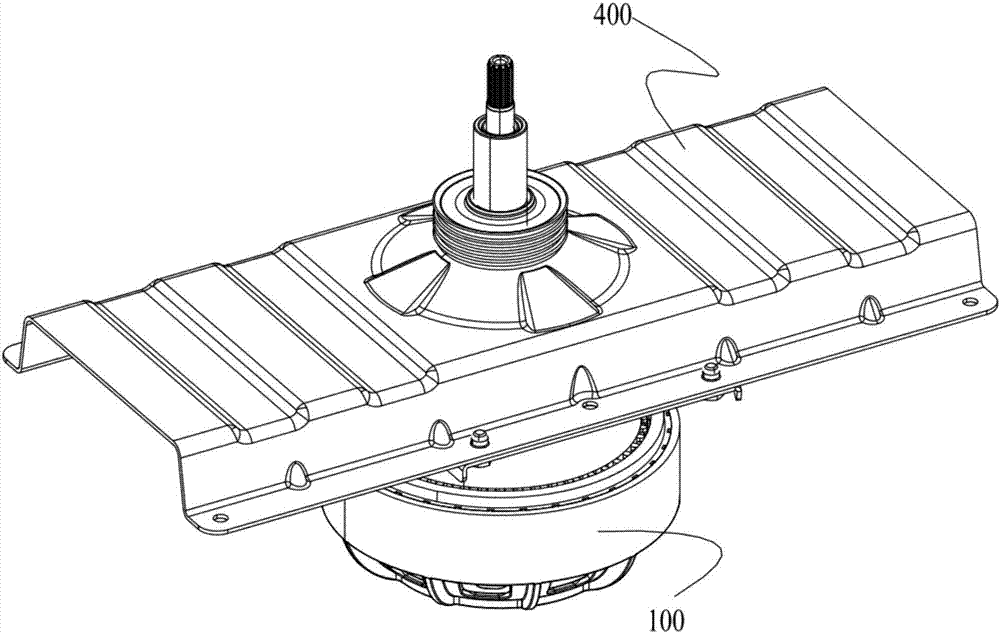

Clutch mechanism used for washing machine driving system and washing machine driving system

A technology of drive system and clutch mechanism, which is applied in the field of washing machines, can solve the problems of cumbersome connection structure between the clutch and the rotor, the structure is not compact enough, and the cost of the motor is high, so as to achieve the effect of easy batch assembly, low cost, and reduced installation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

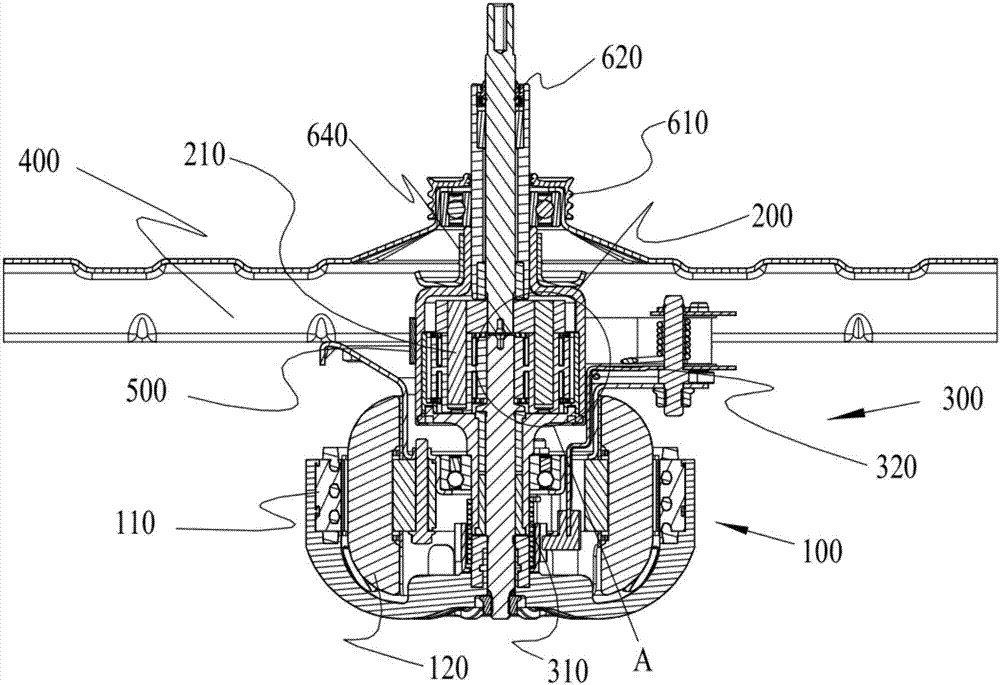

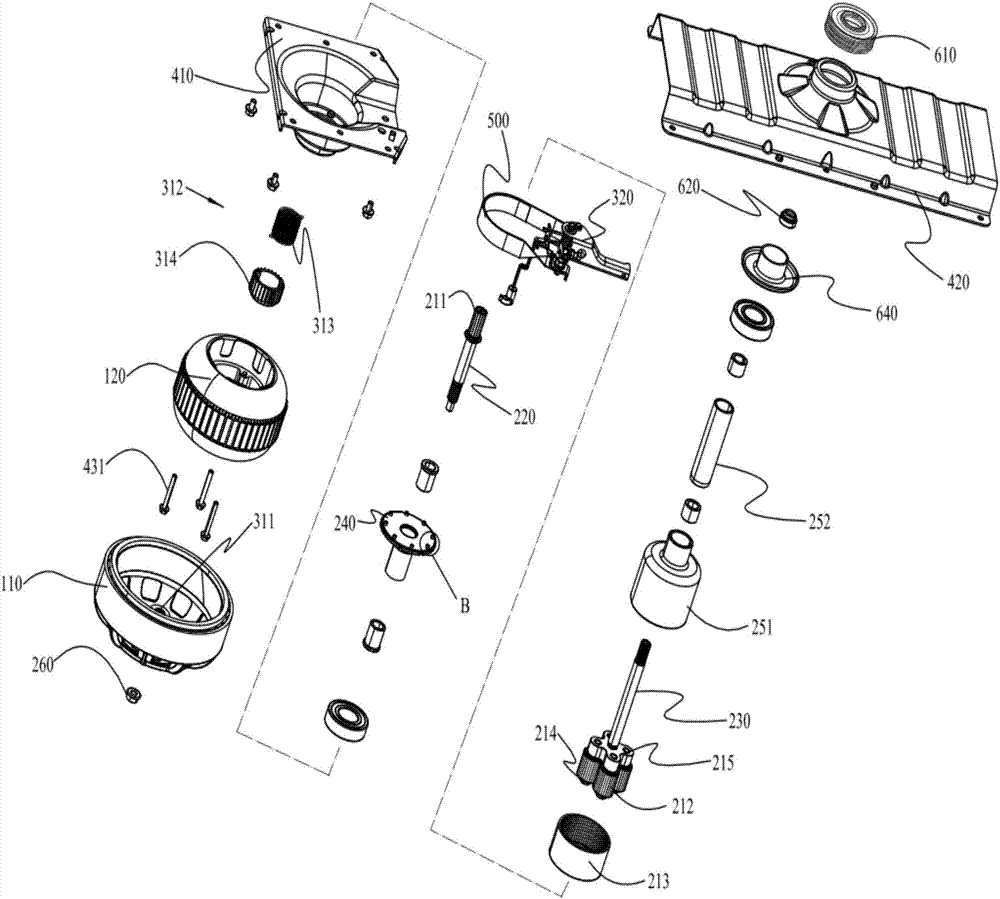

[0059] The embodiment of the present invention discloses a clutch mechanism for a washing machine drive system, which includes a clutch assembly and a lever assembly, and selectively transmits driving force to the clutch assembly through the lever assembly, so that the drive shaft and the drive sleeve are in a separated state and a locked state The clutch assembly is provided with a clutch shaft sleeve and a wrapping spring assembly, and the clutch shaft sleeve is arranged outside the input end of the drive shaft of the washing machine drive system, and is fixedly connected with the rotating body of the washing machine drive system; the wrap spring assembly includes a spiral spring and a sleeve The ratchet is connected to the outside of the coil spring, and the coil spring is sleeved on the outside of the input end of the clutch sleeve and the drive sleeve; wherein, the ratchet includes the first ratchet and the second ratchet coaxially sleeved on the outside of the coil spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com