Functional resin composition for phase-shifting modulation element in which liquid crystal is used

A resin composition and phase modulation technology, applied in electrical components, waveguide devices, circuits, etc., can solve the problems of large scale and expensive equipment, and achieve the effect of high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

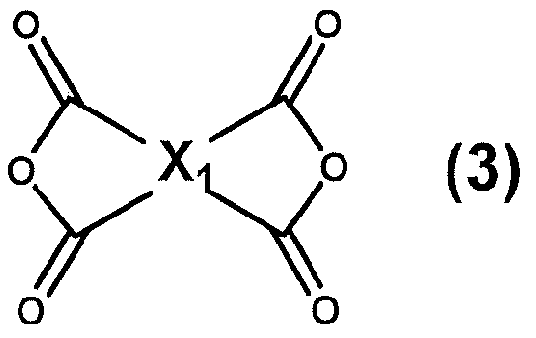

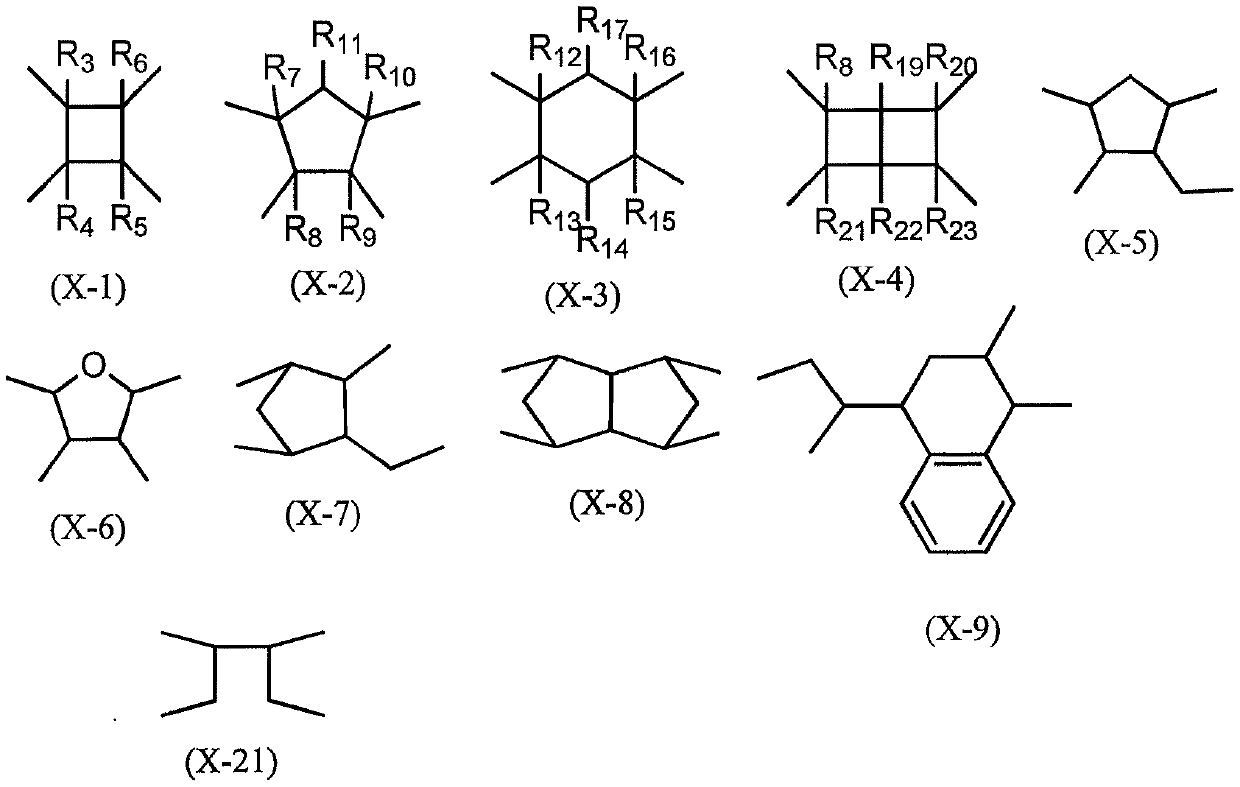

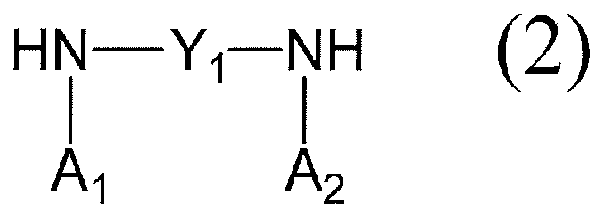

Method used

Image

Examples

preparation example Construction

[0171] As an example of a method of manufacturing a liquid crystal cell, a liquid crystal drive element with a passive matrix structure will be described as an example. It should be noted that a phase modulation element of an active matrix structure in which a switching element such as a TFT (Thin Film Transistor) is provided in each pixel portion may also be used.

[0172] Specifically, transparent glass substrates were prepared, a common electrode was provided on one substrate, and a segment electrode was provided on the other substrate. These electrodes can form, for example, ITO electrodes, and are patterned so as to realize desired driving of liquid crystals.

[0173] Next, drive control films are formed on the respective substrates, and the other substrate is stacked on one substrate so that the faces of the drive control films face each other, and the periphery is adhered with a sealant. In order to control the substrate gap, spacers are usually mixed in advance in the...

Embodiment 1

[0197] Take 2.10g (1.40mmol) of diamine (Z-1) and put it into a 100mL four-neck flask equipped with a stirrer, add 28.1g of N-methyl-2-pyrrolidone, and stir to dissolve it while feeding nitrogen gas. While stirring this solution, 2.69 g (1.37 mmol) of tetracarboxylic dianhydride (T-1) was added, and 7.03 g of N-methyl-2-pyrrolidone was added, and stirred at 23° C. for 15 hours under a nitrogen atmosphere to obtain Polyamic acid solution. The viscosity of the polyamic acid solution at a temperature of 25° C. was 104 mPa·s.

[0198] Take 15.0g of this polyamic acid solution in a 100mL conical flask equipped with a stirring bar, add 16.5g of N-methyl-2-pyrrolidone, 13.5g of butyl cellosolve, and stir for 2 hours with a magnetic stirrer to obtain a polyamic acid solution. Amic acid solution.

Embodiment 2

[0200] Take 4.09g (3.00mmol) of diamine (Z-12) and put it into a 100mL four-neck flask equipped with a stirrer, add 31.2g of N-methyl-2-pyrrolidone, and stir to dissolve it while feeding nitrogen gas. While stirring this solution, 5.77 g (2.94 mmol) of tetracarboxylic dianhydride (T-1) was added, and 7.79 g of N-methyl-2-pyrrolidone was added, and stirred at 23° C. for 15 hours under a nitrogen atmosphere to obtain Polyamic acid solution. The viscosity of the polyamic acid solution at a temperature of 25° C. was 653 mPa·s.

[0201] Take 15.0g of this polyamic acid solution in a 100mL conical flask equipped with a stirring bar, add 37.5g of N-methyl-2-pyrrolidone, 22.5g of butyl cellosolve, and stir for 2 hours with a magnetic stirrer to obtain a polyamic acid solution. Amic acid solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com