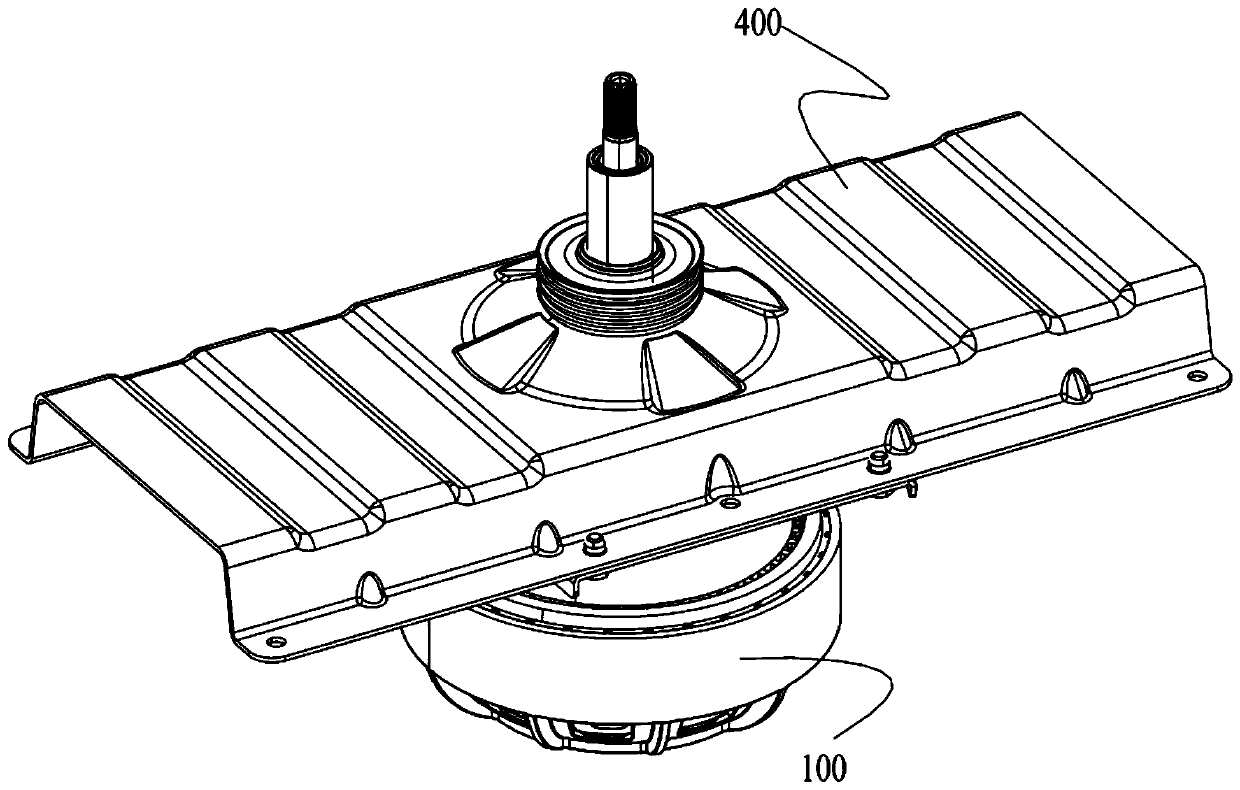

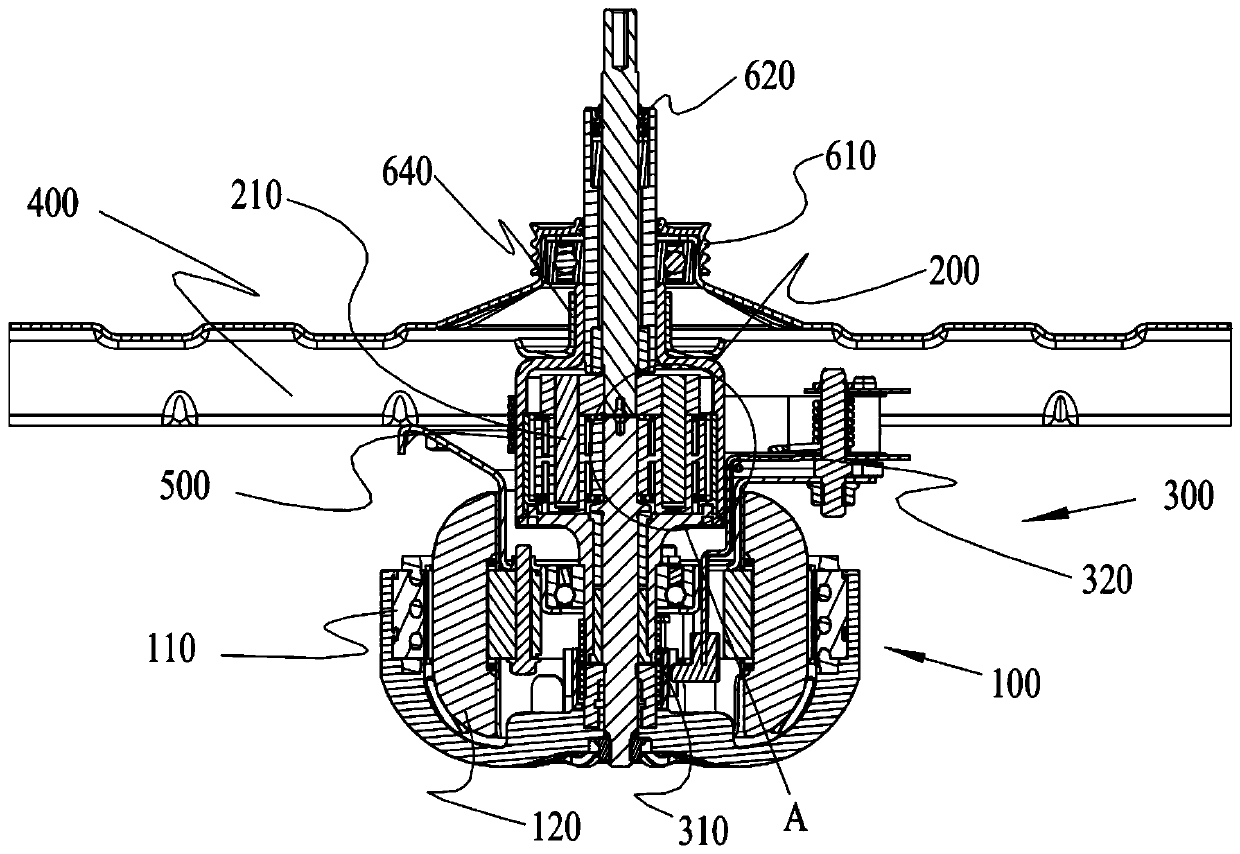

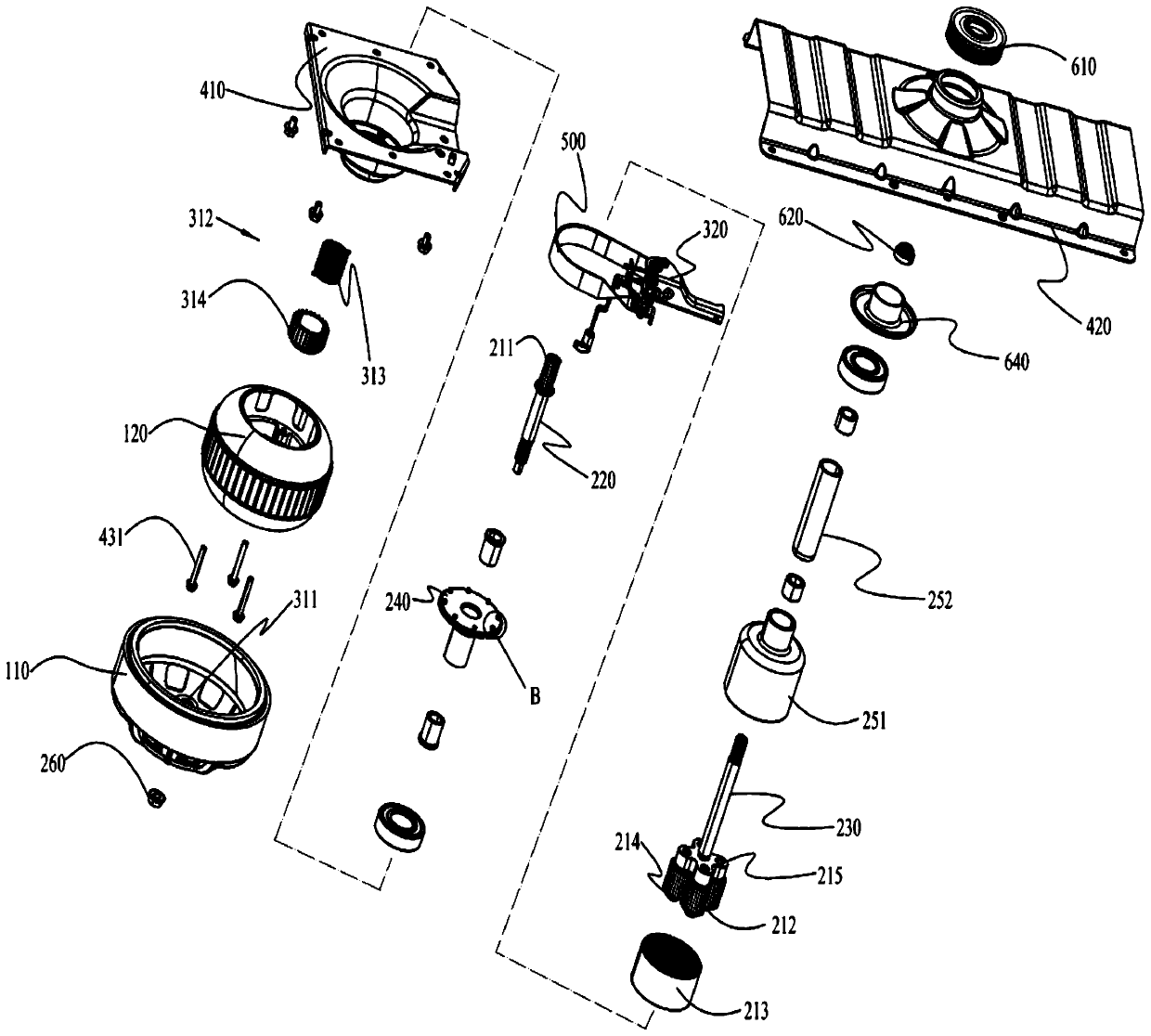

Driving clutch assembly of washing machine

InactiveCN107059340ALow costSimple connection structureOther washing machinesTextiles and paperDrive shaftLower grade

The invention discloses a driving clutch assembly of a washing machine. The driving clutch assembly of washing machine comprises a rotary body and a driving device. The driving device comprises a reducing mechanism, a clutch mechanism and an installation shell. The rotary body is an outer-rotor motor and comprises an outer rotor assembly and an inner stator assembly, wherein the inner stator assembly is located in the outer rotor assembly; the clutch mechanism comprises a clutch assembly and a shift lever assembly, the input end of a driving shaft and the input end of a driving shaft sleeve are sleeved with the clutch assembly, and driving force is transmitted to the clutch assembly through the shift lever assembly, wherein the clutch assembly is provided with a clutch shaft sleeve and a wrap spring assembly, and the input end of the driving shaft is sleeved with the clutch shaft sleeve. According to the driving clutch assembly of the washing machine, while the conditions that the structure is simple and compact and the occupied space is small are met, the cost is low, few connection parts are used, the manufacturing process is simple, and the driving clutch assembly is very suitable for large-scale application and popularization and especially suitable for being used in the field of medium-low-grade washing machines which are used in wide households.

Owner:CHANGZHOU XINYA ELECTROMOTOR

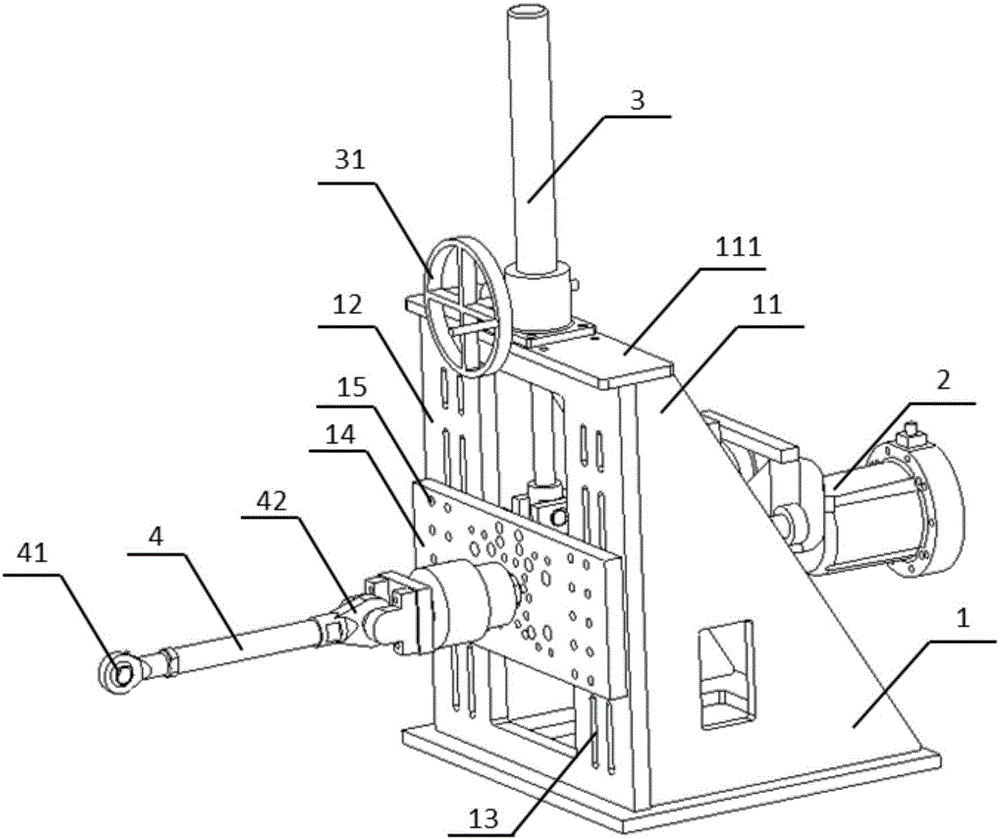

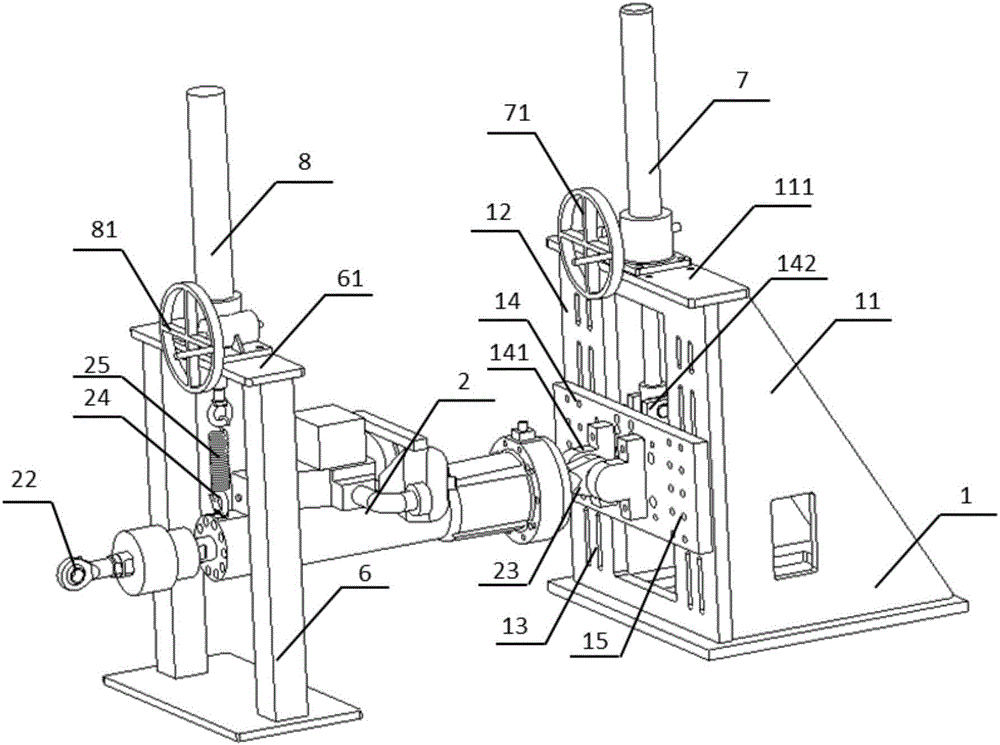

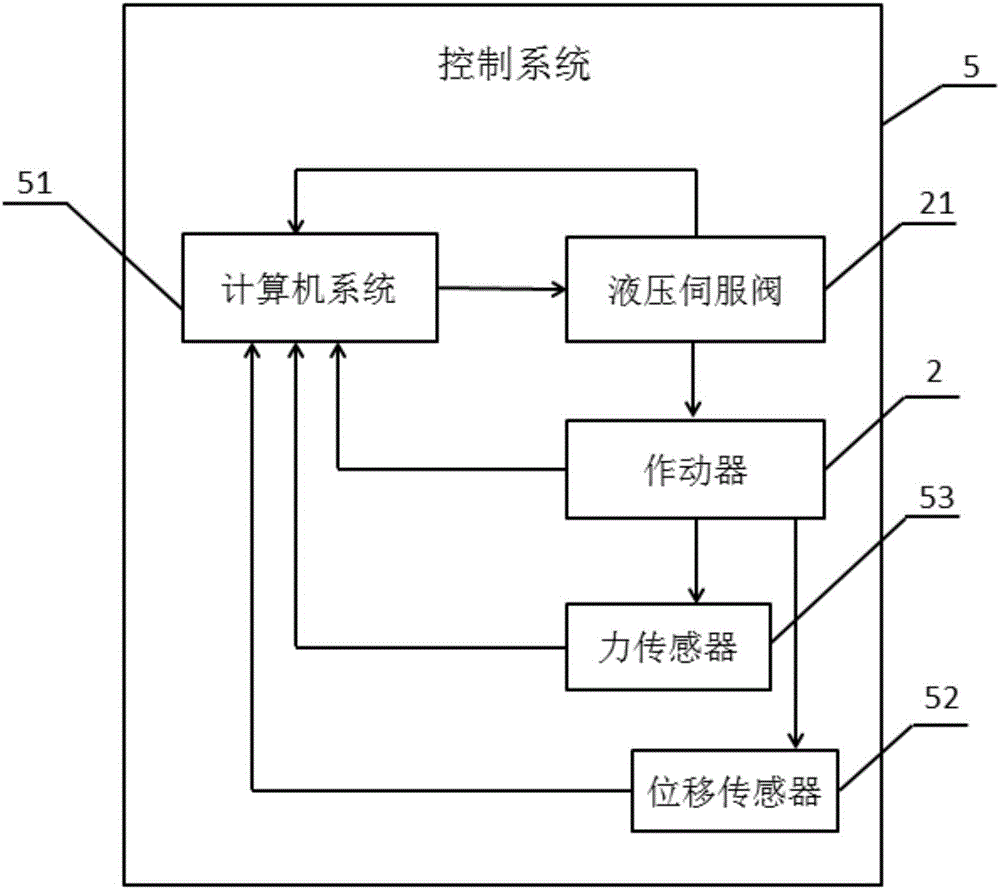

Multifunctional automobile chassis component test bench

The invention discloses a multifunctional automobile chassis component test bench, relates to a test bench. The test bench comprises a basic fixed bracket for supporting a whole actuator, the actuator for providing driving force to the test bench frame, a lifting mechanism which is removably arranged on the basic fixed bracket and is used for driving the actuator to actuator to carry out up and down precise adjustment, a connection rod which is connected to the actuator, and a control system which is electrically connected to the actuator and is used for precisely controlling the driving power needed by a test. According to the multifunctional automobile chassis component test bench, through the control system and the lifting mechanism, the driving of the whole actuator is precisely controlled, thus the whole test bench is more intelligent and accurate, the precise adjustment of the actuator is realized, and the test precision and working efficiency are improved. By using different modes, the actuator is fixedly connected, the test bench can test the stiffness, strength and durability of different automobile chassis components, the use of the multifunctional automobile chassis component test bench is flexible, and the application range of the test bench is increased.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

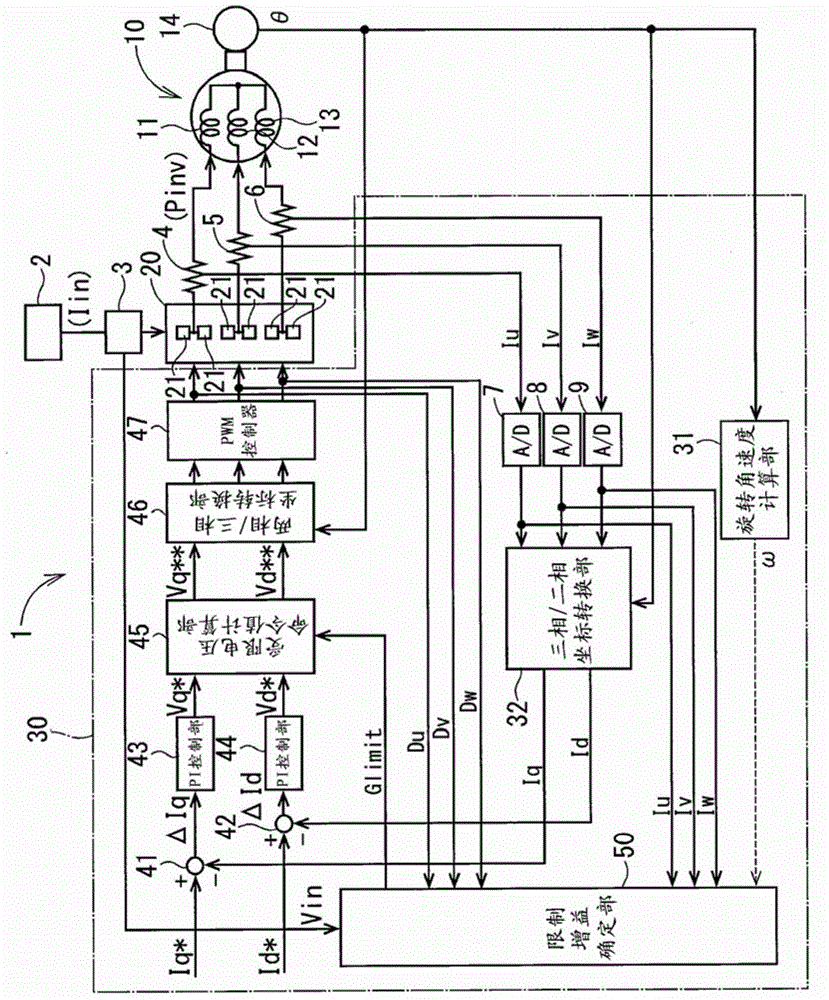

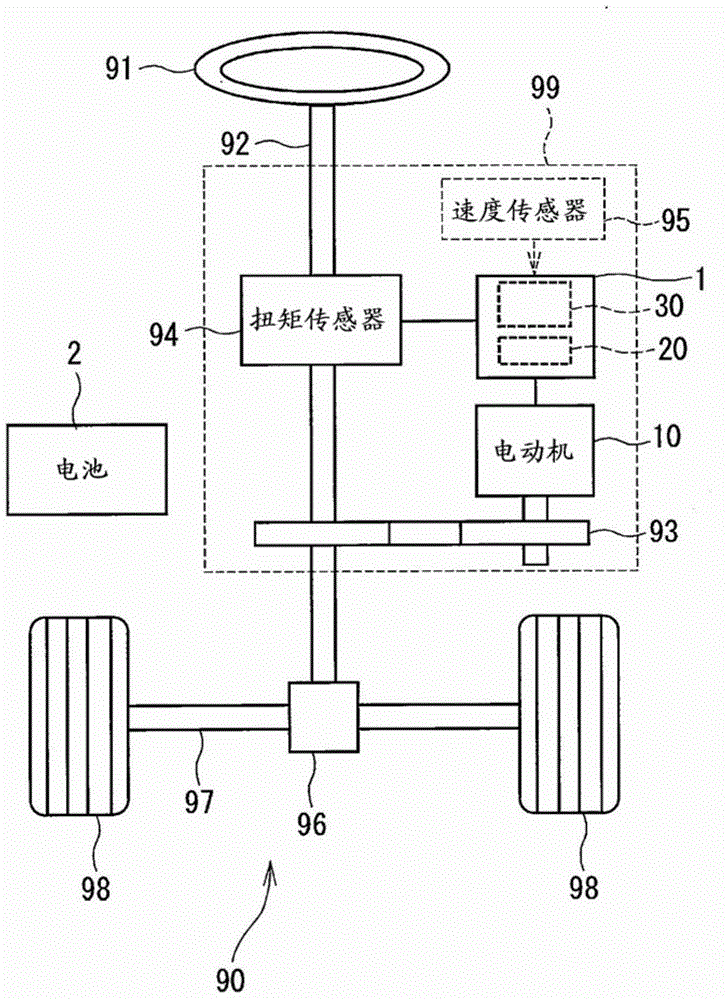

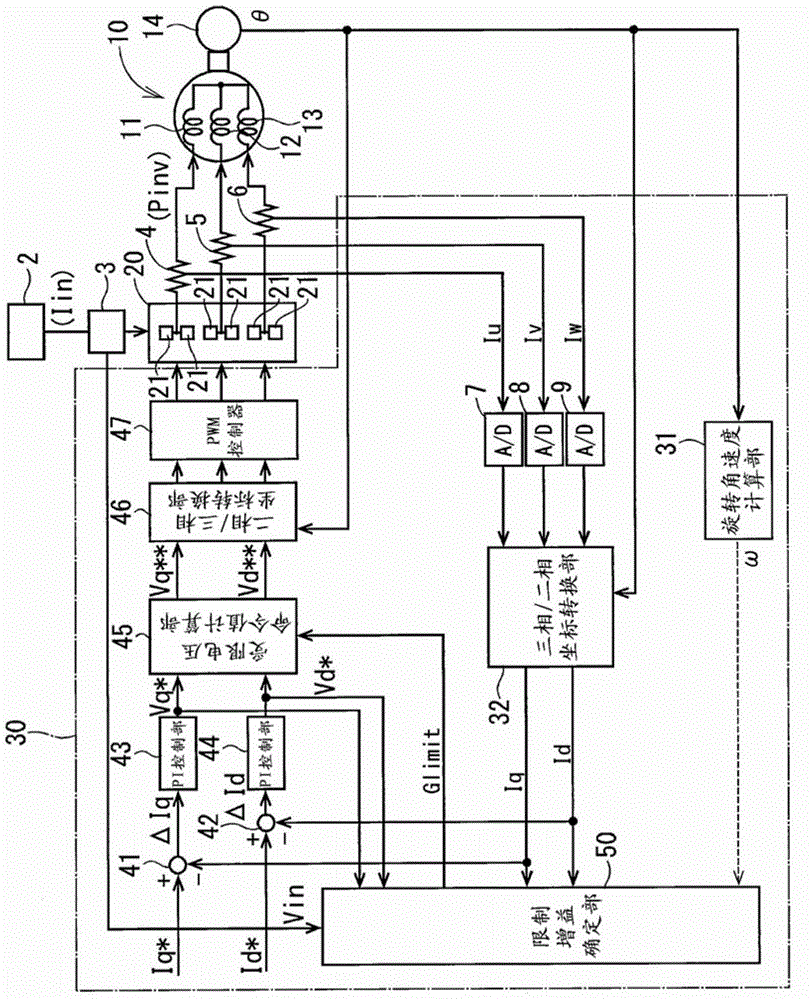

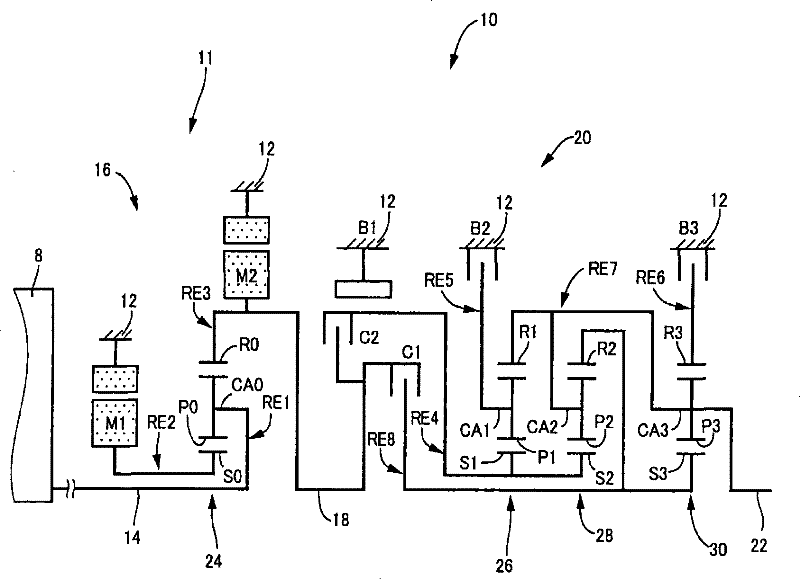

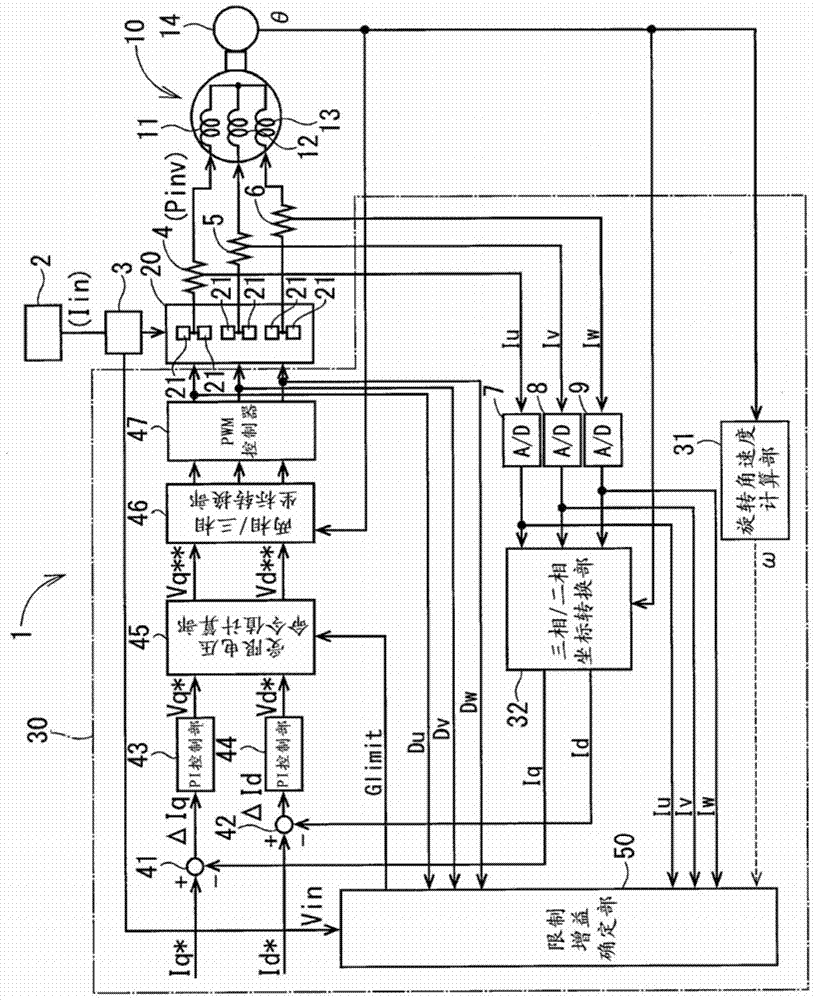

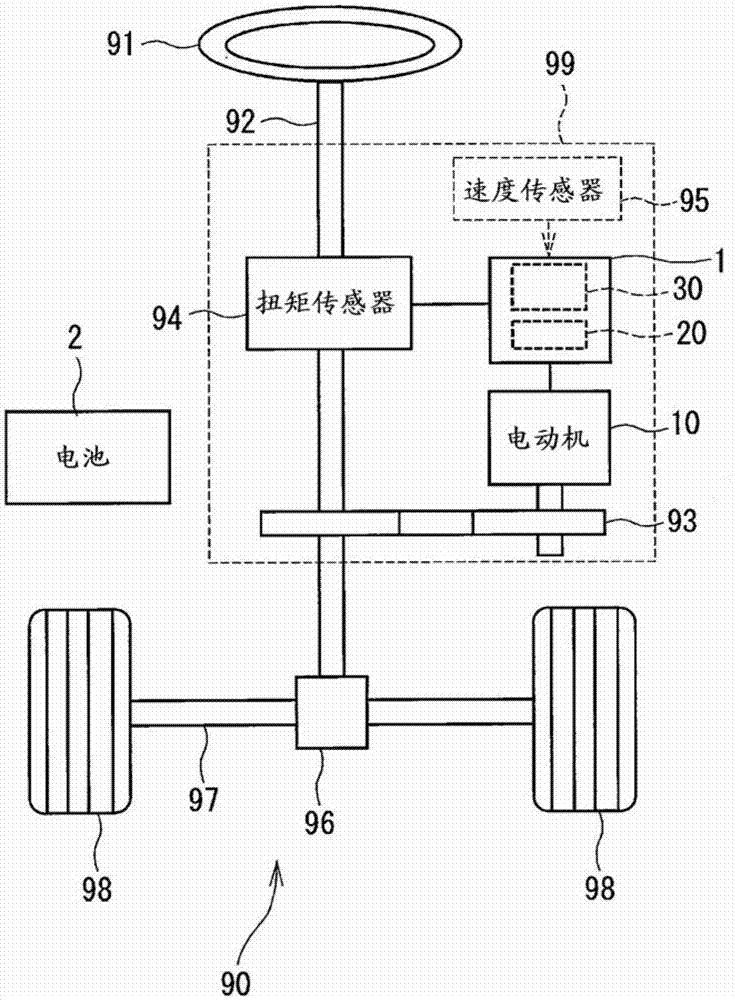

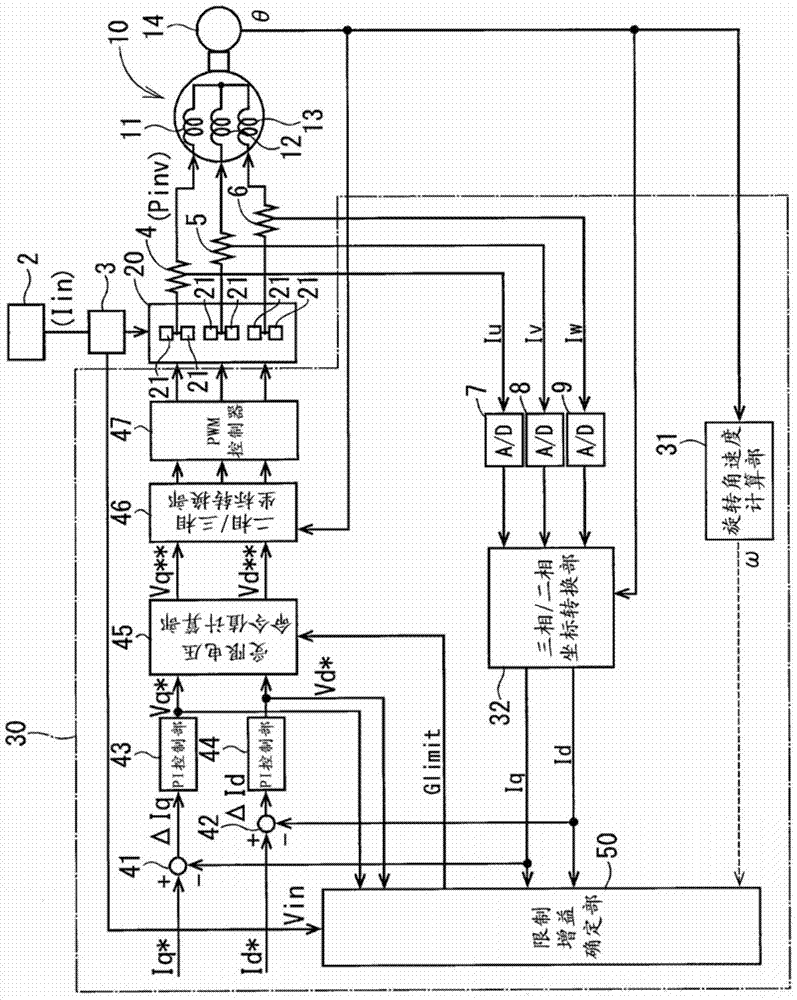

Rotating electric machine control device and electric power steering apparatus

ActiveCN104052344AControl driveAC motor controlElectric motor controlElectric power steeringCurrent limiting

In a rotating electric machine control device, a voltage command value calculation section calculates a voltage command value based on a current command value and a motor current. An inverter power estimation section estimates an inverter power based on the motor current. A power supply current estimation section estimates a power supply current based on the inverter power and a power supply voltage. A limit gain determination section determines a limit gain based on the power supply current and a target power supply current. A limited voltage command value calculation section calculates a limited voltage command value based on the voltage command value and the limit gain. A current limitation section is capable of limiting the power supply current by outputting a command value corresponding to the limited voltage command value to an inverter portion.

Owner:DENSO CORP

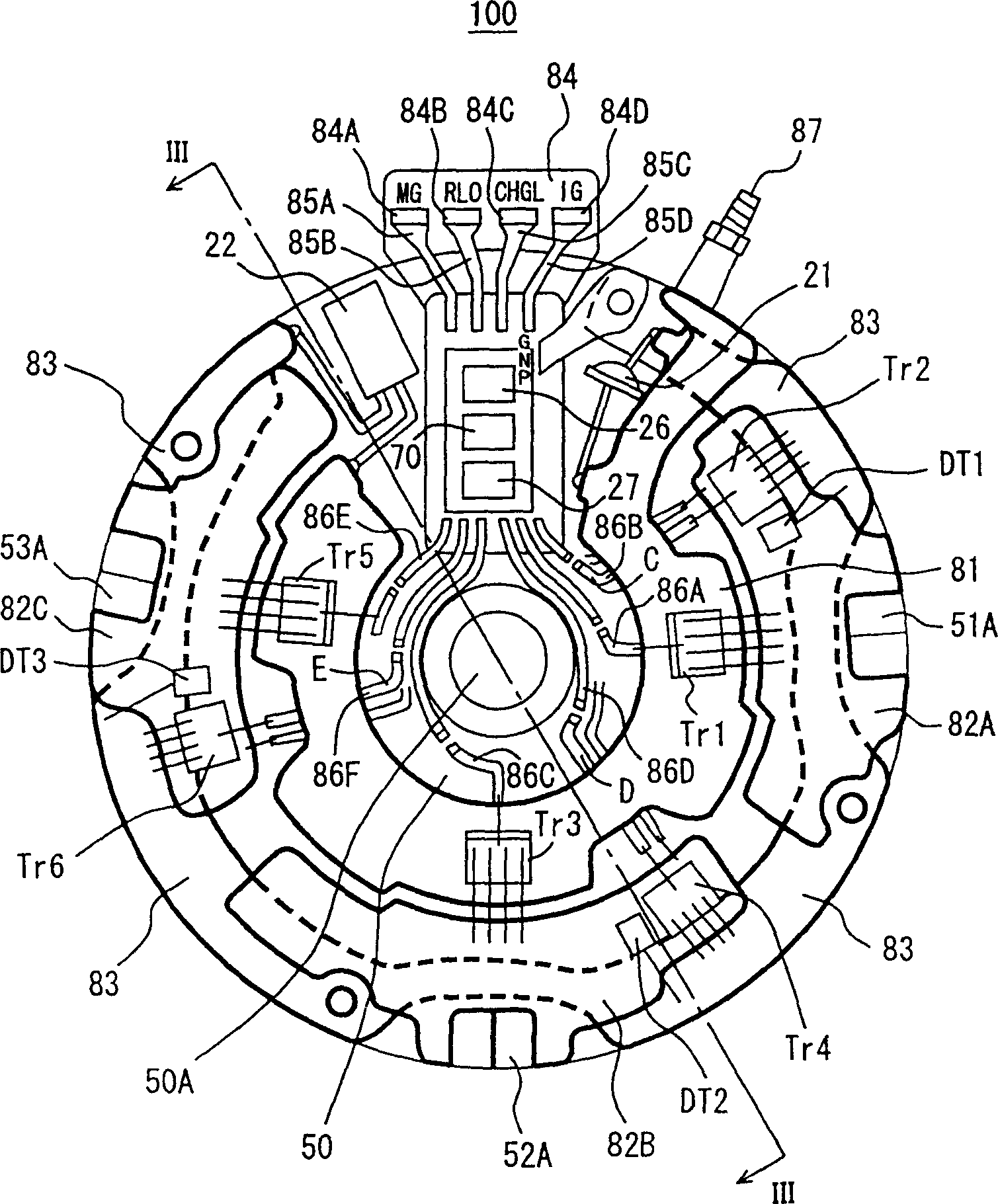

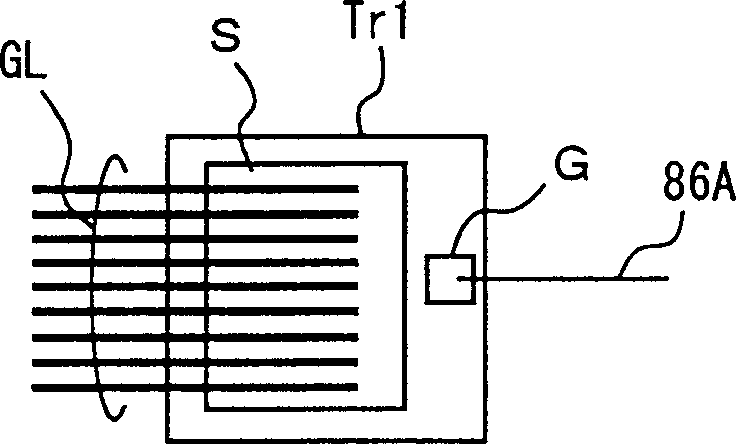

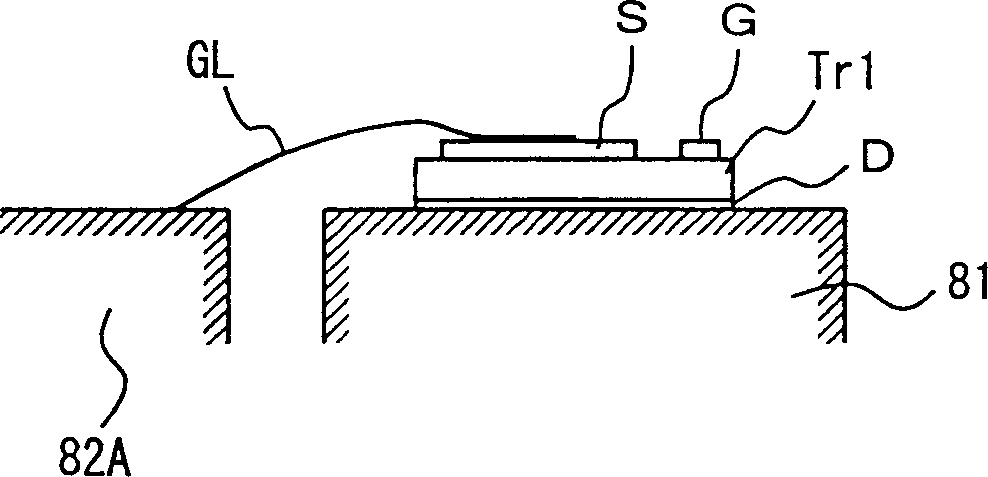

Generator-motor

A power-generating dynamo-electric apparatus 100 is equipped with an alternator 50, electrode plates 81, 82A-82C, 83, a board 84, MOS transistors Tr1-Tr6, and a MOS driver 27. The electrode plates 81, 82A-82C, and 83 are arranged in roughly U shape such that they surround the rotating shaft 50A of the alternator 50 at the end face of the alternator 50. The MOS transistors Tr1, Tr3, and Tr5 are arranged on the electrode plate 81, and the MOS transistors Tr2, Tr4, and Tr6 are arranged on the electrode plates 82A, 82B, and 82C, respectively. The MOS driver 27 is arranged on the board 84 arranged in a roughly U-shaped cut so as to control the ON / OFF of the MOS transistors Tr1-Tr6.

Owner:TOYOTA JIDOSHA KK

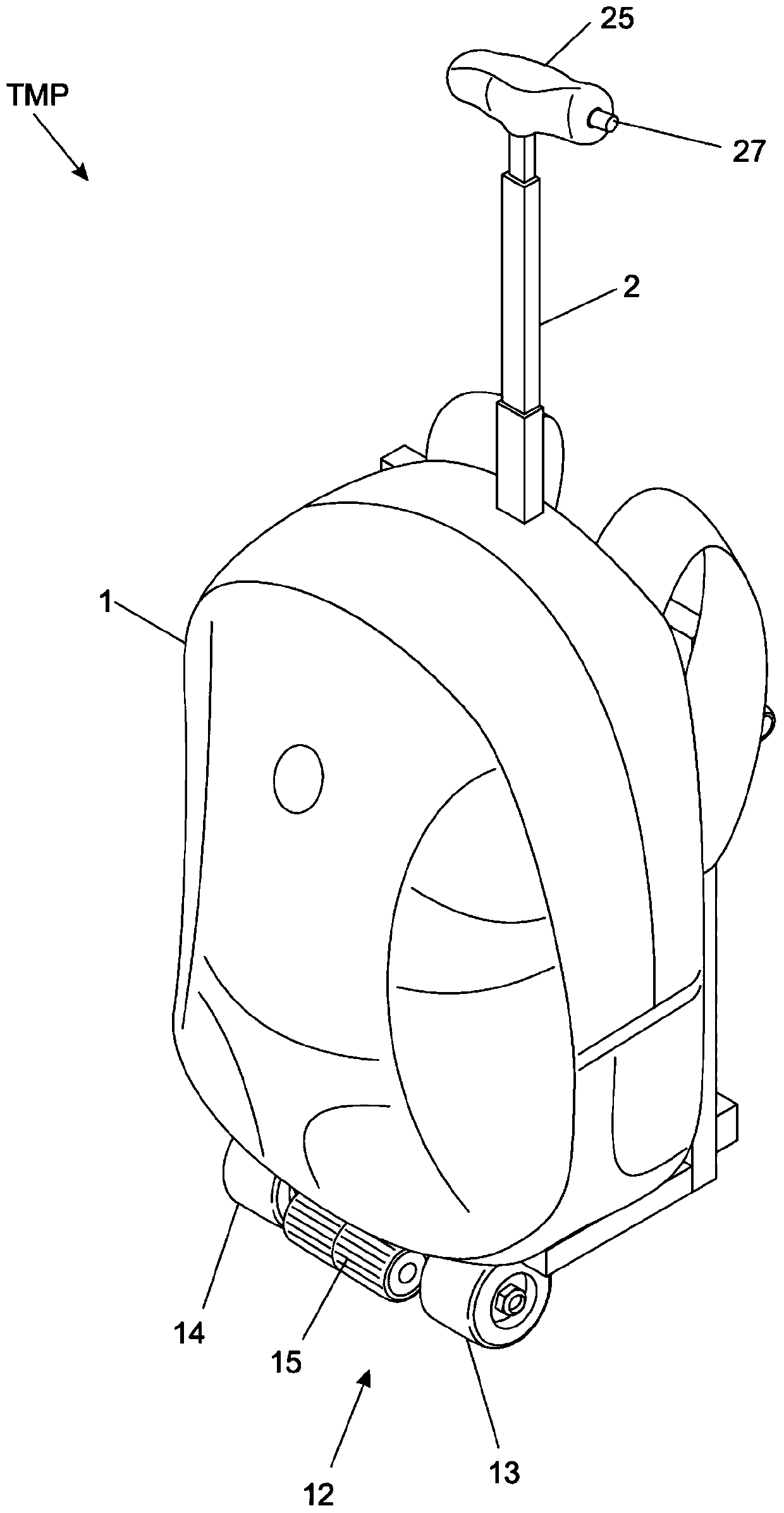

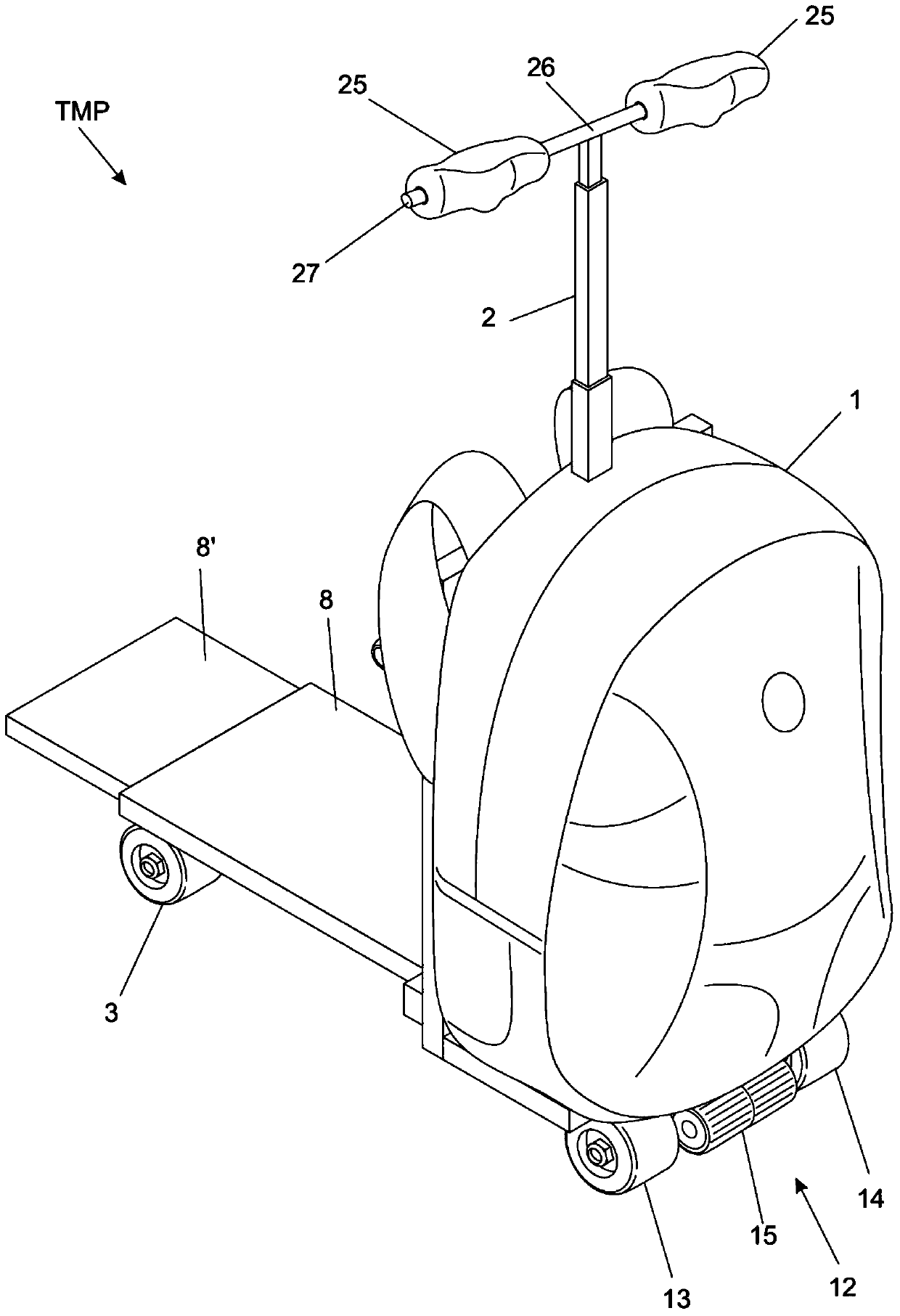

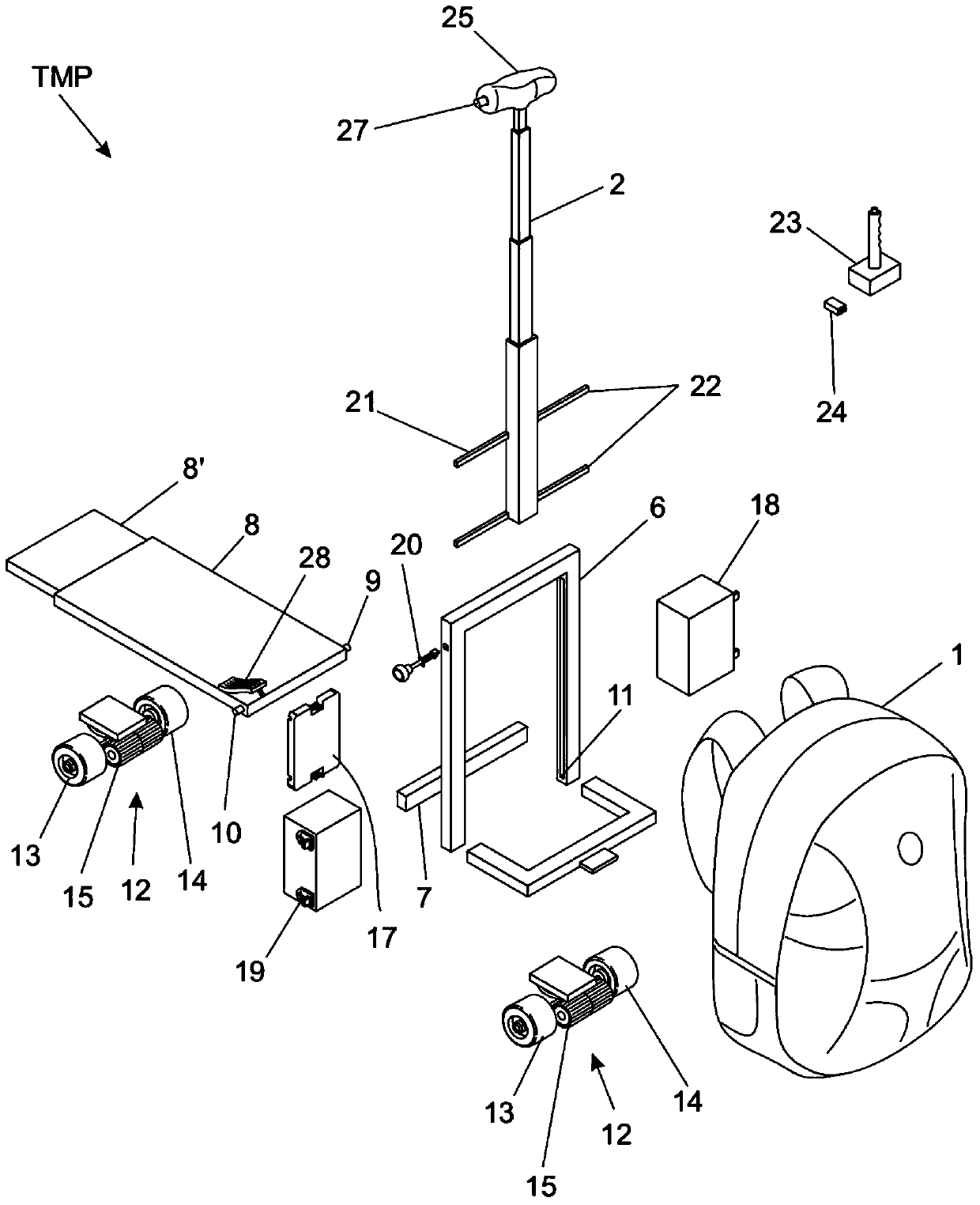

Portable motor-driven transportation means

InactiveCN104270989AVersatilityAccommodate user improvementsTravelling sacksLuggageFreewheelMotor drive

A portable motor-driven transportation means essentially consists of a personal, portable motor-driven transportation means (TMP) with a grip (25) introduced into the upper portion of the telescopic handle (2), the means being preferably conditioned in a backpack (1) which houses the device after destination is reached or when the device can no longer be used, and is easily carried on the back, in a simple, convenient and quick manner. The board (8) is of the collapsible or foldable type and is provided with an additional extension (8') which is extremely convenient in use, since this additional space (8') can accommodate an object, carry a seat or even a companion. The personal, portable motor-driven transportation means (TMP) comprises driving and rolling assemblies, such as: drive axle (12) with freewheel (13) and driven wheel (14); free axle (3) with freewheels (4); simple axle (31) with free wheel (4), with various possible layout combinations, of simultaneous or partial operation, with front or rear four wheel (4X4), two wheel (4X2) or one wheel (2X1) drive, with traction assisted by the electric motor actuation system (15), providing a personal, multifunctional, environmentally friendly, portable motor-driven transportation means (TMP).

Owner:雨果·利奥纳多·多拉多

Washing machine driving system and washing machine

InactiveCN107083644ALow costSimple connection structureOther washing machinesTextiles and paperManufacturing technologyDrive shaft

The invention discloses a washing machine driving system and a washing machine. The system comprises a rotating body and a transmission device, the transmission device comprises a speed reducing mechanism, a clutch mechanism and a mounting shell, the rotating body is a PSC motor and comprises an outer rotor component and an inner stator component located inside the outer rotor component; the speed reducing mechanism comprises a gear speed reducer, a drive shaft connected with the gear speed reducer and a drive shaft sleeve which is arranged outside the drive shaft in a sleeving mode and rotationally connected with the drive shaft, and the input end of the drive shaft is fixedly connected with the outer rotor component; the mounting shell comprises a stator mounting disc and a mounting plate, and the speed reducing mechanism is located in a cavity formed by the stator mounting disc and the mounting plate which are fixedly connected. Accordingly, the conditions that the structure is simple and compact, and the occupied space is small are met, and meanwhile the motor size is small, the cost is low, few connecting parts exist, the manufacturing technology is simple, and the washing machine driving system is very suitable for large-scale application and popularization and especially suitable for being applied to the field of mid-low-end washing machines used by wide households.

Owner:CHANGZHOU XINYA ELECTROMOTOR

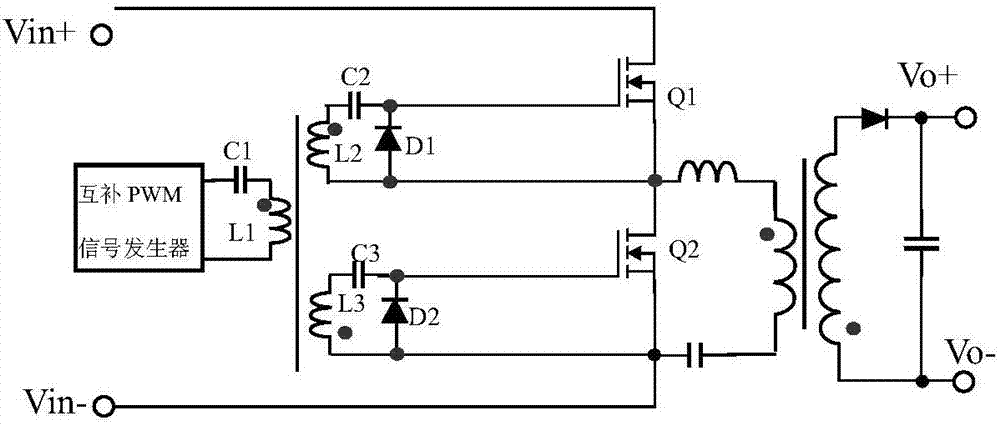

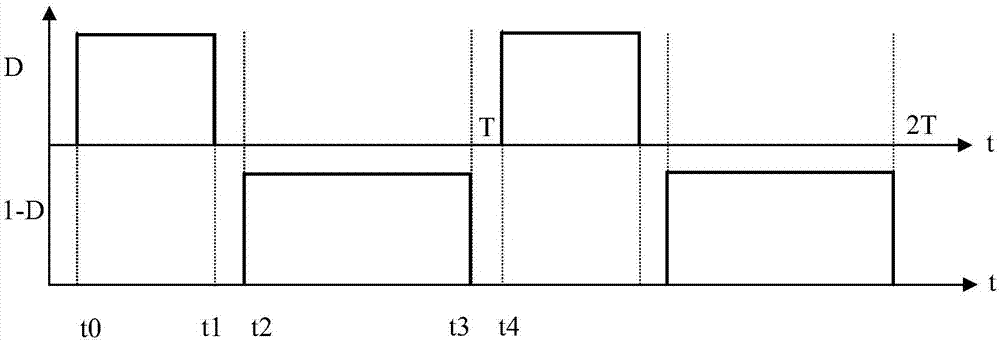

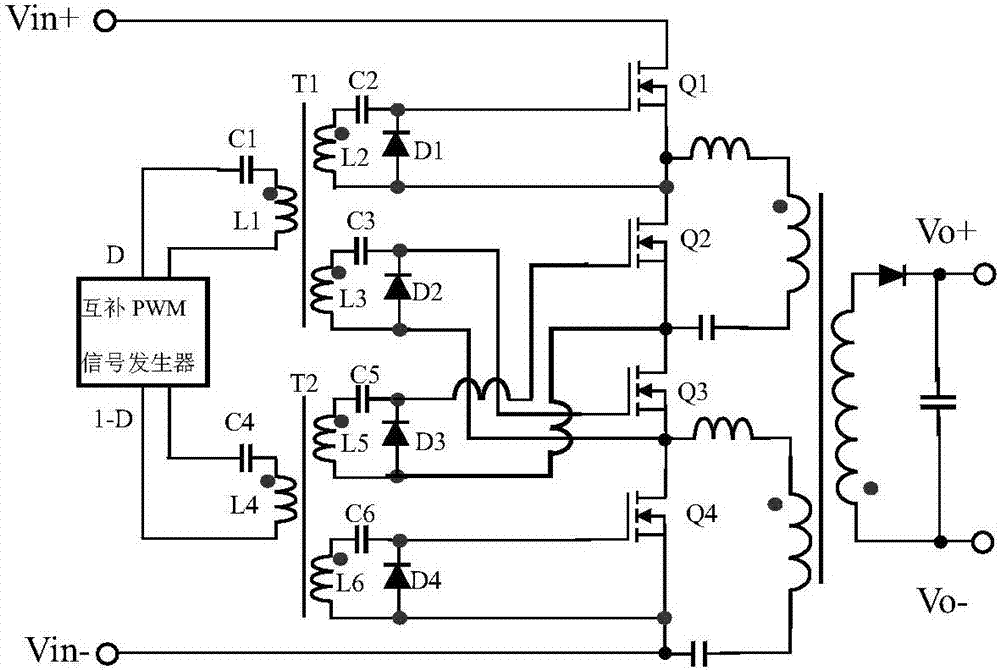

Asymmetric half-bridge flyback drive circuit

PendingCN107276374AImprove consistencyEasy to set upEfficient power electronics conversionDc-dc conversionTransformerEngineering

The invention discloses an asymmetric half-bridge flyback drive circuit, and the circuit comprises a complementary PWM generator, two drive transformers, and a series asymmetric flyback circuit. The separation of the drive transformers enables on / off switching tubes of the circuit to be respectively controlled, thereby improving the quality of a drive signal, and reducing the false triggering caused by the level changes. The dead zone time between the switching tubes is mainly controlled by a complementary signal because of the separated winding, thereby enabling the impact on the dead zone from the drive transformers to be the minimum. In a wide-range and high-input-voltage switching power application, the circuit, compared with the prior art, enables the reliability of a product to be improved.

Owner:MORNSUN GUANGZHOU SCI & TECH

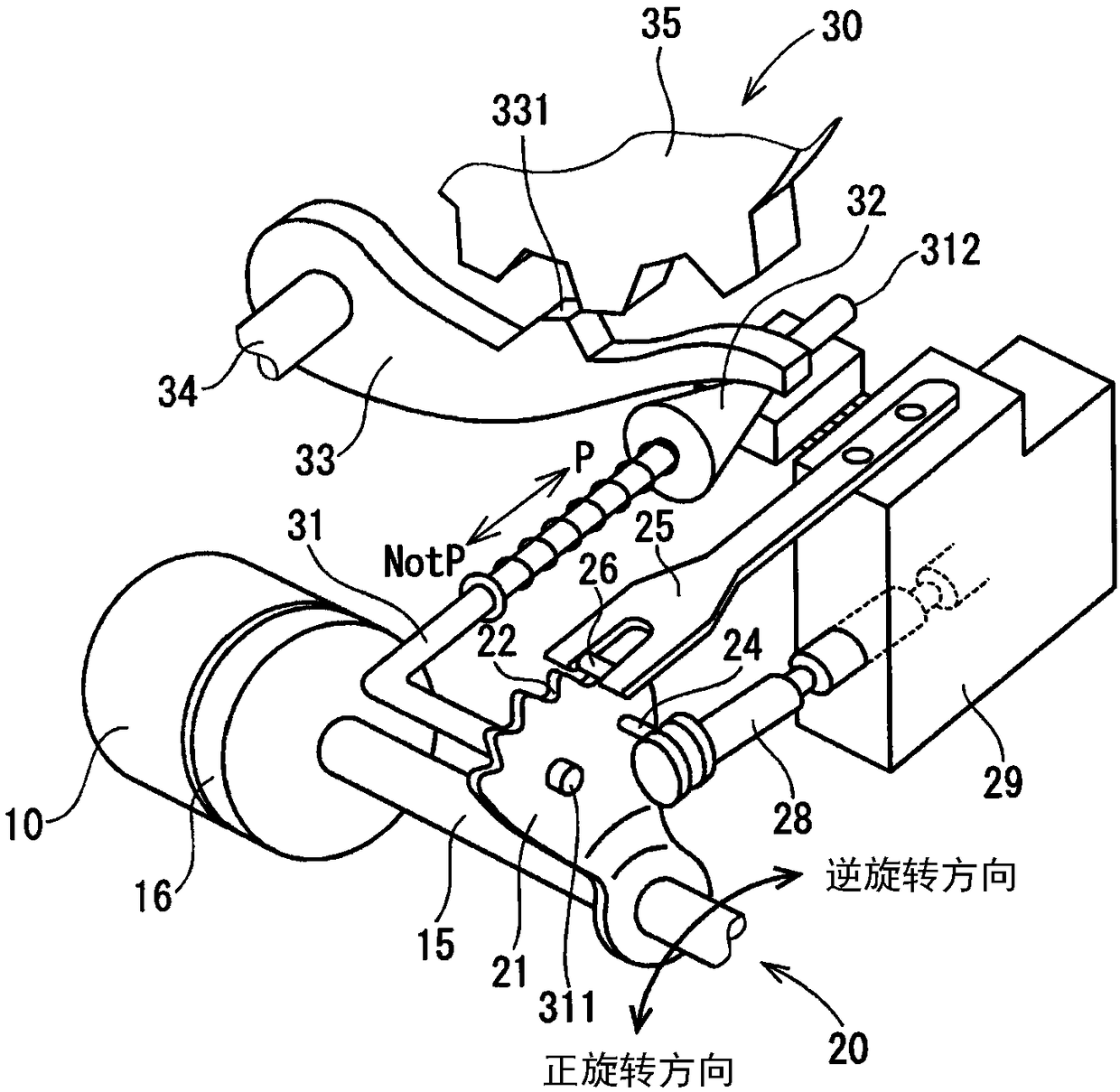

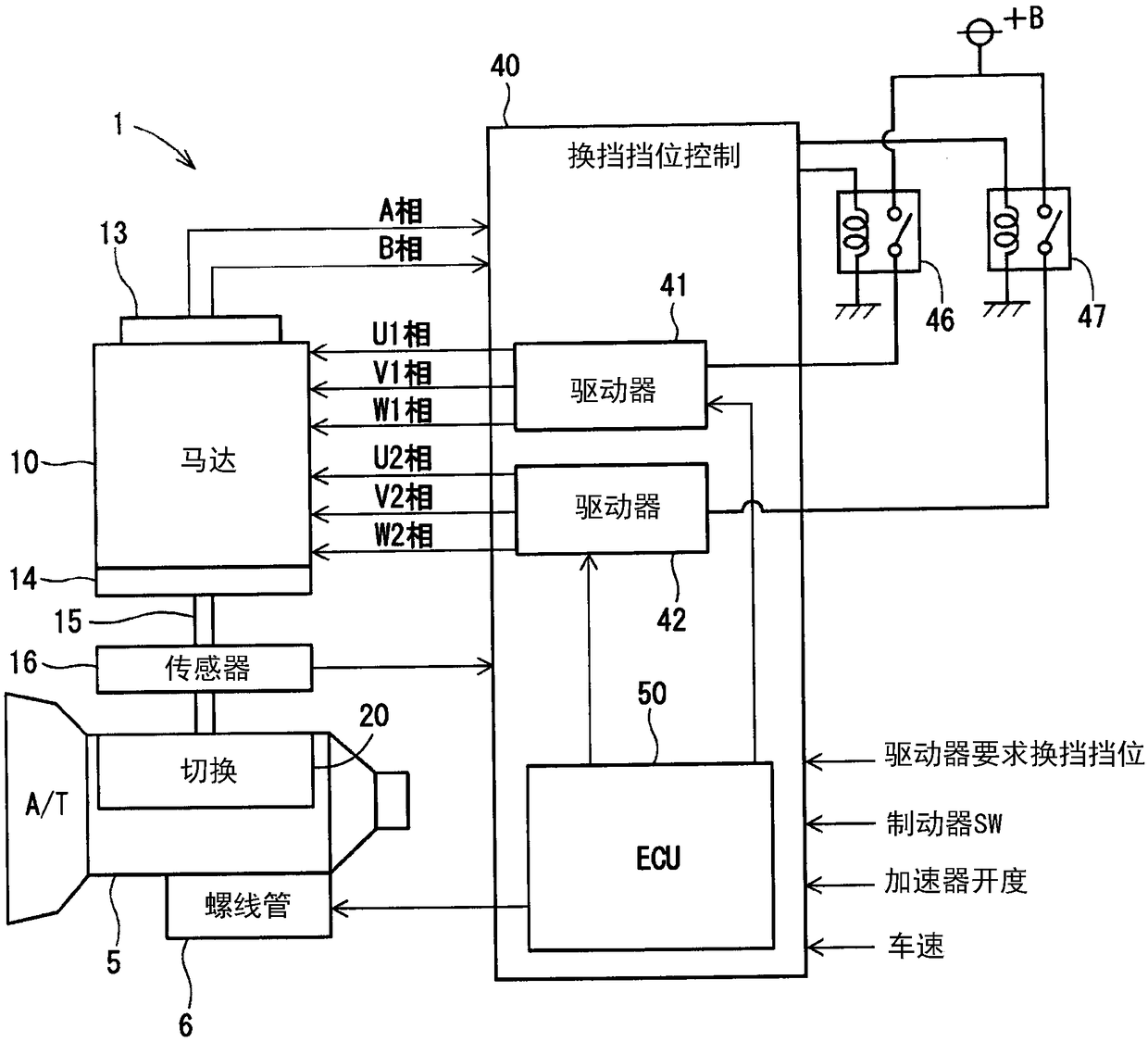

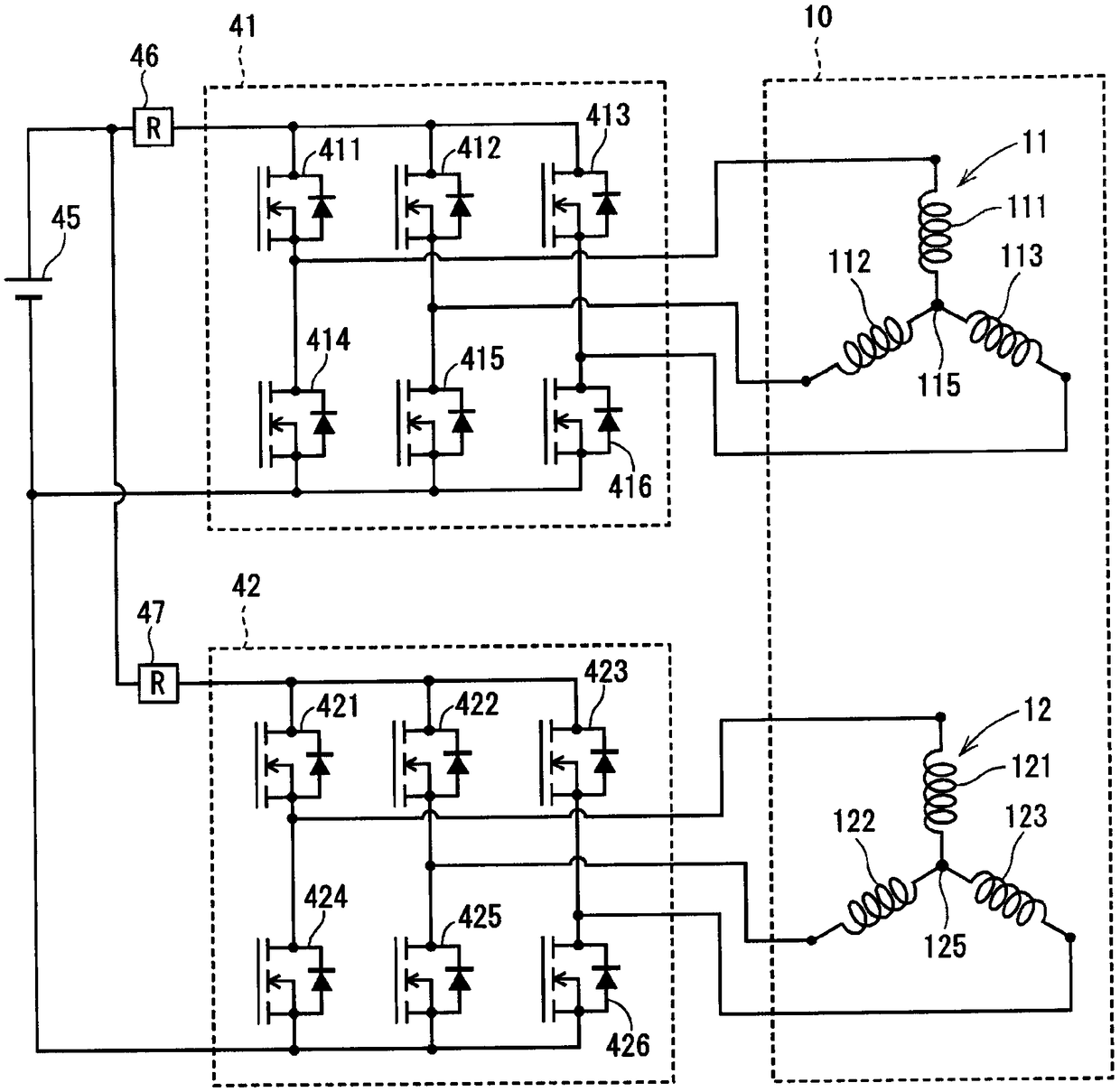

Shift range control device

ActiveCN109075728AControl driveProper stopAC motor controlGearing controlFeedback controlControl unit

This shift range control device switches shift range by controlling the drive of a motor (10). The shift range control device comprises a feedback control unit (52) that performs position feedback control on the basis of a target angle determined according to the requested shift range and the actual angle of the motor; a fixed phase ON / OFF control unit (61) that performs fixed phase ON / OFF controlthat provides power to a fixed phase selected according to an actual angle; and a switching control unit (65) that switches between motor control states. The switching control unit switches the control state to position feedback control when the requested shift range is switched. If the difference between the target angle and the actual angle drops to or falls below an angle determination threshold, the switching control unit switches the control state from position feedback control to fixed phase ON / OFF control.

Owner:DENSO CORP

Drive controller and control method for reciprocating compressor

InactiveCN1242169CReduce cooling capacityNo re-expansion lossLighting and heating apparatusDomestic refrigeratorsMicrocomputerValue set

Disclosed is an apparatus for controlling a driving of a reciprocating compressor and a method thereof, in which a cooling capacity is decreased without a re-expansion loss by controlling a driving of a compressor used in a refrigerator by using a current offset when the cooling capacity of a refrigerator is varied. To this end, in the compressor which controls the cooling capacity by varying an inner stroke according to a stroke reference value set by a user, the apparatus comprises a storage unit for storing a current offset value corresponding to a cooling capacity variable amount; an adding unit for adding the current offset value to a current value applied to the compressor in accordance with that the cooling capacity is varied by a user; a microcomputer for generating a switching control signal corresponding to the current value added from the adding unit; and a power supply unit for controlling a driving of the compressor by applying the added current to the compressor under a dependent state on the switching control signal.

Owner:LG ELECTRONICS INC

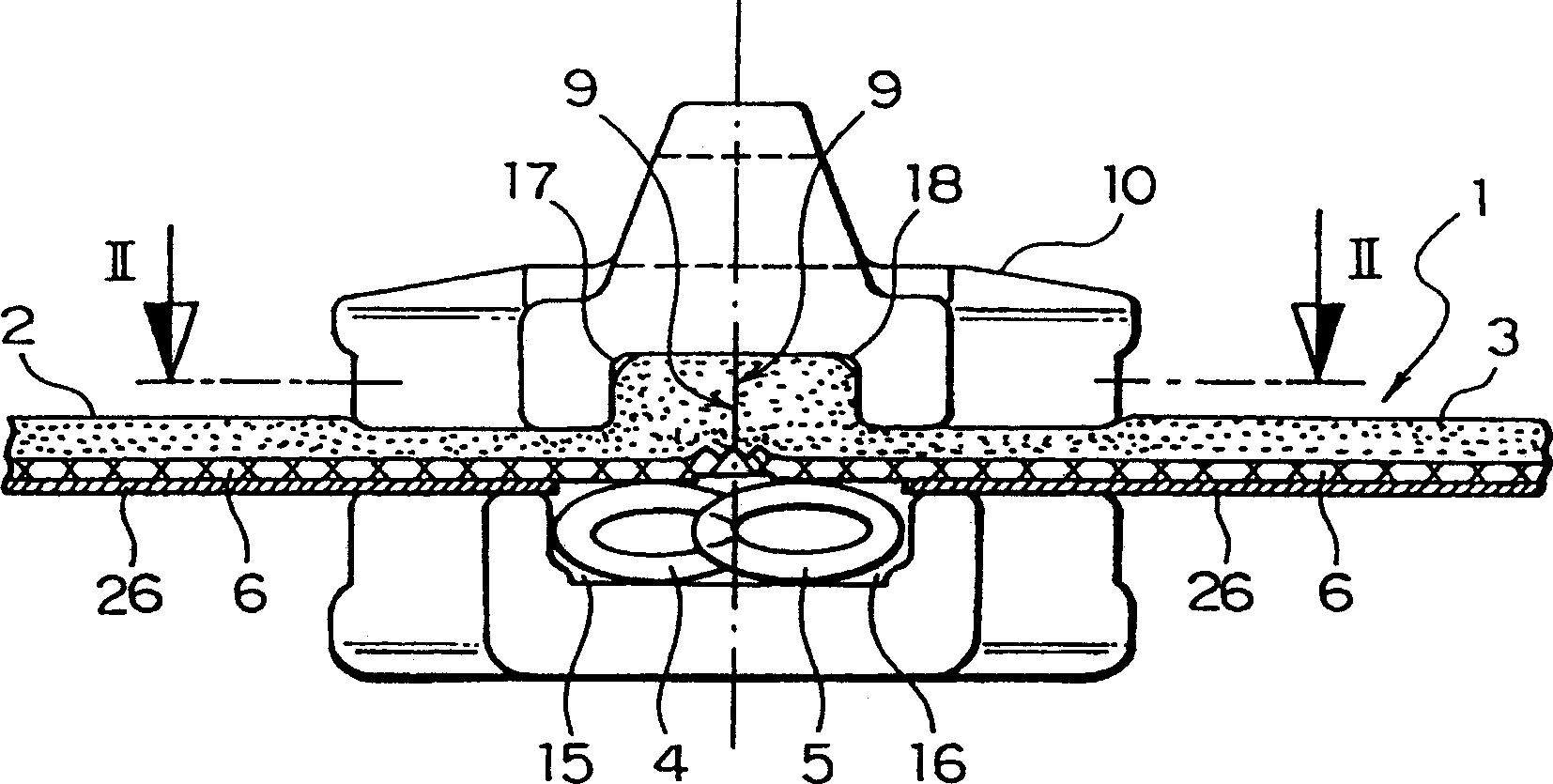

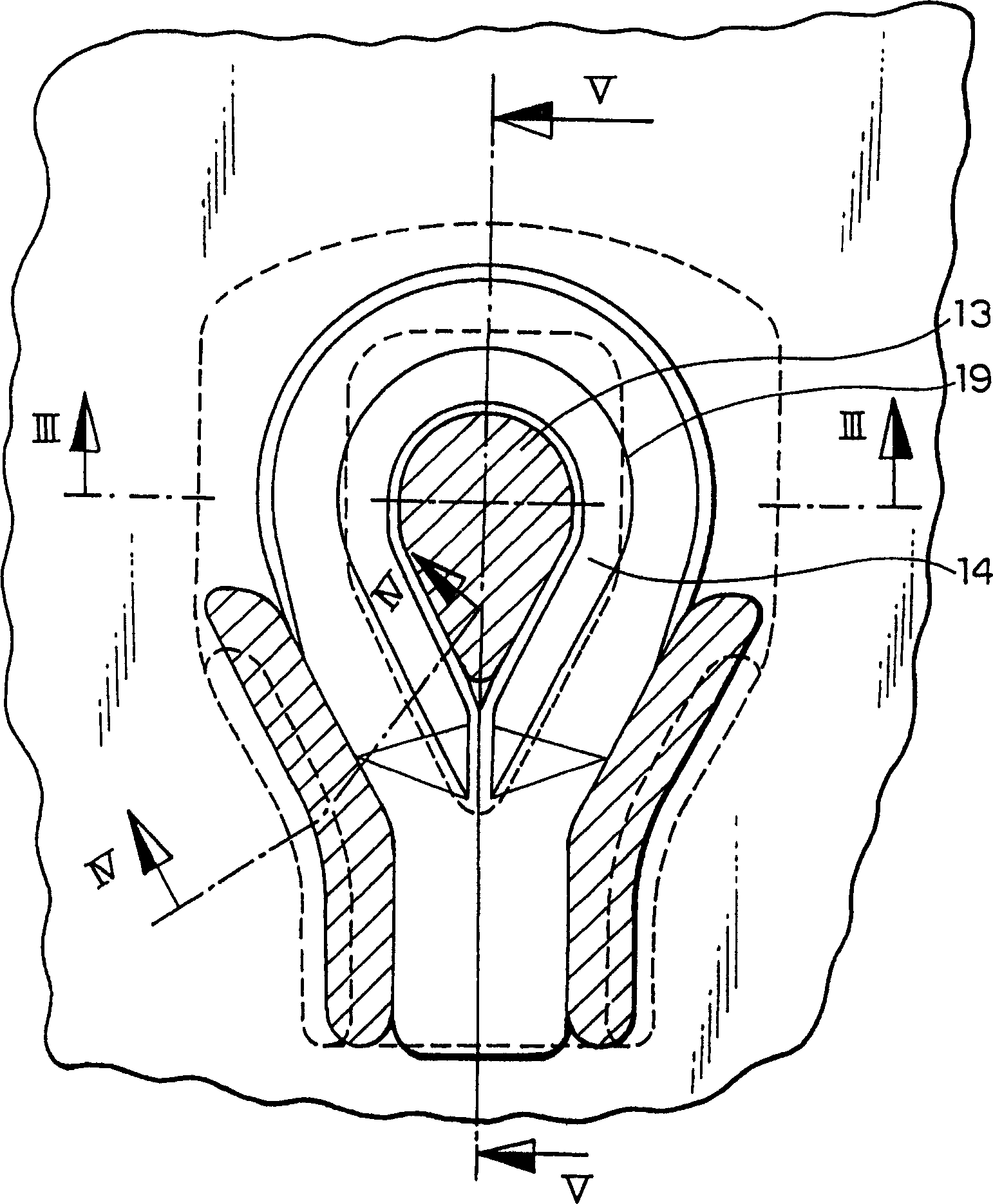

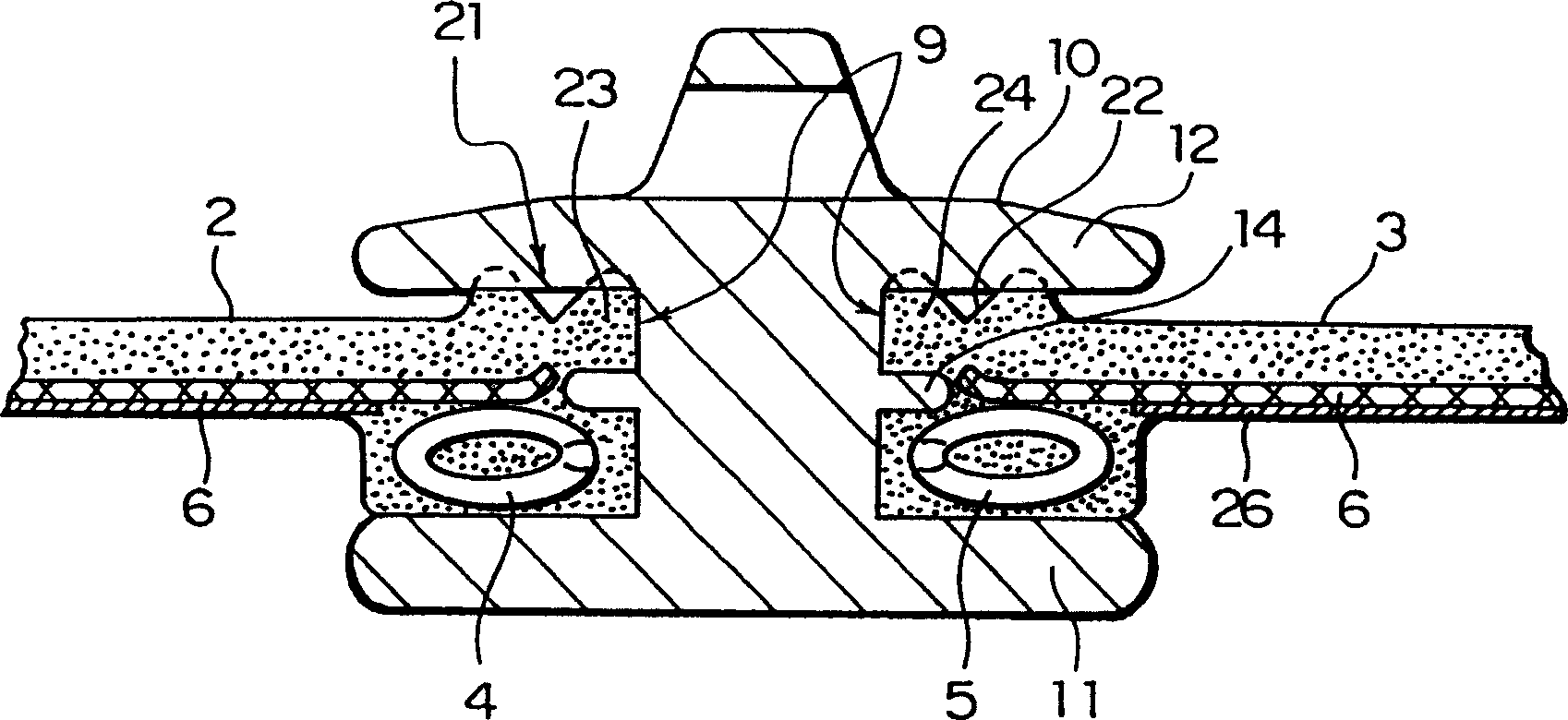

Sealed zipper

The present invention aims at providing a sealing zipper which, with a relatively simple structure, also ensures absolute fluid tightness even in the region of the slider of the zipper. A pair of zipper support strips (2, 3) of the sealed zipper (1) are further provided with a flexible cover at the connected end portion above the guide edge (14), the size of which is limited to make the slider (10) smoothly Elastomer that is guided and has the necessary compressive force to ensure a seal. And, on the side away from the joint ends of the above-mentioned zipper support tapes (2, 3) away from the coupler row (4, 5), due to the formation of a suitable size, elastic, engaged in the slider (10 ) is a U-shaped elastic cam (21) on the underside of the upper plate (12), so the slider (10) can slide smoothly at the connected ends of the support belts (2, 3), and can ensure an absolutely reliable seal sex.

Owner:YKK CORP

Steel belt steady-speed operation control method

InactiveCN105714100AHigh outputControl speedFurnace typesHeat treatment process controlControl signalMotor resonance

Owner:ANGANG STEEL CO LTD

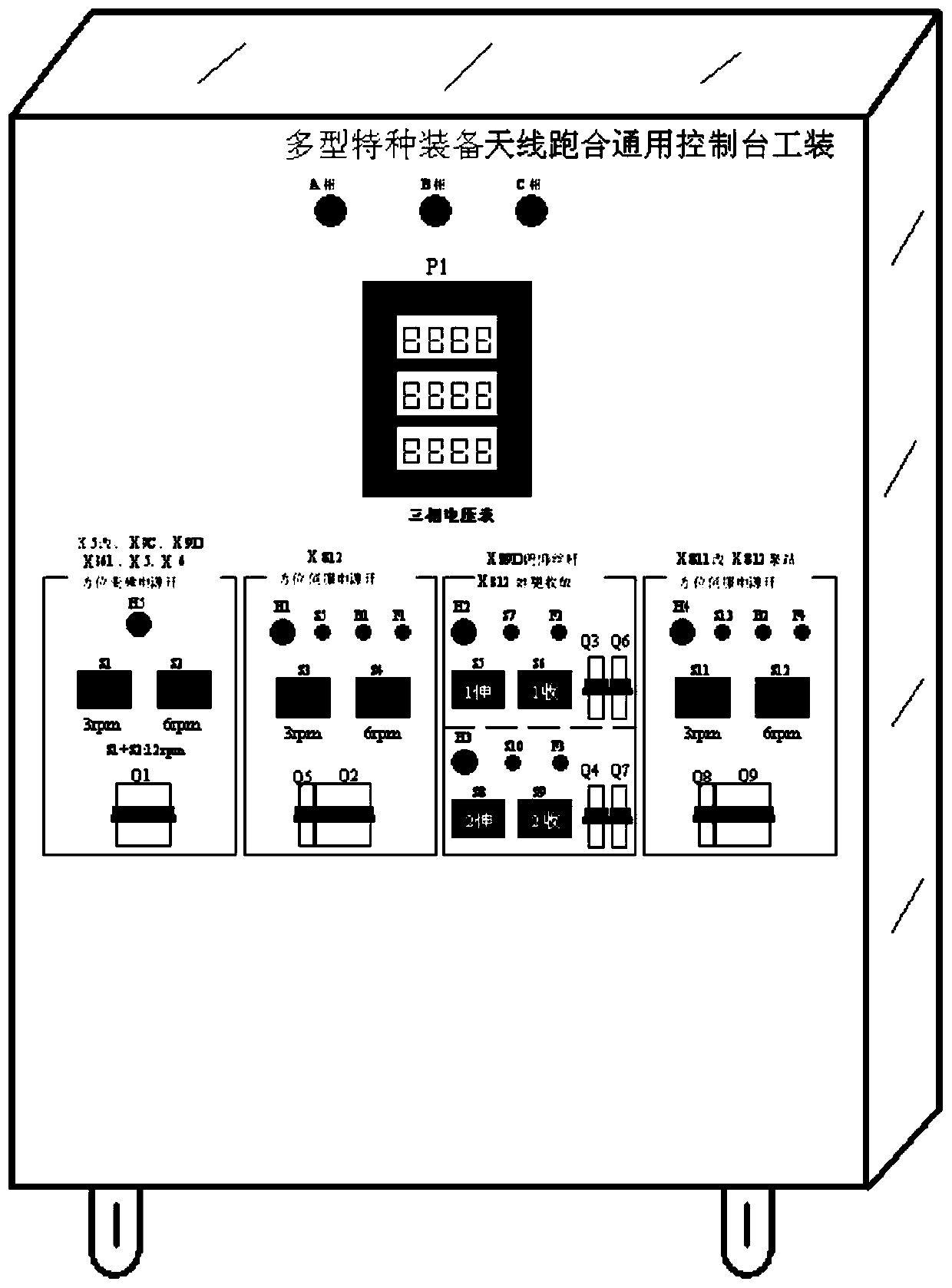

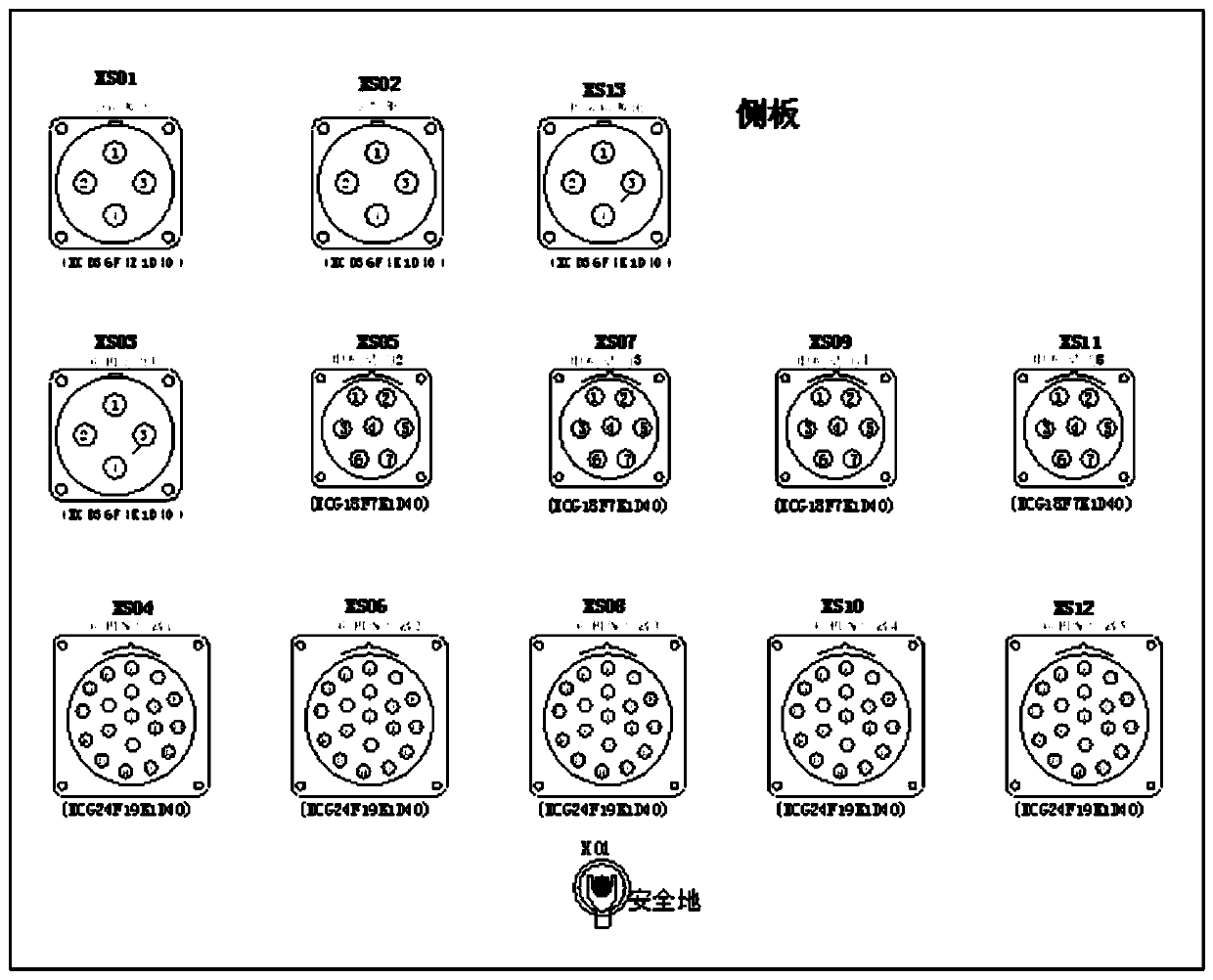

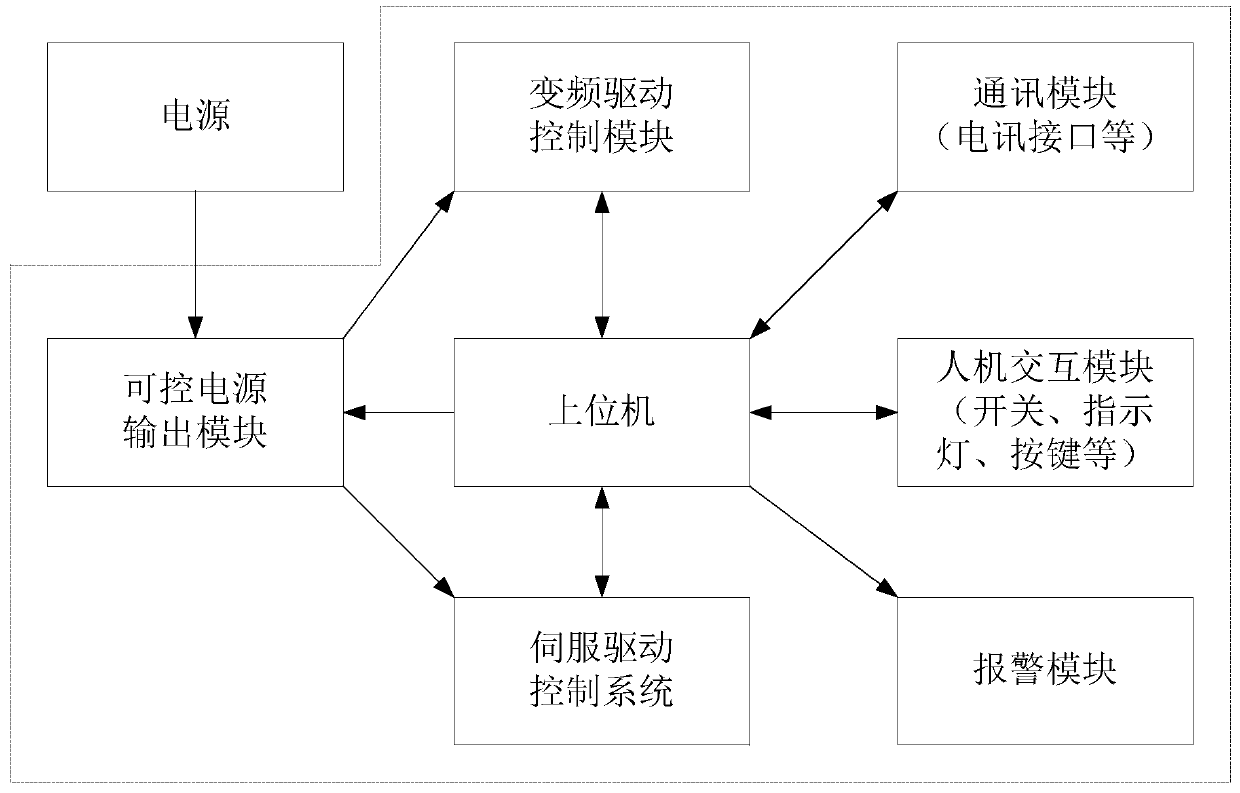

Multi- type special equipment antenna running-in general console

PendingCN110531694AEasy to operateImprove reliabilityProgramme control in sequence/logic controllersTime-sharingFrequency conversion

The present invention discloses a multi-type special equipment antenna running-in general console. The console comprises a cabinet. The cabinet is provided with an upper machine, a frequency-conversion driving module mutually connected with the upper machine, a servo driving control module, a communication module, a man-machine interaction module and a controllable power supply output module connected with the output end of the upper machine. The frequency-conversion driving module and the servo driving control module are the execution parts of the multi-type special equipment antenna running-in experiment and test. The output end(s) of the controllable power supply output module are separately connected with the frequency-conversion driving module and the servo driving control module, andthe controllable power supply output module is used for performing time-sharing control on the power supplies of the frequency-conversion driving module and the servo driving control module. The console is applicable to the running-in execution mechanism experiment and test, such as antenna position, pitch and fold, of the multi-type special equipment, and the console has the advantages of simpleand convenient operation, high reliability, fast response, good stability, maintenance easiness, applicability for multi-task time-sharing work and expansibility.

Owner:ANHUI BOWEI CHANGAN ELECTRONICS

Clutch mechanism used for washing machine driving system and washing machine driving system

InactiveCN107034624ALow costSimple connection structureOther washing machinesTextiles and paperEngineeringState switching

The invention discloses a clutch mechanism used for a washing machine driving system and the washing machine driving system. The clutch mechanism comprises a clutch assembly and a shift lever assembly, and the clutch assembly is provided with a clutch shaft sleeve and a wrapping spring assembly; the wrapping spring assembly comprises a spiral spring and a ratchet wheel, wherein the spiral spring is sleeved with the ratchet wheel. The ratchet wheel comprises a first ratchet wheel body and a second ratchet wheel body which are coaxially connected to the outer side of the spiral spring in a sleeving mode and different in ratchet wheel taper direction, one end of the spiral spring is limited on the first ratchet wheel body, and the other end of the spiral spring is limited on the second ratchet wheel body. The shift lever assembly comprises a shift fork assembly which is arranged on the outer side of the ratchet wheel in a sleeving mode and installed on an installation shell of the washing machine driving system, and the shift fork assembly is provided with first ratchet thorns meshed with the first ratchet wheel body and second ratchet thorns meshed with the second ratchet wheel body. The clutch mechanism is simple in structure and convenient to control, by the adoption of the double-ratchet-wheel and double-ratchet-thorn meshing drive clutch mode, the two ends of the wrapping spring assembly are loosened, and the clutch state switching precision can be further effectively ensured.

Owner:CHANGZHOU XINYA ELECTROMOTOR

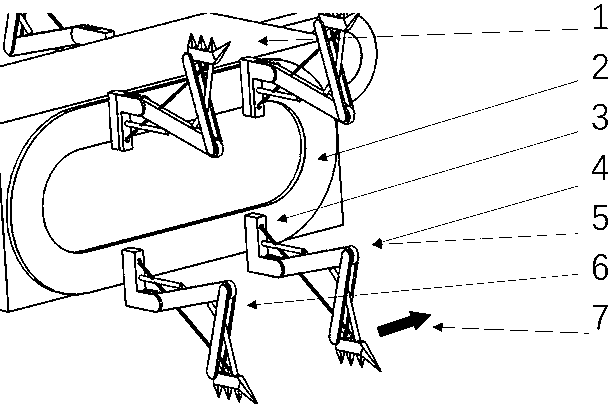

Walking mechanism of multi-foot robot

The invention belongs to the field of mobile robots and particularly relates to a walking mechanism of a multi-foot robot. The provided walking mechanism of the multi-foot robot comprises robot walking feet, a robot walking foot posture control device and a robot walking crawler belt, wherein each robot walking foot comprises three joints which are fixed to the robot walking crawler belt and can be controlled by the robot walking foot posture control device, and the robot walking feet have the function of providing a force for gripping the ground and supporting other supported objects; the robot walking foot posture control device is mainly used for controlling the walking feet to be opened for gripping in time. Instead of directly touching the ground, the robot walking crawler belt touches the ground through the walking feet fixed to the robot walking crawler belt to achieve forward and backward movement of a robot. The walking mechanism combines the characteristics of multi-foot walking and crawler-type walking, not only is the obstacle crossing capability improved, but also the structure and control complexity of the multi-foot robot is reduced, and the walking mechanism of themulti-foot robot has a significant meaning on the mobile robots under a complex environment.

Owner:屈娟娟

Sharp-curve tunnel track-laying vehicle

PendingCN107386020ARealize any rotationEasy to layTrack superstructureRailway couplingsMaterial resourcesControl theory

The invention relates to a sharp-curve tunnel track-laying vehicle, comprising at least two vehicle body segments, driving devices and a track gripping mechanism; the adjacent vehicle body segments are connected through a flexible rotating pendulum, each vehicle body segment is provided with one driving device, the driving devices are used for driving the vehicle body segments to move, and the track gripping mechanism is arranged on the vehicle body segments and used for picking and laying a track. The sharp-curve tunnel track-laying vehicle has the advantages that vehicle body segments can optionally rotate relative to one another, laying of a small-radius curve track is facilitated, and a power system has lower consumption of manpower and material resources.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

Flexible circuit board, photographing device, photographing optical device and electronic instrument thereof

InactiveCN102447825BEffectively absorb elastic reaction forceSmall footprintTelevision system detailsPrintersFlexible circuitsElectronic instrument

Owner:RICOH KK

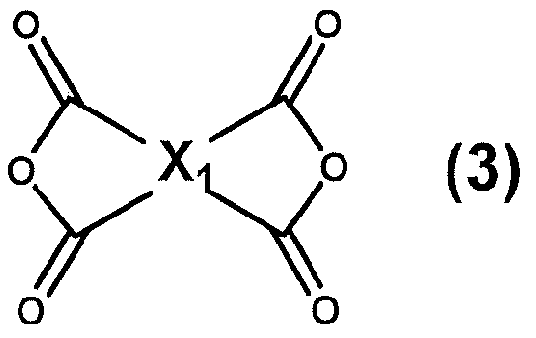

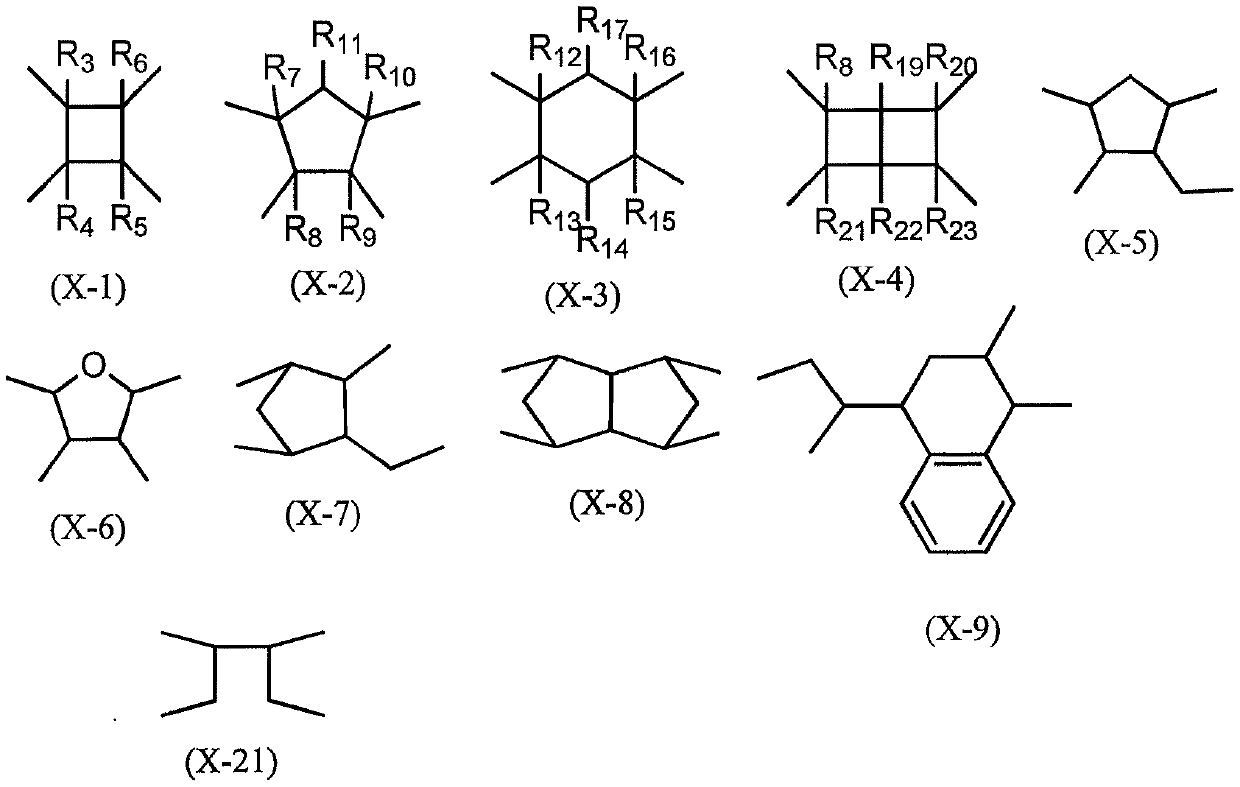

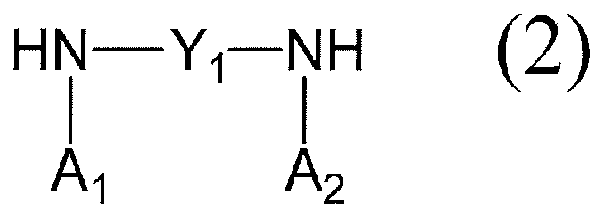

Functional resin composition for phase-shifting modulation element in which liquid crystal is used

The present invention provides: a functional resin composition with which a high-durability drive control film can be obtained with which it is possible to maintain, with high precision, voltage applied during liquid crystal driving; and a planar antenna equipped with a drive control film obtained from the composition. The present invention pertains to a functional resin composition for a liquid crystal drive control film of a microwave phase-shifting modulation element in which a liquid crystal is used, the functional resin composition containing at least one polymer selected from polyamic acid derivatives and polyimides that are imidized compounds thereof.

Owner:NISSAN CHEM IND LTD

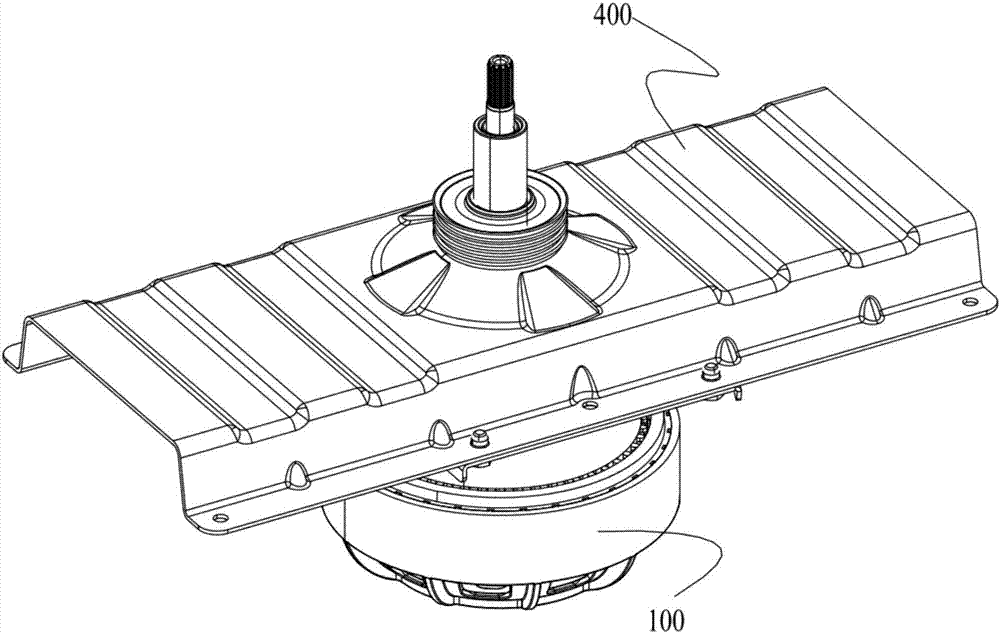

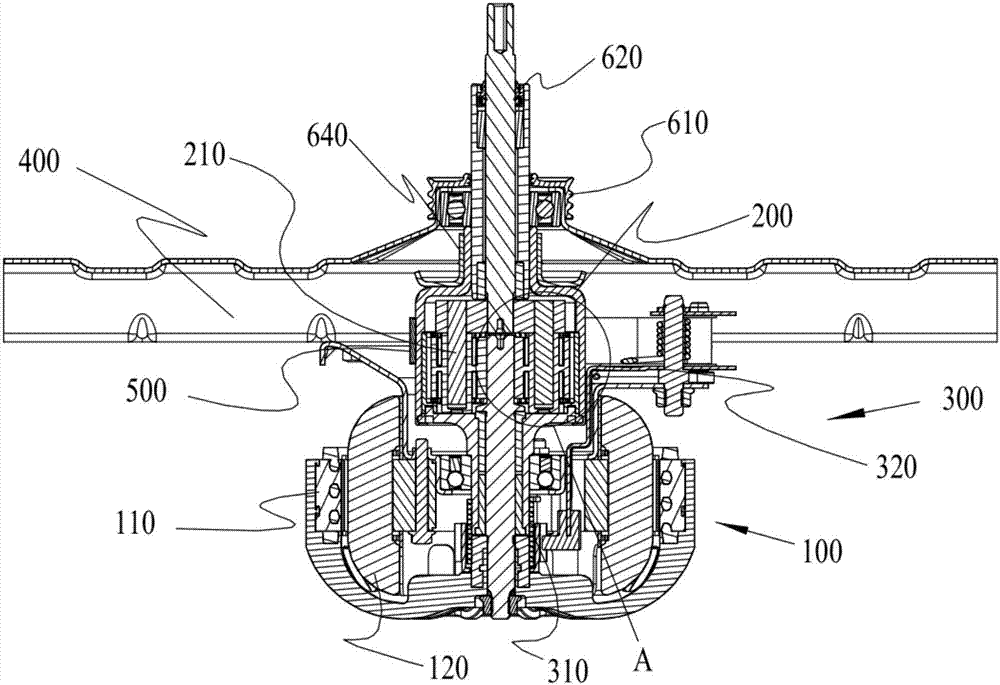

A vehicle kinetic energy conversion and recovery device

ActiveCN105059274BImprove efficiencyIncrease energy densityHybrid vehiclesBraking element arrangementsLow speedHydraulic circuit

The invention discloses an automobile kinetic energy conversion and recovery device. The automobile kinetic energy conversion and recovery device is used for storing energy during subway braking and recovering kinetic energy during starting. The automobile kinetic energy conversion and recovery device mainly comprises an eccentric wheel, hydraulic plungers and a corresponding hydraulic loop. During subway braking, the eccentric wheel and an axle rotate synchronously, so that the built-in hydraulic plungers conducts reciprocating radial motion; hydraulic oil is pressed into an energy accumulator through the hydraulic plungers on the basis of the design of the corresponding hydraulic loop, and therefore kinetic energy of the automobile is converted into hydraulic energy to be stored. During subway starting, the device is used as a low-speed large-torque hydraulic motor on the basis of switching control over an electromagnetic valve to push a subway to achieve kinetic energy recovery. According to the automobile kinetic energy conversion and recovery device, the hydraulic mode is utilized for energy storage, braking energy is not converted into electric energy and is just stored as hydraulic energy, and the efficiency is much higher than that of the existing energy storage mode.

Owner:王林翔

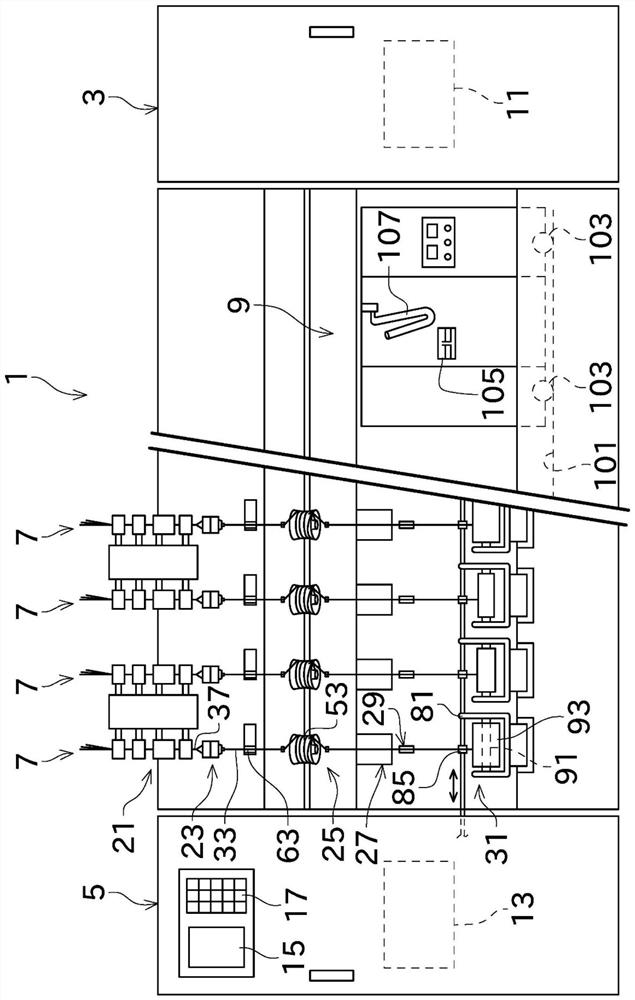

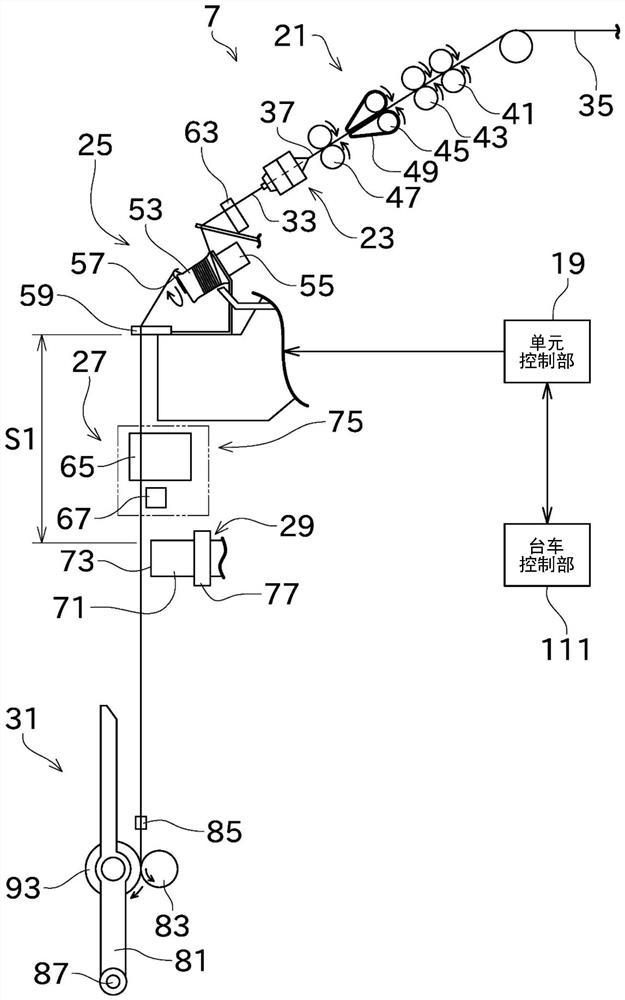

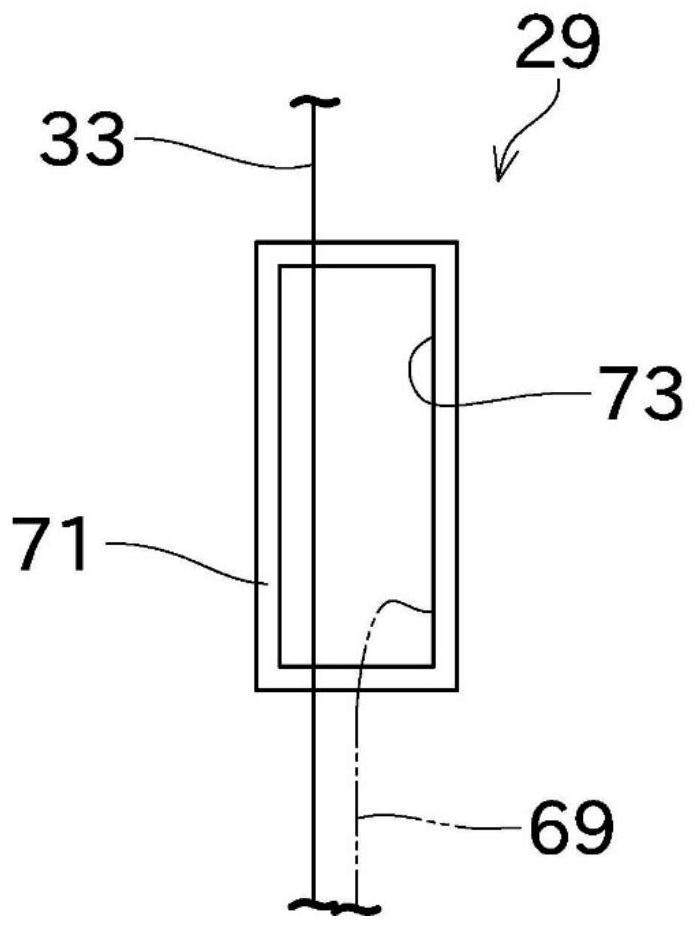

Air spinning machine

PendingCN113774526AControl drivePiercing arrangementsContinuous wound-up machinesYarnPolymer science

The invention provides an air spinning machine, comprising a drafting device (21), an air spinning device (23), a yarn accumulating device (25), a yarn intervening device (27), a suction device (29) and a winding and taking device (31). The air spinning device (23) twists the sliver (35) that is drafted by a drafting device (21), that is, a fiber bundle (37) by twisting air flow to generate a spun yarn (33). The air spinning device (23) twists sliver (35) that is drafted by the drafting device (21), that is, the fiber bundle (37) by the twisting air flow to generate the spun yarn (33). The yarn accumulating device (25) temporarily accumulates the spun yarn. The yarn intervention device (27) intervenes in the spinning. The suction device (29) is configured to suction and spin the yarn. The winding and taking device (31) winds up the spun yarn to form a package (93). The drafting device, the air spinning device, a yarn accumulating device, the yarn intervening device, the suction device, and the winding device are arranged in this order from a high position to a low position. The yarn intervention device (27) is a waxing device (65) and a yarn travel sensor (67).

Owner:MURATA MASCH LTD

Clutch mechanism for driving system of washing machine and driving system of washing machine

InactiveCN107034624BLow costSimple connection structureOther washing machinesTextiles and paperEngineeringState switching

The invention discloses a clutch mechanism used for a washing machine driving system and the washing machine driving system. The clutch mechanism comprises a clutch assembly and a shift lever assembly, and the clutch assembly is provided with a clutch shaft sleeve and a wrapping spring assembly; the wrapping spring assembly comprises a spiral spring and a ratchet wheel, wherein the spiral spring is sleeved with the ratchet wheel. The ratchet wheel comprises a first ratchet wheel body and a second ratchet wheel body which are coaxially connected to the outer side of the spiral spring in a sleeving mode and different in ratchet wheel taper direction, one end of the spiral spring is limited on the first ratchet wheel body, and the other end of the spiral spring is limited on the second ratchet wheel body. The shift lever assembly comprises a shift fork assembly which is arranged on the outer side of the ratchet wheel in a sleeving mode and installed on an installation shell of the washing machine driving system, and the shift fork assembly is provided with first ratchet thorns meshed with the first ratchet wheel body and second ratchet thorns meshed with the second ratchet wheel body. The clutch mechanism is simple in structure and convenient to control, by the adoption of the double-ratchet-wheel and double-ratchet-thorn meshing drive clutch mode, the two ends of the wrapping spring assembly are loosened, and the clutch state switching precision can be further effectively ensured.

Owner:CHANGZHOU XINYA ELECTROMOTOR

Engine start-up device for hybrid vehicle power transmitting device

ActiveCN101342902BControl driveIncrease speedHybrid vehiclesElectrical controlDriver/operatorControl theory

Owner:TOYOTA JIDOSHA KK

Rotating motor controls and electric power steering equipment

ActiveCN104052344BControl driveAC motor controlElectric motor controlElectric power steeringCurrent limiting

The present invention relates to a rotary electric machine control device and an electric power steering apparatus. In the rotary electric machine control device, a voltage command value calculation section (41, 42, 43, 44) calculates a voltage command value based on a current command value and a motor current. An inverter power estimating section (50) estimates inverter power based on motor current. A power supply current estimating section (50) estimates the power supply current based on the inverter power and the power supply voltage. A limit gain determination section (50) determines a current value of the limit gain based on a power supply current, a target power supply current, and a previous value of the limit gain. A limited voltage command value calculation section (50) calculates a limited voltage command value based on the voltage command value and the limit gain. The current limiting section (46, 47) can limit the power supply current by outputting a command value corresponding to the limited voltage command value to the inverter section.

Owner:DENSO CORP

Swing direct drive device and method built in solenoid coil

ActiveCN105449922BCompact structureIncrease the range of motionOperating means/releasing devices for valvesSwitch power arrangementsMagnetic tension forceCoil structure

The invention provides a swinging direct drive device arranged inside solenoid coil and a method. A magnet 2 is positioned inside the solenoid coil 1; the magnet 2 is connected to a transmission assembly 3 which is extended from the inside of the solenoid coil 1 to the outside of the solenoid coil 1; the solenoid coil 1 enables the magnet 2 to rotate after applying force on the magnet 2; and the magnet 2 is rotated and drives the transmission assembly 3. The invention realizes a high efficiency driving device with the strongest magnetic field part of the coil as an excitation driving position by using the coil and the framework thereof as a structure body. Because of using the coil structure, the whole driving device is compact in structure, and the small volume, big motion displacement and the big output power driving effect can be realized. The component parts are less, the magnets are connected in series or in parallel or are arranged in a staggering manner in the rotation body / shaft, presenting certain angles, and an identical rotation body is embedded, so that the maximal output torque can be realized under the condition of the same volume and the electromagnetic excitation intensity.

Owner:杨斌堂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com